Archiv des Autors: Sebastian Trella

Austin-based Apptronik Inks Partnership with NASA for Humanoid Robots

AUSTIN, TEXAS (PRWEB) SEPTEMBER 20, 2022

Apptronik, an Austin-based company specializing in the development of versatile, mobile robotic systems, is announcing a partnership with NASA to accelerate commercialization of its new humanoid robot. The robot, called Apollo, will be one of the first humanoids available to the commercial markets.

At Apptronik’s headquarters in Austin, Texas, the first prototype of Apollo is now complete, with the expectation of broader commercial availability in 2023. Unlike special-purpose robots that are only capable of a single, repetitive task, Apollo is designed as a general-purpose robot capable of doing a wide range of tasks in dynamic environments. Apollo will benefit workers in industries ranging from logistics, retail, hospitality, aerospace and beyond.

NASA is known across the globe for its contributions to the advancement of robotics technology. NASA first partnered with Apptronik in 2013 during the DARPA Robotics Challenge (DRC), where founders were selected to work on NASA’s Valkyrie Robot. The government agency has now selected Apptronik as a commercial partner to launch a new generation of general-purpose robots, starting with Apollo.

“Continued investment from NASA validates the work we are doing at Apptronik and the inflection point we have reached in robotics. The robots we’ve all dreamed about are now here and ready to get out into the world,” said Jeff Cardenas, CEO and co-founder of Apptronik. “These robots will first become tools for us here on Earth, and will ultimately help us move beyond and explore the stars.”

In addition to its work with NASA, Apptronik’s team has partnered with leading automotive OEMs, major transportation and logistics companies, and government agencies. Boasting notable names including Dr. Nicholas Paine, Co-founder and Chief Technology Officer of Apptronik and Dr. Luis Sentis, Co-Founder and Scientific Advisor, its team is respected as among the best in the world. A growing hub for robotics, the Austin-based company continues to recruit top talent looking to bring their innovations to market now.

Apptronik is recognized for its emphasis on human-centered design, building beautifully designed and user-friendly robotic systems. As part of this commitment, it selected premier design firm argodesign as its partner in designing Apollo with the goal of creating robots capable of working alongside humans in our most critical industries. The team’s focus now is to scale Apollo so that it can be customer-ready in 2023.

About Apptronik:

Apptronik is a robotics company that has built a platform to deliver a variety of general-purpose robots. The company was founded in 2016 out of the Human Centered Robotics Lab at the University of Texas at Austin, with a mission to leverage innovative technology for the betterment of society. Its goal is to introduce the next generation of robots that will change the way people live and work, while tackling some of our world’s largest challenges. To learn more about careers at Apptronik, visit https://apptronik.com/careers/.

