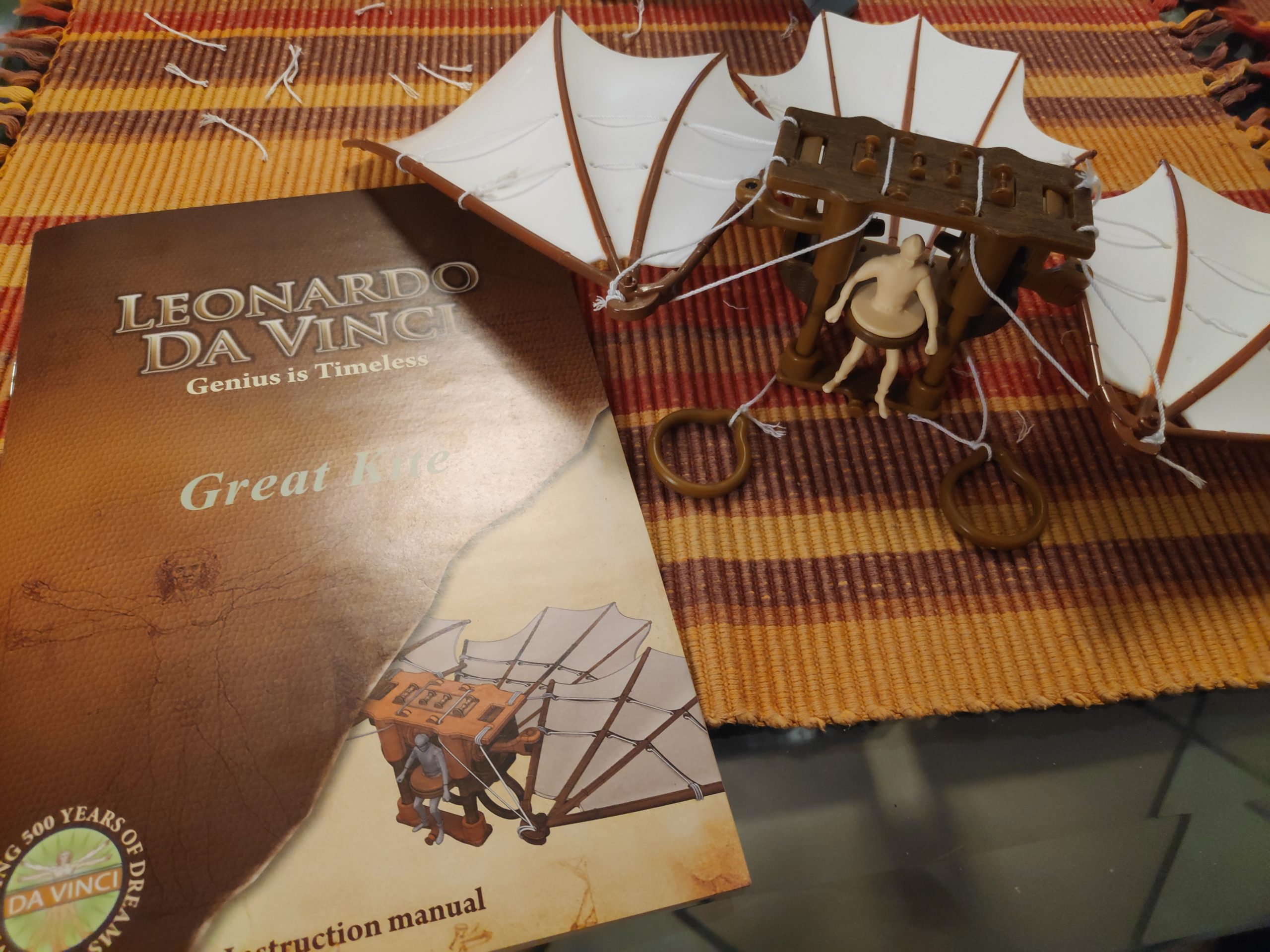

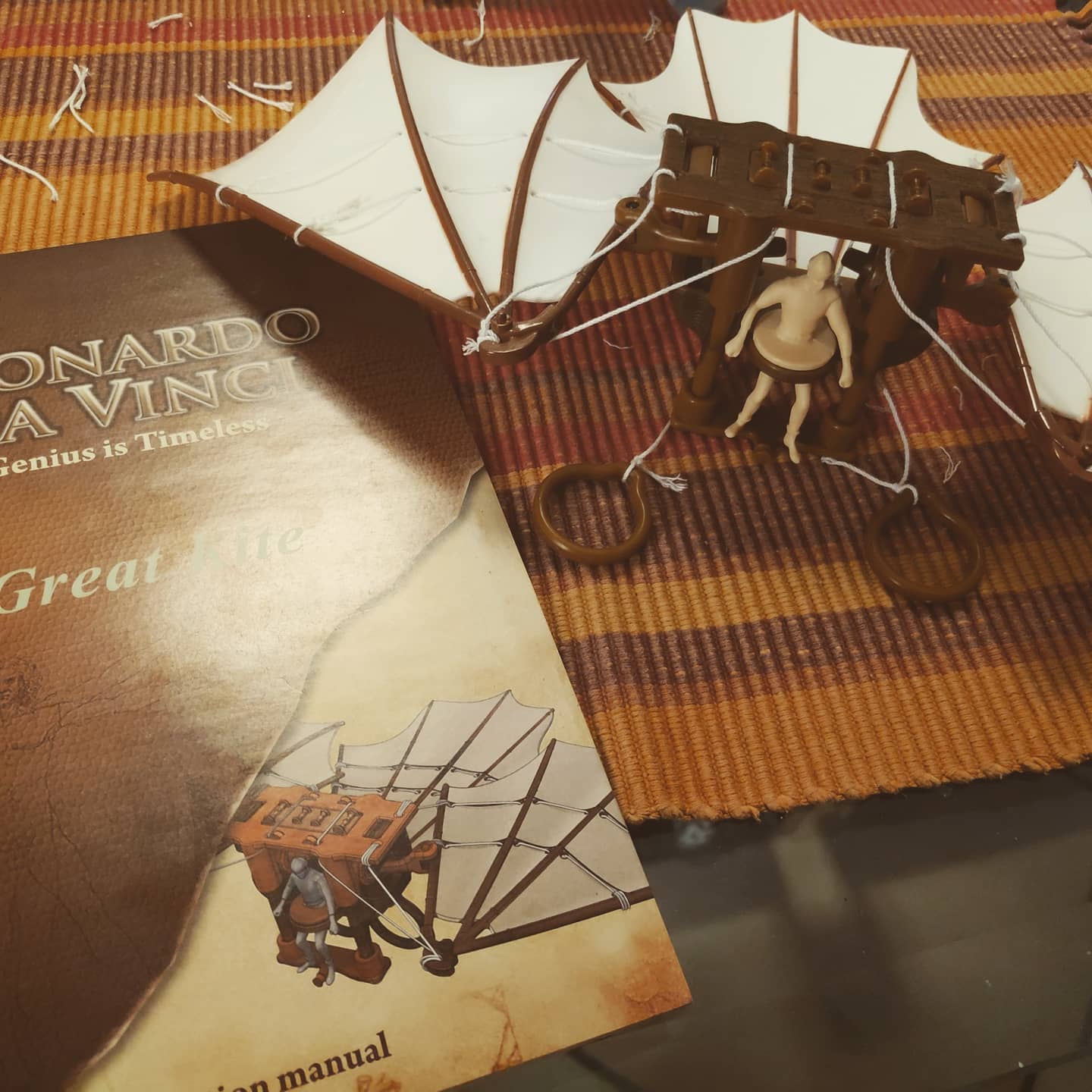

Leonardo Da Vinci Great Kite/Flugdrache Building Kit by EDU-Toys (medu-scientific.de) Timelapse Build

Leonardo Da Vinci Great Kite/Flugdrache Building Kit by EDU-Toys (medu-scientific.de) Timelapse Build

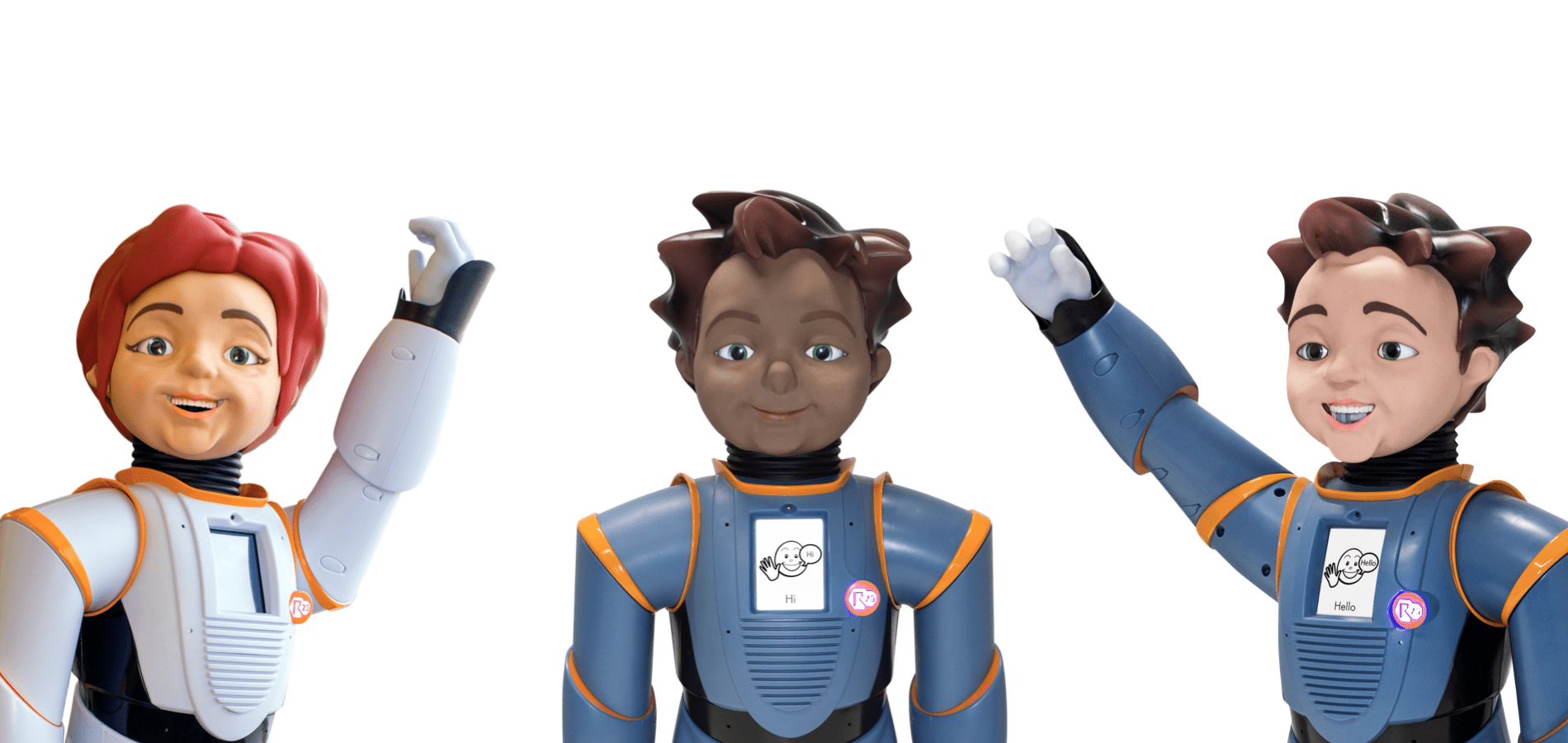

Education Technology Leader RoboKind Grows Team, Introduces New Robot Models.

Education Technology Leader RoboKind Grows Team, Introduces New Robot Models.

DALLAS, Feb. 25, 2021 /PRNewswire/ — RoboKind officially announced a new initiative to support diverse, equitable, and inclusive education. The announcement comes during Black History Month, after almost a full-year of development and research into what RoboKind can and should do to improve access and equity in exceptional student populations.

„During the last 10 years, we demonstrated the impact of our technology and its ability to empower students with Autism to break down social-emotional barriers,“ commented Mary Shaw, RoboKind’s new Sr. Director of Professional Development and Content. „For us, that now extends beyond developmental differences and prioritizes diversity and inclusivity in the classroom.“

Each of its robots are inspired by the values and commitments of the individuals for whom they are named. „Importantly, we are guided by each of these values,“ added Mary. „Sure, we sell innovative robots and curriculum; but we are actually in the business of improving outcomes. We don’t take our mission lightly and are clearer now than ever that DEI is an important piece of our company.“

Carver, after George Washington Carver, the scientist who arguably saved American agriculture, represents the motives of one’s actions, specifically improving your talents and abilities to become the impact you wish to make.

