Nach dem Auspacken des Roboters hatte ich den Eindruck, ein Tablet auf Rädern zu meiner Robotersammlung hinzuzufügen. Der kleine Roboter, der sich selbst „Anna“ nennt, wie ich später herausfinden sollte, hatte auf jeden Fall ein Android-Tablet als Gesicht. Ein Tablet-Roboter.

Nach dem Einschalten erwartete mich jedoch nicht der übliche Einrichtungsprozess, wie er bei Android-Geräten üblich ist. Stattdessen wurde ich mit Musik und einem kurzen Animationsvideo begrüßt. Danach landete ich, nach einer kurzen Wartezeit (die nur beim ersten Start auftrat), auf einer kindlich-verspielten App-Übersicht. Meine erste Idee war, im Einstellungsmenü zunächst eine Verbindung zum WLAN herzustellen. Im Handbuch hatte ich bereits gelesen, dass der Roboter nur mit einem 2,4-GHz-WLAN kompatibel ist. Das WLAN meiner FritzBox arbeitet im Dual-Mode und stellt sowohl ein 5-GHz- als auch ein 2,4-GHz-Signal zur Verfügung. Der Roboter fand dieses WLAN, fragte nach dem Passwort, bestätigte die richtige Eingabe und verband sich – allerdings nur für wenige Sekunden, bevor er wieder „nicht verbunden“ anzeigte. Anscheinend mag er ausschließlich reines 2,4-GHz-WLAN. Nachdem ich mein reines 2,4-GHz-WLAN ausgewählt hatte, gab es keine weiteren Verbindungsprobleme.

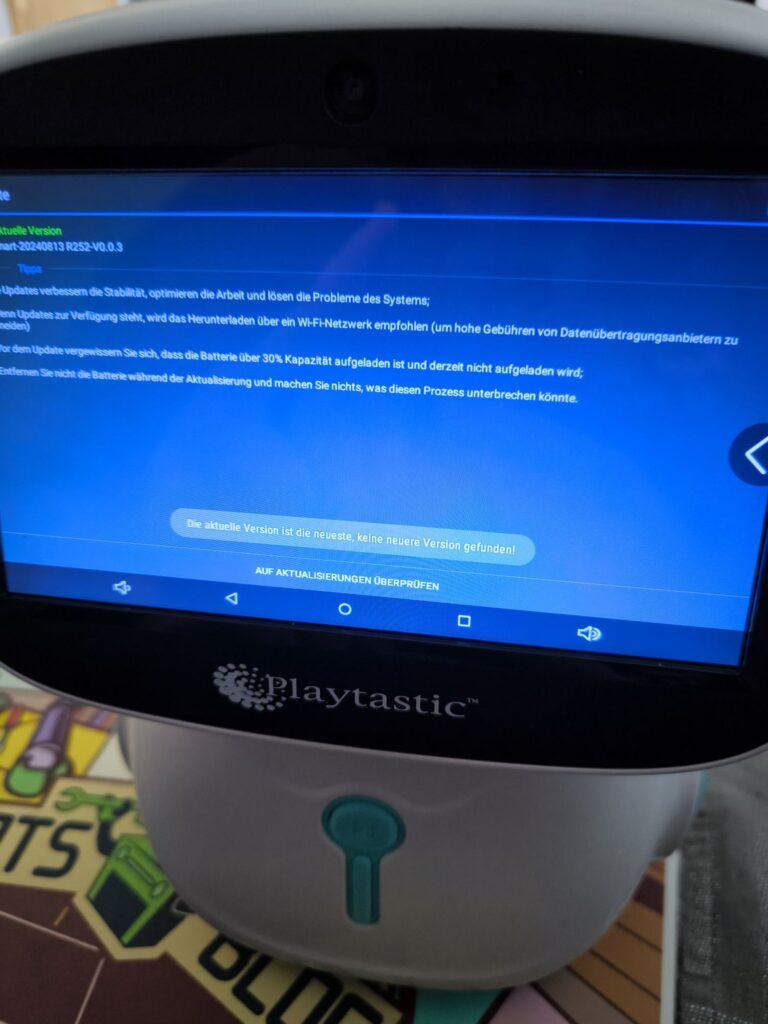

Die Android-Betriebssystemversion und die installierten Apps waren anscheinend aktuell; zumindest wurden keine Updates gefunden. Neben den vorinstallierten Lern-, Musik- und Spiele-Apps fielen mir direkt die YouTube-(Kids)- und Spotify-App auf. Hier ahnte ich auch etwas Spaß für Erwachsene!

Der erste Start der YouTube-App (nachdem das WLAN eine Internetverbindung bot) forderte leider ein Update der Google-Dienste, was wiederum die Anmeldung mit einem Google-Konto erforderte. Macht es besser nicht wie ich und legt kein neues Google-Konto direkt über das Display des Roboters an. Nutzt stattdessen einen Computer oder euer Smartphone und gebt dem Roboter anschließend nur die Zugangsdaten. Das geht deutlich schneller als über das etwas träge „Tablet“ des Roboters.

Nach der Anmeldung gelang dann auch der Start der YouTube-App. Dabei stellte ich fest, dass es sich um die YouTube-Kids-App handelte, die ich bisher nicht kannte. Die App bietet kindgerechte Videos für verschiedene Altersstufen, aber nicht das vollwertige YouTube-Erlebnis, wie man es beispielsweise vom Fernseher kennt. Es können verschiedene Kinder-/Nutzerprofile angelegt werden, und mit einem „Eltern-Account“ lässt sich genau steuern, welche Videos und Kanäle verfügbar sind oder ob das Kind eigenständig andere Kanäle suchen darf.

