BATTLEBOTS: BOUNTY HUNTERS’ Premieres Monday, January 4, on the Launch of Discovery’s Streaming Service Discovery+

(LOS ANGELES) – In the BattleBots universe, from the moment you start building a robot, everyone dreams of a chance to fight against the best in the world — the legends that define the sport. Rarely does David get to face Goliath. Until now… BATTLEBOTS: BOUNTY HUNTERS, premiering Monday, January 4 on Discovery+, will bring the top robots from all over America to battle it out against a BattleBots legend in the ultimate robot combat.

In BATTLEBOTS: BOUNTY HUNTERS, the sport has some of the top robot legends including Tombstone, Bronco, Witch Doctor, Son of Whyachi, Beta and Icewave. Each of the them have many knockouts and have smashed countless competitors before them.

In each episode, challengers will compete for the right to become the Bounty Hunter and fight a Legend. The prize: a unique place in BattleBots history, and the major share of a $25,000 cash prize payout in every episode.

Like in the regular season of BattleBots, each episode highlights the design and build of the competing robots and profiles the teams behind them. Competitors come from all types of backgrounds – from families to university students and everything in between. Every machine is homemade and constructed from a variety of materials with custom-built weaponry to destroy the competition.

In addition to watching BATTLEBOTS: BOUNTY HUNTERS on Discovery+, viewers can join the conversation on social media by using the hashtag #BattleBots and following Discovery on Facebook, Twitter, and Instagram. Fans can also use the BattleBots AR filter (WT) on Instagram, Facebook, and Snapchat to share which bot the randomizer selects for them.

BATTLEBOTS remains the most popular robotic combat sport in the world, created by Ed Roski and Greg Munson and now seen in over 150 countries. It is produced by BattleBots, Inc. and Whalerock Industries. Executive producers are Chris Cowan, Edward P. Roski (Trey), Greg Munson, Tom Gutteridge and Aaron Catling. For Discovery Channel, Scott Lewers, Joseph Boyle and Wyatt Channell are executive producers and Paola Espinosa is associate producer.

About Discovery Channel

Discovery Channel is dedicated to creating the highest quality non-fiction content that informs and entertains its consumers about the world in all its wonder, diversity and amazement. The network, which is distributed to 88.3 million U.S. homes, can be seen in 224 countries and territories, offering a signature mix of compelling, high-end production values and vivid cinematography across genres including, science and technology, exploration, adventure, history and in-depth, behind-the-scenes glimpses at the people, places and organizations that shape and share our world. For more information, please visit www.discovery.com.

About Discovery

Discovery, Inc. (Nasdaq: DISCA, DISCB, DISCK) is a global leader in real life entertainment, serving a passionate audience of superfans around the world with content that inspires, informs and entertains. Discovery delivers over 8,000 hours of original programming each year and has category leadership across deeply loved content genres around the world. Available in 220 countries and territories and nearly 50 languages, Discovery is a platform innovator, reaching viewers on all screens, including TV Everywhere products such as the GO portfolio of apps; direct-to-consumer streaming services such as Eurosport Player, Food Network Kitchen and MotorTrend OnDemand; digital-first and social content from Group Nine Media; a landmark natural history and factual content partnership with the BBC; and a strategic alliance with PGA TOUR to create the international home of golf. Discovery’s portfolio of premium brands includes Discovery Channel, HGTV, Food Network, TLC, Investigation Discovery, Travel Channel, MotorTrend, Animal Planet, Science Channel, and the forthcoming multi-platform JV with Chip and Joanna Gaines, Magnolia, as well as OWN: Oprah Winfrey Network in the U.S., Discovery Kids in Latin America, and Eurosport, the leading provider of locally relevant, premium sports and Home of the Olympic Games across Europe. For more information, please visit corporate.discovery.com and follow @DiscoveryIncTV across social platforms.

About Whalerock Industries

Whalerock Industries is a West Hollywood-based production and consulting company founded by Lloyd Braun. Its Whalerock Studios produces highly acclaimed and popular unscripted series, including BattleBots (Discovery), Hyperdrive (Netflix), Savage Builds (Discovery), and Ravi Patel’s Pursuit of Happiness (HBO Max). The company’s award-winning team of producers, digital product developers and marketers has created and operated multiple #1 direct-to-consumer apps and web properties with the world’s most influential celebrities and brands. Fans can join in the conversation by following BattleBots Facebook and Instagram.