To Learn More About The Story Behind Carver, Jemi, and RoboKind’s Other Robots, Visit:

https://www.robokind.com/advanced-social-robots

Jemi, for NASA Astronaut and Social Activist Dr. Mae Jemison, the first woman of color to visit space, symbolizes the ambition and drive to break down barriers that prevent us from reaching our greatest potential.

Mark Nixon, RoboKind’s CRO and newest team member, concluded, „Last year, it became clear that DEI will be at the forefront of any conversation about improving educational outcomes. Leaders in EdTech must commit resources to a mission of a more inclusive, diverse, and equitable classroom. And, that is exactly what we are doing.“

About RoboKind

RoboKind (www.robokind.com) is an education technology company based in Dallas, Texas. The company develops evidence-based robots and curriculum for students with Autism. Recently endorsed by the Council of Administrators of Special Education, RoboKind is committed to working with PK-12 institutions in delivering and developing solutions that help educators break down barriers of growth and improve outcomes for students with developmental differences.

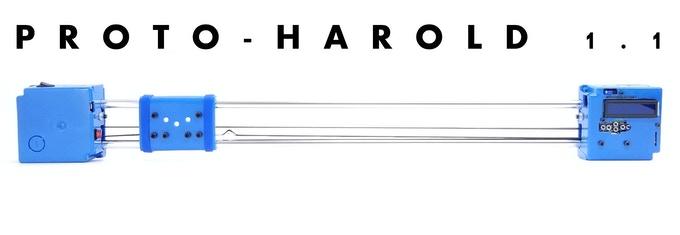

The PROTO-HAROLD 1.1 is a simple, light weight robot, designed to easily bring a CINEMATIC element to any video project. Designed, Machined and Hand Assembled in Cleveland, Ohio, USA.

Your smartphone can go from pocket to stunning motion shot in under 10 seconds as the PROTO-HAROLD 1.1 has ZERO assembly or setup, programming or technical know-how required for use. Simply insert your smartphone, press „ON“, followed by „GO“ and you have a MOVING VIDEO.

Perfect for live streams, nature documentaries, music videos, interviews, YouTubers, TikTokers, movie projects for screens large and small, commercials, presentations, video demonstrations, school projects, home movies, advertisements, video production, unboxing videos, reaction videos, literally… any video project imaginable.

BOUNCE: When turned on, the PROTO-HAROLD 1.1 will begin running „BOUNCE“, a custom-written, pre-loaded program which will move the CAMERA SLED from one end of the track to the other. Instead of only traveling only one time like other systems, or harshly running back and forth, BOUNCE slowly brings the camera sled to a smooth, full stop, before reversing and smoothly accelerating backwards to full speed, endlessly repeating this choreographed process.

The speed and travel length are both adjustable, with a max travel speed of ~1cm per second, or ~50 seconds to go 52cm / 20.5″ from one end to the other.

This is useful as an extra „camera man“ during an interview process to provide an extra moving camera angle, or set it up to capture a moving shot when you aren’t exactly sure when the action will start, let it run for a bit and choose the best moving shot.

MOVING TIME LAPSE: Use the backlit LCD screen and EASY MENU to change modes to TIME LAPSE and set a desired time frame of 2 – 60 minutes. The PROTO-HAROLD 1.1 does the math and will travel from one end to the other, slowly accelerating, reaching full speed, decelerating and smoothly coming to a stop within the time frame selected. Once done, it will park and then ask to run a second time in reverse.

FEATURES:

Please support this project on Kickstarter: https://www.kickstarter.com/projects/simplerobot/the-proto-harold-11-bounce-by-simple-robot-llc/description

Education Technology Leader Brings the Future to 2021, With New Robotic Technology and Curriculum to Support Students with Autism Spectrum Disorder (ASD)

DALLAS, TX (January 28, 2021) – Today, RoboKind, an education technology company that builds robotic technology and curriculum for students with Autism Spectrum Disorder (ASD), announced the release of robots4autism: Avatar, a remote learning software built specifically to help educators support students during remote and blended learning.

“Students with autism are one of the most at-risk student populations to be left behind during COVID-related virtual and blended learning,” said Richard Margolin, RoboKind’s Founder and CTO. “This new software provides the consistency these students need in order to progress toward their Individual Education Program (IEP) goals, regardless of the student’s location.”

Avatar is a version of RoboKind’s social-emotional learning program, robots4autism®, that was recently endorsed by the Council of Administrators of Special Education (CASE). Based on development theory and the principles of applied behavioral analysis (ABA), the program includes a modular, evidence-based curriculum, combining facially expressive avatar robots with social narratives, visual aids, video, and natural modeling to help students learn and, eventually, master basic social-emotional skills.

To Learn More About Remote Social-Emotional Learning and Educators FAQ’s, Visit: https://www.robokind.com/robots4autism-avatar

Richard added, “We as a team and company have invested heavily in bringing virtual, digital options to educators knowing that, now more than ever, schools and districts need the support and innovation companies like RoboKind can provide. For us, it’s about improving student outcomes and we have already begun seeing students across North America make tangible progress toward their IEP goals.”

The program was developed as part of an expanded platform the company says will allow for educators to help students, regardless of background or abilities, in a variety of implementations and learning models.

About RoboKind

Founded in 2011 by Richard Margolin, RoboKind (www.robokind.com) is an education technology and robotics company based in Dallas, Texas. The company developed the world’s most Advanced Social Robots™ and an award-winning, evidence-based social-emotional instructional curriculum for students in grades K-12. Milo, one of RoboKind’s facially expressive robots, was named as Tech & Learning’s Most Inspiring Game Changer in 2019, the first non-human ever to win the award. Recently endorsed by the Council of Administrators of Special Education (CASE), RoboKind is committed to working with PK-12 institutions in delivering and developing solutions that allow students to build the confidence and master the lifelong skills they need.

Image processing is a complex and very extensive topic. In order to be able to use the multitude of different application possibilities and functions optimally, EVT has been offering training courses on various topics of image processing for several years. The participants will learn how to use it correctly, as well as the numerous functions and possible uses of the innovative EyeVision software.