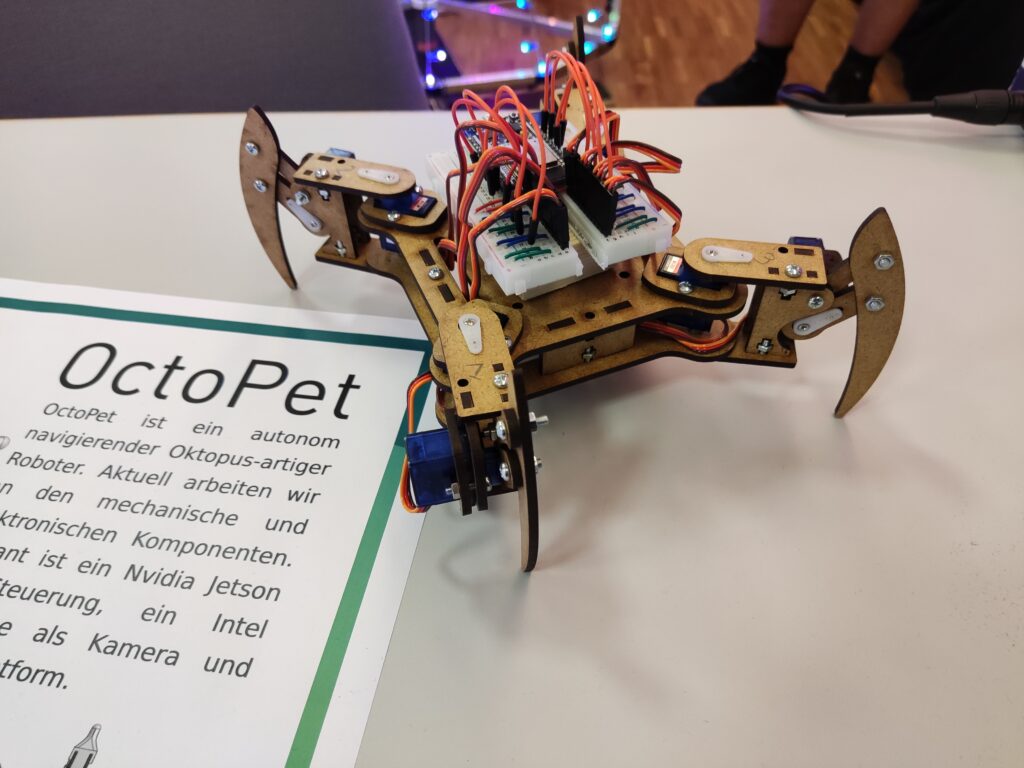

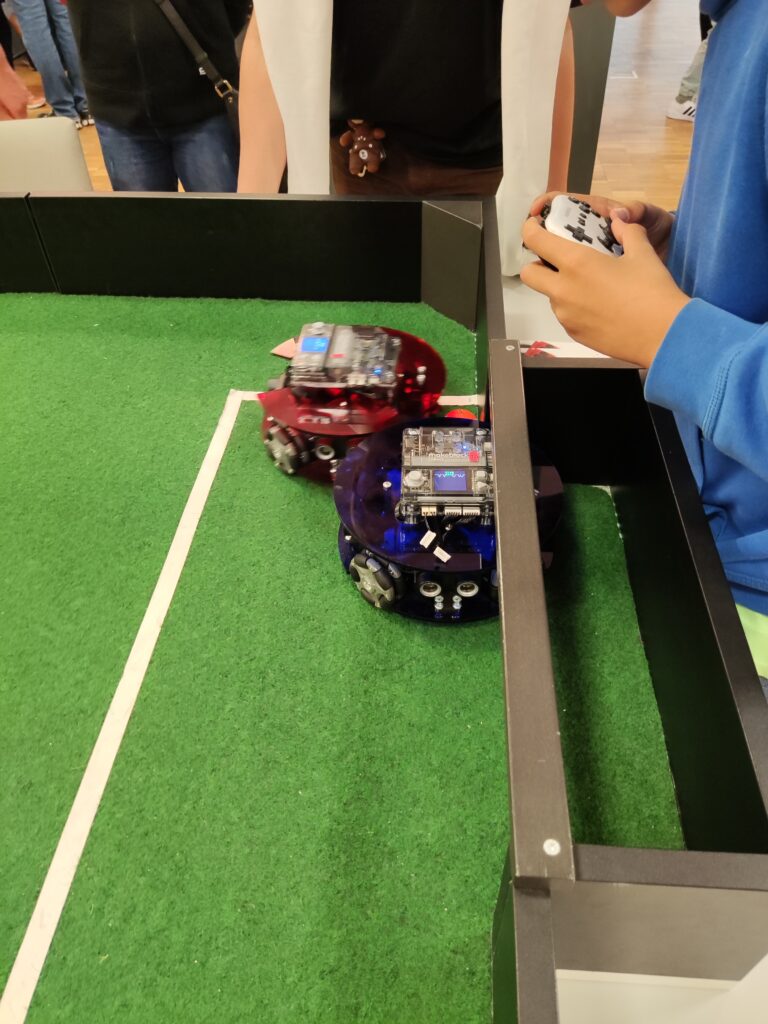

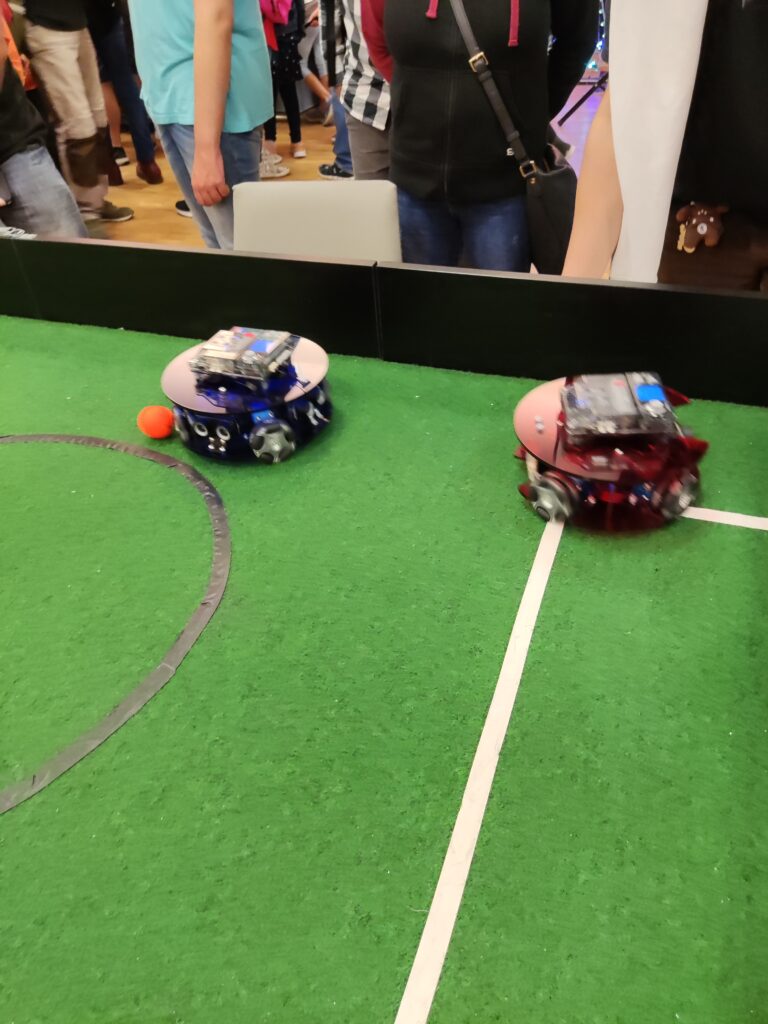

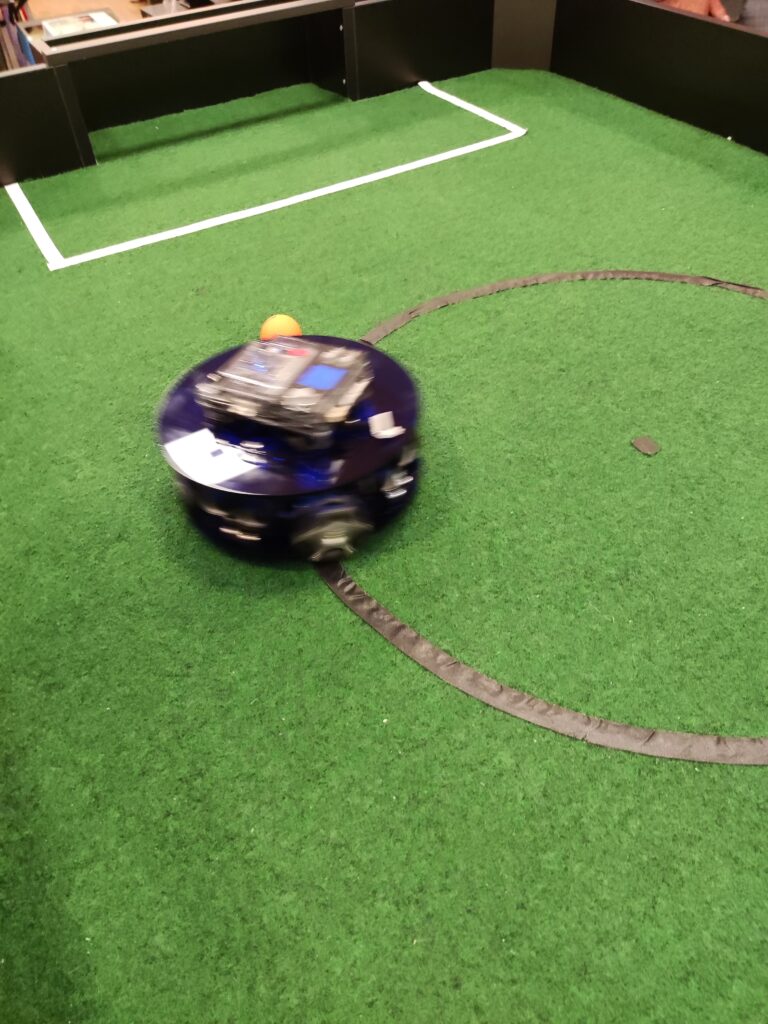

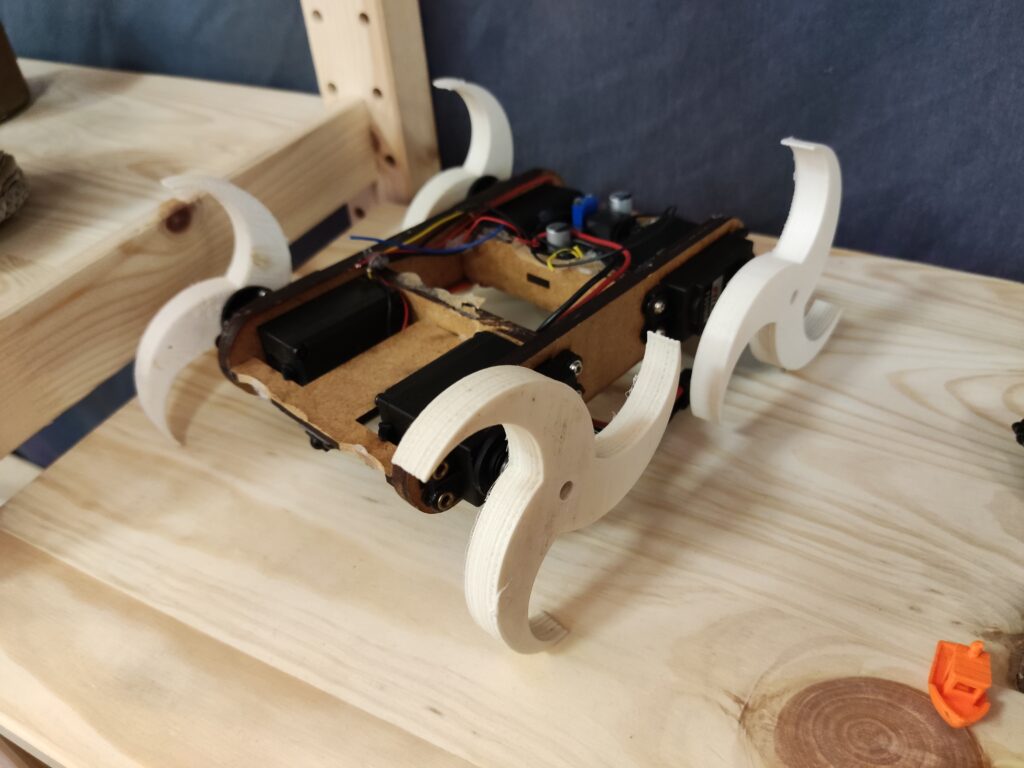

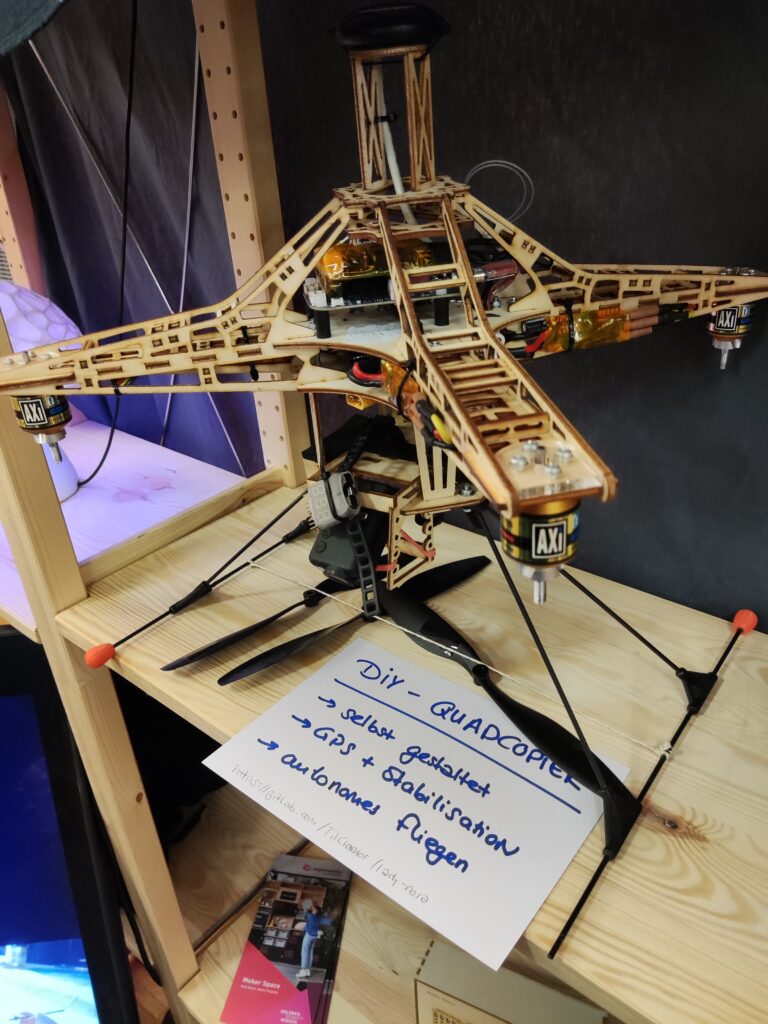

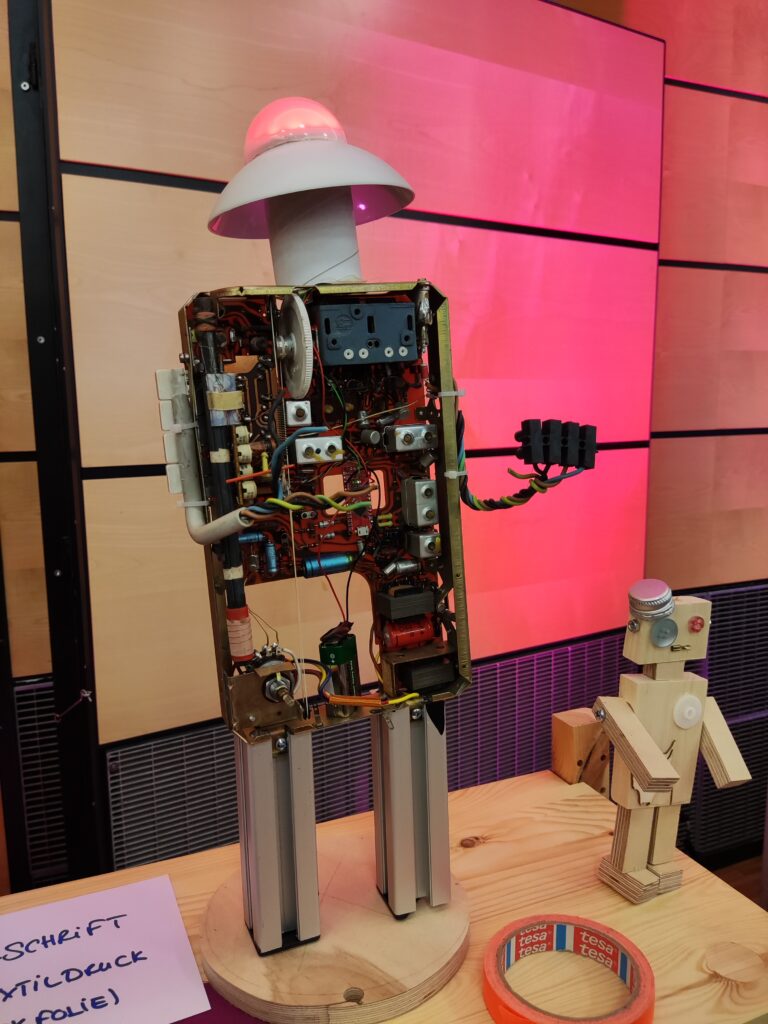

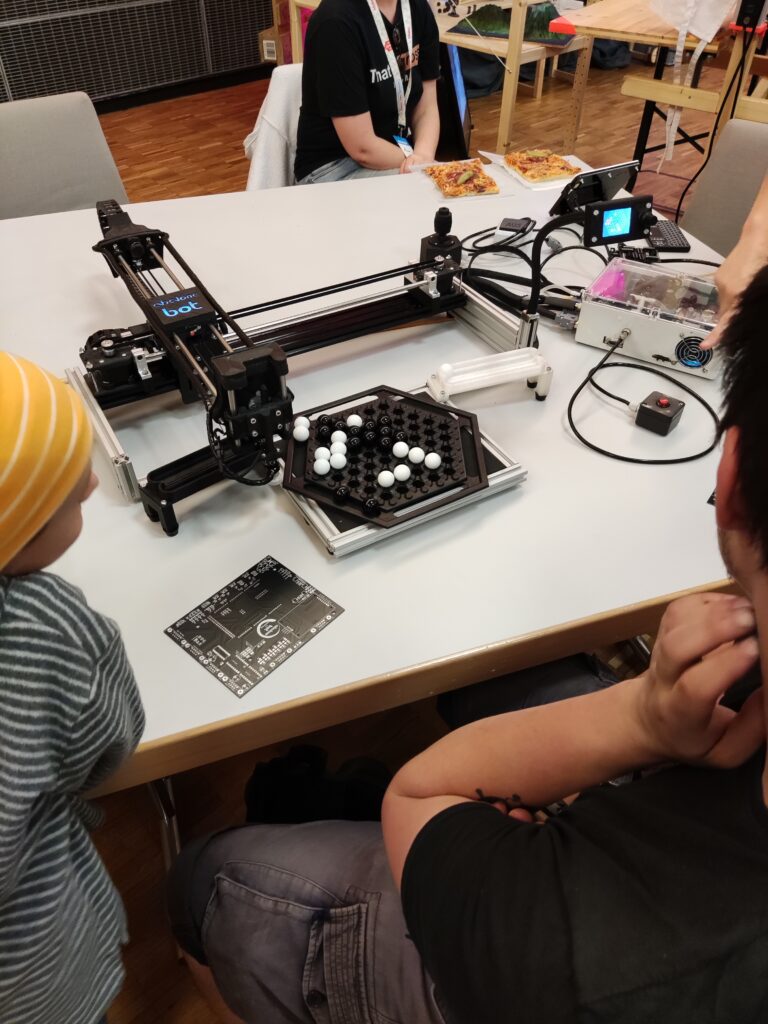

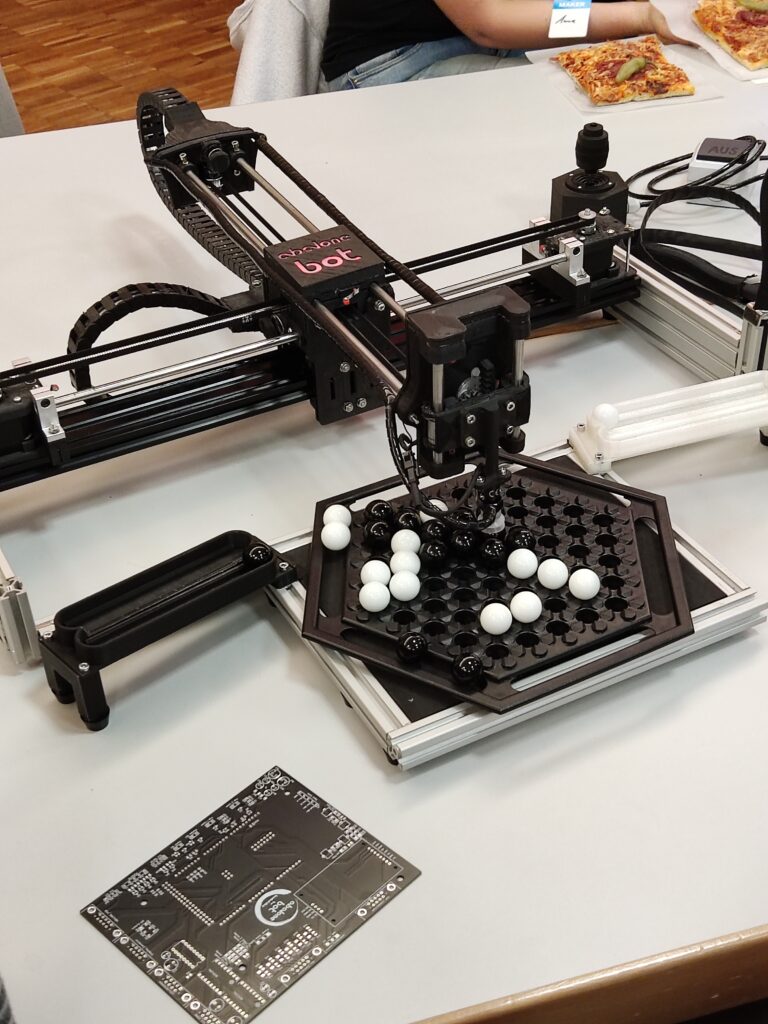

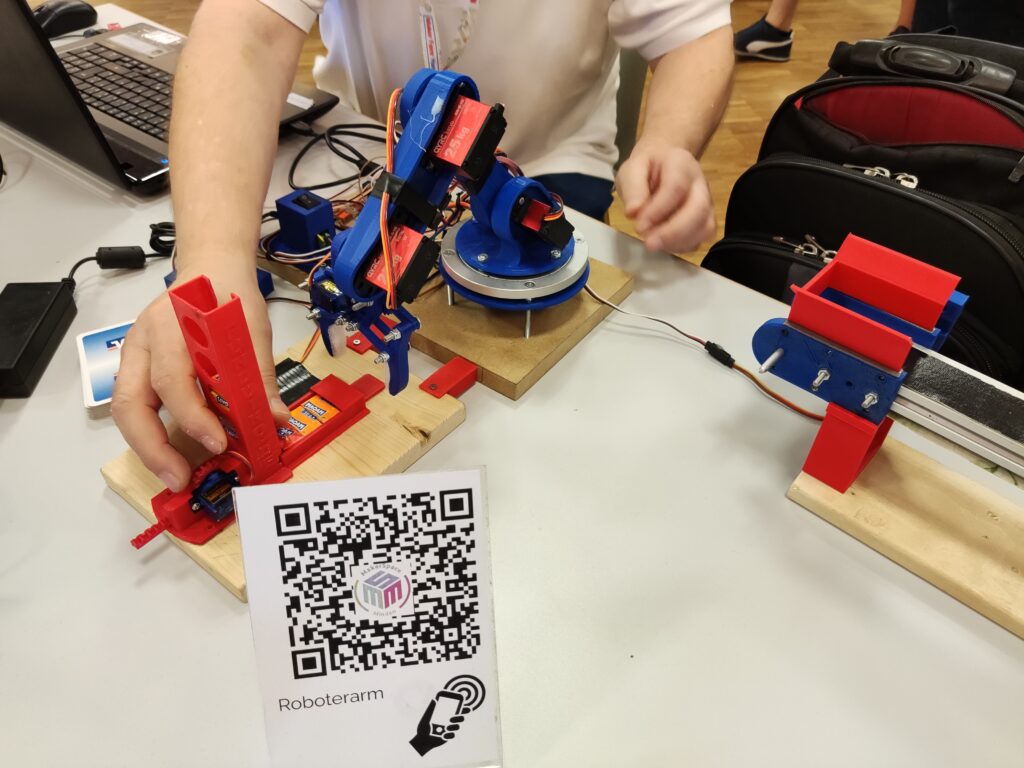

