Education Technology Leader Brings the Future to 2021, With New Robotic Technology and Curriculum to Support Students with Autism Spectrum Disorder (ASD)

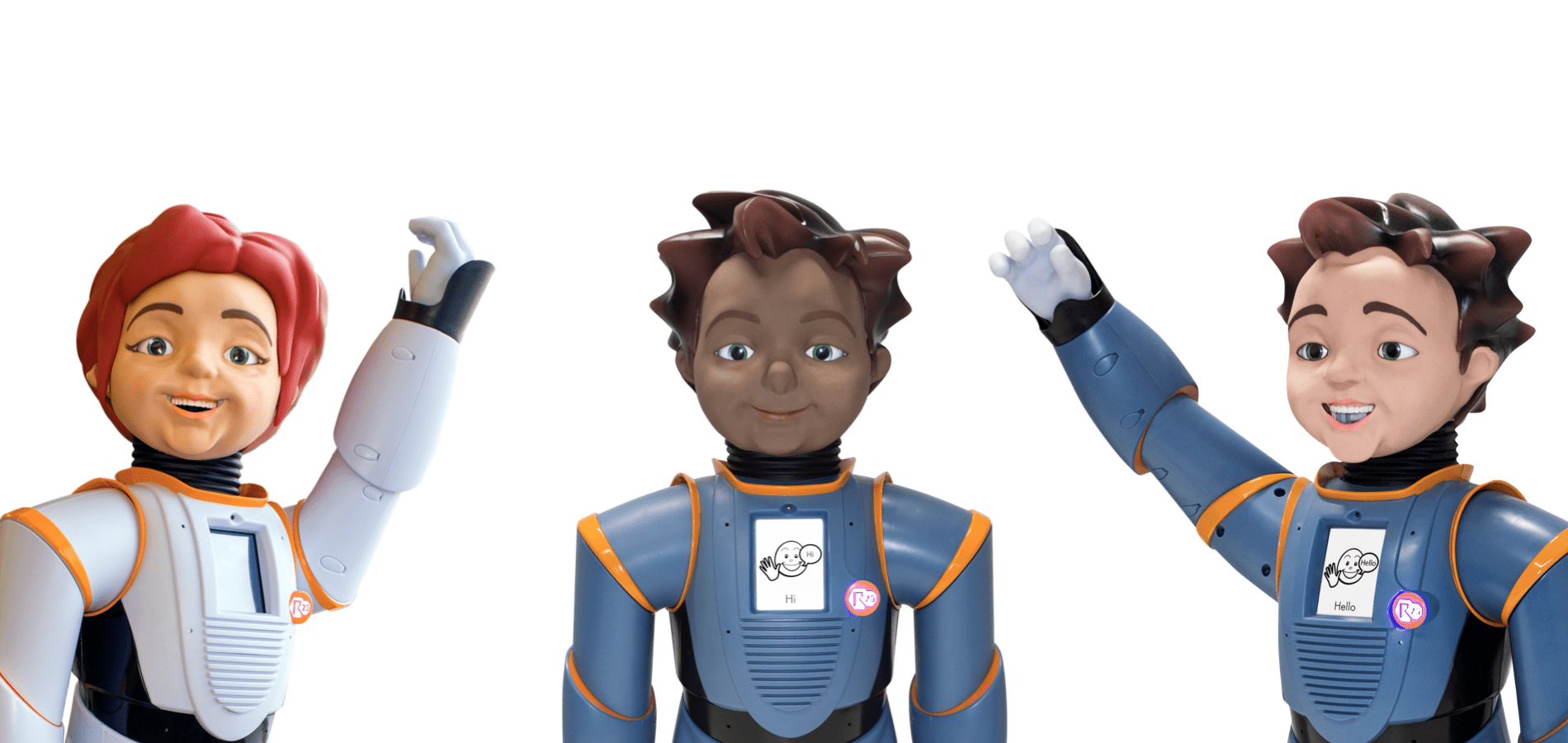

DALLAS, TX (January 28, 2021) – Today, RoboKind, an education technology company that builds robotic technology and curriculum for students with Autism Spectrum Disorder (ASD), announced the release of robots4autism: Avatar, a remote learning software built specifically to help educators support students during remote and blended learning.