Für erwachsene Nutzer bleiben immerhin alle Spotify-Inhalte verfügbar. Die vorinstallierte Spotify-App funktioniert identisch zu der Version auf meinem Smartphone. Der Klang des Roboters ist laut und basslastig; manchmal hört man dadurch das Plastikgehäuse etwas vibrieren. Für Kinder und ältere Karaoke-Fans gibt es in der App „KinderFernsehen“ eine Karaoke-Videosammlung. Ein mitgeliefertes Mikrofon lässt sich an der Rückseite des Roboters einstecken. Nach dem Einschalten des Mikrofons wird der eigene Gesang mit ordentlich Hall-Effekt durch den Roboter wiedergegeben. Ein Anschluss für ein zweites Mikrofon für Duett-Partner ist ebenfalls vorhanden; allerdings wird nur ein Mikrofon mitgeliefert – ein Tablet-Karaoke-Musik-Video-Roboter.

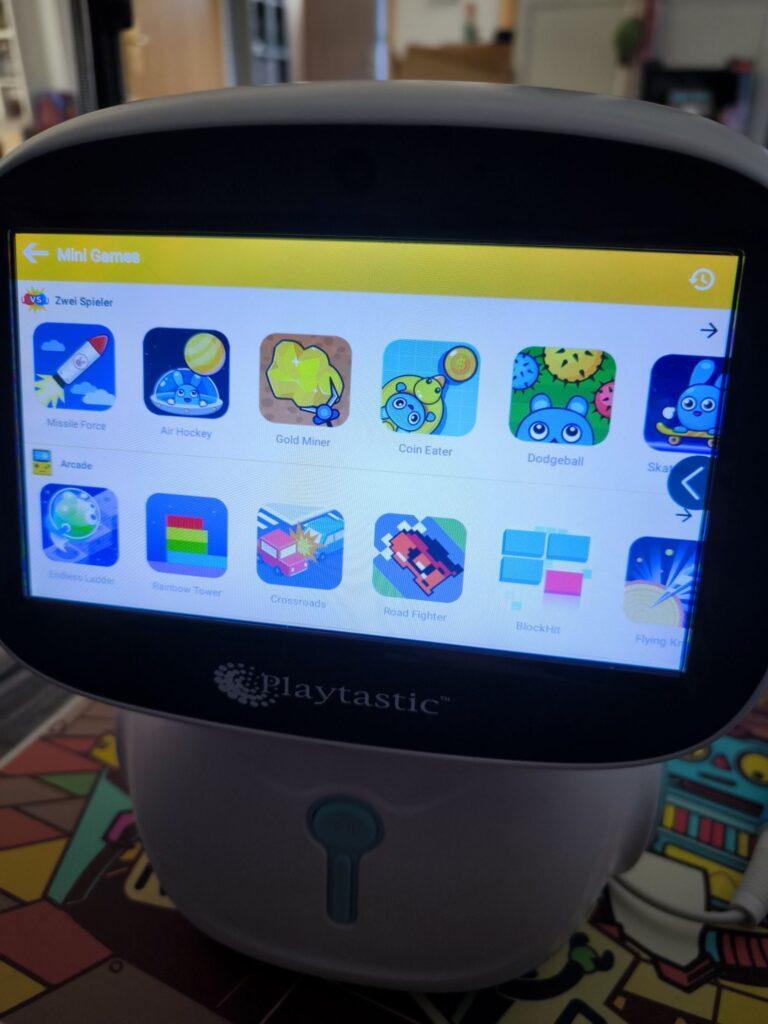

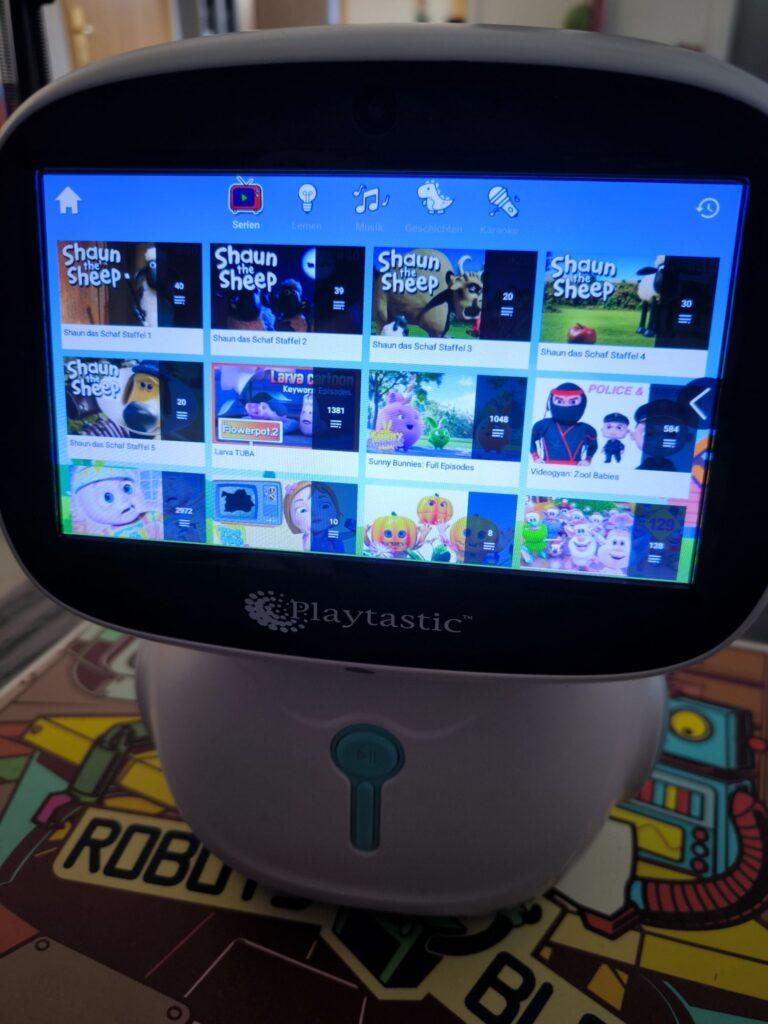

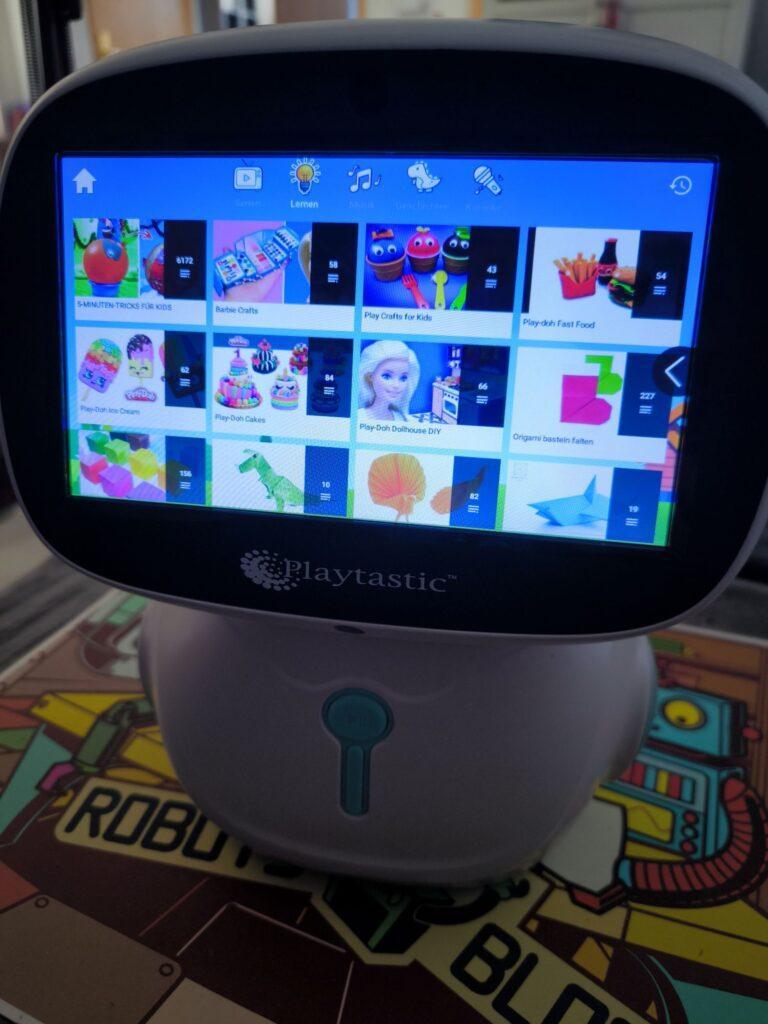

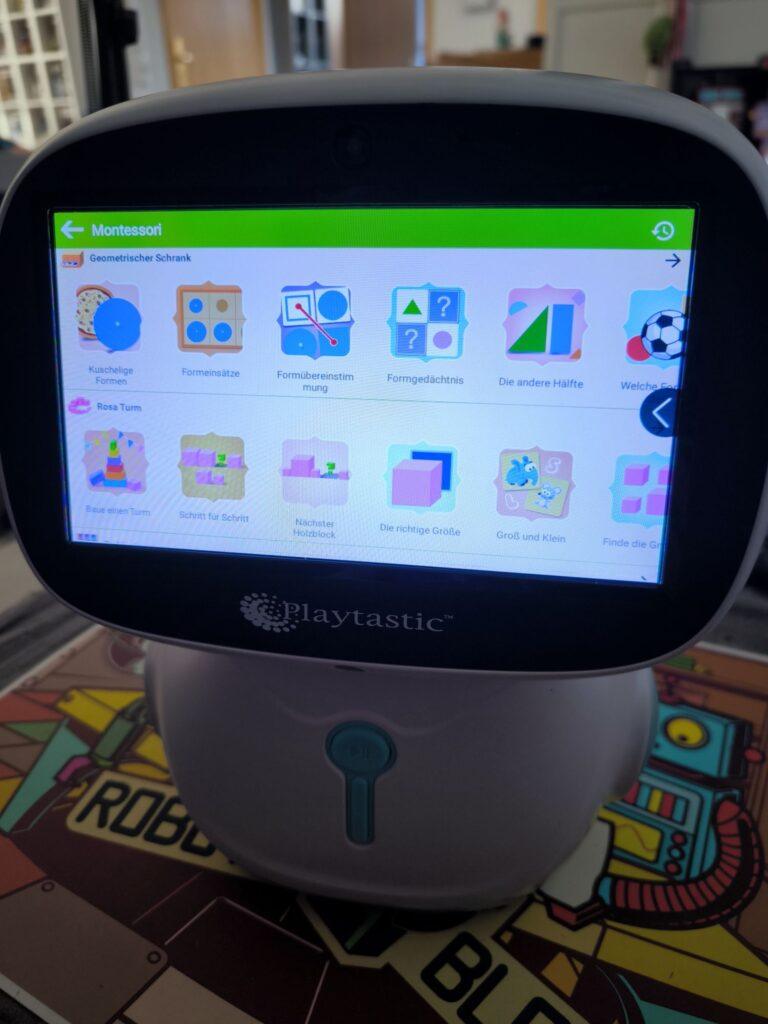

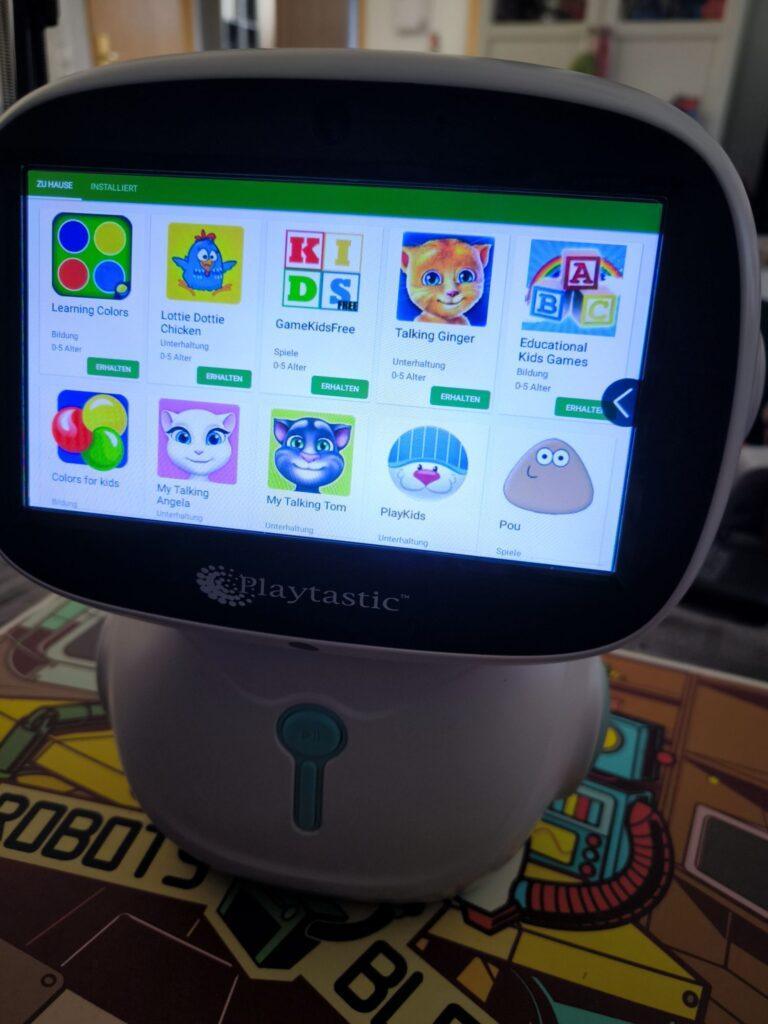

