Einen Blick in die »Blackbox« werfen und Künstliche Intelligenz (KI) selbst programmieren – das ermöglichen das Fraunhofer-Institut für Intelligente Analyse- und Informationssysteme IAIS, das Ministerium für Schule und Bildung des Landes Nordrhein-Westfalen, die Universität zu Köln und die InterScience-Akademie für Algorithmik. Nach der Einführung des Pflichtfachs Informatik zum Schuljahr 2021/22 in NRW hat auch KI einen festen Platz im Unterricht für die Sekundarstufe I in den Klassen 5 und 6. In dem Zuge können die Schüler*innen in NRW, aber auch darüber hinaus, auf der Fraunhofer-Programmierplattform »Open Roberta Lab« künftig Künstliche Neuronale Netze selbst programmieren und testen. Ab Sommer 2022 bietet das Fraunhofer IAIS jungen Menschen weltweit einen einmaligen Zugang zur KI.

Künstliche Intelligenz ist eines der bedeutendsten und zugleich kritischsten Zukunftsthemen. Sie findet schon heute in zahlreichen Bereichen unseres Alltags Anwendung, zum Beispiel bei Gesichtserkennung, automatischer Textergänzung, Sprachassistenten, personalisierter Werbung, Übersetzungsprogrammen und Gesundheits-Apps. Um den Schülerinnen und Schülern einen praxisnahen Einstieg in diese Thematik zu erleichtern, fördert das Ministerium für Schule und Bildung des Landes Nordrhein-Westfalen die Entwicklung von KI-Lerninhalten und Materialien im Rahmen des Projekts »KI-Algorithmen im Informatikunterricht« seit September 2021.

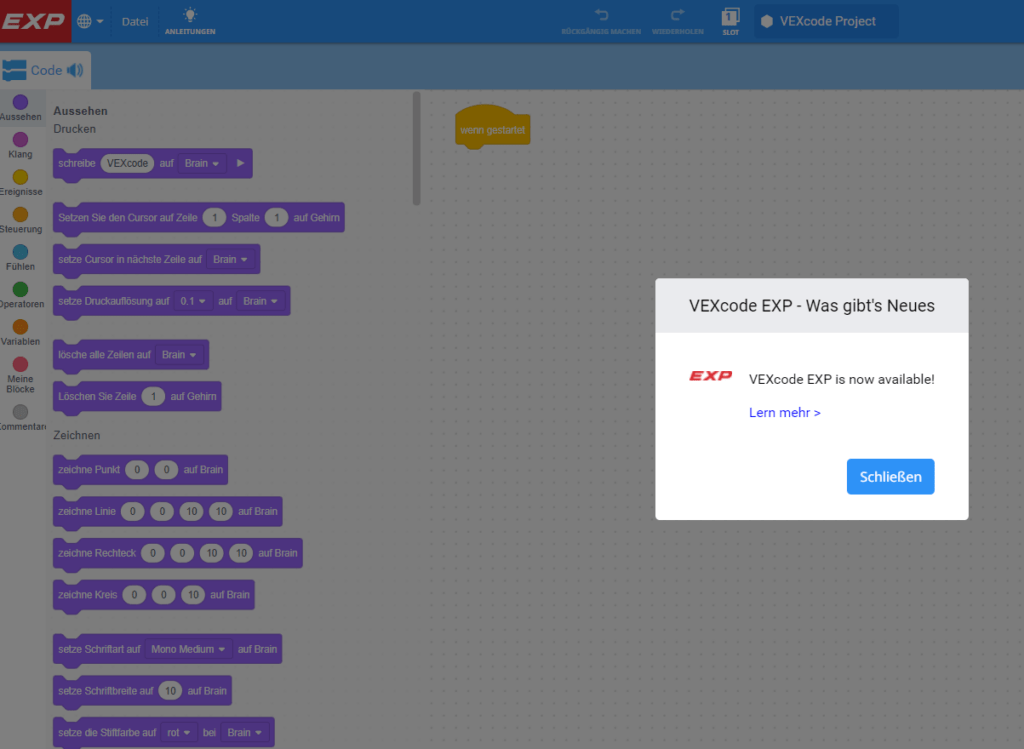

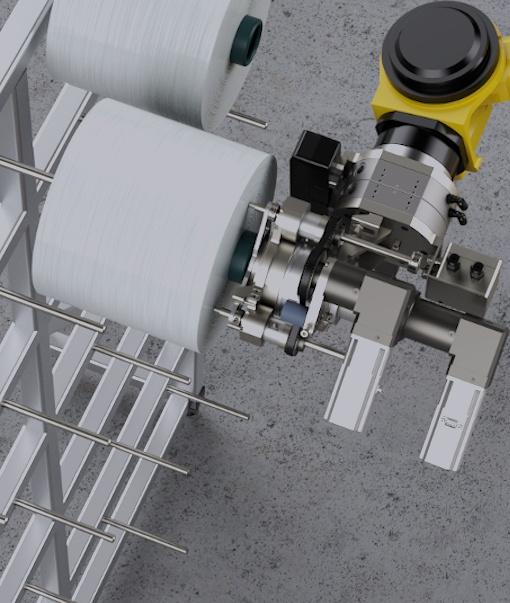

Das Fraunhofer IAIS hat erstmals Künstliche Neuronale Netze auf seiner Programmierplattform Open Roberta integriert.