“Students with autism are one of the most at-risk student populations to be left behind during COVID-related virtual and blended learning,” said Richard Margolin, RoboKind’s Founder and CTO. “This new software provides the consistency these students need in order to progress toward their Individual Education Program (IEP) goals, regardless of the student’s location.”

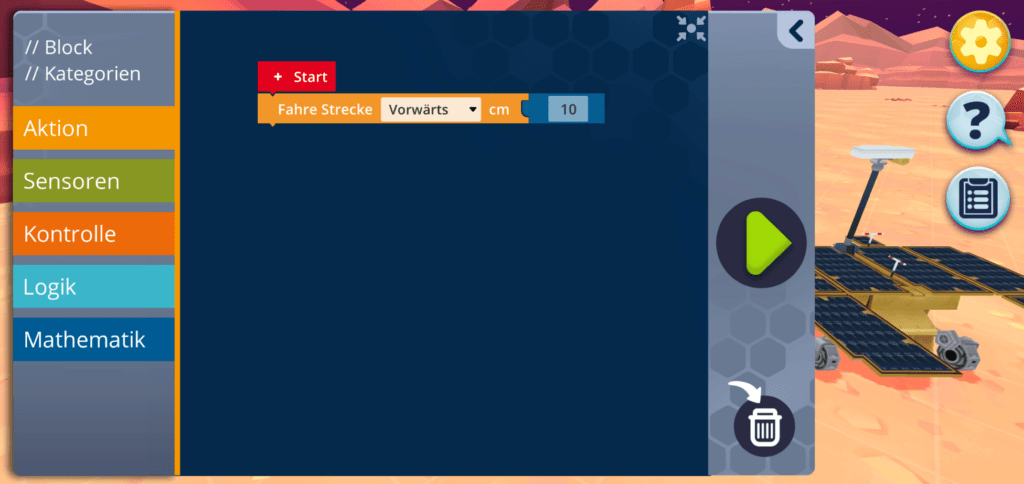

Avatar is a version of RoboKind’s social-emotional learning program, robots4autism®, that was recently endorsed by the Council of Administrators of Special Education (CASE). Based on development theory and the principles of applied behavioral analysis (ABA), the program includes a modular, evidence-based curriculum, combining facially expressive avatar robots with social narratives, visual aids, video, and natural modeling to help students learn and, eventually, master basic social-emotional skills.

To Learn More About Remote Social-Emotional Learning and Educators FAQ’s, Visit: https://www.robokind.com/robots4autism-avatar

Richard added, “We as a team and company have invested heavily in bringing virtual, digital options to educators knowing that, now more than ever, schools and districts need the support and innovation companies like RoboKind can provide. For us, it’s about improving student outcomes and we have already begun seeing students across North America make tangible progress toward their IEP goals.”

The program was developed as part of an expanded platform the company says will allow for educators to help students, regardless of background or abilities, in a variety of implementations and learning models.

About RoboKind

Founded in 2011 by Richard Margolin, RoboKind (www.robokind.com) is an education technology and robotics company based in Dallas, Texas. The company developed the world’s most Advanced Social Robots™ and an award-winning, evidence-based social-emotional instructional curriculum for students in grades K-12. Milo, one of RoboKind’s facially expressive robots, was named as Tech & Learning’s Most Inspiring Game Changer in 2019, the first non-human ever to win the award. Recently endorsed by the Council of Administrators of Special Education (CASE), RoboKind is committed to working with PK-12 institutions in delivering and developing solutions that allow students to build the confidence and master the lifelong skills they need.

