Das kanadische Technologieunternehmen Vention hat ausgewertet, wie Hersteller den „Do-it-yourself“-Ansatz (DIY) nutzen, um ihre Produktion zu automatisieren. Die Studie basiert auf anonymisierten Daten von weltweit über 4.000 B2B-Nutzern der Manufacturing Automation Platform (MAP) von Vention.

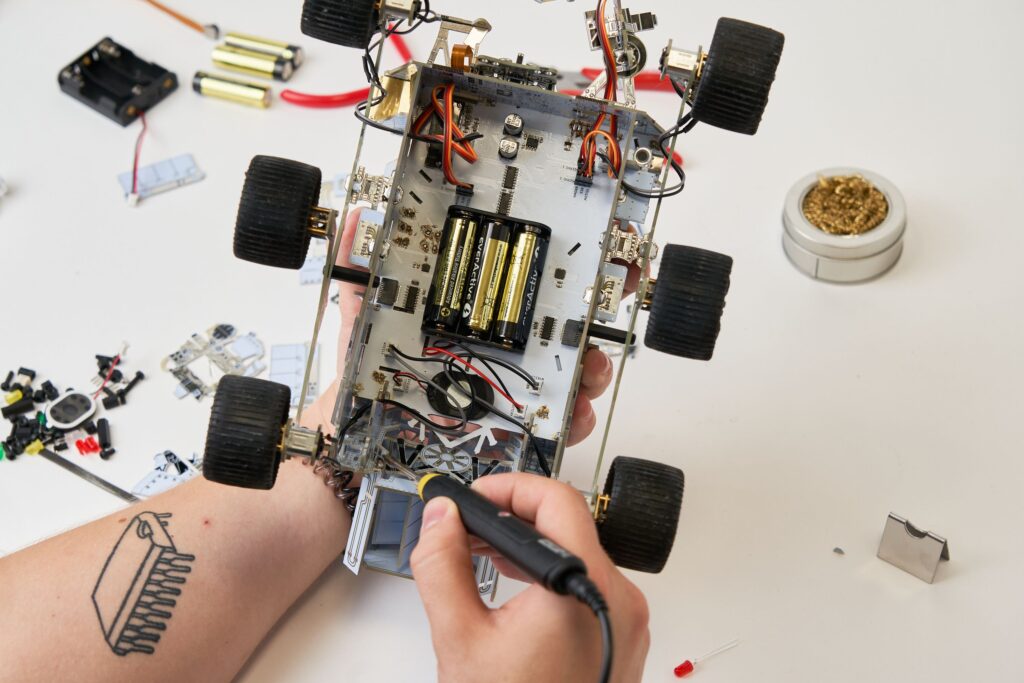

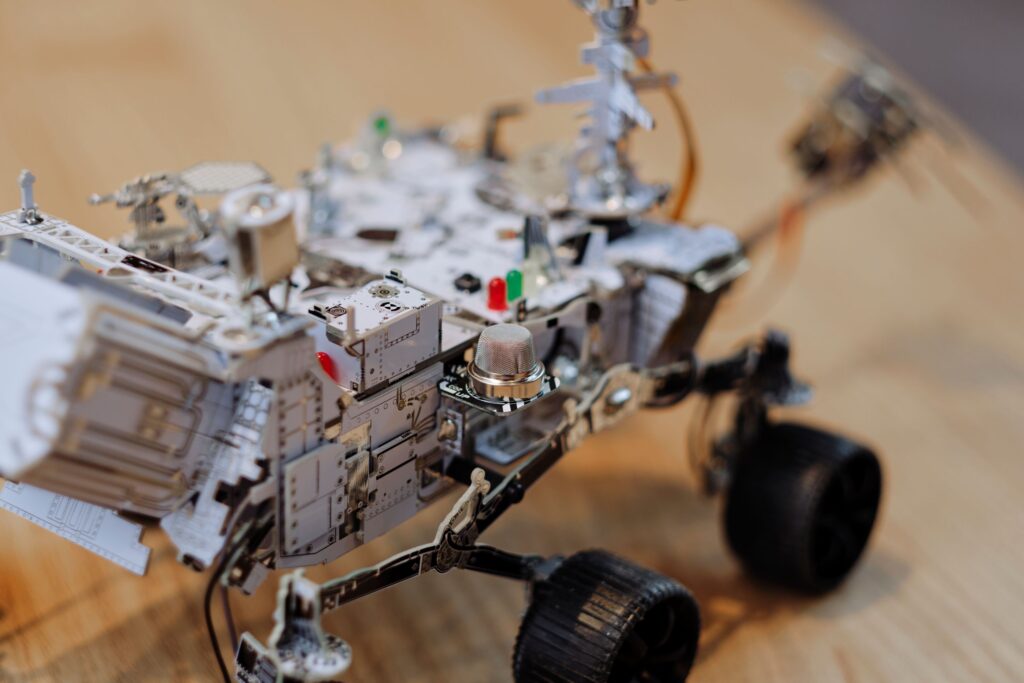

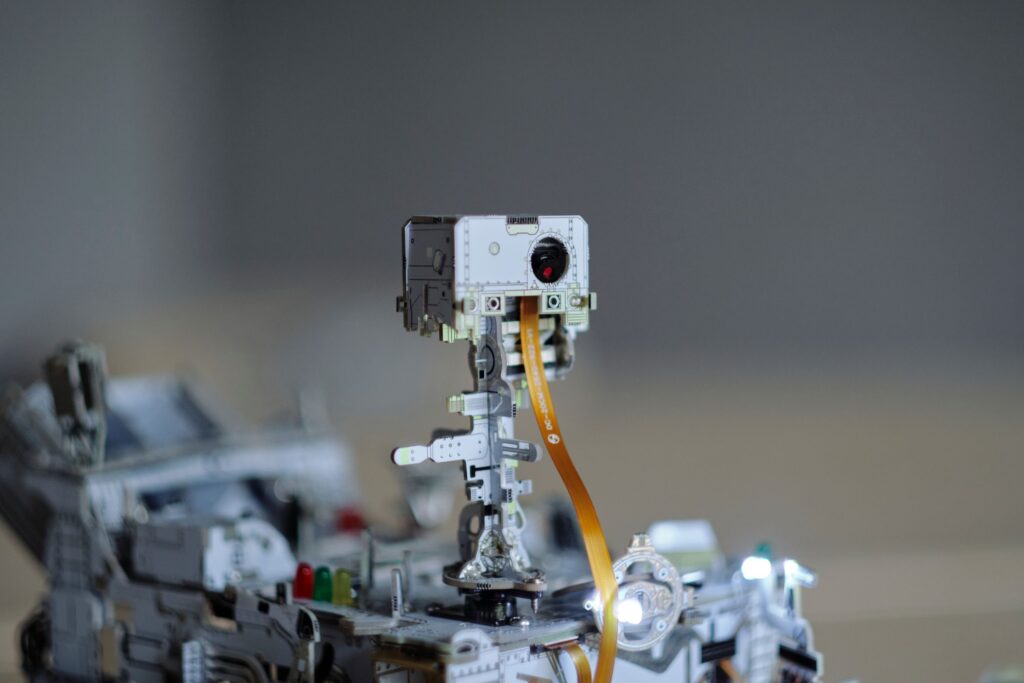

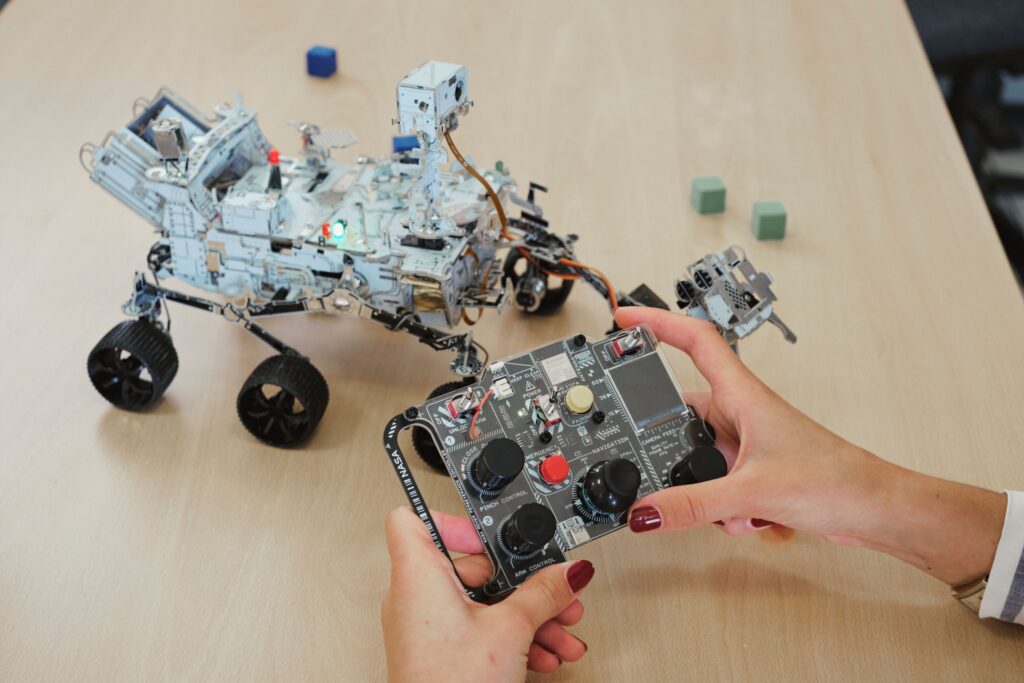