EVT now also offers the first free certification program in addition to free knowledge sharing. The webinar participants can participate and benefit from the advantages. After successfully completing a test that is independent of time and location, the participants receive a certificate and are allowed to bear the title “certified Eye Vision Technology professional in image processing”. The certification comes with numerous advantages, such as saving 10 percent with every order via EVT, the permission to use prioritized support via an exclusive acceptance point and an entry as a certified professional in image processing on the highly frequented Eye Vision homepage.

Certification not only benefits companies, but also customers. Because the certificate enables transparency about the knowledge of the person responsible in the field of image processing and the use of image processing software.

You can find out more about the criteria and registration for the free certification program at www.evt-web.com.

St-Sulpice, Switzerland, February18, 2021 – BlueBotics, the global leader in natural feature navigation, has announced its Autonomous Navigation Technology (ANT®) is now estimated to have driven automated guided vehicles (AGVs) and autonomous mobile robots (AMRs) over 10 million kilometers, in applications ranging from warehousing and manufacturing to commercial cleaning services, UVC disinfection and more.

Dr. Nicola Tomatis, CEO of BlueBotics, said, “The timing of this milestone is perfect as it comes the same month that we celebrate the company’s 20-year anniversary. It is amazing to think that our customers’ ANT® driven vehicles have driven over 10 million kilometers, almost 250 times the circumference of the globe. This achievement really speaks to the robustness of our industry-proven ANT® technology.”

ANT® navigation is popular with manufacturers and end users of AGVs, automated forklifts and AMRs, since it simplifies and shortens vehicle installation times as well as providing flexible, accurate and user-friendly operation. The technology suits a myriad of vehicle types and kinematics, from small 100 kg AMRs to 30-ton heavy load transporter AGVs. In addition, with BlueBotics’ accompanying ANT® server software, users whose vehicles are driven by BlueBotics’ ANT® lite+ product can create and operate a synchronized fleet of ANT® driven vehicles, no matter what the type or even brand. All of these vehicles are able to interact seamlessly with on-site equipment and machinery, including an organization’s existing WMS/MES/ERP software, using ANT® server’s simple API.

Dr. Tomatis continued, “In arriving at our 10-million-kilometer milestone, we conservatively estimate that AGVs driven by ANT® technology have worked more than one million days – over 2,500 years – of commercial operation.”

“It is exciting to see the impact ANT® technology is having, both on the AGV market and – most importantly – on the efficiency of those companies that operate ANT® driven vehicles. With our continuing strong growth, it shouldn’t be long before ANT® driven products will have circumnavigated the globe 500 times!”

About BlueBotics

BlueBotics is the reference in natural feature navigation and has the mission to help companies meet the challenge of vehicle automation. With its 20 years of industry experience, the company provides the autonomous navigation technology (ANT®) and expert support customers need to bring their AGV, automated forklift or mobile robot successfully to market. Today, there are more than 2,000 ANT® driven vehicles in operation worldwide. https://www.BlueBotics.com