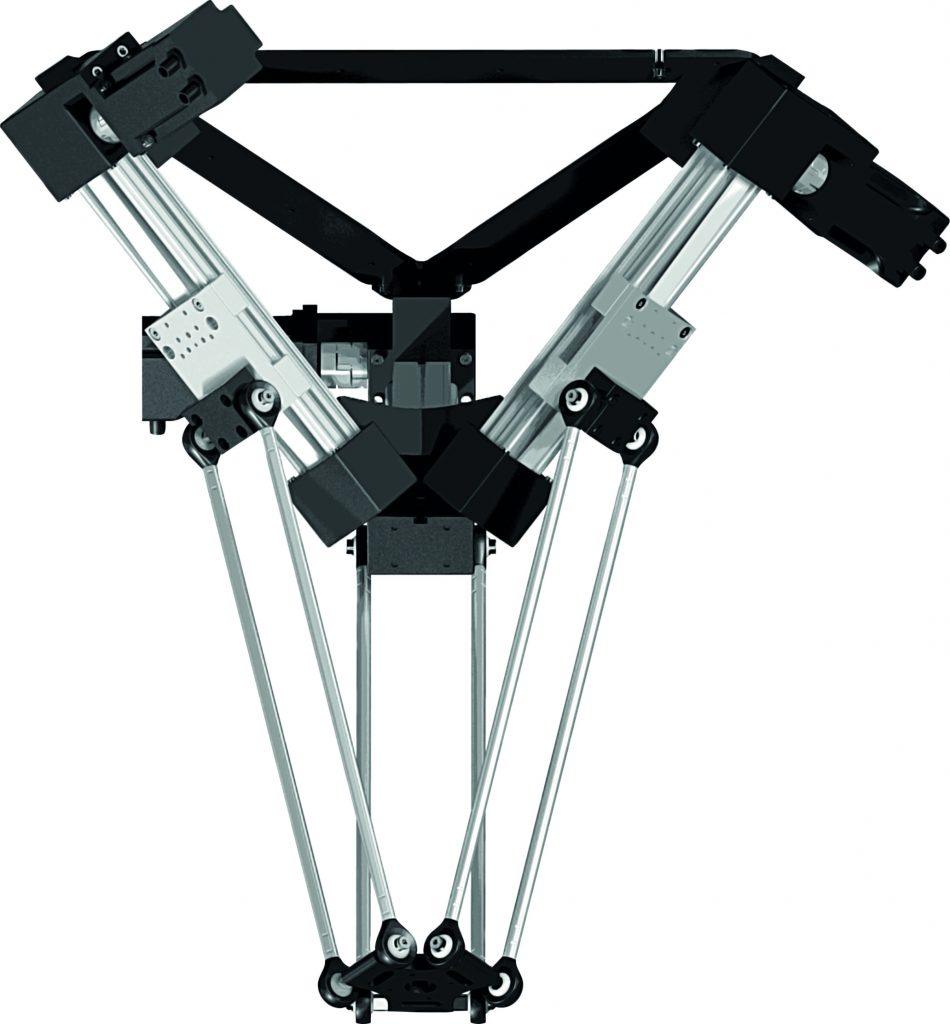

That’s precisely what the RoboGym development team is dealing with, along with similar questions in a research project entitled RoSylerNT, which is being funded by the Federal Ministry of Education and Research. Over the past three years, the experts at RWTH Aachen University, the German Sport University Cologne, and BEC GmbH have jointly developed a multifunctional, robotic weightlifting device that will, on the one hand, help athletes to increase their own performance even further and to shorten the recuperation period following an injury. On the other hand, individual adjustments to the requirements of the person exercising also make it suitable for training in later years in a way that’s gentle on the joints and thus preserves muscle strength and prevents injuries.

That’s precisely what the RoboGym development team is dealing with, along with similar questions in a research project entitled RoSylerNT, which is being funded by the Federal Ministry of Education and Research. Over the past three years, the experts at RWTH Aachen University, the German Sport University Cologne, and BEC GmbH have jointly developed a multifunctional, robotic weightlifting device that will, on the one hand, help athletes to increase their own performance even further and to shorten the recuperation period following an injury. On the other hand, individual adjustments to the requirements of the person exercising also make it suitable for training in later years in a way that’s gentle on the joints and thus preserves muscle strength and prevents injuries.