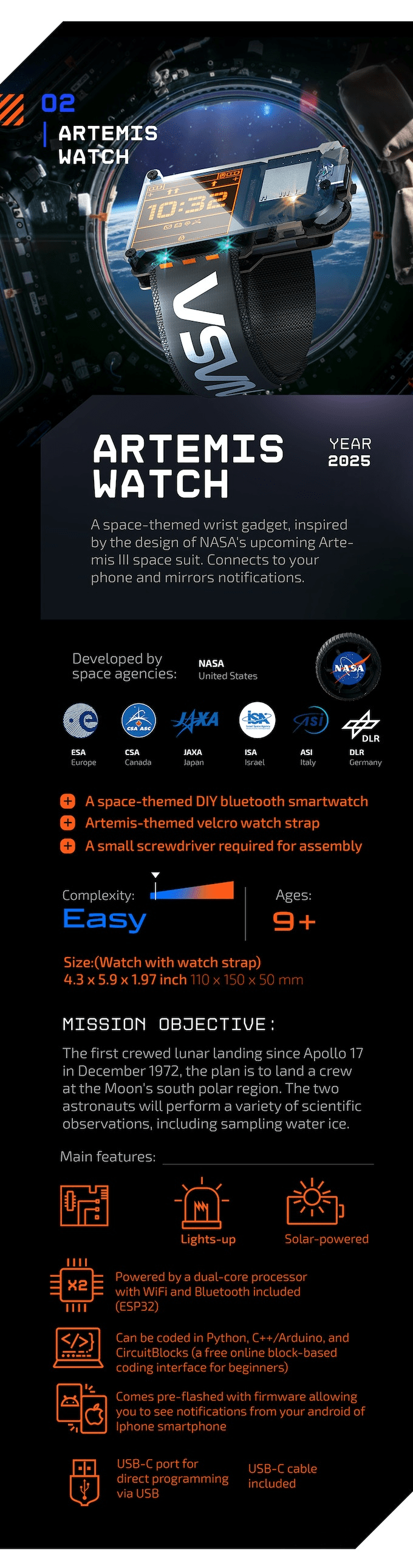

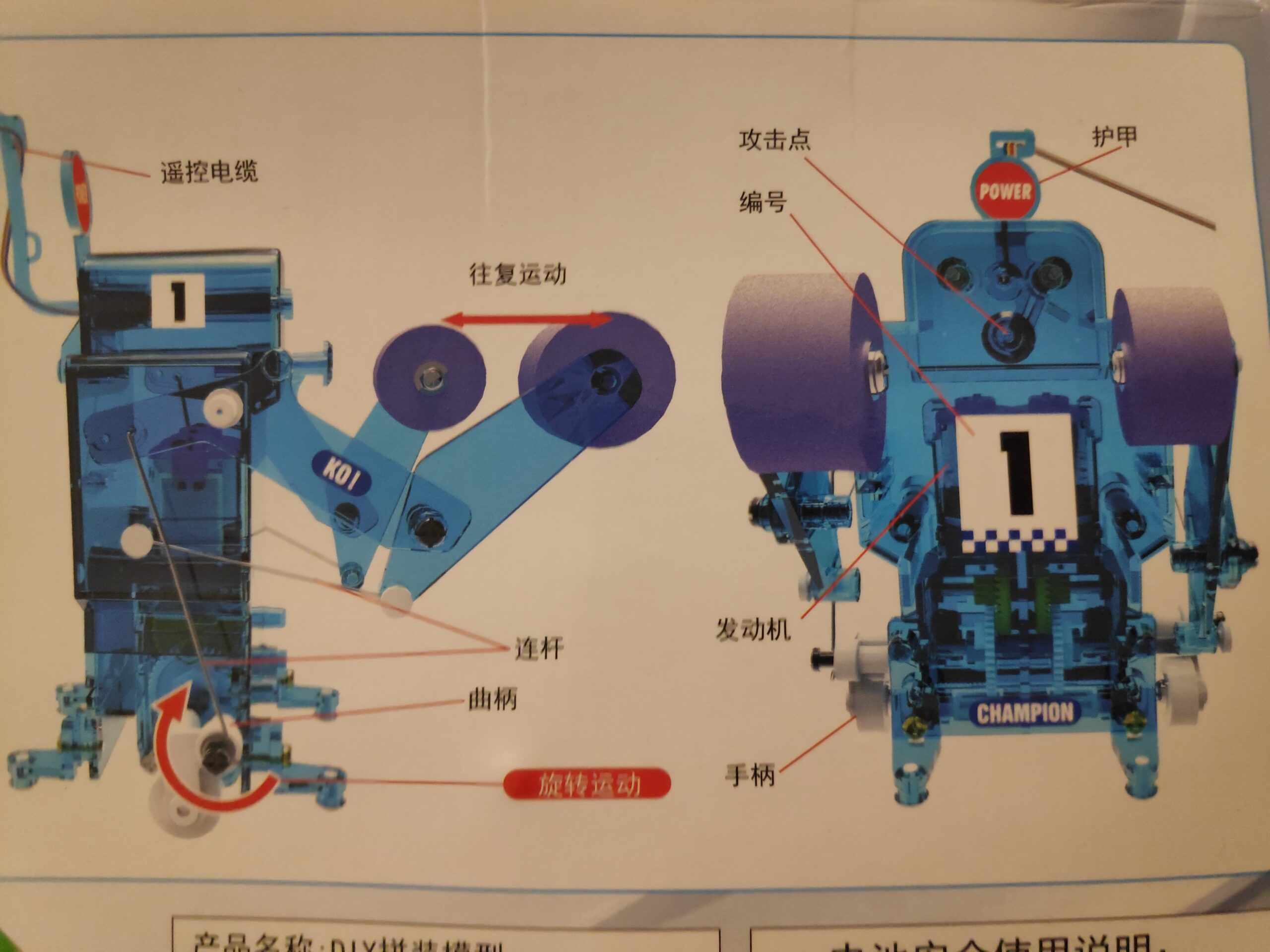

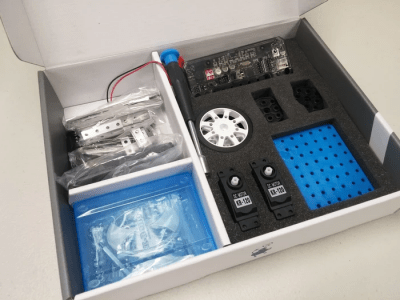

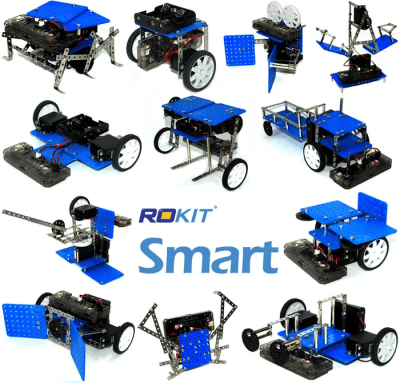

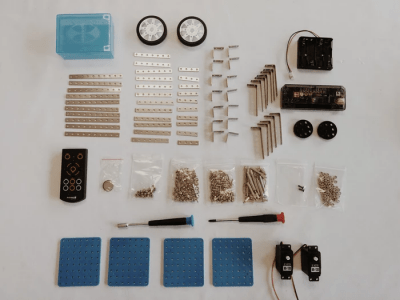

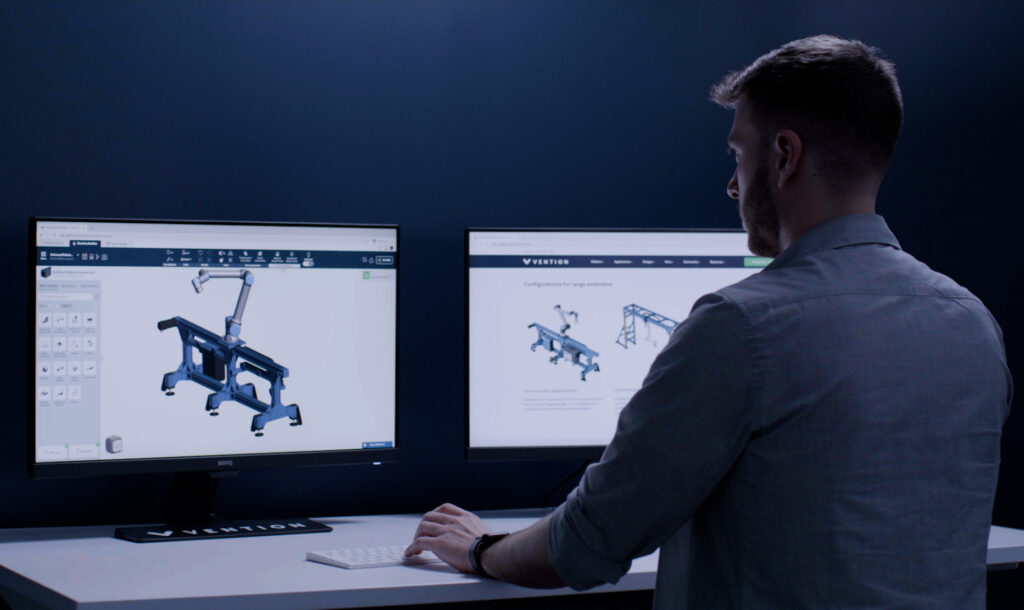

Unter „DIY-Automatisierung“ versteht man den Prozess des selbständigen Entwerfens und Implementierens industrieller Automatisierungssysteme unter Verwendung von Plug-and Play-Hardware- und Softwarekomponenten. Ein