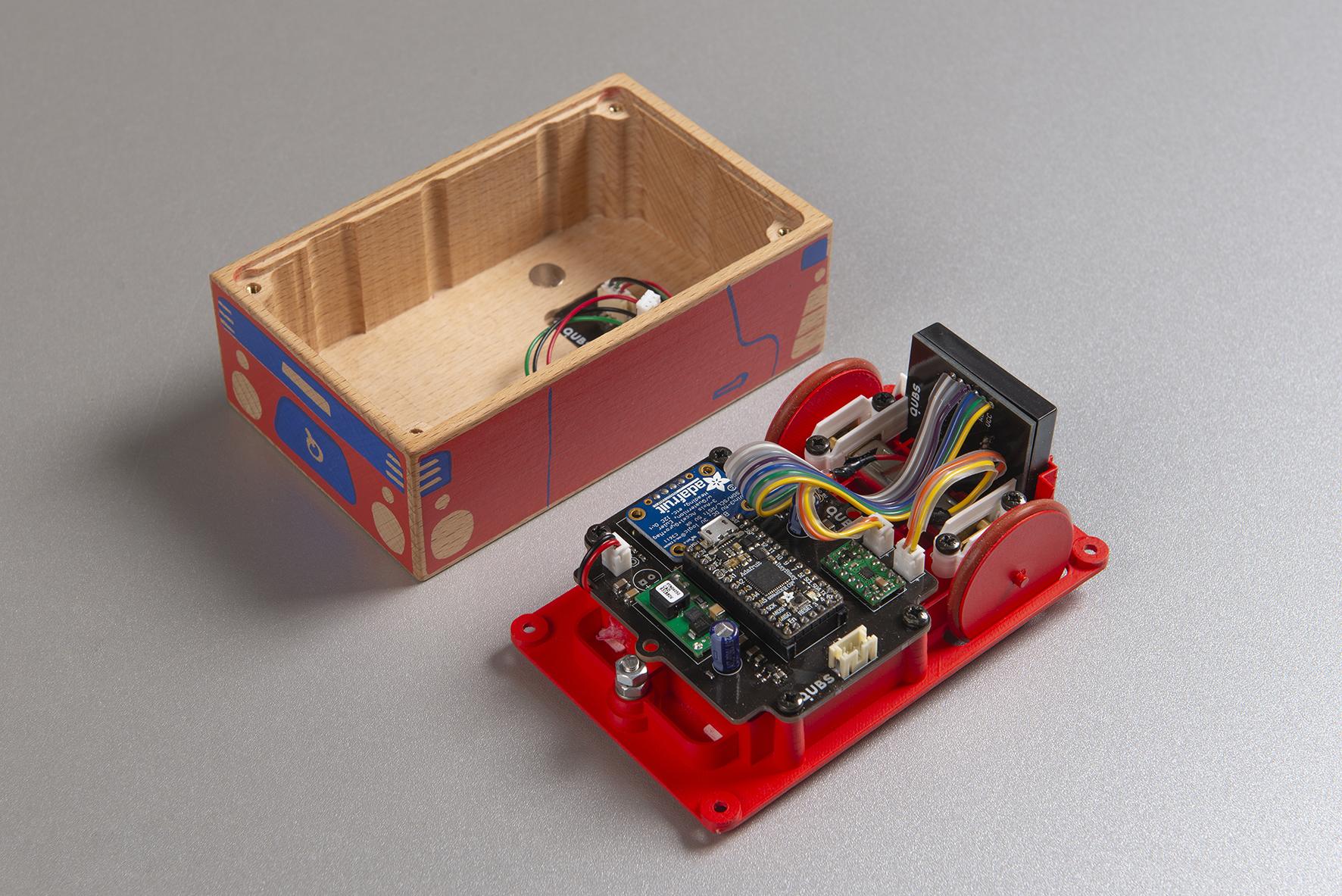

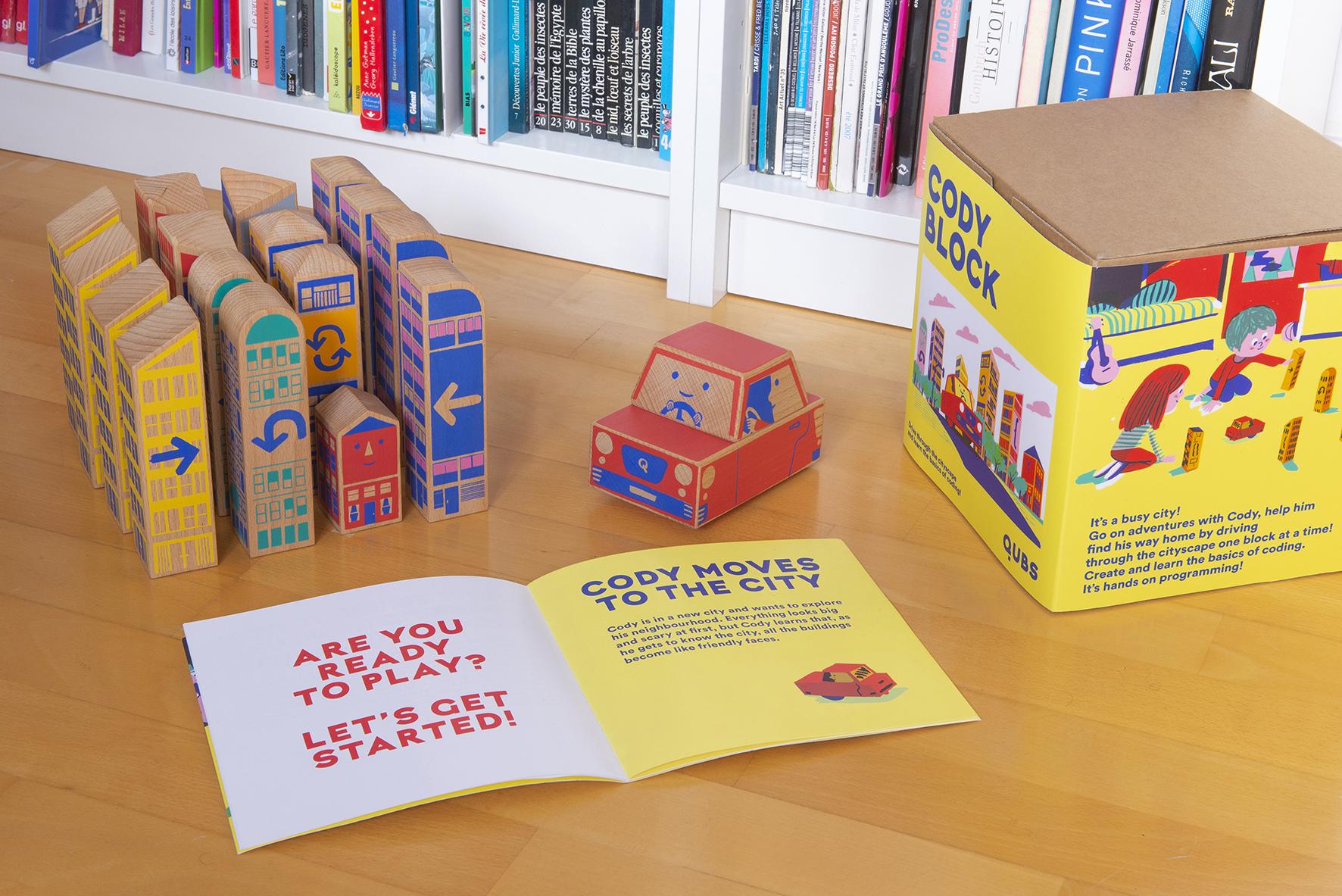

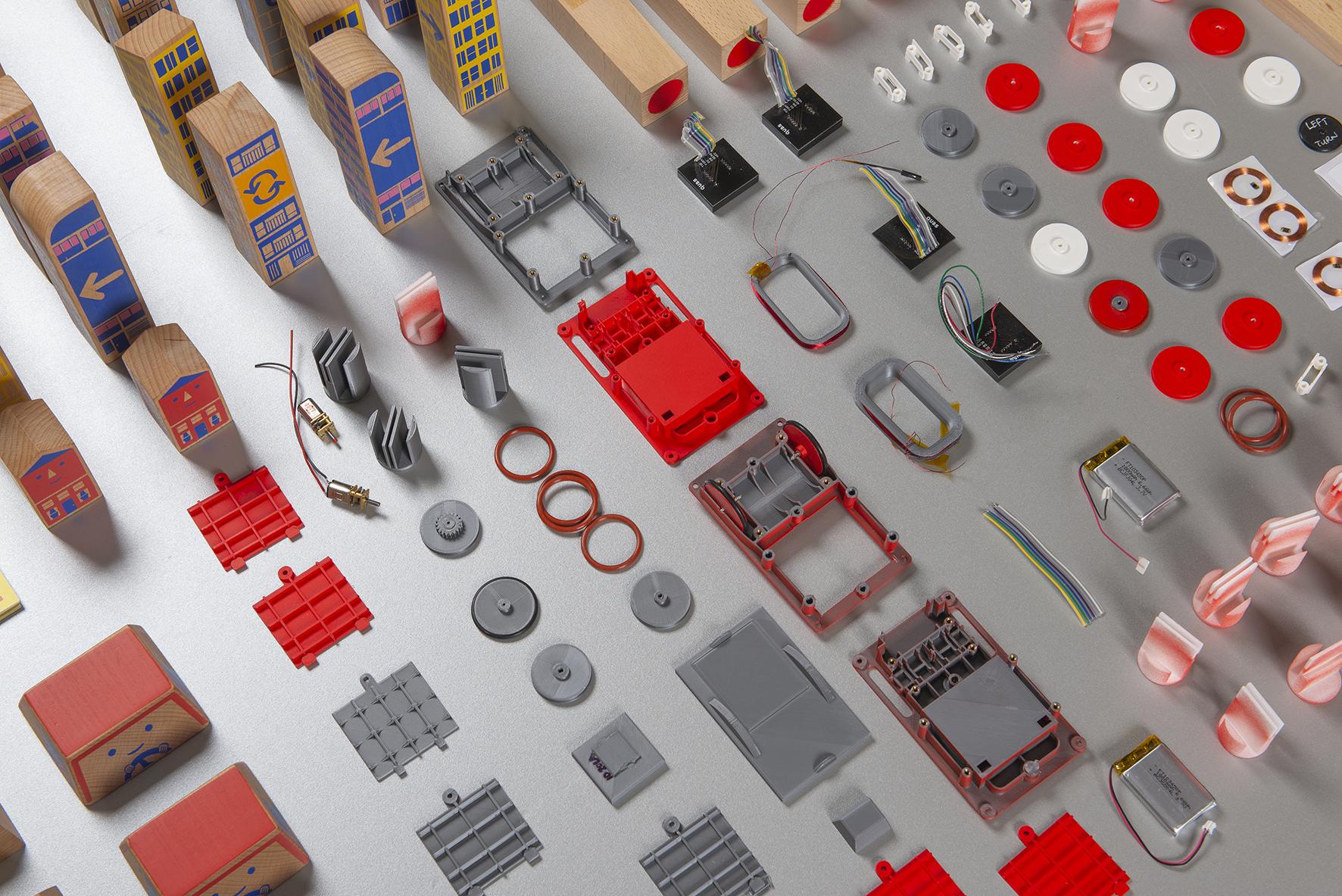

Cody Block is centered on a little wooden car called Cody that has to find its way home through 16 Building Blocks which act as commands. The task for children is to lay out a path that leads Cody back to his house by positioning the Building Blocks in the correct order.

Children put Cody at the starting point and watch as the electronic car moves through the Building Blocks. Each of the Blocks gives a unique directional command to the car through

RFID tags.

Cody will follow the sequence of instructions provided by the Blocks and – if the blocks are arranged correctly – make it to his goal. If not, children have to figure out how to rearrange the blocks in order to fix the sequence and help Cody get home.

The patented RFID technology embedded in every wooden block allows children to play with

Cody for hours without the need of any smartphone, laptop or screen. The design of Cody Block takes its inspiration from classic wooden toys and the Montessori philosophy in its material and shape: solid beech wood and intuitive design.

Cody Block provides gender-neutral play that stimulates a child’s critical thinking, creativity, problem solving abilities and resilience.

QUBS and Cody Block was started by Hayri Bulman, a Swiss IT entrepreneur and father of 2 children. In 2016, Hayri started exploring how to bring technology and classic wooden toys together to help his children learn the basics of coding through play. After prototyping a number of concepts at home which incorporated RFID technology inside of wooden blocks he brought together a team of designers, engineers and illustrators to launch Cody Block.

Hayri wanted to bring Cody Block to the market because he is convinced that by enabling kids to gather new skills through play, we encourage the next generation of innovators, tinkerers, creators and makers of the future.

“My aim is to create a toy that blends classic wooden toys with electronics and helps kids navigate this increasingly digital world. There are thousands of wooden toys and there are thousands of electric toys but with Cody we can bridge these two very far worlds together, and close the gap between them,” said Hayri Bulman, founder of QUBS.

“I want to bring children closer to coding, a very essential skill for the future. I hope Cody Block will help them understand how to think and problem solve, all of this while having fun. I believe children will play with Cody Block in many different ways, more than we can ever imagine.”

Cody Block is being launched at a time when coding and STEM subjects are getting more attention both from the education system and from parents.