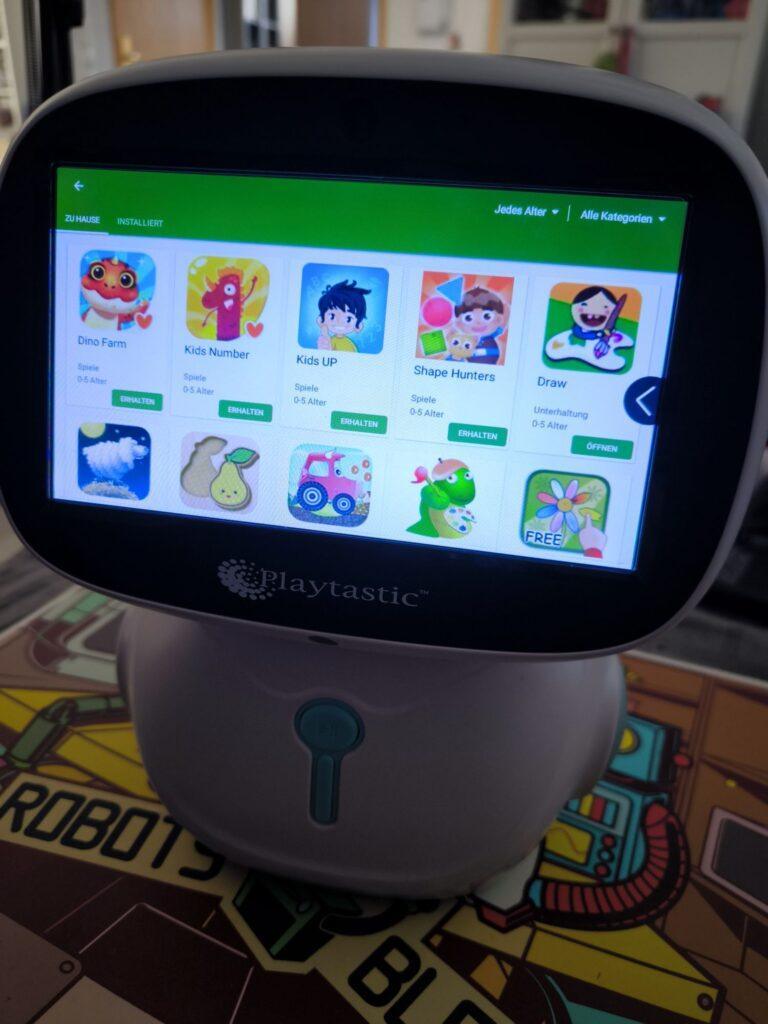

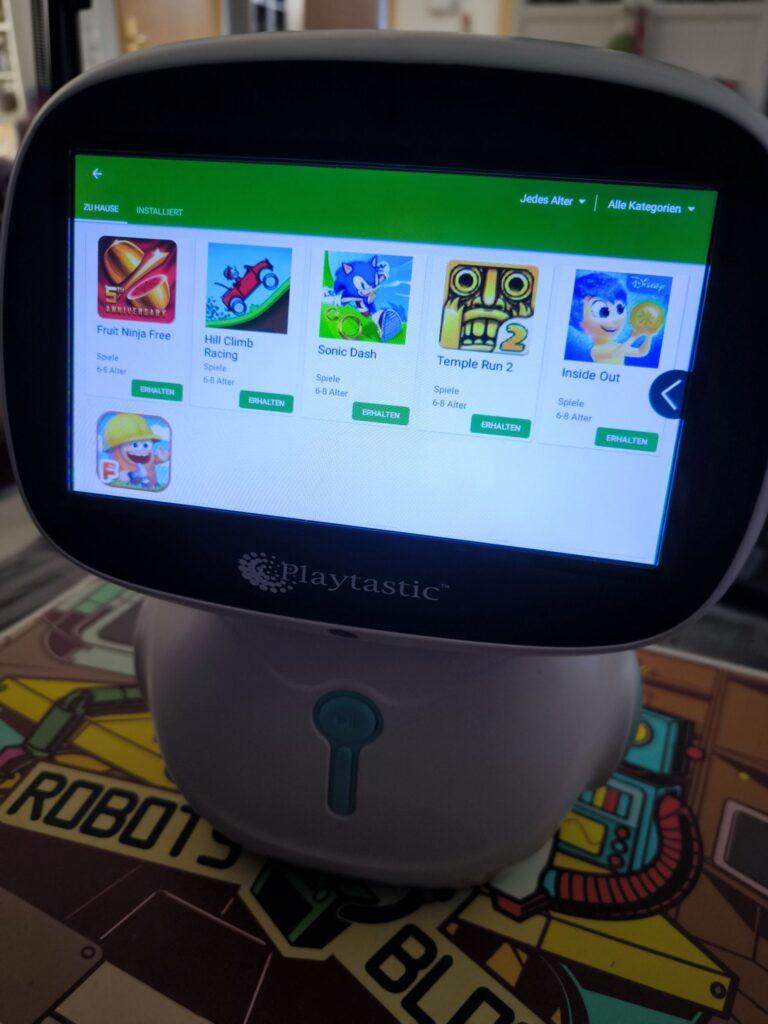

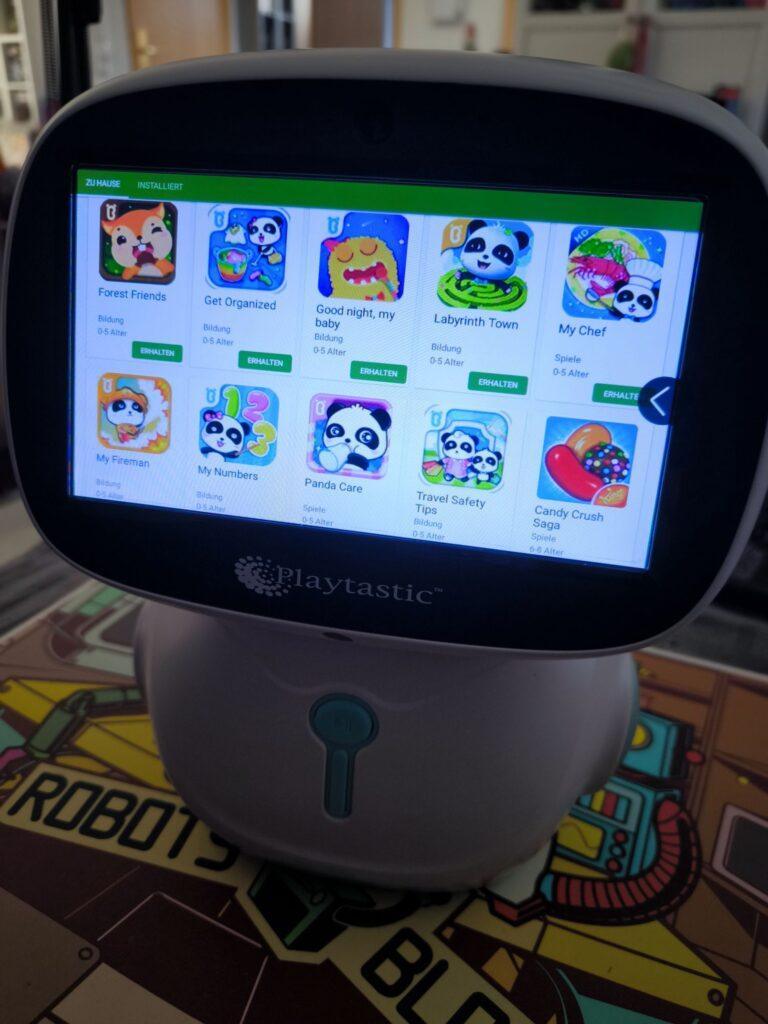

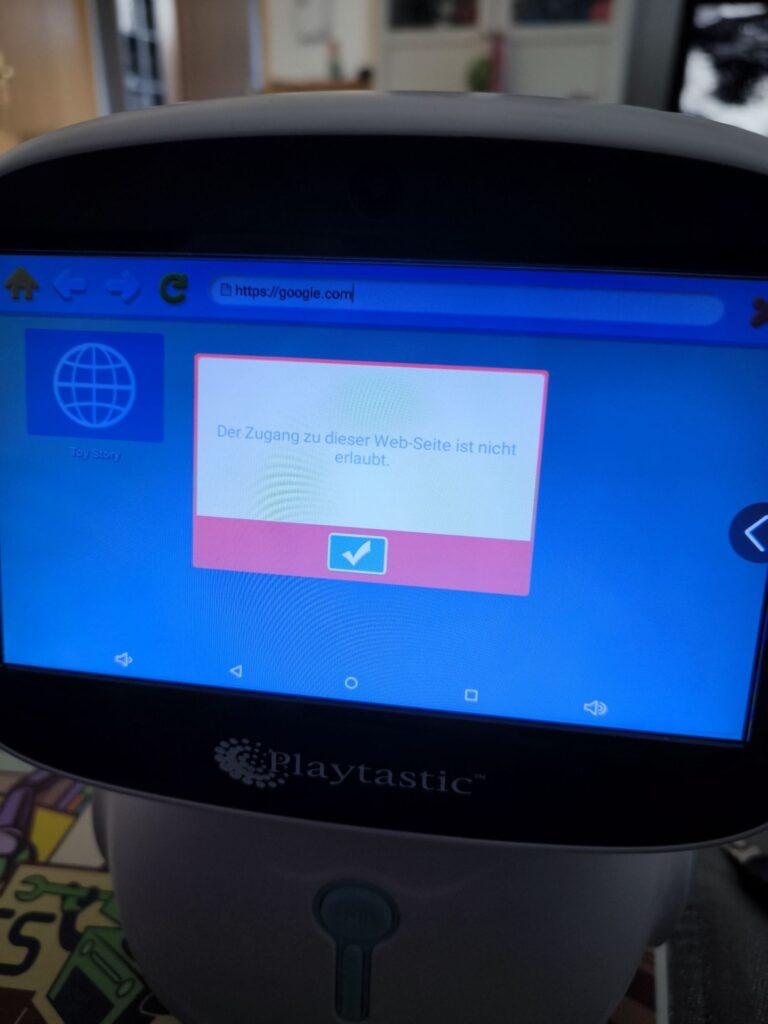

In der KinderFernsehen-App finden sich bekannte Videoreihen (wie Shaun das Schaf), Musik- und Lerninhalte sowie Spiele. Außerhalb dieser App gibt es die üblichen Anwendungen wie Wecker, Stoppuhr oder Bildergalerie sowie diverse weitere Lern-Apps: Rechnen, Malen, Schreiben, Musizieren oder Sprachen lernen – für fast alles gibt es eine App. Und wenn nicht, bietet der „Kinderladen“ eine abgespeckte Version des App-Stores mit Spielen, Lern-Apps und anderen kinderfreundlichen Inhalten. Ein Tablet-Karaoke-Musik-Video-Lern-Roboter also! Andere Android-Apps lassen sich hier jedoch nicht finden. Mir ist es auch nicht gelungen, fremde Apps zu installieren – weder per SD-Karte noch per Browser-Download –, da der integrierte Browser nur vorher freigegebene Webseiten öffnet. Wie man diese hinzufügt, habe ich nicht herausgefunden. Im PIN-geschützten „Elternmodus“ konnte ich zwar installierte Apps ausblenden (quasi vor Kindern verstecken), aber keine neuen Apps „sideloaden“. Es gibt einen erweiterten Modus, der nach mehrfachem Tippen auf die Versionsnummer des Roboters in den Einstellungen erscheint – leider geschützt durch ein mir unbekanntes Passwort. Was sich wohl dahinter verbirgt? Vielleicht die Möglichkeit zum Installieren eigener Apps?