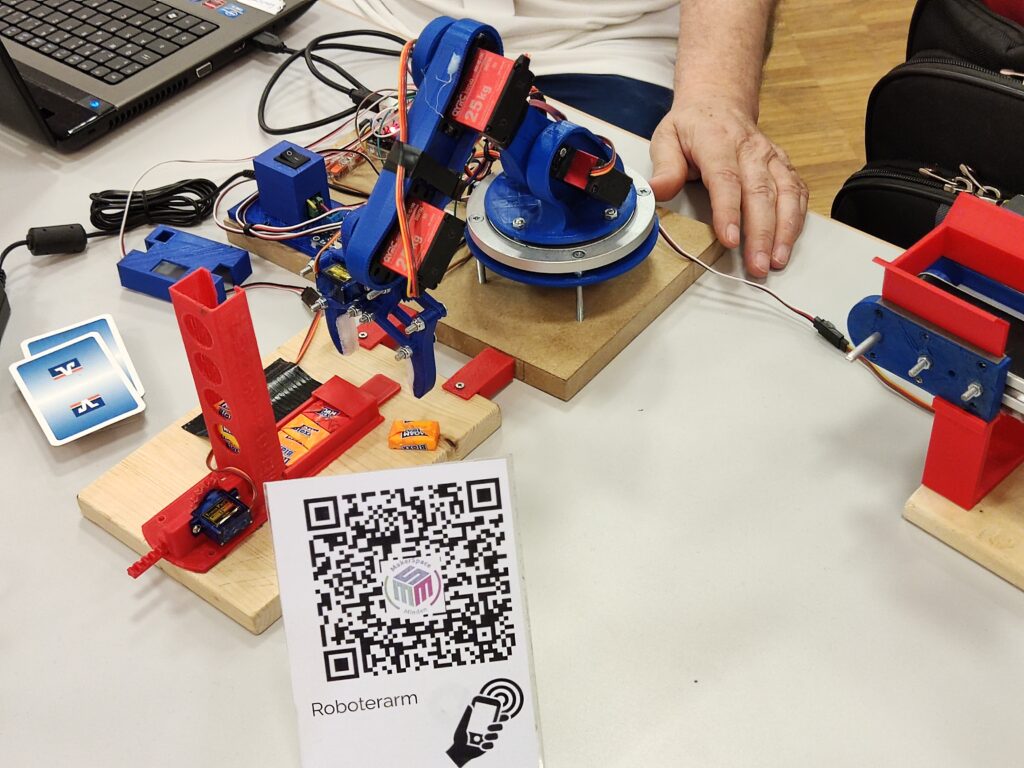

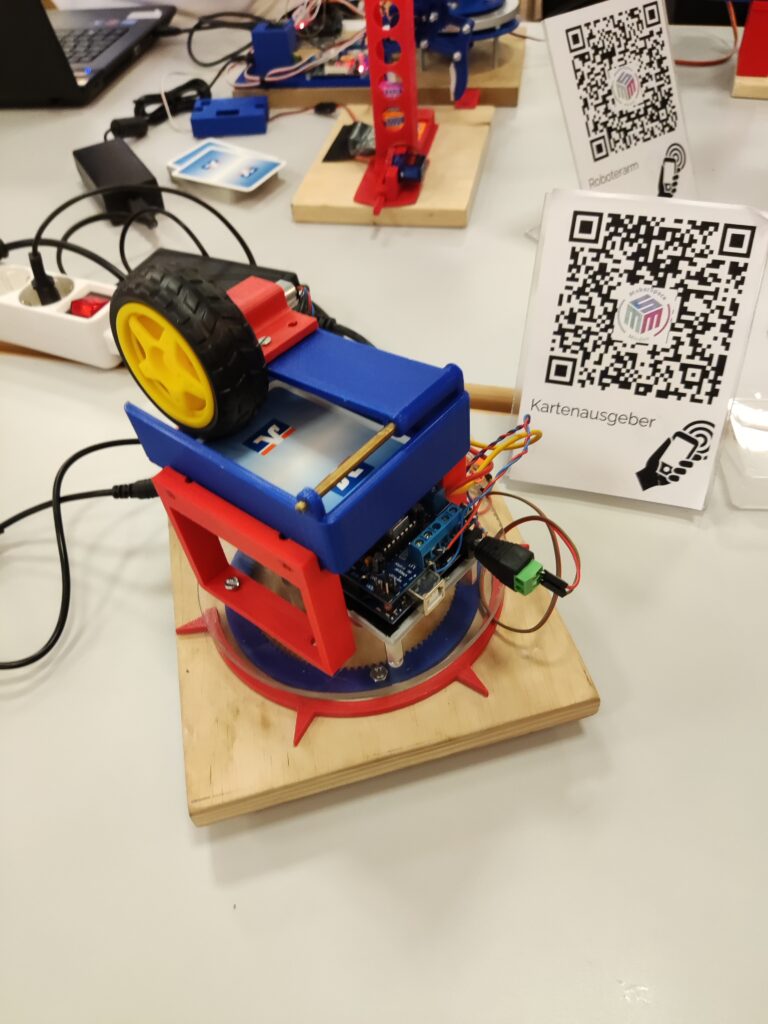

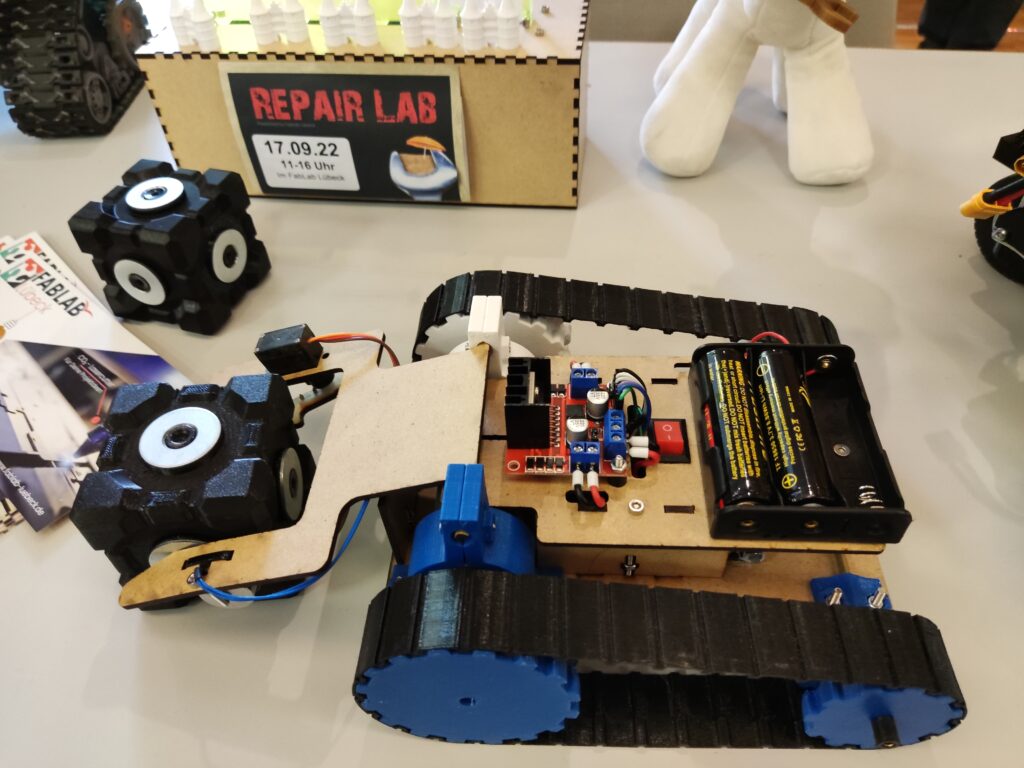

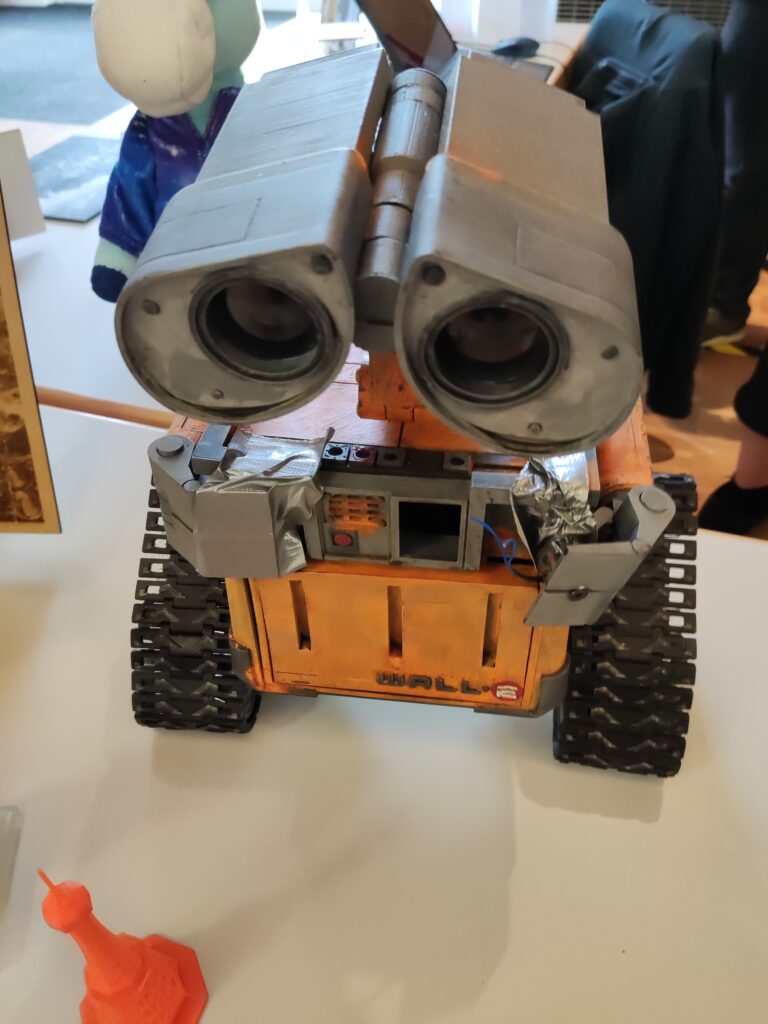

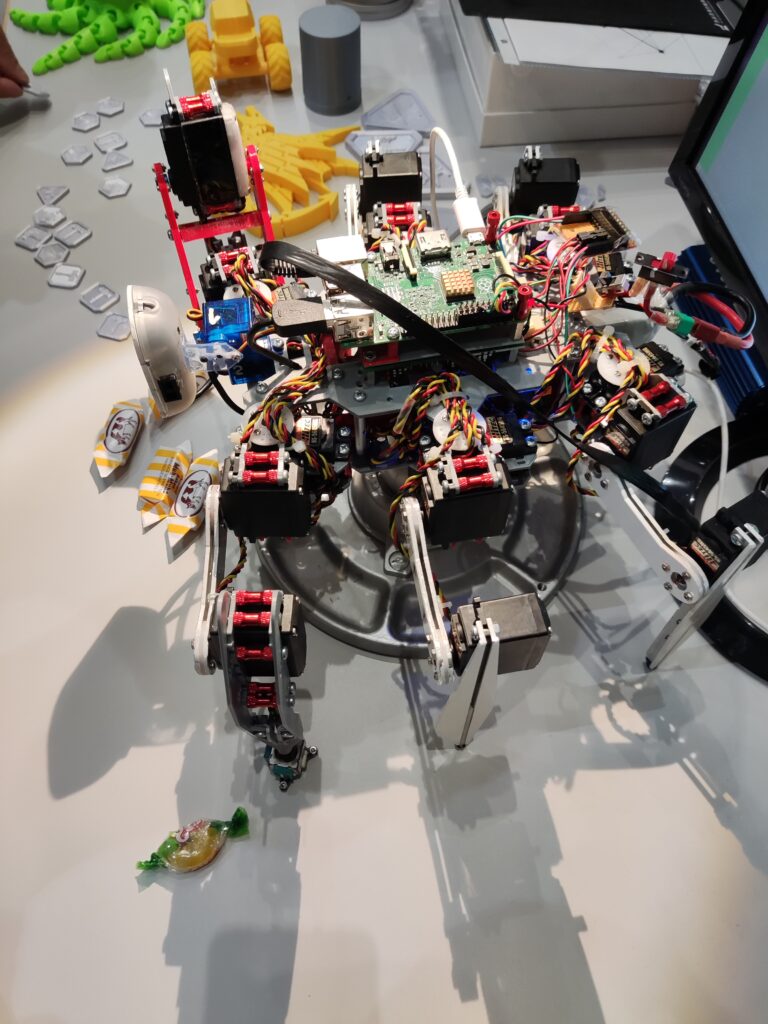

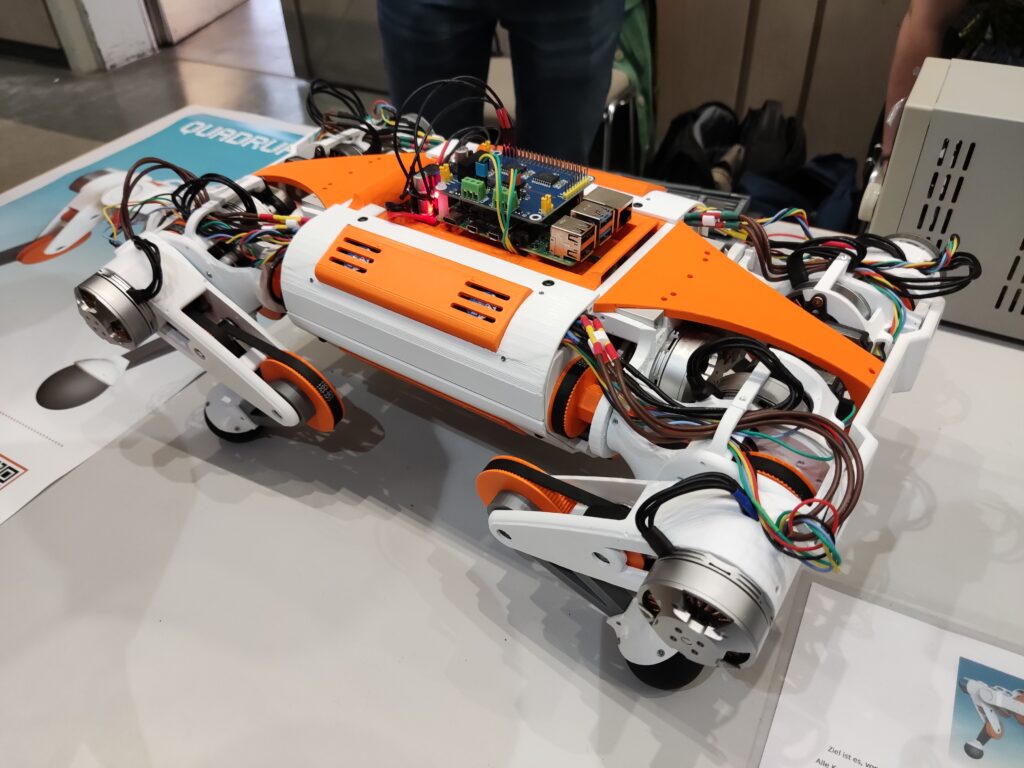

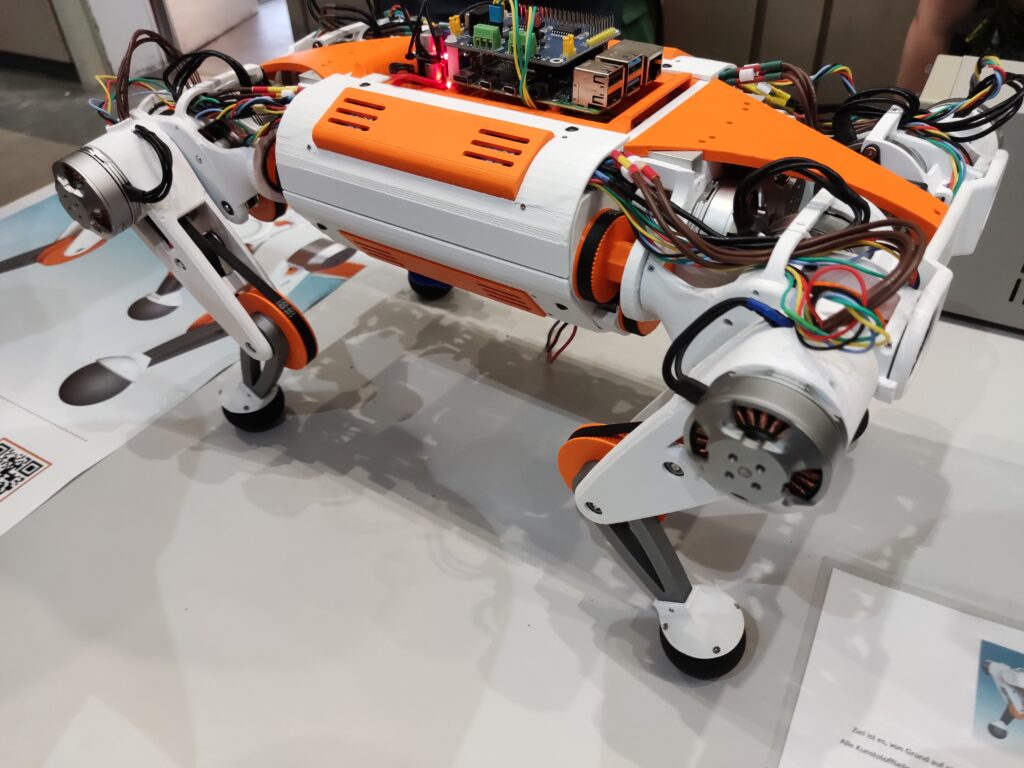

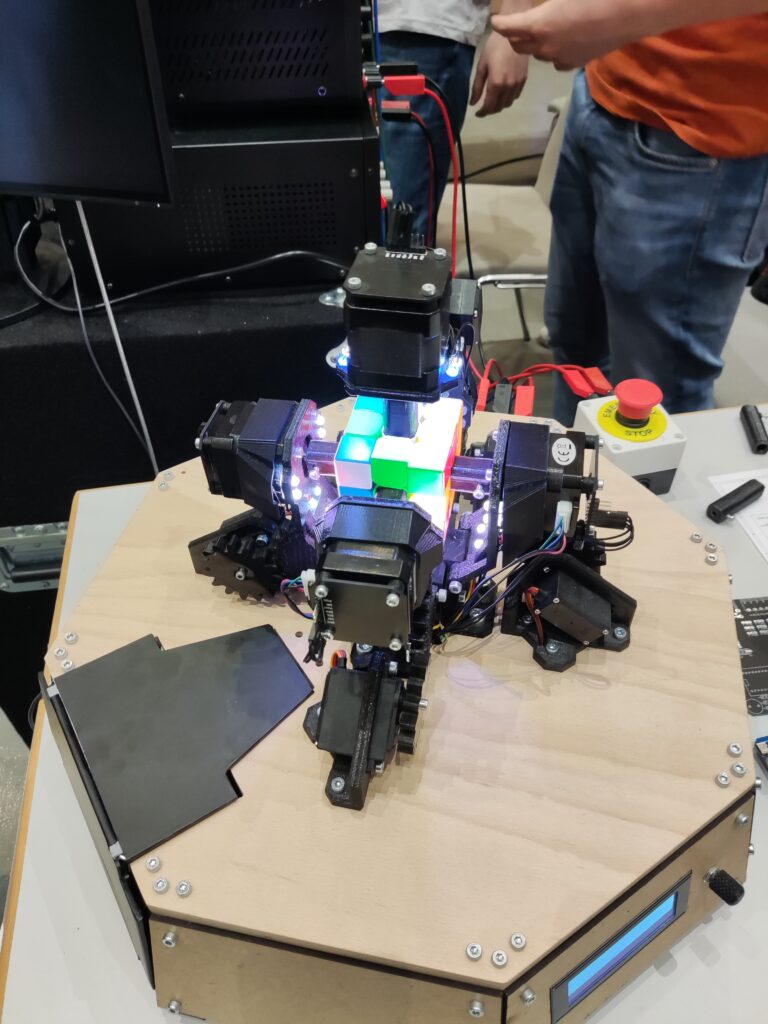

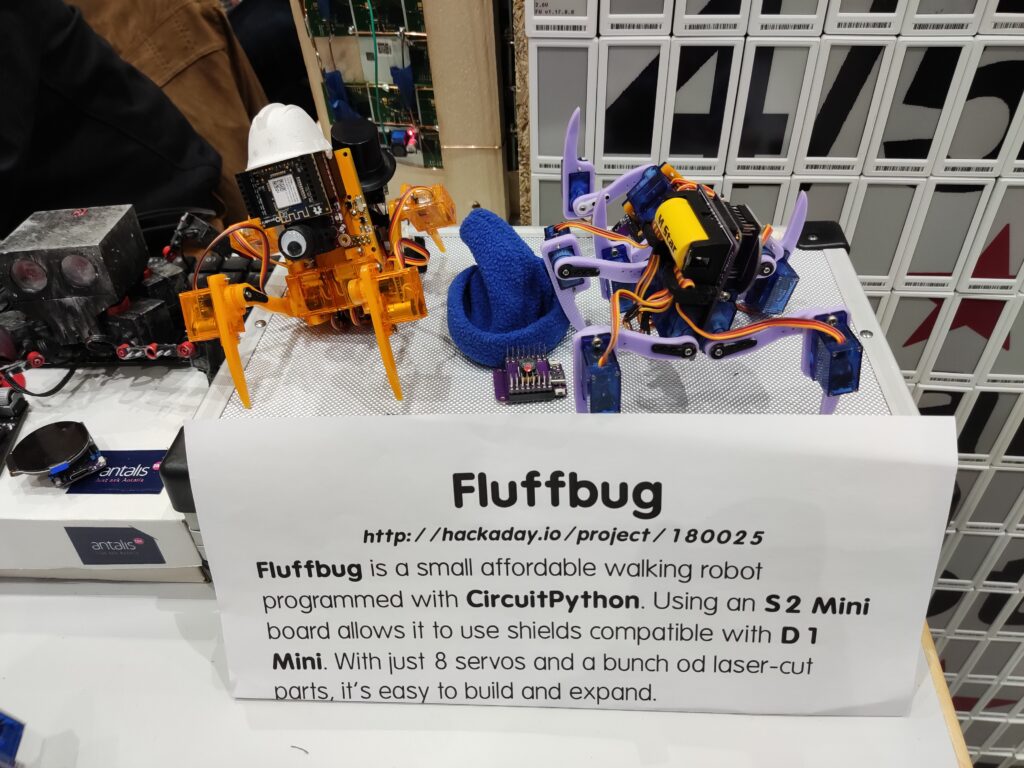

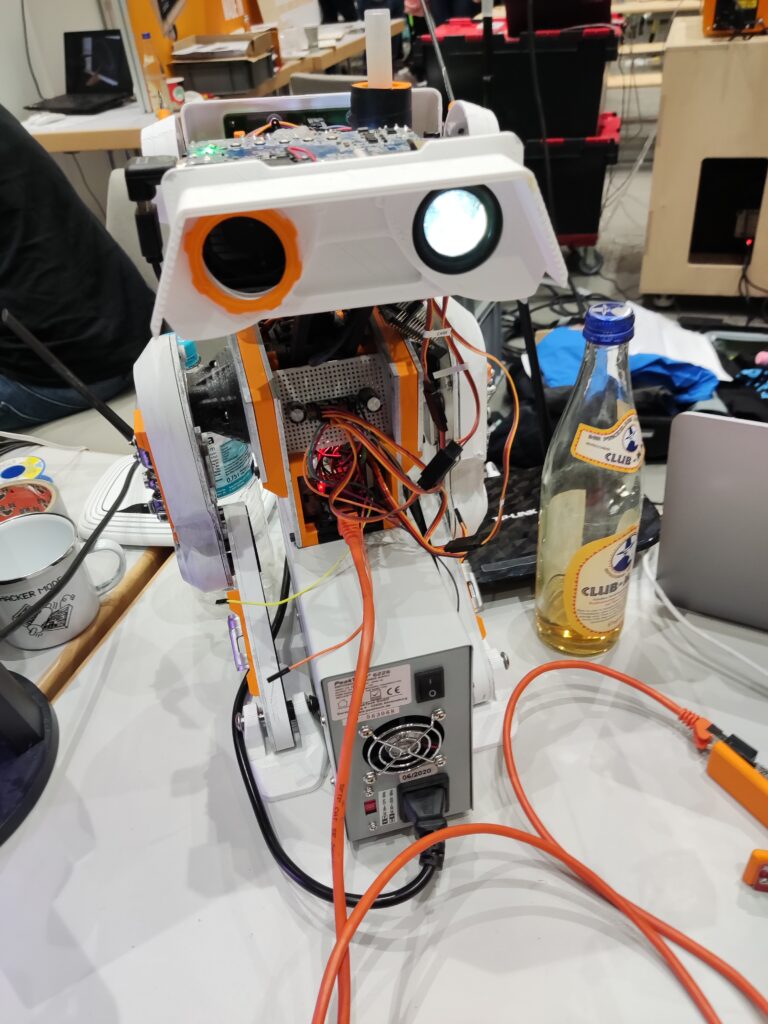

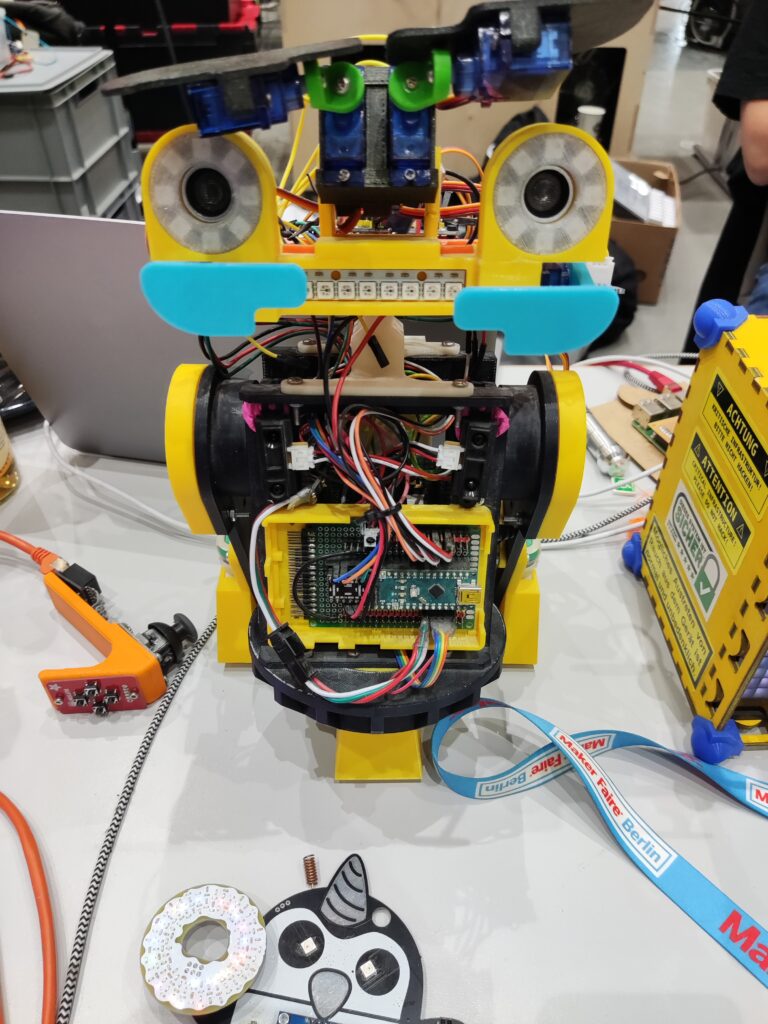