Mit dieser Unterstützung hat das Fraunhofer-Institut für Intelligente Analyse- und Informationssysteme IAIS erstmals Künstliche Neuronale Netze auf seiner Programmierplattform Open Roberta integriert. In dem Projekt arbeiten Fraunhofer und die Universität zu Köln zusammen, um die Schulen bei der Unterrichtsentwicklung im Bereich der KI zu unterstützen. Initiator des Projekts ist Prof. Dr. Ulrich Trottenberg, der die Projektpartner ehrenamtlich unterstützt.

Staatssekretär Mathias Richter vom Ministerium für Schule und Bildung des Landes Nordrhein-Westfalen: »Vor dem Hintergrund der rasant steigenden Bedeutung von Künstlicher Intelligenz in der Lebens- und Arbeitswelt ist es dringend geboten, möglichst früh Kompetenzen im Bereich Künstliche Intelligenz und Maschinelles Lernen aufzubauen. Wir wollen es unseren Schülerinnen und Schülern ermöglichen, ihre eigene Zukunft mitzugestalten, denn die Auswirkungen von KI machen sich zunehmend bemerkbar. Ich danke allen am Projekt Beteiligten herzlich für ihre Unterstützung zur Stärkung der informatischen Bildung in Nordrhein-Westfalen insbesondere im Bereich der KI.«

Künstliche Intelligenz erhält einen festen Platz im Informatikunterricht

KI wird oft als komplexe Technologie wahrgenommen, die nur von Fachleuten verstanden und gestaltet werden kann. Dabei können Kompetenzen in diesem Teilgebiet der Informatik schon in der Schule altersangemessen vermittelt werden. Deshalb hat seit der Einführung des Pflichtfachs Informatik in Klasse 5/6 aller weiterführenden Schulen zum Schuljahr 2021/22 in NRW auch der Bereich Künstliche Intelligenz einen festen Platz im Informatikunterricht. Hier werden unter anderem Anwendungsbeispiele von KI aus der Lebenswelt der Schülerinnen und Schüler thematisiert sowie Grundprinzipien des Maschinellen Lernens altersgerecht vermittelt.