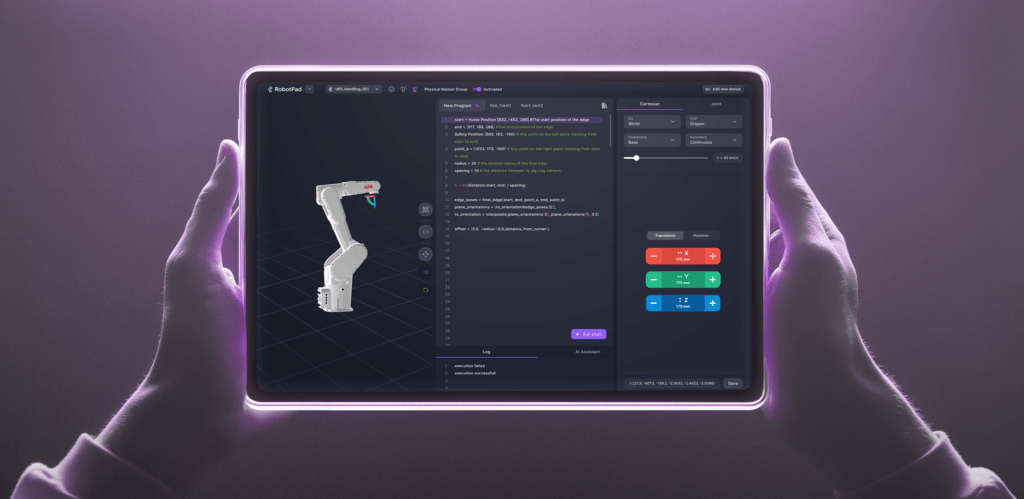

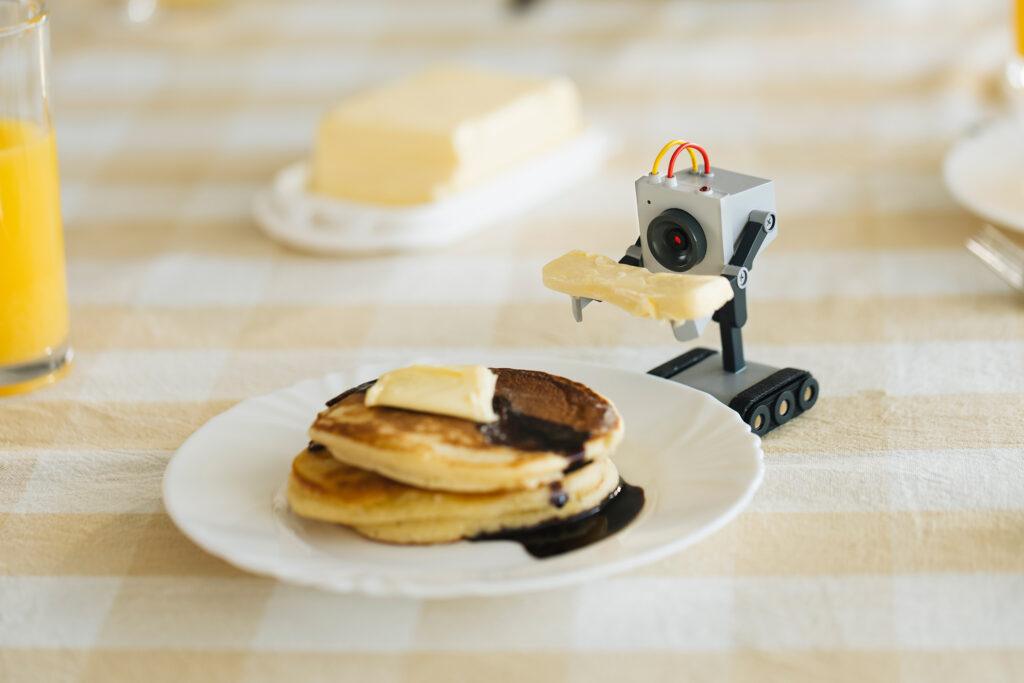

Die App „Musik und Tanz“ öffnet einen Musikplayer, mit dem MP3s – auch von einer eingesteckten SD-Karte – abgespielt werden können. Der Unterschied zur normalen „Musik“-App: Der Roboter tanzt zur abgespielten Musik und fährt mehr oder weniger wild „tanzend“ durch die Gegend. Ich hätte mir an dieser Stelle gewünscht, eigene Bewegungsabläufe programmieren zu können – oder sogar eine Lern-App, die mir das Programmieren des Roboters beibringt und die Möglichkeiten der integrierten Motoren meines „Roboter-Tablets“ nutzbar macht. Vielleicht sogar in Kombination mit der integrierten Kamera einen Linienfolger programmieren? Vielleicht wird hierfür ja irgendwann noch eine passende App entwickelt.

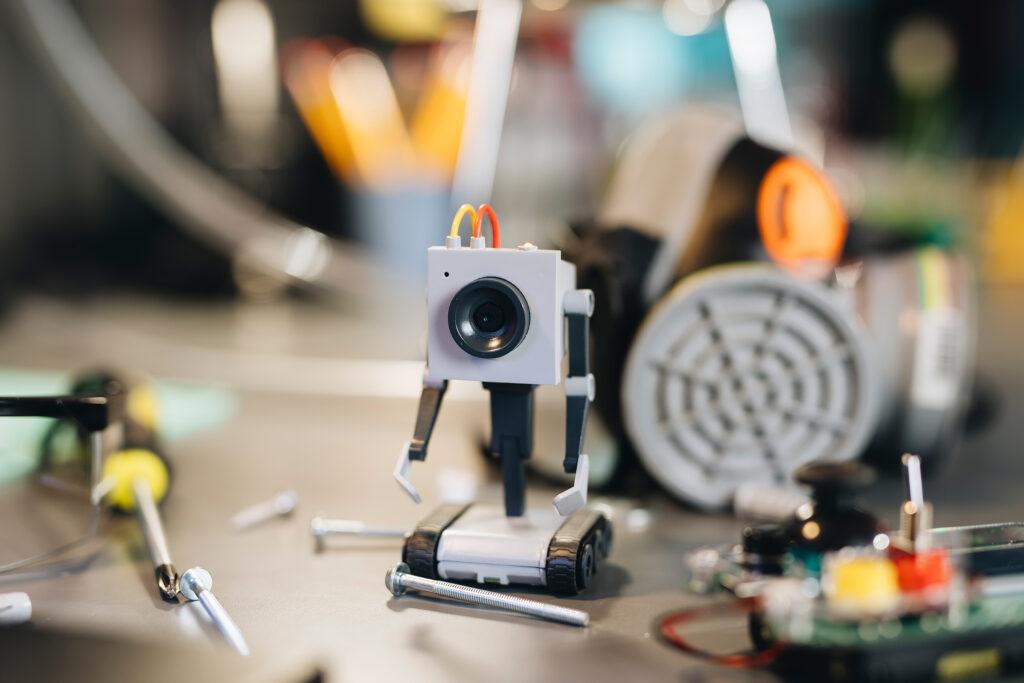

Die integrierte Kamera lässt sich zum Aufnehmen von Fotos und Videos in niedriger Auflösung nutzen. Leider habe ich keine App gefunden, die die Kamera für Bewegungsspiele nutzt – so wie beim Miko 3-Roboter bekannt. Vielleicht dürfen wir auch hier noch auf Erweiterungen per App hoffen?

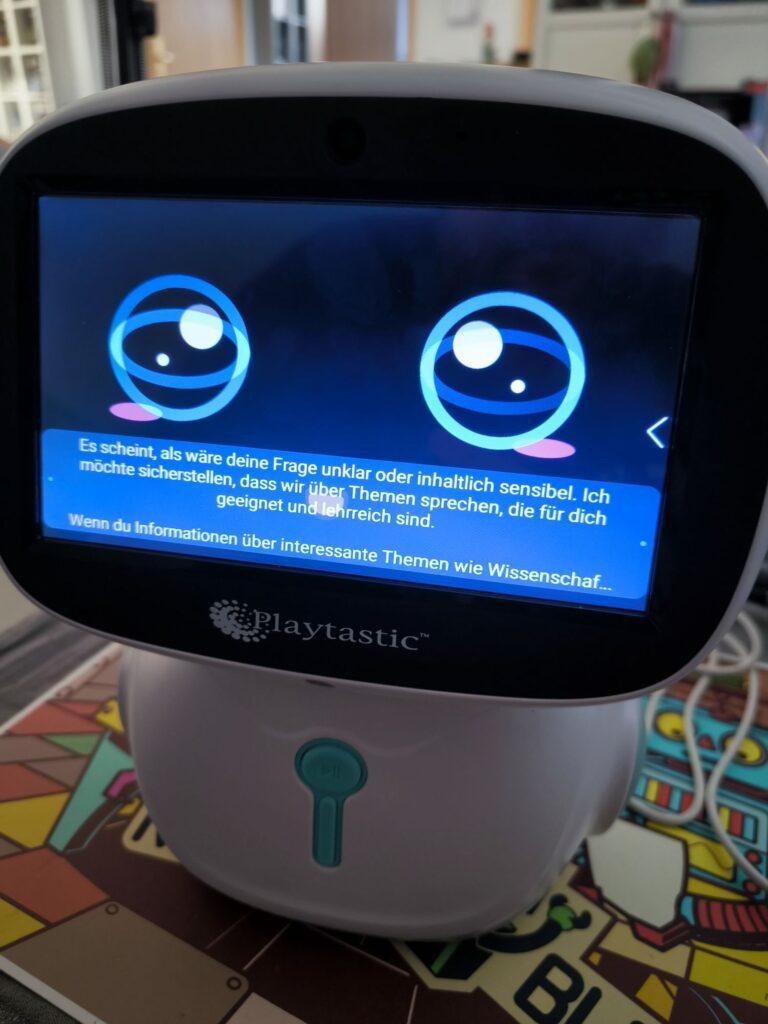

Und dann gibt es noch den ChatGPT-Assistenten-Modus: Auf dem Display erscheint ein Robotergesicht, mit dem man sich auch ohne eingestecktes Mikrofon unterhalten kann. Die Antworten kommen dabei nach etwas Verzögerung von einer ChatGPT-Instanz. Diese scheint auf Unterhaltungen mit Kindern spezialisiert zu sein und schlägt automatisch Themen wie Dinosaurier, Weltraum oder Tiere vor. Jede Antwort liefert direkt Ideen für neue Nachfragen oder Themenvorschläge und führt so aktiv durch das Gespräch. Die ChatGPT-Instanz hat keinen Zugriff auf aktuelle Online-Inhalte und ist ausreichend moderiert: Nicht kindgerechte Themen werden in vielen Fällen ignoriert oder übergangen. Zu genaue Nachfragen oder geschicktes Prompting können jedoch manchmal zumindest fragwürdige Inhalte liefern – allerdings bleiben aktiv vorgeschlagene Themen stets kindgerecht (besonders gerne Dinosaurier). Auch Rekorde aus der Tierwelt oder Umweltphänomene werden als Gesprächsthemen vorgeschlagen.

Ein Tablet-Karaoke-Musik-Video-Lern-KI-Assistenten-Roboter.

Der Roboter ist ein vielseitiges Spielzeug mit gut funktionierenden vorinstallierten Apps. Für Erwachsene gibt es nur wenige Inhalte; diese sind hier aber definitiv nicht die Zielgruppe. Als auffälliger Spotify-Player mit einigen Zusatzfeatures ist der Roboter jedoch auch für Erwachsene interessant – erwartet aber keine Höchstleistung vom integrierten Tablet! Es ist eindeutig nur für die mitgelieferten Apps ausgelegt; diese sind dafür kindgerecht und sicher … solange man keine allzu neugierigen Fragen an den ChatGPT-Assistenten stellt. Insgesamt handelt es sich um ein lehrreiches Spielzeug für Kinder – auch um erste Erfahrungen im Umgang mit KI zu sammeln. Für den Preis bekommt man sonst nur ein günstiges Tablet; hier gibt es jedoch gleich einen ganzen Roboter dazu!