“The ability to solve problems is a skill that is useful in life in general, we all want our children to become excellent problem solvers, so that they can overcome any adversity they face. Learning code gives children the possibility to learn this type of skills while they’re young, and this will give them advantage in life. Cody Block is the perfect way for them to play and learn at the same time,” said Bruce Lamont, a primary school teacher and Lead Teacher with 32 years of experience in the field.

“Cody Block helps children develop a way of thinking and how to find creative and logical solutions to problems, skills that are really looked for in education nowadays.”

The basic pack includes Cody (the car), 16 Building Blocks, and a City Guide with exercises.

Additional educational discounts will be available for classroom packs of 5 and 10 sets.

About QUBS

QUBS AG is a Swiss company based in Zurich and founded by Hayri Bulman, a father of 2 children and with a passion for wooden toys and new technologies. QUBS is the only toy maker that merges classic designs and screen-free technology in early years learning.

QUBS’ mission is to empower children to explore the learning world in a fun and accessible way. The company makes wooden toys that are loved by children and trusted by parents & educators. By enabling kids to gather new skills through play, QUBS aims to encourage the next generation of innovators, tinkerers, creators and makers of the future.

www.qubs.toys

New slip ring-free igus cable unwinder allows easy cable management

February 9, 2021 – igus has developed the e-spool® flex 2.0, a new cable reel that has no slip ring that is perfect for industrial robot users. This allows for easy management of robot teach pendants and the system even supplies bus signals without interruptions, which can be typical with slip rings.

The solution can extend cables up to 50 feet and is flexible, movable, and easily stowed. Installation into a robot’s control center is simple with the included mounting hardware.

The new e-spool flex captured the attention of ARAGON in Germany, as it offers a complete solution including a standard harnessed cable with connectors and mounting hardware for the company’s industrial robots.

Cable drum without a slip ring

The e-spool® flex 2.0 is igus’ version of a cable drum without a slip ring. The cable is safely routed through a feed-through to ensure that it is always properly wound. Cable diameters of 5-15 millimeters can be used.

The unit can be installed on the floor, ceiling, or wall and safely guides media power, data, or air in one system. The space-saving design includes a locking mechanism on the cable, and is adaptable to technological developments by simply replacing the used cable. The design is also cost-effective in case of repair as it allows for the replacement of individual components.