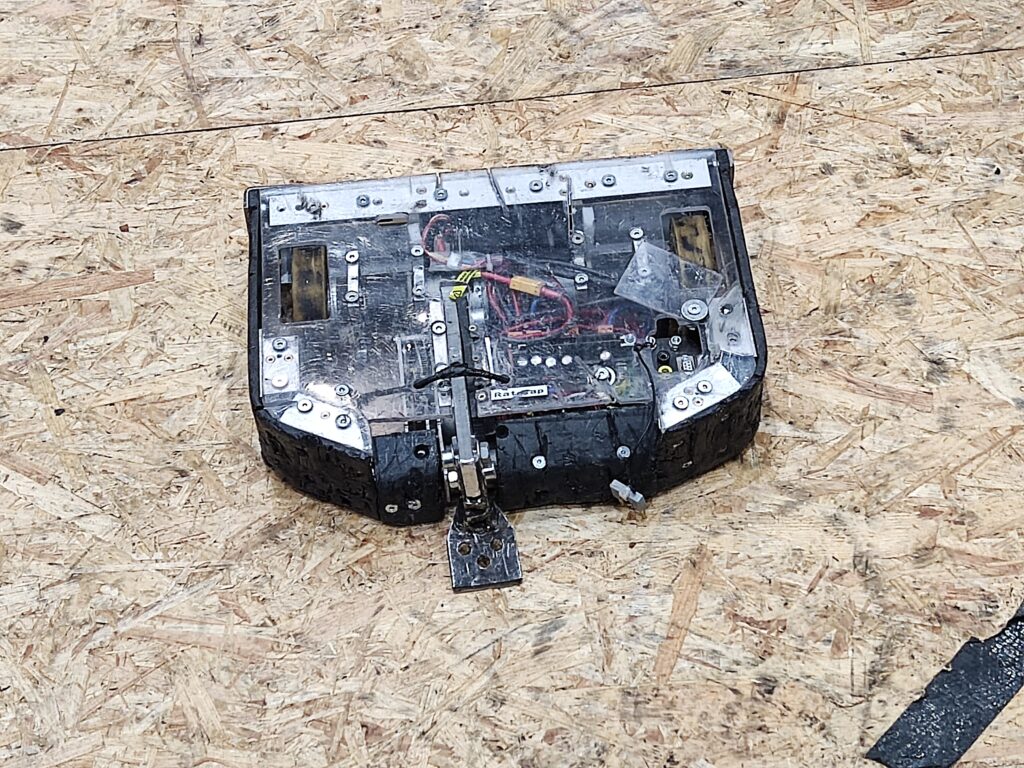

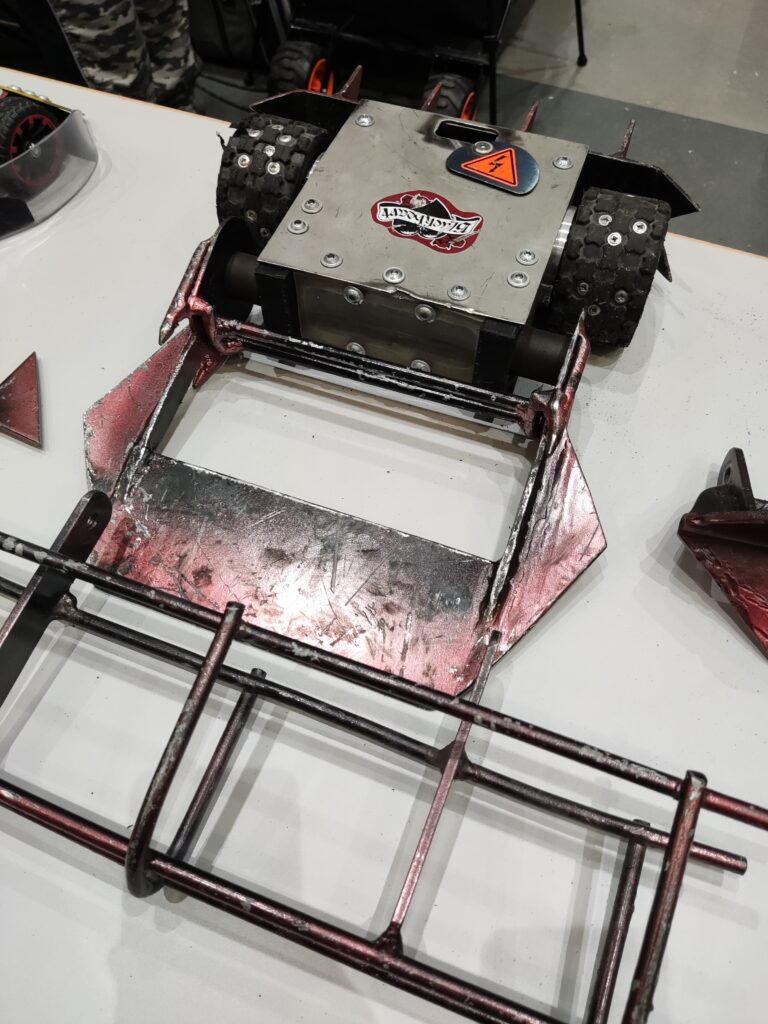

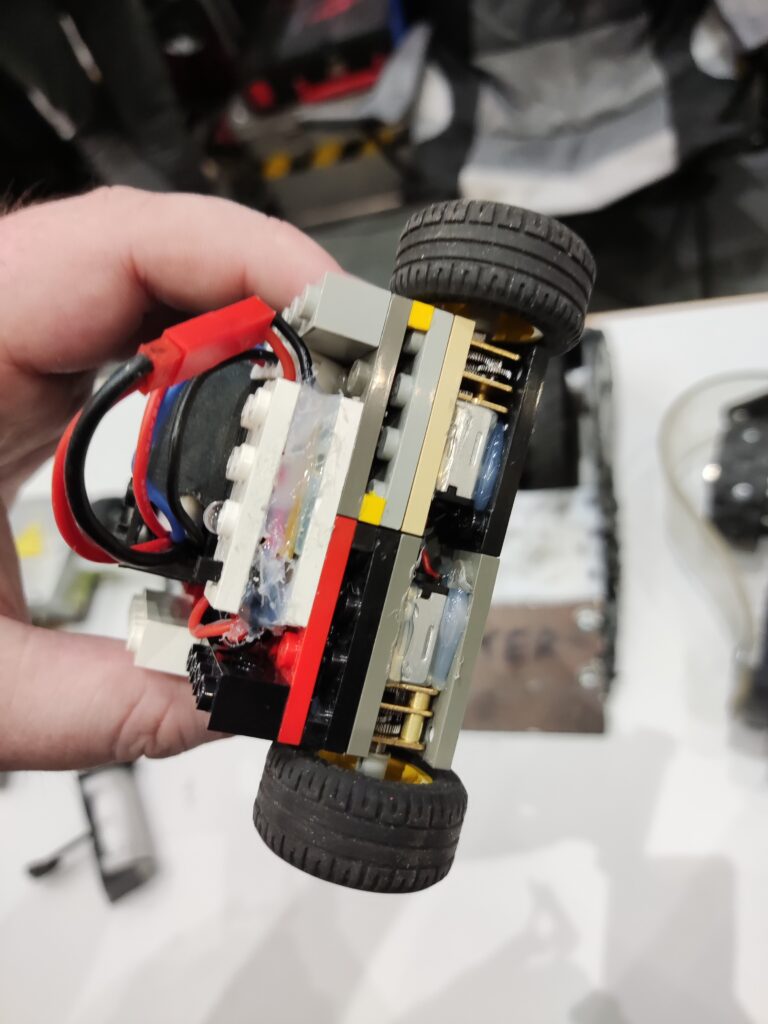

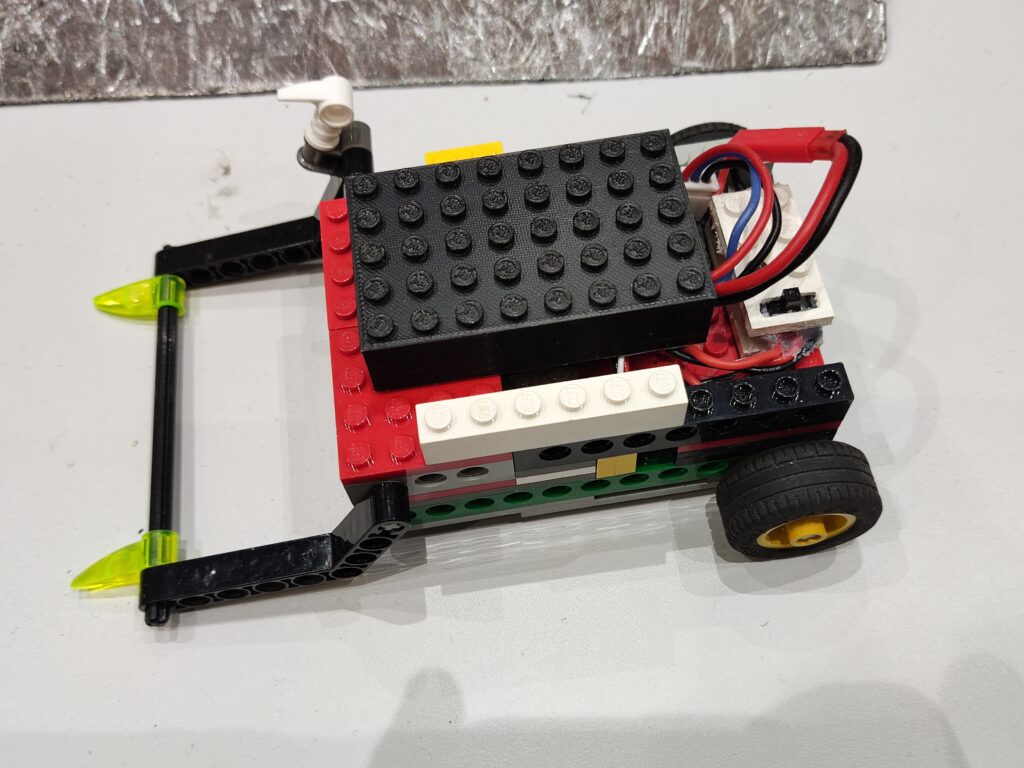

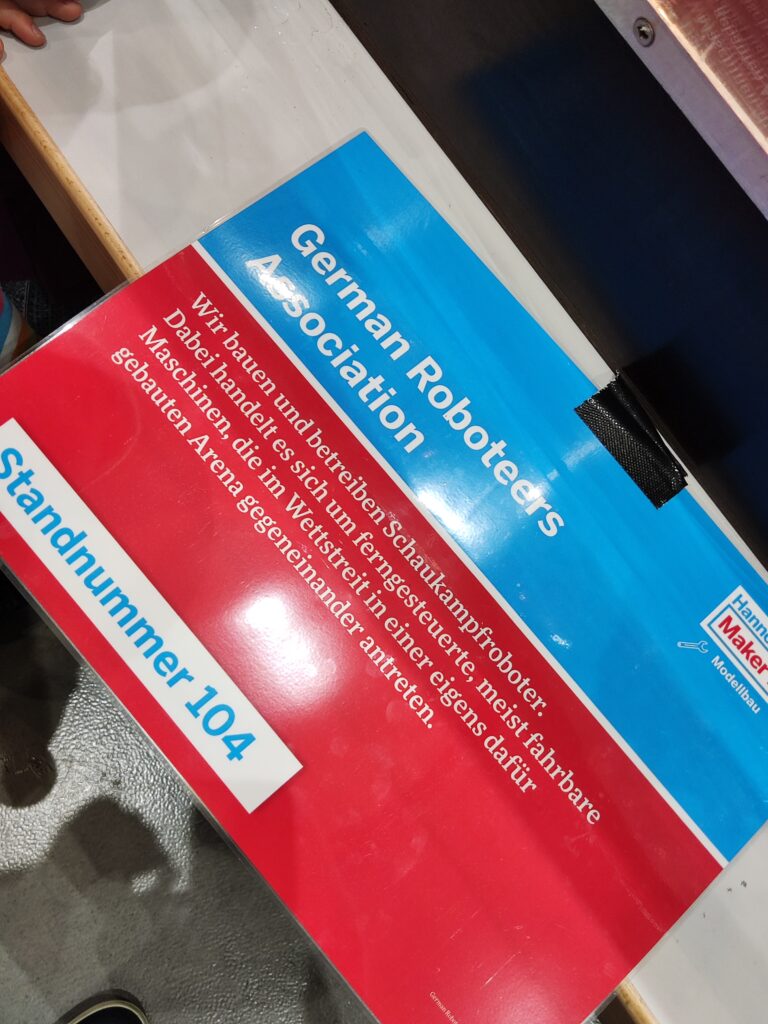

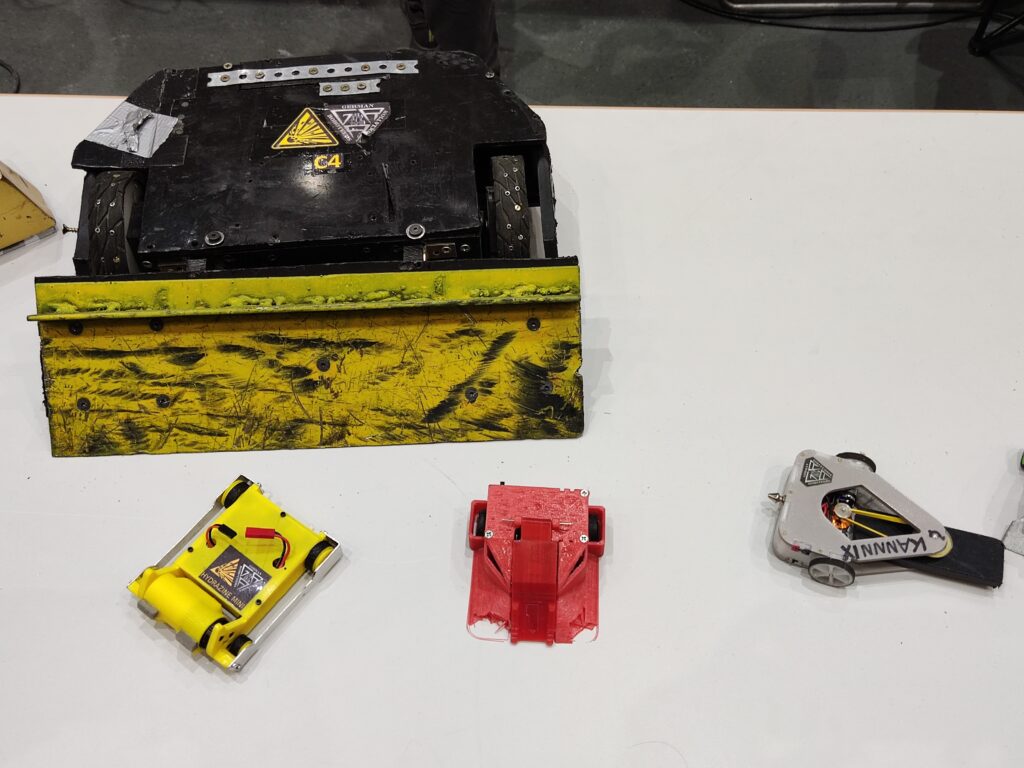

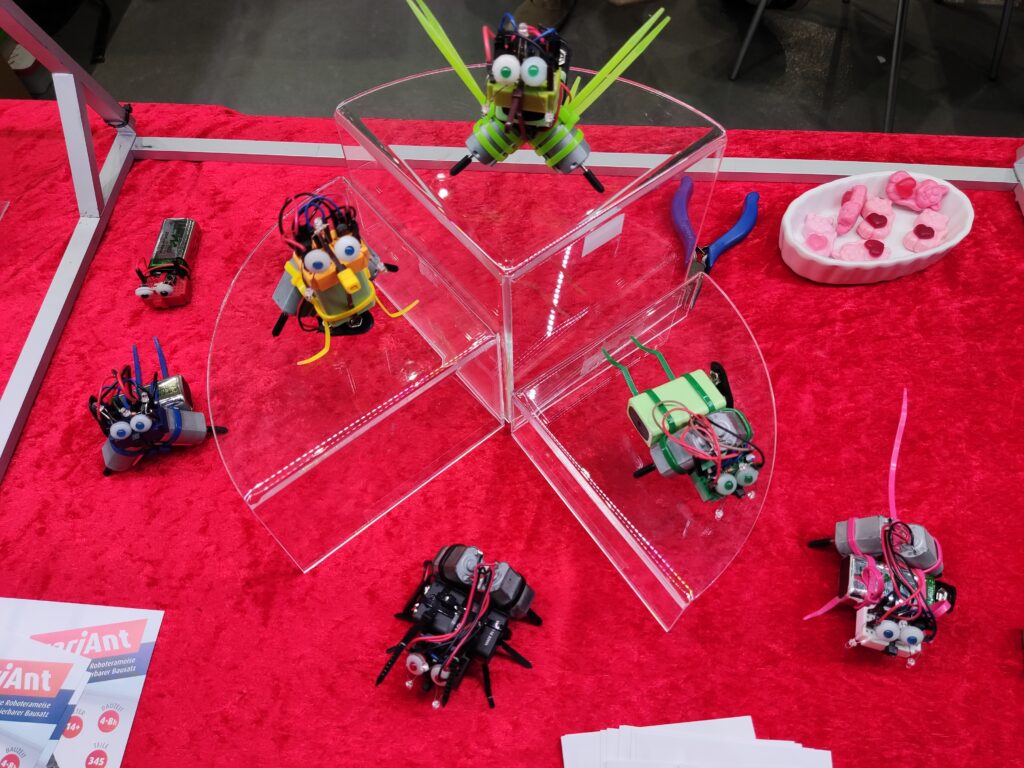

Robots-Blog visiting Maker Faire Hanover – Photos

Automatisierung und Digitalisierung werden immer einfacher

Konstanz, 13. September 2022 – fruitcore robotics zeigt erstmalig auf der Motek 2022 seine neuen Komplettlösungen horstCUBE plug & play sowie die neue Version von horstFX. Die Bediensoftware der Robotik-Expert:innen aus Konstanz wurde vollständig überarbeitet. Die neue Version von horstFX macht die Bedienung einfacher sowie komplexer Anwendungen noch leichter und setzt damit einen neuen Benchmark. fruitcore robotics stellt in Halle 7 am Stand 7304 aus.

Die neue Version der Bediensoftware horstFX bringt viele neue Features mit sich. „Globale Funktionen“ machen die HORST-Roboter in verschiedenen Anwendungen noch schneller einsetzbar, weil Funktionen mit einem Klick in andere Programme übernommen werden können. Neu ist auch die Möglichkeit zur „Individuellen Anpassung der Bedienoberfläche“ durch Kund:innen selbst. „Smart Makro-Buttons“ sind frei mit häufig verwendeten Funktionen belegbar und erleichtern so sowohl die Programmierung als auch den Betrieb des Roboters. Häufig verwendete Funktionen können beispielsweise das Anfahren der Grundstellung oder Start und Stopp eines Förderbandes sein. Ein weiteres neues Hauptfeature ist die „Nutzerspezifische Ansicht“. In ihr wird die Bedienoberfläche auf drei Bedienelemente sowie eine Anzeige des Prozessstatus reduziert. Zudem besteht die Möglichkeit, in den Screen „Smart Makro Buttons“ zur Ausführung gewünschter Funktionen zu integrieren. So ist im Betrieb der Automatisierungsanwendung maximale Einfachheit für den Bediener gegeben.

Die neue Version von horstFX stellt darüber hinaus die Grundlage für die Soft-SPS-Funktion zur Steuerung paralleler und komplexer Prozesse dar, deren Einführung fruitcore robotics in der Zukunft plant. „Die Soft-SPS-Funktion wird eine zusätzliche SPS-Steuerung für einen Großteil der Anwendungen überflüssig machen und dadurch bei unseren Kund:innen zu einer weiteren Vereinfachung und Kostenreduktion führen, so Patrick Heimburger, Geschäftsführer von fruitcore robotics. „Es sind dann keine Kenntnisse in der SPS- oder Roboterprogrammierung mehr notwendig, um mit horstFX und HORST-Robotern zu automatisieren.“

Die neue Bediensoftware steht sowohl als Online-Version als auch als Desktop-Version ab sofort zur Verfügung. Mit Trial-Varianten können sich Nutzende von der Einfachheit der Bedienung überzeugen und schon vor der Kaufentscheidung testen, ob HORST ihren Anforderungen entspricht. Auch am High-End-Spektrum der Software werden die Grenzen mit weiteren Features künftig verschoben: Die grafische Programmierung komplexer Pfade und nutzerspezifische Koordinatensysteme helfen bei der Umsetzung von pfadabhängigen Anwendungen, wie beispielsweise dem Schweißen oder Kleben und bei Anwendungen, bei denen eine relative Orientierung des Roboters zu bestimmten Objekten, beispielsweise einer zu beladenden Maschine, bei der Programmierung hilft.

horstCUBE plug & play Laser erweitert Portfolio der Komplettlösungen

Im Mittelpunkt des Messeauftritts steht außerdem die Neuheit horstCUBE plug & play. Das Publikum kann auf der Motek 2022 erstmals gleich zwei standardisierte Anwendungsfälle live erleben. Denn neben der bereits auf der automatica 2022 vorgestellten Komplettlösung horstCUBE plug & play Vereinzelung zeigt fruitcore robotics die neue Komplettlösung horstCUBE plug & play Laser, eine All-in-One Beschriftungslösung. Die Laserbeschriftungszelle ist mit einem Hochleistungslaser ausgestattet, der eine flexible 360° Beschriftung von Bauteilen ermöglicht. Beide Komplettlösungen basieren auf der Roboterplattform horstCUBE und sind bereits mit allen Komponenten ausgestattet, die für diese Anwendung notwendig sind. horstCUBE wird von fruitcore robotics auch als Einzelprodukt angeboten, denn die flexible Roboterplattform bietet die optimale Basis, um verschiedenste Anwendungen mit den Robotern von fruitcore robotics einfach, schnell und sicher zu realisieren.

Digital Robots: Zentraler Baustein der Automatisierung und Digitalisierung

Als Automatisierungs-Lösung umfassen die Digital Robots von fruitcore robotics nicht nur eine leistungsstarke und preisgünstige Hardware. Sie folgen einem in sich abgestimmten Bedienkonzept, durch welches nicht nur die Bedienung des Roboters besonders einfach ist, sondern auch die Umsetzung der gesamten Anwendung. Alle am Prozess beteiligten Komponenten, wie Greifer, CNC-Anlagen und Sicherheitssysteme werden über die grafische Bedienoberfläche horstFX bedient und zentral mit der IIoT-Plattform horstCOSMOS vernetzt. Auch die beiden horstCUBE plug & play Lösungen für die Teilevereinzelung und die Laserbeschriftung sind voll vernetzt und ohne Vorkenntnisse einsetzbar. Neben der Anbindung an die IIoT-Plattform ist bei allen Robotik-Lösungen von fruitcore robotics ein IIoT-Surfstick mit SIM-Karte standardmäßig im Lieferumfang enthalten. Dieser bietet Unternehmen die Möglichkeit, mit dem Robotersystem online zu gehen, ohne es in ihr Firmennetzwerk einbinden zu müssen. Kund:innen können nach Bedarf eine Internetverbindung aufbauen und via horstCOSMOS auf Dashboards ihre Roboterflotte samt Prozessdaten der Roboteranwendung einsehen. Auf Grundlage dessen lassen sich Prozesse optimieren und eine vorausschauende Wartung realisieren. Die Expert:innen von fruitcore robotics geben auf der Motek Einblicke in die Funktionalitäten und Vorteile der IIoT-Plattform und stehen für Fragen rund um HORST und seine Möglichkeiten bereit.

RoboHeart is Spanning New Realms of Technology

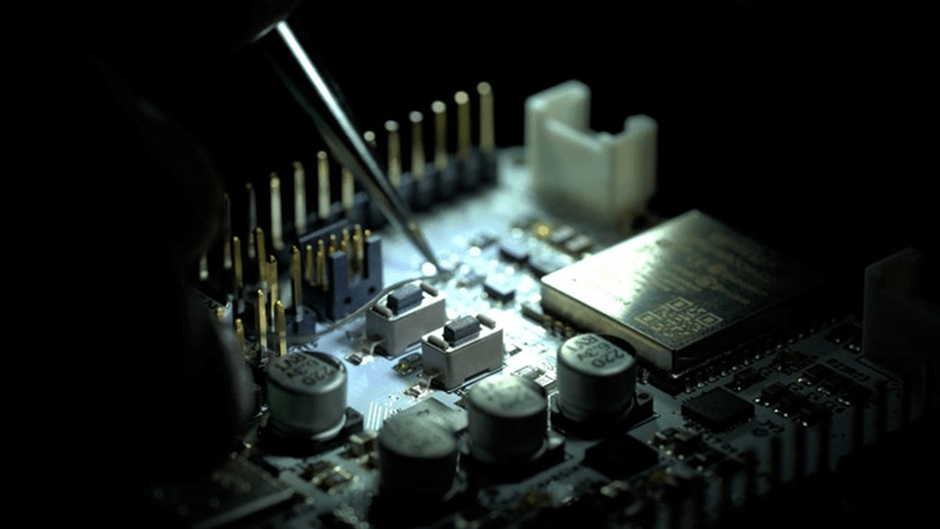

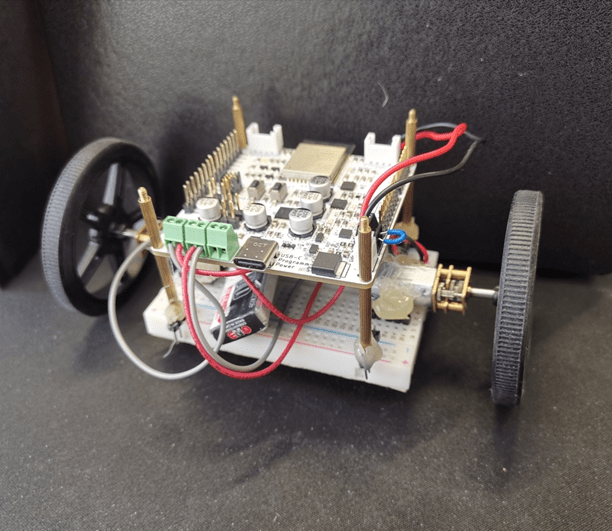

If you are an experienced Maker, or even just a passing Tinkerer, the RoboHeartTM Hercules development board may be just what you are looking for.

RoboHeart is an exceptional development board that proudly boasts: “One board to rule them all!” This exceptional circuit board is just what is sounds like: the heart of your robotics Maker project.

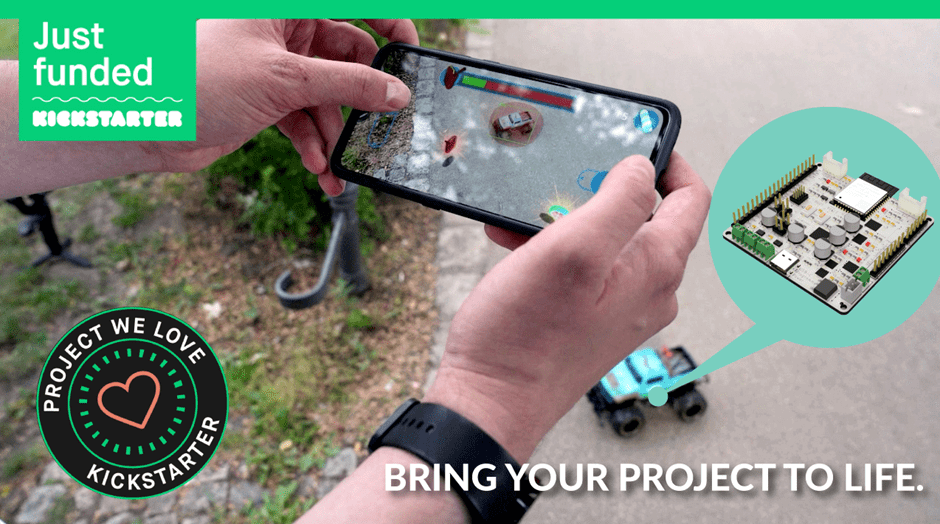

At Augmented Robotics, we have gone the extra mile by combining the magic of Augmented Reality with embedded mobile systems, so you can play and manipulate brave new worlds using only your smartphone. This allows you to control any RC device or creative Maker project with connectivity in WiFi, BLE and even 5G when paired with out RoboHeart Vela board. On Tuesday, August 23, 2022, RoboHeart was launched on Kickstarter, and it reached its funding goal in less than three hours! In only two short days, RoboHeart was selected as the coveted “Project We Love” by Kickstarter – an award given to projects that really stand out with creative innovation.

By replacing the circuit board inside your RC car with RoboHeart, you can drive the car with only your smartphone – so we have decided to add an original AR game on top of that. Drive around and collect candies to get the most points… but careful not to run out of fuel! As we reach more stretch goals, the game will get increasingly complex. We have already reached our first stretch goal – Gamepad compatibility – but there are many more to come.

The Maker community is the most creative community out there, so RC cars are definitely not the only thing your RoboHeart board can be used for. Put the board into any electronics project and watch it come to life!

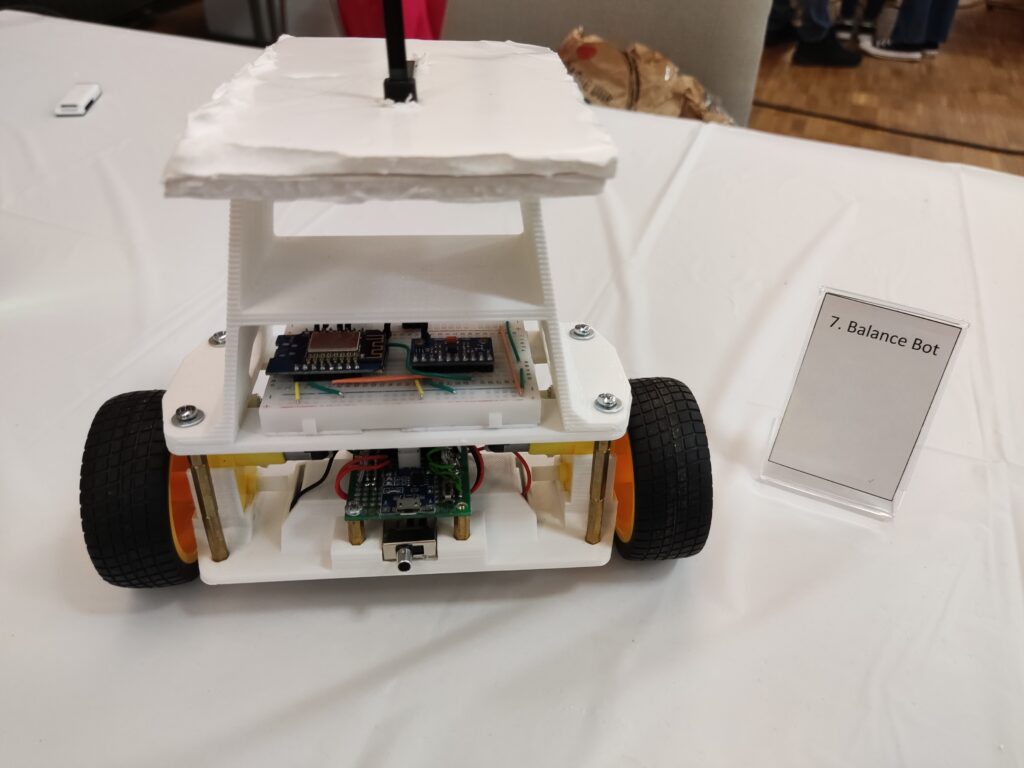

Get RoboHeart and dive right into building projects with an open-source RoboHeart Arduino library on GitHub! Our repository has several cool examples at varied complexities, from reading the IMU sensor data to controlling things with your smartphone. For example, we have built our own Balancing Bot using only one board:

The RoboHeart Hercules has all the features one needs to start building:

- ESP32-WROOM32 with dual-core and WiFi+Bluetooth capabilities

- Arduino compatibility for easy programming

- An integrated Inertial Measurement Unit (IMU) for motion data

- Three DC motor outputs

- USB-C connector with auto-download feature: flashing is a piece of cake!

- LiPo battery input with auto-charging feature: where do you need Power most, at USB or LiPo? RoboHeart will automatically distribute power where it is most needed

- Convenient peripherals for Makers: GROVE, JST and JTAG

… and with the addition of the RoboHeart Vela extension board, Makers can unlock the power of 5G, and no longer be dependent on the BLE range of 50m.

So the only question that remains is: What will YOU do with RoboHeart?

https://www.kickstarter.com/projects/augmented-robotics/robohearttm-by-augmented-robotics

2D, 3D and AI: IDS presents numerous new products and camera developments at VISION

Today, cameras are often more than just suppliers of images – they can recognise objects, generate results or trigger follow-up processes. Visitors to VISION Stuttgart, Germany, can find out about the possibilities offered by state-of-the-art camera technology at IDS booth 8C60. There, they will discover the next level of the all-in-one AI system IDS NXT. The company is not only expanding the machine learning methods to include anomaly detection, but is also developing a significantly faster hardware platform. IDS is also unveiling the next stage of development for its new uEye Warp10 cameras. By combining a fast 10GigE interface and TFL mount, large-format sensors with up to 45 MP can be integrated, opening up completely new applications. The trade fair innovations also include prototypes of the smallest IDS board-level camera and a new 3D camera model in the Ensenso product line.

IDS NXT: More than artificial intelligence

IDS NXT is a holistic system with a variety of workflows and tools for realising custom AI vision applications. The intelligent IDS NXT cameras can process tasks „on device” and deliver image processing results themselves. They can also trigger subsequent processes directly. The range of tasks is determined by apps that run on the cameras. Their functionality can therefore be changed at any time. This is supported by a cloud-based AI Vision Studio, with which users can not only train neural networks, but now also create vision apps. The system offers both beginners and professionals enormous scope for designing AI vision apps. At VISION, the company shows how artificial intelligence is redefining the performance spectrum of industrial cameras and gives an outlook on further developments in the hardware and software sector.

uEye Warp10: High speed for applications

With 10 times the transmission bandwidth of 1GigE cameras and about twice the speed of cameras with USB 3.0 interfaces, the recently launched uEye Warp10 camera family with 10GigE interface is the fastest in the IDS range. At VISION, the company is demonstrating that these models will not only set standards in terms of speed, but also resolution. Thanks to the TFL mount, it becomes possible to integrate much higher resolution sensors than before. This means that even detailed inspections with high clock rates and large amounts of data will be feasible over long cable distances. The industrial lens mount allows the cameras to fully utilise the potential of large format (larger than 1.1″) and high resolution sensors (up to 45 MP).

uEye XLS: Smallest board-level camera with cost-optimised design

IDS is presenting prototypes of an additional member of its low-cost portfolio at the fair. The name uEye XLS indicates that it is a small variant of the popular uEye XLE series. The models will be the smallest IDS board-level cameras in the range. They are aimed at users who, e.g. for embedded applications, require particularly low-cost, extremely compact cameras with and without lens holders in large quantities. They can look forward to Vision Standard-compliant project cameras with various global shutter sensors and trigger options.

Ensenso C: Powerful 3D camera for large-volume applications

3D camera technology is an indispensable component in many automation projects. Ensenso C is a new variant in the Ensenso 3D product line that scores with a long baseline and high resolution, while at the same time offering a cost-optimised design. Customers receive a fully integrated, pre-configured 3D camera system for large-volume applications that is quickly ready for use and provides even better 3D data thanks to RGB colour information. A prototype will be available le at the fair.

Learn more: https://en.ids-imaging.com/ueye-warp10.html

Szene-Treff Maker Faire Hannover – Wo sich DIY-YouTuber, Cosplayer und Lichtkünstler begegnen

Hannover, 31. August 2022 – Am 10. und 11. September treffen sich auf der achten Maker Faire im HCC wieder DIY-YouTuber und geben Einblicke in ihre Maker-Welt. Auch etliche Cosplayer haben sich zum Festival verabredet, um dort ihre farbenfrohen, aufwändig hergestellten Kostüme zu präsentieren. Leuchtende Exponate haben die verschiedenen Lichtkünstler im Gepäck, mit denen sie die Besucherinnen und Besucher in der Dark Gallery verzaubern wollen.

Maker Faire – das heißt anfassen, ausprobieren, voneinander lernen und vernetzen: Auch in der achten Auflage der Maker Faire ist das Angebot der rund 1000 ausstellenden Maker vielfältig. Bereits zum vierten Mal sind Szene-YouTuber aus dem Genre DIY/Handwerk zu Gast. Angekündigt hat sich die bekannte Makerin Laura Kampf, die gemeinsam mit „HABU“, Felix Schelhasse, Franks Shed, Jonas Winkler und Karoline Hinz an den Paneltalks am Samstag um 16:30 Uhr und am Sonntag um 12:10 Uhr teilnehmen wird.

Bild: Jürgen Klöck

Darüber hinaus zeigen unter anderem die YouTuber Pero Cetkovic aka Der Kompressorschrauber und Marcel von Bau Boom Bang sowie Ellen Brilhuis-Meijer von Crafts with Ellen ihre Werke und bieten Mitmachaktionen an.

Sie heißen Babyroods, Karamelori, Anxietea.exe oder weeiiird.cos und lieben es, fiktive Charaktere durch ihre Cosplays in die Realität zu holen. Die Cosplayerinnen sowie Instagram- und TikTok-Stars nutzen die Maker Faire, um ihre ausgefallenen Kostümideen vorzustellen und über ihre Vorbilder aus Animes, Mangas oder Videospielen zu erzählen.

In der Dark Gallery – die verdunkelte Halle gibt es nach 2019 zum zweiten Mal auf der Maker Faire – sind es vor allem Jonas Vorwerk, Teammitglieder von Tim Davies, die jungen Maker von ARTandTECH.space, Jürgen Klöck und Franz Betz, die als Lichtkünstler faszinierende Projekte mitgebracht haben.

Ein Hingucker ist „Pixels“, eine interaktive Lichtinstallation von Jonas Vorwerk , einem niederländischem Multimedia-Künstler, der sich audiovisueller Kunst mit Schwerpunkt Interaktion widmet. Pixels besteht aus verschiedenen LED-Blöcken, die bei Interaktion die Farbe und Intensität wechseln und von den Besuchern vielfältig zu verschiedenen Kreationen zusammengebaut werden können.

Als unübersehbares Highlight gleitet ISO durch die Dark Gallery: ein sieben Meter langes und fünf Meter hohes Monster, das einer Tiefsee-Assel ähnelt und vollständig mit LEDs beleuchtet wird. Das Projekt stammt von Tim Davies , einem britischen Bildhauer und Ingenieur mit Vorliebe für großformartige kinetische Kreaturen. Iso wird von einer Person gesteuert, die dem Unterwassertier Leben einhaucht.

Das Projektlabor Berufskolleg Rheine und die Jugendkunstschule Rheine präsentieren viele ausgefallene Lichtobjekte, die im ARTandTECH.space entstanden sind. Jürgen Klöck stellt seine Upcycling-Ideen – er baut aus schrottreifen Geräten warm leuchtende Lampen – ebenfalls in der Dark Gallery vor.

Zudem können große und kleine Besucher die Discokugel aus CDs bestaunen, die der stadtbekannte Lichtbildhauer Franz Betz im vergangenen Jahr als Außenwette der digitalen Maker Faire gebaut hat. Der Hannoveraner wird nicht nur das Schwarmkunstwerk mit einem Durchmesser von zwei Metern präsentieren, sondern gemeinsam mit Besuchern weitere kleine Discokugeln bauen und so die Halle zum Strahlen bringen.

Infos und Tickets zum bunten DIY-Familienfestival gibt es unter www.maker-faire.de/hannover.

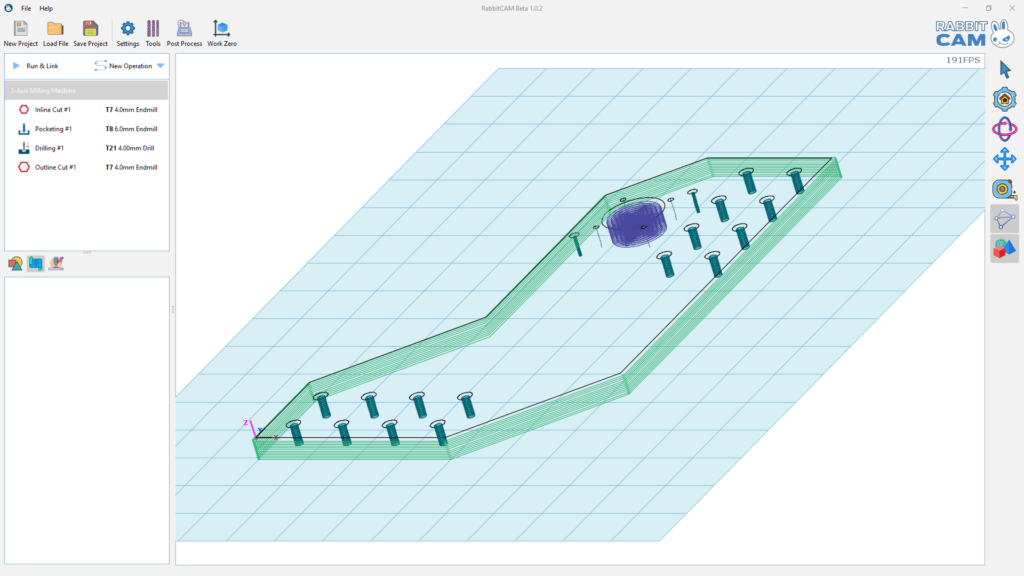

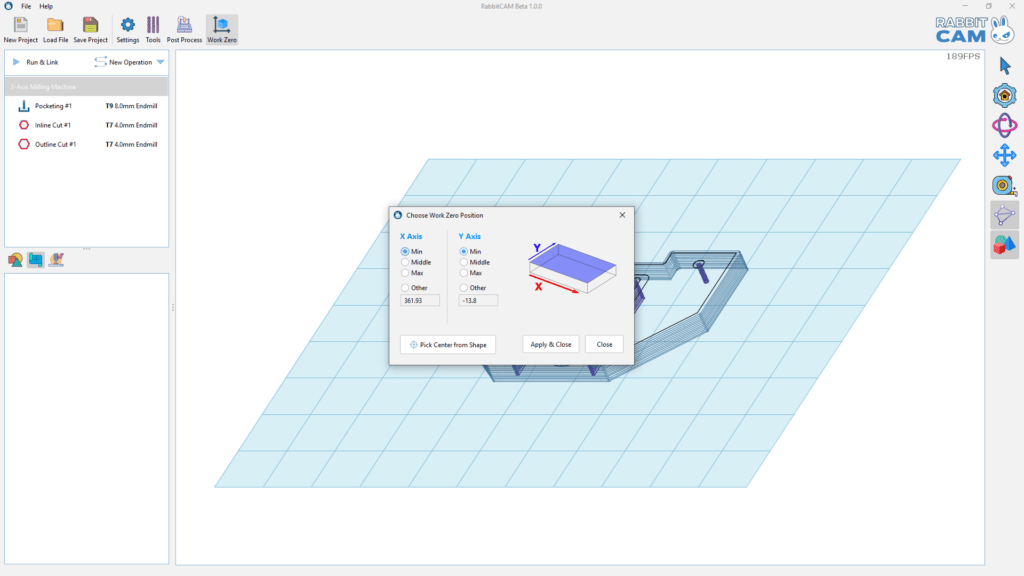

SourceRabbit released a new Computer Aided Manufacturing (CAM) software

If you are a hobbyist or beginner in CNC machining or one who intermittently uses CNC routers, you might be looking for an easy CAM software for your CNC machining.

SourceRabbit, a Greek CNC machine tool manufacturer, released a new CAM software called RabbitCAM. Their new software is cross platform, meaning it works under Windows, MacOS and Linux, it features a user-friendly user interface and lets anyone generate toolpaths from 2D DXF files.

We managed to obtain a statement from Nikos Siatras, CEO of SourceRabbit, who told us

“Today’s CAM software is expensive and difficult to use for most users. Our primary goal with RabbitCAM is to create software that is easy to use, fast, affordable and able to work

under any modern operating system.”

RabbitCAM is a cross-platform software for rapid programming of 3-Axis CNC machine tools from 2D DXF files.

We built RabbitCAM to provide our customers with the fastest and easiest solution for turning their designs into parts and final products through simple material removal strategies.

The multithreaded core of RabbitCAM takes advantage of all system processors during toolpath calculations, in order to reduce user’s waiting time, while its user-friendly work interface displays them on screen almost in real time.

RabbitCAM was created with the Java programming language and works on all operating systems (Windows, MacOS, Linux, Haiku and more).

Maker Faire Hannover – Die größte DIY-Technikmesse geht wieder live

Feuer, Metall und wirbelnde Mechanik: Auf dem DIY-Festival in der niedersächsischen Landeshauptstadt geht es am 10. und 11. September heiß zu: Ein riesiger feuerspeiender Vogel und ein stählernes brennendes Hamsterrad in XXL-Größe sind die diesjährigen Top-Acts auf der Maker Faire Hannover im HCC. Darüber hinaus zeigen private Maker und Bastler auf dem Community-Treffen ihre faszinierenden Projekte und werben für die Macherkultur und den kreativen Umgang mit Technik. Seien Sie dabei, wenn sich Hannover neu erfindet und zeigen Sie Ihren Lesern, Ihrem Publikum was heute in Deutschland so alles getüftelt und gebastelt wird.

Neben Robotik, 3D-Druck, Elektronik oder klassischem Handwerk, erwarten Sie spannende und faszinierende Highlights wie die sechs Meter große hydraulische Kreatur, die mit ihren imposanten 15 Meter breiten Flügeln an einen Drachen erinnert. Der niederländische Künstler und Maker Matthias Vijvermann nahm sich Garuda, die Tiergottheit Garuda aus der hinduistischen Mythologie sich zum Vorbild und erbaute Stahl-Skulptur. Über ein Jahrzehnt tüftelte der gelernte Wirtschaftsingenieur und Bildhauer seinem feuerspeienden Vogel und ließ dabei seiner Leidenschaft für Mechanik freien Lauf. Vor drei Jahren tat er sich mit dem Künstler Ronald Duikersloot zusammen und feilte weiter an seiner Arbeit.

Mit dem Element Feuer spielt auch der PropanePunk Circus aus Tschechien. Im MansterWheel, einem Hamsterrad aus Stahl mit fünf Metern Durchmesser, können waghalsige Menschen auch laufen. Die Installation wurde ursprünglich für das Nowhere Festival, der spanischen Variante des Burning Man-Festivals aus den USA, gebaut und sorgte dort für Aufsehen.

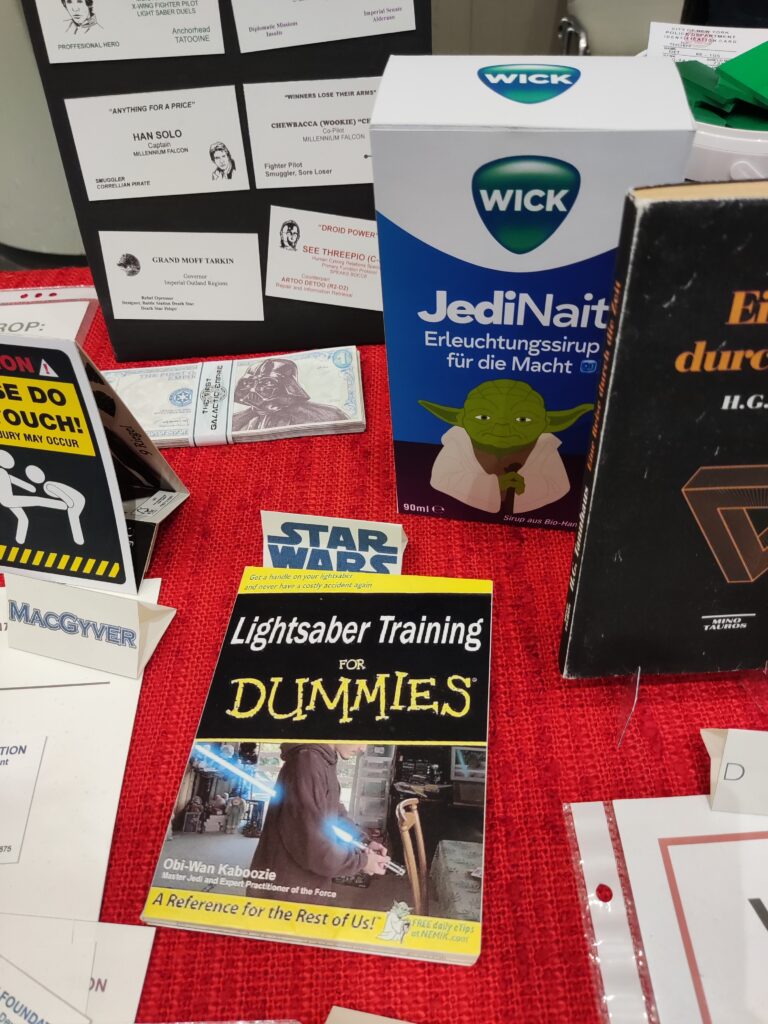

Zu den weiteren Attraktionen der Maker Faire Hannover – insbesondere für Star-Wars-Fans – zählen auch in diesem Jahr die originalgetreuen R2D2-Nachbauten des R2-Builders-Clubs sowie die zwei Meter große, aus 1500 CDs und Kugelschreibern gebaute Discokugel von dem hannoverschen Lichtbildhauer Franz Betz, die in der Dark Gallery für blinkende Effekte sorgt. „Für die Dark Gallery planen wir noch ein weiteres spannendes Highlight, auf das sich die Besucherinnen und Besucher freuen können“, verspricht Daniel Rohlfing, Leiter Events und Produktmanagement.

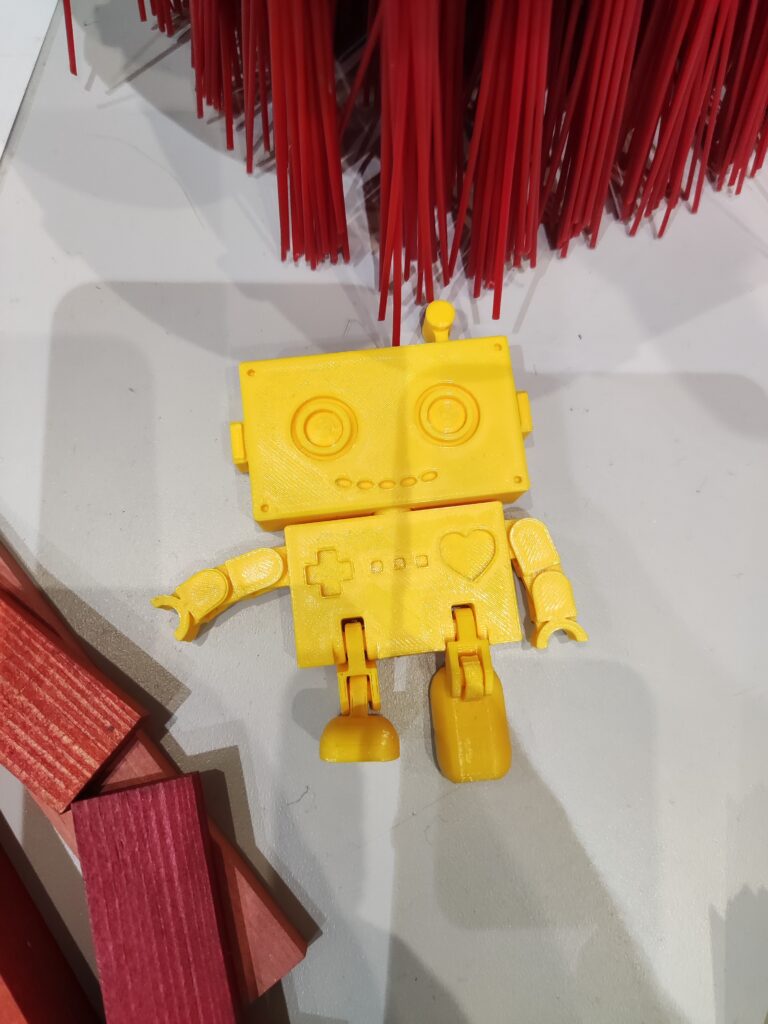

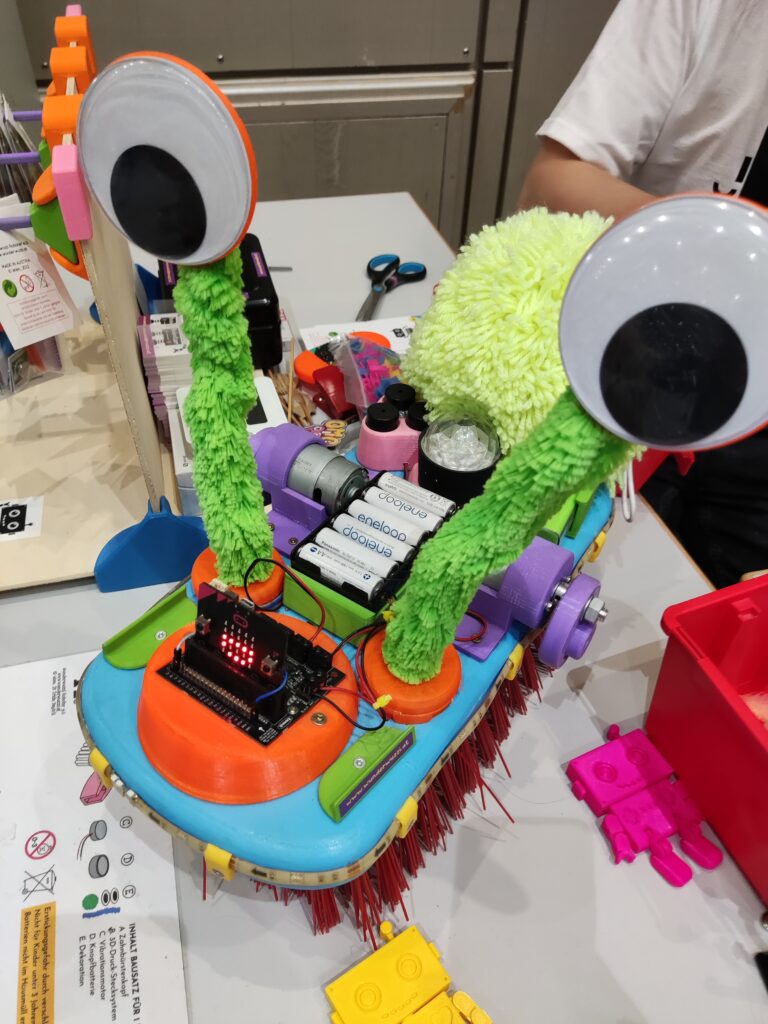

Aber eine Maker Faire heißt nicht nur staunen, sondern auch lernen, fachsimpeln, netzwerken, ausprobieren und vor allem selbermachen. Für den Nachwuchs ist die Maker Faire ein Ort für spielerisches Lernen. MINT-Themen werden kreativ vermittelt. Hier werden Roboter programmiert und der Umgang mit dem Lötkolben gelernt. Erwartet werden unzählige DIY-Ideen und -Projekte aus den folgenden Themenbereichen: 3D-Druck, Arduino, Coding und Software, Cosplay, Elektronik, Handwerk, Hardware Hacking, Internet of Things, Lasercutter, Modellbau, Nachhaltigkeit, Raspberry Pi, Robotik, Smart Home, Steampunk, Upcycling, Virtual Reality, Wearables, u.v.m.

Darüber hinaus finden neben den vielen Projekten zum „Anfassen und Ausprobieren“ auch zahlreiche Workshops und Vorträge zu den unterschiedlichen Selbermach-Themen statt. Dabei werden Energiesparen und Energie selbst erzeugen sowie Nachhaltigkeit ebenfalls ganz großgeschrieben.

Bitcoin-Roboter und KI: Wie werden Roboter beim Handel mit Kryptowährungen eingesetzt?

Wer etwa plant, in Kryptowährungen zu investieren, der wird sich vermutlich schnell überfordert fühlen: Es gibt mehr als 4000 Kryptowährungen am Markt – in welche digitale Währungen sollte man also investieren? Ist es ratsam, in noch eher neue und unbekanntere Kryptowährungen zu investieren oder sollte nur Geld in die bekannten Klassiker – Bitcoin, Ether oder auch Litecoin – gepumpt werden?

Man kann aber nicht nur langfristig in verschiedene Kryptowährungen investieren, sondern auch mit der weiteren Preisentwicklung spekulieren und darauf setzen, ob die Preise der einen oder anderen Kryptowährung nach oben oder nach unten gehen. Da der Kryptomarkt sehr volatil ist, kann man hier auch mit geringeren Summen hohe Gewinne erzielen.

Aber die Volatilität ist Fluch und Segen zugleich. Und wer sich schon mit dem Kryptomarkt befasst hat, der weiß, Vorhersagen müssen nicht immer zutreffen.

Trading Bots als Unterstützung: Kann das überhaupt funktionieren?

Dass das Trading mit Kryptowährungen enorm zeitaufwendig ist, mag kein Geheimnis sein. Denn letztlich muss man den Markt und seine Entwicklungen beobachten, analysieren und dann die entsprechenden Positionen eröffnen und wieder schließen. Und da der Markt 24 Stunden am Tag geöffnet ist, gibt es hier am Ende keine Verschnaufpause für den Trader, wenn er keinen Trend verpassen möchte.

Getradet werden kann über einen Broker, der Kryptowährungen im Sortiment hat. Man kann aber auch mit einem automatisierten Trading Bot arbeiten und diesem die Aufgabe übertragen, mit Kryptowährungen zu spekulieren. Aber worauf ist zu achten, wenn man plant, die Dienste eines automatisierten Trading Bots in Anspruch nehmen zu wollen? Kann wirklich dem Trading Bot zu 100 Prozent das Vertrauen geschenkt werden oder ist es besser, hier stets einen kontrollierenden Blick auf die Entscheidungen zu werfen?

Anbieter miteinander vergleichen

Es gibt viele automatische Trading Roboter, sodass man im Vorfeld einen Vergleich der verschiedenen Anbieter anstellen sollte. Dabei geht es zuerst um die Seriosität. Gibt es Hinweise, die darauf schließen lassen, dass der Anbieter unseriös ist? Hilfreich sind hier mitunter Test- oder auch Erfahrungsberichte, die im Internet zu finden sind. Des Weiteren geht es um die Gebühren und um die Trefferquote. Denn wer mit automatisierten Trading Bots arbeitet, der will, dass diese natürlich richtig liegen und man sodann in die Gewinnzone kommt.

Doch man muss vorsichtig sein: Wer mit einem Trading Bot arbeitet, der muss im Vorfeld selbst ein paar Einstellungen vornehmen – stellt man fest, dass man nicht in die Gewinnzone kommt, so sollte man mitunter auch die Einstellungen verändern. Wobei anzumerken ist, dass es auch über einen Trading Bot keine Gewinngarantie gibt.

Volatilität: Fluch und Segen, Chance und Risiko

Beobachtet man den Kryptomarkt, so wird man relativ schnell zu dem Ergebnis kommen, dass es hier immer wieder steil nach oben wie nach unten gehen kann. Wer hat sich nicht schon einmal gedacht, hätte man bloß zum richtigen Zeitpunkt investiert, dann wäre man jetzt alle finanzielle Sorgen los. Aber man zögert, lässt sich vom Bauchgefühl beeinflussen – und genau das ist die Stärke der Trading Bots.

Denn der automatisierte Trading Bot analysiert den Markt, erkennt Trends und eröffnet dann Positionen, die geschlossen werden, wenn die Analysen zu dem Ergebnis kommen, dass es wieder in die andere Richtung geht. Basierend auf bestimmte Algorithmen, erkennen die Systeme, wann der richtige Zeitpunkt zum ein- bzw. aussteigen ist. Doch die Betreiber der Plattformen halten sich bedeckt: Gearbeitet wird zwar mit KI, aber wie am Ende die Berechnungen durchgeführt werden, das bleibt das Geheimnis der im Hintergrund agierenden Köpfe.

Letztlich muss man jedoch anmerken, dass mit Trading Bots nur mit Blick auf kurzfristige Preisbewegungen spekuliert werden kann. Wer plant, langfristig zu investieren, muss selbst aktiv werden.

Sollte man auch langfristig investieren?

Aber lohnt sich ein langfristiges Investment in Kryptowährungen oder sollte man nur mit den Trading Bots arbeiten? Wer sich mit den langfristigen Prognosen befasst, ist gut beraten, auch einen Teil des Ersparten direkt zu investieren. Viele Experten sind überzeugt, der Kryptomarkt wird mit den Jahren an Stärke gewinnen, sodass das automatisch zu Gewinnen führen kann.