How will the technologies available today impact tomorrow’s fitness training? Can robots help us pump iron and get improved training results? What do high-performance sports, weightlifting for seniors, and rehabilitation all have in common?

That’s precisely what the RoboGym development team is dealing with, along with similar questions in a research project entitled RoSylerNT, which is being funded by the Federal Ministry of Education and Research. Over the past three years, the experts at RWTH Aachen University, the German Sport University Cologne, and BEC GmbH have jointly developed a multifunctional, robotic weightlifting device that will, on the one hand, help athletes to increase their own performance even further and to shorten the recuperation period following an injury. On the other hand, individual adjustments to the requirements of the person exercising also make it suitable for training in later years in a way that’s gentle on the joints and thus preserves muscle strength and prevents injuries.

That’s precisely what the RoboGym development team is dealing with, along with similar questions in a research project entitled RoSylerNT, which is being funded by the Federal Ministry of Education and Research. Over the past three years, the experts at RWTH Aachen University, the German Sport University Cologne, and BEC GmbH have jointly developed a multifunctional, robotic weightlifting device that will, on the one hand, help athletes to increase their own performance even further and to shorten the recuperation period following an injury. On the other hand, individual adjustments to the requirements of the person exercising also make it suitable for training in later years in a way that’s gentle on the joints and thus preserves muscle strength and prevents injuries.

A robot as training partner

The systems available on the market today only allow for individual exercises such as rowing or leg presses. And that means doing several repetitions of the same movement with a fixed weight. To get more efficient and gentler training, however, it’s necessary for training to be ergonomically adapted to the person’s anatomy and for the forces to be tuned to protect the joints. Sure, there are high-performance training machines on the market, but adjusting the settings can be quite a hassle, freedom of movement is largely restricted, and as a result the range of exercises is limited. Where these systems reach their limits is where a robot as your perfect training partner begins.

RoboGym is a big improvement over conventional training methods in many ways, since the system actively and dynamically adapts to your anatomy and thus helps noticeably increase the effectiveness of the training. For example, the resistance and the movements of the robot can be specially adapted to the athlete for different positions and points in time. To do this, the applied muscle force is recorded, the stress on the joints is calculated, and the robot’s movements are then adjusted – all in real time. If the force exerted on the knee joint is too much, then the robot reduces the weight. Contrarily, if more weight is better for building muscle elsewhere in the body, the robot adjusts the weight accordingly.

Weightlifting with a digital twin

With the digital twin, anatomical, functional and performance-related parameters of the athlete are brought together in a biomechanical muscle and skeletal model. The training exercises can be individually adapted based on these metrics. During the training session, all data and weights are displayed in real time and saved in the cloud. Since a huge amount of data is produced and collected, much more precise filtering is naturally possible, allowing the forces actually applied and the training performance to be seen more precisely during each part of the exercise. This lets you adapt your fitness routine to your own individual needs. Stored training data and system settings can be accessed on every RoboGym machine for every new training session. That’s one advantage that top athletes who travel a lot really appreciate. For more information, visit http://www.robogym.de

Safe and versatile

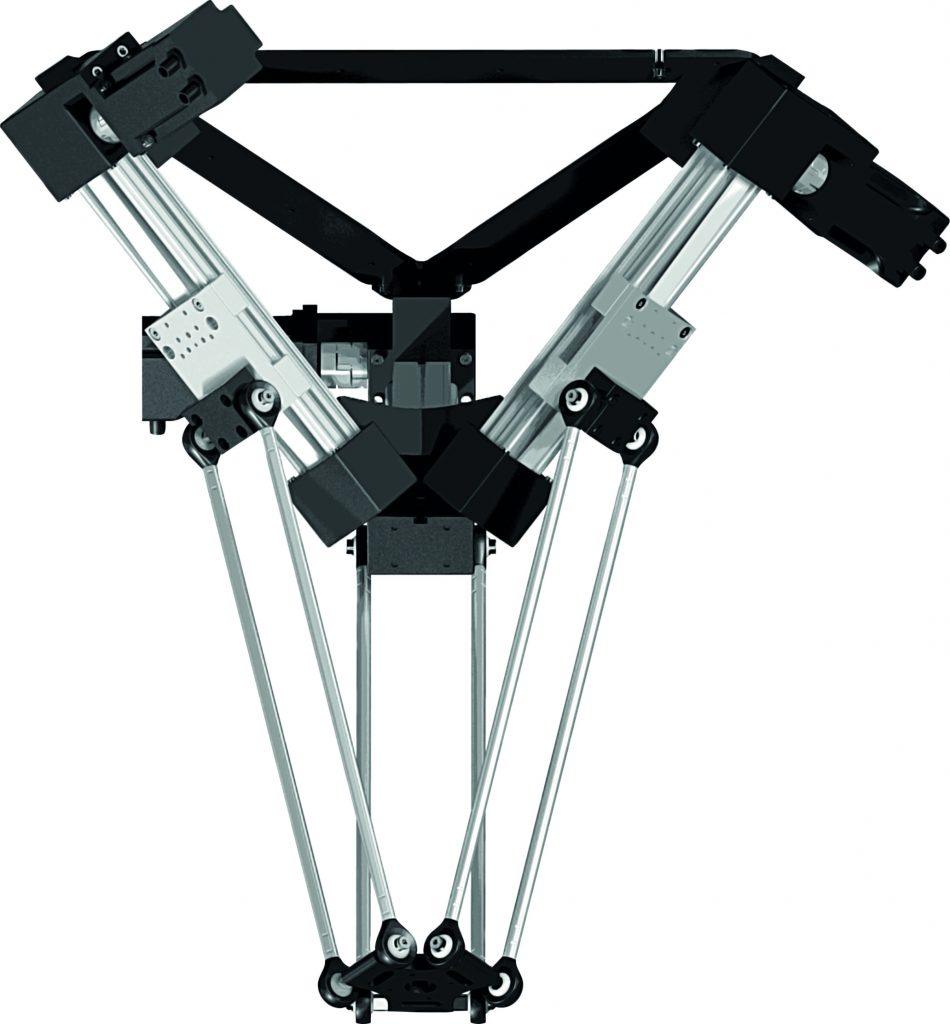

To be able to put an industrial robot to use as a training partner, in addition to lots of experience in the fields of medical technology and human-robot interaction, takes intelligent configuration of various monitoring mechanisms. Working inside RoboGym is a robot from Augsburg-based KUKA AG, which, in addition to the necessary safety features, also offers high-performance real-time control. This makes training not only more efficient, but also safe.