Other features on the product include a snail mechanism that allows for uninterrupted cable connection and easy insertion of existing cable even when connectors are already attached. The system also has high-transmission reliability and various winding variants.

The e-spool® flex 2.0 can be used whenever a cable must be moved freely during use and must be stowed away safely and cleanly after use.

Successful robot rehabilitation

ARAGON Industrieelektronik GmbH’s successfully proved the effectiveness of the e-spool® flex 2.0. The business’ primary objective is to breathe new life into old robots. The leading industrial robotics provider offers global solutions for repairing, maintaining, retrofitting, and tuning industrial robots. The company was looking for a practical cable solution specifically for use in control panels.

“We are always trying to ensure our customers’ safety with innovative solutions. Until now, the cable was always on the floor, which made it easy to damage or trip over. We went looking for a cable reel that had no interruptions and was quick and easy to retrofit,” said Iryna Geike, Global Country Manager at ARAGON.

The company found what it was looking for in igus. “The new e-spool® flex cable reel system was introduced to us and won us over immediately,” Geike said.

A critical advantage for the company was the ability of the e-spool® flex 2.0 to allow existing panel cables to be inserted into the system’s spiral guide and automatically rolled up. “Our customers now receive a pre-assembled set consisting of the e-spool flex, ARAGON panel mount, cable, and a robot control cabinet mounting bracket for their control panels. The e-spool flex greatly extends the service life of the cable used and ensures more safety and order in the control panel,” Geike said.

Rolling and unrolling cables: manually or automatically

igus offers the e-spool® flex in several variants. One is a low-cost version with a manual turner or a cordless screwdriver to wind up the cable. Another is an automatic solution with a spring-driven return mechanism, a locking mechanism, and an optional retraction brake.

ARAGON decided on the variant with the retaining spring. The cable roller is available in three sizes for cables with diameters of 5 to 15 millimeters and extension lengths of 5 to 15 meters.

Cables can be replaced quickly at any time. In addition to subsequent integration of the e-spool® flex into an existing cable system, igus offers the cable reel solution fully harnessed with chainflex cables specifically designed for moving applications. Cable durability in the e-spool® flex is currently being extensively tested in the in-house 3,800 square meter igus test laboratory. For more information on the e-spool flex 2.0 visit the igus website.

Nach neuem Nutzer*innen-Rekord auf der Open-Source-Programmierplattform »Open Roberta« startet Fraunhofer IAIS jetzt eine neue Lernspiel-App, basierend auf einer Mars-Mission der ESA.

Programmieren wie die Profis, forschen wie die Weltraumfahrer*innen – die Spiele-App »NEPO Missions« ermöglicht beides. Das Fraunhofer IAIS veröffentlicht ein Lernspiel, in dem Kinder und Jugendliche spielerisch einen virtuellen Mars-Rover programmieren können, der auf »Rosalind Franklin« basiert: Den realen Rover will die Europäische Weltraumorganisation ESA auf die Forschungsmission »ExoMars 2022« schicken. Die Idee zu der App hatte sich 2018 bei der »Google.org Impact Challenge« durchgesetzt und wurde als Leuchtturmprojekt gefördert. NEPO Missions basiert auf der Fraunhofer-Plattform »Open Roberta Lab«, mit der allein in 2020 rund drei Millionen Menschen weltweit ins Programmieren eingestiegen sind.

Digitale Kompetenzen praxisnah stärken – das ist seit mehr als 18 Jahren Ziel der Initiative »Roberta® – Lernen mit Robotern« des Fraunhofer-Instituts für Intelligente Analyse- und Informationssysteme IAIS. Mit der zugehörigen Open-Source-Programmierplattform »Open Roberta® Lab« ermöglicht das Team aus Didaktik- und Robotik-Expert*innen Menschen weltweit, ihre Hardware kostenfrei zu programmieren. Mit rund drei Millionen Zugriffen auf lab.open-roberta.org allein im Jahr 2020 hat sich die Nutzer*innenzahl aus dem Vorjahr versechsfacht. Mit einer neuen Programmier-App für Kinder ab zehn Jahren setzt die Initiative den bisherigen Erfolgsweg von Open Roberta fort: »NEPO Missions« ist ab sofort kostenfrei im Google Play Store und im App Store verfügbar.

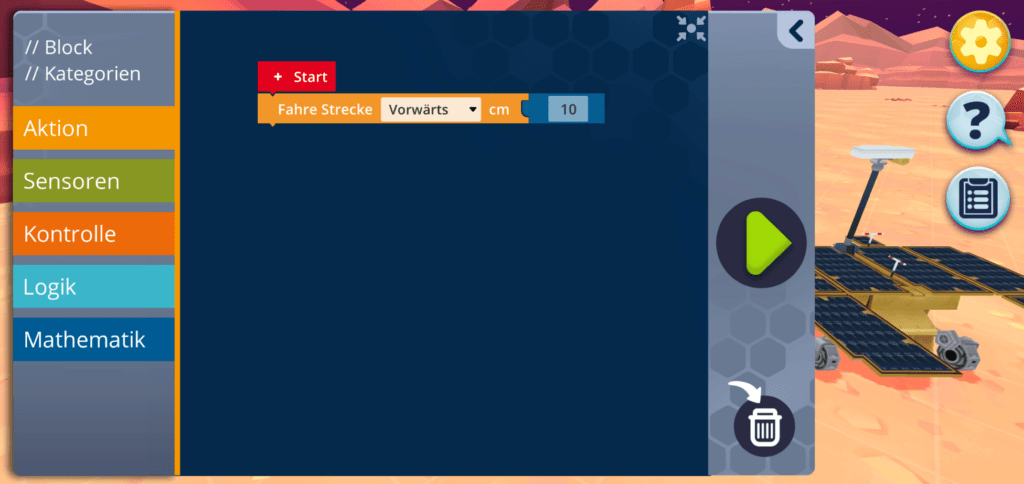

NEPO Missions setzt auf das Konzept des visuellen Programmierens, das im Open Roberta Lab seit 2014 Kindern ab dem lesefähigen Alter den spielerischen Einstieg ins Programmieren ermöglicht. Per »drag and drop« werden die Blöcke der grafischen Fraunhofer-Programmiersprache »NEPO« zusammengesteckt und schließlich von realen oder simulierten Robotern und Mikrocontrollern ausgeführt.