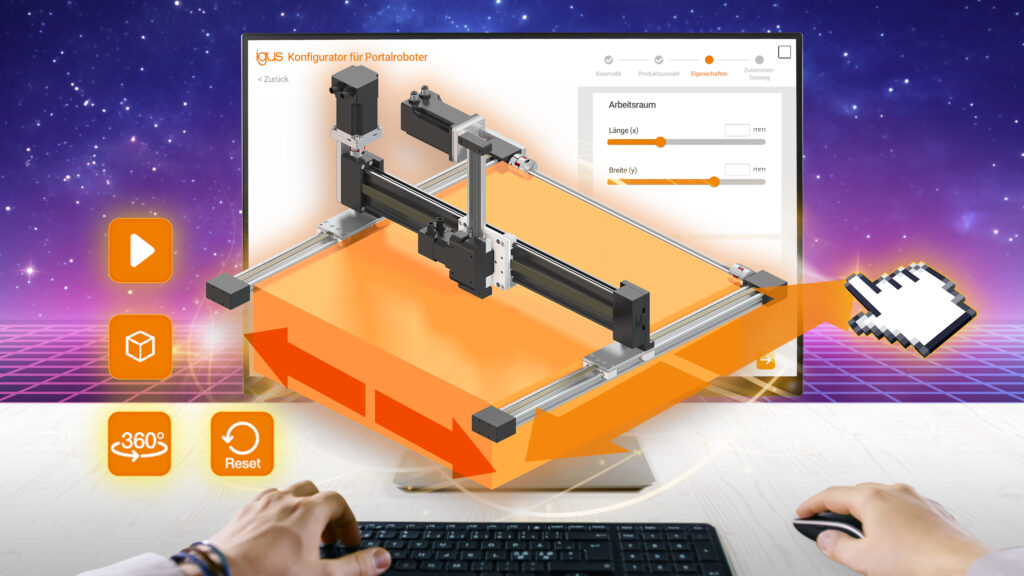

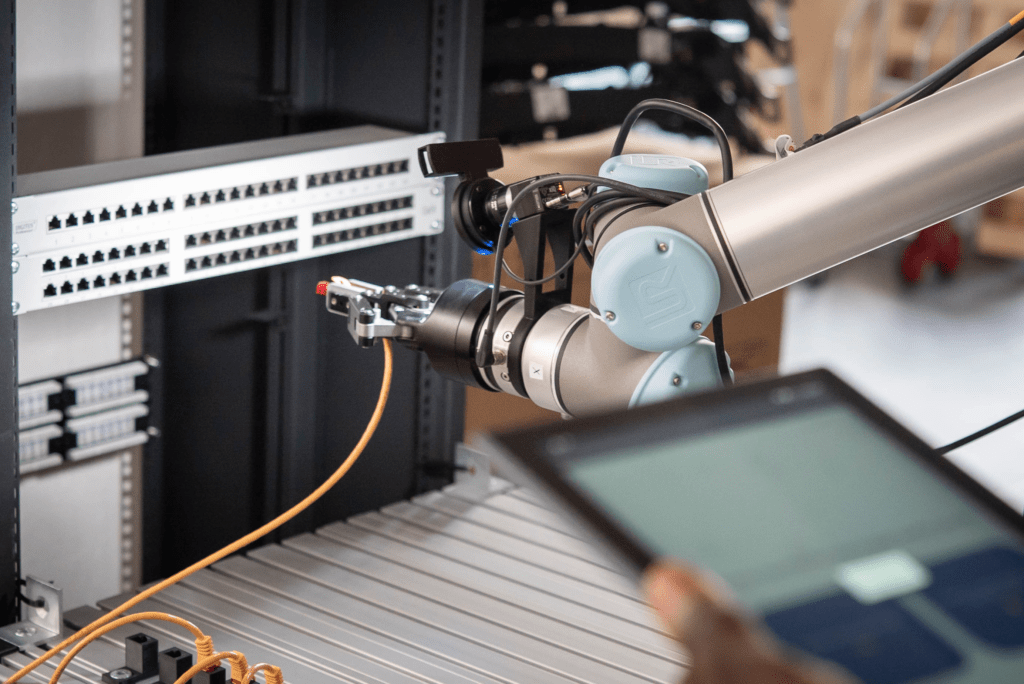

Im Rahmen des Projekts wird die bereits weit verbreitete Open-Source-Programmierumgebung Open Roberta Lab des Fraunhofer IAIS insbesondere um die Integration Künstlicher Neuronaler Netze (KNN) erweitert, um KI-Algorithmen durch grafische Programmierung intuitiv erleb- und verstehbar zu machen. Ziel ist es, dass Schülerinnen und Schüler ab den Klassen 5 und 6 verstehen, was ein Künstliches Neuronales Netz ist, wie es funktioniert und wie sie selbst ein KNN programmieren können, welches zum Beispiel einem Roboter ermöglicht, sich selbstständig in seiner Umwelt zu bewegen. Dabei steht im Vordergrund, dass die grundlegenden Prinzipien eines KNN verstanden und selbst umgesetzt werden können.

Praxisnaher Blick in die »Blackbox«

Thorsten Leimbach, Leiter der Roberta-Initiative und des Geschäftsfelds Smart Coding and Learning am Fraunhofer IAIS: »Üblicherweise wird KI – wenn überhaupt – in der Schule als eine Art Blackbox-Anwendung behandelt. Als eines der führenden Wissenschaftsinstitute auf den Gebieten KI und Maschinelles Lernen freuen wir uns, gemeinsam mit dem Schulministerium NRW und unseren Projektpartnern einen praxisnahen Blick in diese Box zu ermöglichen. Künstliche Neuronale Netze werden zu einem begreifbaren Element, das Schülerinnen und Schüler selbst programmieren können. Sie nähern sich so den Themen Maschinelles Lernen und KI auf innovative Weise.«

Neben dem Fraunhofer IAIS ist das Institut für Mathematikdidaktik (IMD) unter Leitung von Prof. Dr. Inge Schwank am Projekt beteiligt. Das IMD widmet sich der Frage, wie die KI-Thematik für alle Schulformen aufbereitet werden kann. Weiterhin beteiligt sind das Department Mathematik/Informatik (DMI) der Universität zu Köln sowie die InterScience-Akademie für Algorithmik (ISAFA), die das Projekt initiiert hat und ehrenamtlich unterstützt.

Die KNN-Integration als Bestandteil des Open Roberta Labs soll ab Sommer 2022 für alle Schulen und Interessierte weltweit unter https://lab.open-roberta.org verfügbar sein. Lehrkräfte und weitere Messebesucher*innen können auf der didacta 2022 (am Mittwoch und Samstag) am Stand des Schulministeriums NRW bereits einen ersten Einblick erhalten.