Beispiel ist die Vention Cloud-Plattform MAP, mit deren Hilfe produzierende Unternehmen alle Komponenten selbst konfigurieren, bestellen und implementieren können, die sie zur Automatisierung ihrer Produktion benötigen. Ähnlich wie bei Amazon oder IKEA erfolgen Auswahl und Bestellung über den Webbrowser. Die Komponenten werden kurzfristig geliefert und können nach dem DIY Prinzip in Betrieb genommen werden. Anwender wählen zwischen Automatisierungs komponenten verschiedener Roboterhersteller wie Fanuc, Universal Robots oder Doosan aus. Darüber hinaus bietet Vention ein eigenes Hardware-Kit an.

Für die Studie „The State of DIY Industrial Automation“ hat Vention das Nutzerverhalten seiner Firmenkunden auf der Vention Cloud-Plattform von Januar bis Dezember 2022 ausgewertet. Ziel war es zu sehen, wie Unternehmen unterschiedlicher Größe den DIY Ansatz für ihre Automatisierung nutzen. „Wir haben die Daten zusammengestellt, um zu zeigen, dass DIY-Automatisierung möglich ist. Der Bericht dient als strategischer Leitfaden für alle Hersteller, die eine neue Art der Automatisierung einführen möchten“, sagt Etienne Lacroix, CEO Vention.

Das sind die wichtigsten Erkenntnisse der Studie:

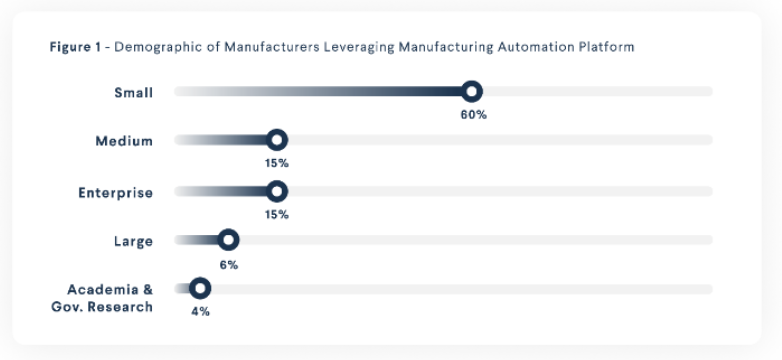

1. Kleine Unternehmen setzen verstärkt auf DIY-Automatisierung.

Kleinere Hersteller mit bis zu 200 Mitarbeitern setzen auf DIY-Industrieautomation. Sie machen 60 % der Unternehmen aus, die automatisierte Ausrüstung über MAP bestellen.

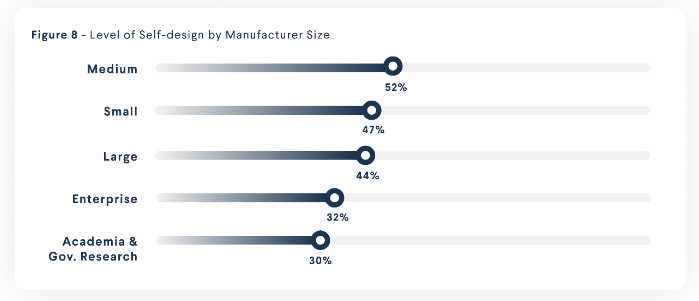

2. Kleine und mittlere Hersteller übernehmen die Führung beim Selbstdesign.

Mittlere und kleine Hersteller verzeichnen auf der Plattform die höchsten Anteile an Selbstdesign. Unter „Selbstdesign“ versteht man Benutzer, die selbstständig auf der Plattform entwerfen, ohne die Designhilfe der Automatisierungsexperten von Vention in Anspruch zu nehmen.

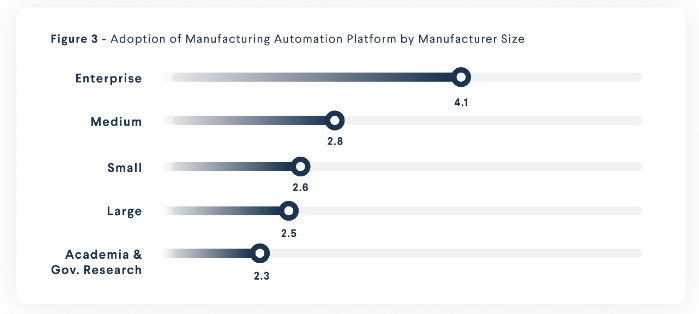

3. Große Hersteller mit über 10.000 Mitarbeitern finden in ihrer Produktion mehr Anwendungsfälle für die Automatisierung.

Große Hersteller, die MAP nutzen, tun dies deutlich häufiger als kleinere Unternehmen. Dies zeigt, dass selbst Hersteller mit hohem Durchsatz erhebliche Vorteile aus dem DIY-Ansatz ziehen können, nachdem sie sich für die Einführung der Vention Cloud-Plattform entschieden haben.

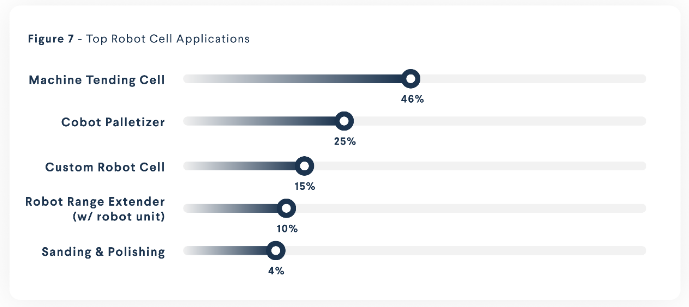

4. Hohe Nachfrage nach der Erstellung von Roboterzellen mit DIY-Automatisierung.

Hersteller, die MAP nutzen, neigen dazu, drei Gerätekategorien zu erstellen: Struktur-, Automatisierungs- und Roboterzellen, wobei in jeder Kategorie zahlreiche Anwendungen zu finden sind. Unter den Top-Roboteranwendungen erweisen sich Maschinenbedienzellen als die am häufigsten eingesetzten Zellen, die knapp 50 % aller Roboterzellenprojekte ausmachen, gefolgt vom Cobot-Palettierer und der kundenspezifischen Roboterzelle.

5. KMU neigen dazu, interne Ressourcen aufzubauen und zu stärken.

Insbesondere kleine und mittlere Unternehmen (KMU) nutzen ihre internen Ressourcen, um interne Automatisierungsteams aufzubauen. Diese Teams sind darauf ausgelegt, die Roadmap für die industrielle Automatisierung in allen Fertigungsanlagen voranzutreiben und Fachwissen in den Bereichen mechanisches Design, industrielle Steuerung und Robotik zusammenzufassen. Anstatt sich auf externe Ingenieurdienstleister zu verlassen, nutzen diese Teams DIY-Technologien, um tiefgreifendes Prozesswissen zu entwickeln und selbst entworfene automatisierte Lösungen bereitzustellen.

Die vollständige Studie in Englisch finden Sie hier.

Über Vention

Vention hilft Unternehmen, ihre Produktionsbereiche durch eine demokratisierte Benutzererfahrung in nur wenigen Tagen zu automatisieren. Mit der digitalen Fertigungsautomatisierungsplattform von Vention können Kunden automatisierte Geräte direkt über ihren Webbrowser entwerfen, automatisieren, bestellen und bereitstellen. Vention hat seinen Hauptsitz in Montreal, Kanada, und Niederlassungen in Berlin und Boston. Die über 300 Mitarbeiter betreuen mehr als 4.000 Kunden auf fünf Kontinenten und in 25 Fertigungsindustrien. Für weitere Informationen besuchen Sie www.vention.io