Reale ESA-Forschungsmission »ExoMars 2022« dient als Inspiration

Wie im Open Roberta Lab können Nutzer*innen auch mit der neuen Lernspiel-App NEPO Missions simulierte Roboter programmieren – jetzt allerdings in einem ganz besonderen Szenario: Die Mission bringt Spieler*innen auf den Mars. Sie erhalten den Forschungsauftrag, mithilfe eines ferngesteuerten Rovers die Oberfläche des Planeten zu erkunden. Schritt für Schritt lösen sie dafür immer schwierigere Programmieraufgaben: vom Fahren auf der Mars-Oberfläche über das Sammeln von Daten mittels Sensoren bis hin zu Bohrungen, um tiefere Bodenschichten zu untersuchen. Wie im Open Roberta Lab stellen die Kinder die Programme intuitiv mit den grafischen NEPO-Blöcken zusammen und erzielen im Handumdrehen erste Erfolgserlebnisse.

Die Mission ist an die reale Forschungsmission »ExoMars 2022« der Europäischen Weltraumorganisation ESA angelehnt. Bei dieser soll der Mars-Rover »Rosalind Franklin« den »roten Planeten« auf biologische Aktivitäten untersuchen und so bestenfalls Spuren von Leben finden. Im Spiel NEPO Missions programmiert der*die Nutzer*in als fiktives Mitglied der ESA eine virtuelle Version des Mars-Rovers. Insgesamt 17 Programmieraufgaben sowie Hinweise und Tipps erhalten die Spieler*innen von dem Roberta-Maskottchen sowie der fiktiven Teamleiterin Dalia, die gleichzeitig eine weibliche Vorbildfunktion einnimmt.

Start zum Internationalen UNESCO-Tag der Frauen und Mädchen in der Wissenschaft

Das Fraunhofer IAIS startet die neue Coding-App passend zum Internationalen Tag der Frauen und Mädchen in der Wissenschaft der UNESCO am 11. Februar 2021. Auch, wenn sich das Lernspiel an beide Geschlechter richtet, ist es seit jeher Ziel der Roberta-Initiative, insbesondere Mädchen für MINT zu begeistern. Dieses Ziel teilt Roberta sich mit Dr. Carmen Köhler von der Initiative »Erste deutsche Astronautin« gGmbH. Sie erforscht in mehrwöchigen internationalen Mars-Simulationen als »Analog-Astronautin« vom Österreichischem Weltraumforum marsähnliche Gebiete auf der Erde. In Zusammenarbeit mit Fraunhofer IAIS bietet sie auch »Code4Space«-Workshops für Kinder und Lehrkräfte an. »Als Analog-Astronautin weiß ich, wie wichtig es ist, in realistischer Umgebung zu trainieren. Man muss meist weit reisen, um marsähnliche Gebiete zu finden. Mit dem Spiel NEPO Missions bekommen Kinder schon im frühen Alter einen realistischen und spielerischen Zugang zum Programmieren und können sich auf ihre Zukunft als Weltraumforscher*innen vorbereiten, egal ob im Wohn- oder Klassenzimmer«, sagt Carmen Köhler.

Die enge Verknüpfung des Lernspiels mit einer realen Mission vermittelt Kindern digitale Kompetenzen sowie einen wirklichkeitsnahen Einblick in die Arbeit von Wissenschaftler*innen. »Als Serious Game dient das Spiel nicht nur der Unterhaltung«, sagt Thorsten Leimbach, Geschäftsfeldleiter Smart Coding and Learning, dessen Team am Fraunhofer IAIS die App in Zusammenarbeit mit dem Serious-Games-Hersteller »Gentle Troll« entwickelt hat. »NEPO Missions verbindet die Faszinationen des Weltraums und der Technik mit einem echten wissenschaftlichen Abenteuer. Mit dem Spiel möchten wir den Forschungsgeist in Kindern wecken und ihnen Mut machen, ihre digitale Welt selbst zu gestalten.«

Künstliche Intelligenz im Einsatz – mit Fraunhofer-»Text-to-Speech-Technologie«

Neben dem intuitiven Programmieransatz kommt in NEPO Missions auch eine Text-to-Speech-Technologie zum Einsatz, die den Spieler*innen Aufgabenstellungen und Informationstexte innerhalb des Spiels vorliest. Im Rahmen des vom Bundesministerium für Wirtschaft und Energie (BMWi) geförderten Projekts SPEAKER rund um eine Sprachassistenzplattform »Made in Germany« haben die Expert*innen des Fraunhofer-Instituts für Integrierte Schaltungen IIS diese Technologie in Kooperation mit dem Fraunhofer IAIS entwickelt. Beide Institute gehören zu den europaweit führenden Forschungseinrichtungen für die angewandte Forschung rund um Künstliche Intelligenz.

NEPO Missions richtet sich an Kinder ab 13 Jahren, unter Aufsicht von Erwachsenen ist auch eine Nutzung ab zehn Jahren möglich. Das Spiel wird ohne In-App-Käufe als Open-Source-Projekt kostenfrei bereitgestellt und ist ab sofort zum Download im Google Play Store und im App Store verfügbar. Die App ist kompatibel mit folgenden Betriebssystemen und neueren Versionen: iPhone iOS 14, iPad iOS 14 und Android 6.0. Die Finanzierung und Entwicklung des Lernspiels wurde mithilfe der »Impact Challenge 2018« von Google.org, dem philanthropischen Arm des Unternehmens, ermöglicht. Dabei wurde die Idee zu NEPO Missions als eines von zehn Leuchtturm-Projekten ausgezeichnet und mit 250 000 Euro gefördert.

Dass der praxisnahe Ansatz der Roberta-Initiative gut ankommt, belegen auch die stetig wachsenden Nutzungszahlen im Open Roberta Lab. »Von Brasilien über Rumänien bis Japan – aus mehr als 120 Ländern programmieren Kinder und Jugendliche aber auch Auszubildende und Manager*innen auf unserer Plattform ›made in Germany‹«, erklärt Thorsten Leimbach. Die Programmier-Plattform wird am Fraunhofer IAIS in Sankt Augustin unter höchsten Datenschutz-Maßnahmen entwickelt. Open Roberta ist als Open-Source-Projekt auf GitHub für jeden frei einsehbar. Seit 2020 werden zudem keine Cookies mehr auf der Plattform gesetzt.

Weitere Informationen: