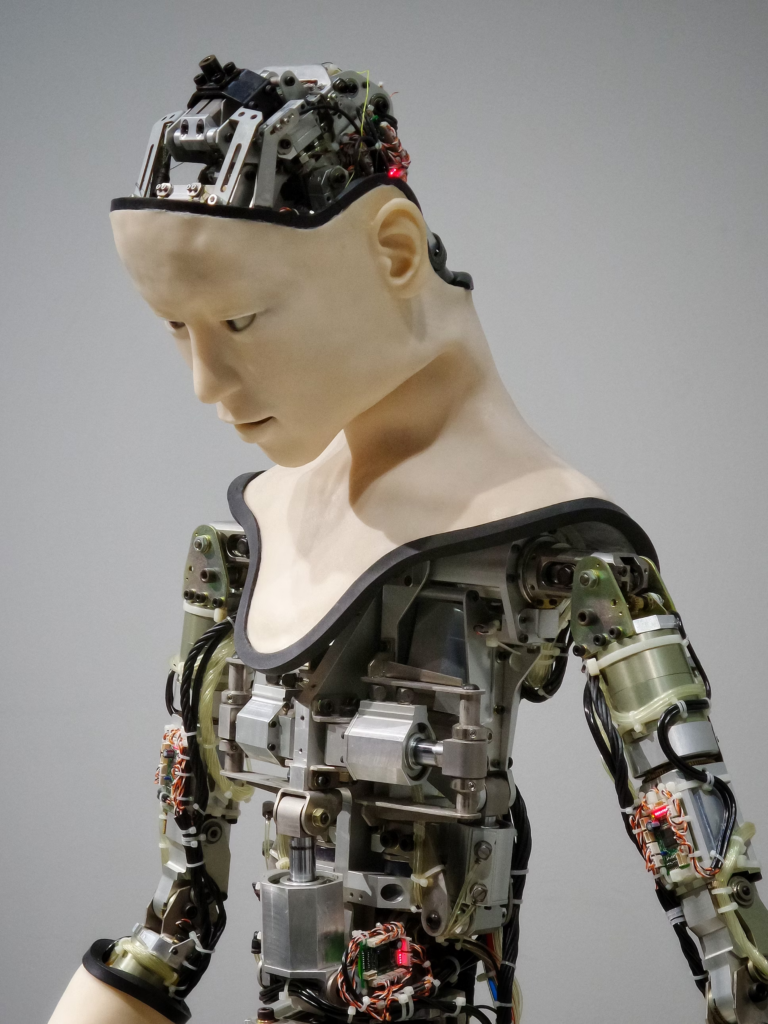

Robotics has quickly become pivotal across industries like manufacturing, health care and agriculture, transforming how work gets done. It boosts productivity and efficiency by taking on repetitive, precise and physically demanding tasks. This tech revolution is now entering construction, a sector known for its grueling physical demands and labor-intensive processes.

Autonomous robots are stepping up to handle critical jobs — from site inspections to heavy lifting — helping jobsites become safer, more efficient and more precise. This shift is fundamental to an industry where advanced robotics and human expertise work together, reimagining what’s possible on the modern jobsite.

Robots in Construction

Autonomous robots are making serious headway in the construction industry. Still, only about 55% of the sector globally is currently harnessing their potential. For companies that have embraced this technology, these devices have already tackled some of the most crucial and challenging tasks on jobsites.

For example, drones can handle aerial inspections, create detailed site maps and monitor progress with remarkable accuracy and speed. Meanwhile, specialized robots enhance bricklaying into a faster, more precise process. Moreover, large-scale 3D printing machines can construct entire structures, revolutionizing project planning and execution.

As these technologies improve, robots increasingly take on the larger and more complex tasks that once required intense physical labor. From foundational work to finishing touches, construction robots‘ capabilities are expanding rapidly. They manage these high-stakes jobs to reshape the industry and set new speed, safety and efficiency standards on modern jobsites.

This movement toward automation opens doors to a construction landscape where advanced technology and skilled labor work in tandem. It paves the way for more ambitious projects and a more streamlined building process.

Types of Autonomous Construction Robots

Robots come in many shapes and sizes, each designed to handle specific tasks that enhance precision. From ground-level operations to overhead site monitoring, these machines help employees plan, manage and execute projects. Here’s a look at some of the types of autonomous robots making a difference on jobsites today:

- Drones for aerial site mapping and monitoring: These high-flying machines create detailed maps, monitor jobsite progress and conduct inspections from a bird’s-eye view.

- Robotic excavators and bulldozers: Built to handle heavy lifting and earth-moving, they take on physically intense tasks. They speed up the early stages of construction and site preparation.

- 3D printing robots for structural building: This advanced technology can build walls and entire structures — layer by layer — directly on-site.

- Bricklaying and welding robots: They are perfect for repetitive and precision-focused tasks because they can lay bricks and weld with remarkable speed and accuracy. This reduces human error and improves efficiency in construction projects.

- Inspection robots for quality control: They come with sensors and cameras to inspect completed work for quality and safety. They ensure workers meet industry standards throughout the project.

Each type of robot plays a specialized role, showing how automation can address the unique demands of construction and reshape what’s possible on jobsites.

Advantages of Robots on Jobsites

Robots benefit construction projects, especially regarding efficiency, precision and safety. Unlike human crews, these devices can work continuously to help reduce project timelines and keep everything on schedule. With their high level of accuracy, they minimize errors and waste, which also reduces costly rework and makes each project more resource-efficient.

Perhaps most importantly, automation makes construction sites safer. For example, taking over repetitive and physically taxing tasks helps prevent injuries related to repetitive stress and fatigue. This creates a safer work environment where human workers can focus on tasks requiring skill and oversight.

Impact on the Workforce

The rise of robotics in construction transforms job roles, shifting the focus from hands-on labor to more specialized oversight and technical maintenance. As robots handle demanding tasks like heavy lifting, bricklaying and site inspections, the U.S. construction industry is expected to need around 500,000 new workers in 2024 to meet project demands.

Robotics could help address this gap while introducing a tech-driven shift on jobsites. Although concerns about job displacement are natural, experts see robots and humans as a powerful team, each enhancing the other’s strengths. Machines can tackle repetitive, high-risk jobs to make sites safer. Meanwhile, human workers focus on decision-making, creativity and complex problem-solving. This collaboration helps build a smarter, safer workforce.

The Future of Autonomous Construction Robots

Over the next decade, construction robotics can make major leaps forward. In fact, experts predict the global market for these technologies could exceed $242 million by 2030. Emerging tools like AI integration and enhanced sensors are expected to bring new levels of functionality to robots. They allow them to analyze data, adapt to changing environments and make intelligent decisions to boost precision and productivity on jobsites.

These advancements may lead to fully autonomous construction sites, where robots manage nearly every aspect of the build, from digging foundations to applying finishing touches. Such a shift would slash project timelines and improve safety by reducing human exposure to high-risk tasks. It also sets the stage for an industry that combines cutting-edge automation with human oversight to deliver faster, safer and more efficient projects than ever before.

New Roles and Challenges in a Tech-Driven Construction Industry

While robots bring tremendous benefits to construction sites, they also open up new roles for workers in areas like oversight, programming and maintenance. However, these advancements come with challenges, which require workers to adapt to a tech-driven environment and develop specialized skills to thrive alongside automation.

Guest article by Ellie Gabel. Ellie is a writer living in Raleigh, NC. She's passionate about keeping up with the latest innovations in tech and science. She also works as an associate editor for Revolutionized.