Archiv des Autors: Sebastian Trella

e-spool flex für eine unterbrechungsfreie Panel-Zuführung an Industrierobotern

Robotik-Dienstleister ARAGON Industrieelektronik GmbH verwendet einen neuen schleifringfreien Kabelabroller von igus

Köln, 6. Januar 2021 – Sie sind die Schaltzentrale für den Roboter: Bedienpanels. Damit sie flexibel eingesetzt werden können, muss ihre Leitung nicht nur einige Meter lang, sondern auch beweglich und sicher verstaut sein. Hierfür hat igus die e-spool flex entwickelt. Die neue igus Kabeltrommel kommt ohne Schleifring aus und kann so selbst Bus-Signale unterbrechungsfrei führen. Die Leitung lässt sich auch einfach nachträglich in das System einsetzen. Vorteile, die den Robotik-Dienstleister ARAGON überzeugt haben. Er bietet als Service für seine Industrieroboter ein Kabel-Komplettset an, bestehend aus e-spool flex mit einer Standardleitung sowie einer vormontierten Panelhalterung.

Alten Robotern neues Leben einhauchen, das ist die Aufgabe der ARAGON Industrieelektronik GmbH. Der führende Anbieter für Industrierobotik bietet weltweit Lösungen rund um die Reparatur, Wartung, den Retrofit und das Tuning von Industrierobotern an. Die Kunden finden sich in kleineren Betrieben, die bis zu 10 Robotersysteme einsetzen. Aber auch größere Unternehmen und OEMs im Bereich Automotive setzen auf die Expertise des Robotik-Spezialisten. Speziell für den Einsatz an Bedienpanels suchte das Unternehmen nach einer praktischen Lösung für die Leitungen: „Wir sind stets bestrebt, die Sicherheit unserer Kunden durch innovative Lösungen zu gewährleisten. Bisher lag das Kabel immer auf dem Boden, wurde schnell beschädigt und stellte eine Stolperfalle dar. Daher waren wir auf der Suche nach einem Kabelaufroller, der unterbrechungsfrei, einfach und schnell nachrüstbar ist“, erklärt Iryna Geike, Global Country Manager bei ARAGON. Fündig wurde das Unternehmen bei igus. „Uns wurde das neue Kabelaufrollsystem e-spool flex vorgestellt und es hat uns direkt überzeugt“, erinnert sich Iryna Geike. Der wesentliche Vorteil der e-spool flex gegenüber anderen Kabelwicklern liegt darin, dass kein Schleifring zum Einsatz kommt. So können auch Medien, Daten und die Strom- und Signalversorgung des Not-Aus-Tasters in das System integriert werden. Bereits bestehende Panelleitungen lassen sich einfach in die Schneckenführung des Systems einlegen und werden automatisch aufgerollt. „Unsere Kunden erhalten nun für ihre Bedienpanels ein vormontiertes Set bestehend aus e-spool flex, ARAGON Panelhalterung, Leitung und einem Bügel zur Befestigung an den Roboterschaltschränken. Mit der e-spool flex verlängern wir die Lebensdauer der eingesetzten Leitung deutlich und sorgen für mehr Sicherheit und Ordnung an den Bedienpanels“, erklärt Iryna Geike.

Kabel auf- und abrollen: automatisch oder von Hand

Die e-spool flex bietet igus in mehreren Varianten an. Als Low-Cost-Version mit einem Handdreher oder einem Akkuschrauber zum Aufwickeln der Leitung, als automatische Lösung mit einem federgetriebenen Rückholmechanismus und einer Rastfunktion sowie optional mit einer Einlaufbremse. ARAGON entschied sich für die Variante mit einer Rückholfeder. Der Kabelroller ist in drei Größen erhältlich, für Leitungen mit einem Durchmesser von 5 bis 15 Millimetern mit einer Auszugslänge von 5 bis 15 Metern. Sie lassen sich jederzeit schnell tauschen. Neben einer nachträglichen Integration der e-spool flex mit einem bestehenden Kabel, bietet igus die Kabeltrommel auch bereits fertig konfektioniert mit speziell für den bewegten Einsatz ausgelegten chainflex Leitungen an. Die Langlebigkeit der Leitungen in der e-spool flex wird derzeit im hauseigenen 3.800 Quadratmeter großen Testlabor ausgiebig untersucht.

Do you love me?

The best Robots video of 2020, just awesome work by Boston Dynamics.

Hyundai’s acquisition of Boston Dynamics can reinforce its position in smart mobility, says GlobalData

Hyundai Motor Group has agreed to acquire approximately 80% stake in American engineering and robotics design company Boston Dynamics from SoftBank Group for US$1.1bn.The move can fuel Hyundai’s long-term goal to become a smart mobility solutions provider by leveraging Boston Dynamics’ robots such as bipedal and quadruped equipped with 3D vision, navigation and advanced intelligence, says GlobalData, a leading data and analytics company.

Venkata Naveen, Senior Disruptive Tech Analyst at GlobalData, says: “Hyundai’s move to acquire major stake in Boston Dynamics polarizes with many automakers competing to add their name to the me-too stack of autonomous carmakers by purchasing self-driving tech startups. Moreover, the strategic location of Boston Dynamics in the Silicon Valley gives an advantage to Hyundai to collaborate with tech startups as well as pool the right talent.”

‘In 2013, Google purchased Boston Dynamics to power its core robotic division and eventually create new robotics technologies for commercial applications. But the startup did not meet any commercial success and began losing talent after Google’s restructuring into Alphabet.

In 2017, SoftBank acquired Boston Dynamics to push its smart robotics capabilities. Apart from a few interesting videos of its humanoid and dog-like robots, there was no direct visible benefit to SoftBank.

Naveen continues: “Integrating Boston Dynamics’ robotic technologies with the automotive expertise can strengthen Hyundai’s position in smart mobility, especially in areas such as robo-taxis, personal air vehicles and last-mile mobility.”

The last two years saw both automakers and tech giants ramp up their bets on autonomous vehicles by acquiring startups into self-driving technology. Apple acquired Drive.ai, Amazon purchased Zoox and Daimler snapped Torc Robotics.

Naveen concludes: “In contrast, Hyundai’s acquisition of Boston Dynamics is the first in line of such strategies in the automotive industry to build a smart mobility ecosystem for faster, cheaper and sustainable transportation.”

Cobot-Pioneer enables modern educational didactics

Munich, November 10, 2020 – While more and more manufacturing companies are using collaborative robots, technology has so far been treated as a secondary consideration in vocational training. Current curricula largely ignore the increasing automation. Universal Robots (UR) wants to change this: With UNIVERSAL ROBOTS EDUCATION, the world market leader in collaborative robotics has developed a holistic concept that allows training officers to easily integrate the topic into the teaching process.

„Our new concept makes it easier for training companies and vocational schools to impart relevant automation knowledge in a practical way“, explains Andrea Alboni, Sales Manager D/A/CH at Universal Robots (Germany) GmbH. „We are thus reacting to an acute discrepancy between training content and professional practice. We finally need up-to-date training directly on the robot in order to qualify the skilled workers of tomorrow for working in modern manufacturing contexts“.

Five modules for hands-on learning

UNIVERSAL ROBOTS EDUCATION is a didactically holistic concept. On the one hand, the measures contained in the program pick up both teachers and those responsible for training as well as students by creating the necessary knowledge base on both sides. On the other hand, theory and practice go hand in hand to ensure the greatest possible learning success. Under these premises, the concept is divided into five building blocks:

- In the free online training courses of the UR Academy, trainees learn the basics of programming.

- With the help of the offline simulator they practice programming on their PC, on the UR user interface. Afterwards, the created program can be tested on a real Cobot.

- The hardware learning stations each include a real robot arm on which trainees can safely try out various applications.

- Teaching materials support the teachers in their lesson planning and offer students the opportunity to deepen their knowledge.

- In face-to-face training sessions, teachers and training officers train themselves to prepare for teaching with Cobots.

Specialists for the industry of tomorrow

„In many areas of the working world, collaborating robots are already part of the standard inventory today,“ Alboni is convinced. „If companies take this to heart in their training operations, they not only give their trainees a clear knowledge advantage. At the same time, they are investing in their own future, because skilled workers with robotics know-how are increasingly essential for competitive success – now also beyond the manufacturing industry in logistics, trade or the laboratory sector.

Modernizing training in SMEs

With the new concept universal robot addresses itself beside vocational schools also to small and medium-size training enterprises. These companies play a central role in the German apprenticeship system: around 80 percent of apprentices in Germany complete their training there. Thanks to the space-saving, profitable lightweight robotics from Universal Robots, automation is now also affordable for SMEs. The industry pioneer has thus sustainably lowered access barriers. Since entering the market in 2008, Universal Robots has sold more than 46,000 Cobots that make the work of employees in companies around the world easier.https://www.universal-robots.com/de/education/

Translated with www.DeepL.com

Ein Roboter, der Nässe trotzt: der neue robolink IP44 von igus

igus entwickelt Low Cost Automation Lösung aus Kunststoff und Edelstahl für Umgebungen mit Spritzwasser

Köln, 16. November 2020 – Feuchte und nasse Umgebungen können schnell die Mechanik eines Roboters angreifen. Daher hat igus jetzt eine Low Cost Automation Neuheit auf den Markt gebracht, die leicht und kostengünstig einfache Aufgaben umsetzen kann und gleichzeitig mit Spritzwasser in Kontakt treten darf.

„Aus den Kundengesprächen konnten wir erfahren, dass viele Anwender eine wirtschaftlich erschwingliche Lösung suchen, die auch in Spritzwasser-Umgebungen einsetzbar ist, zum Beispiel wenn Emulsionen entfernt werden müssen“, erklärt Alexander Mühlens, Leiter Automatisierungstechnik bei der igus GmbH. „Wir haben dann einen Roboter entwickelt, der hierfür geeignet ist.“ Der neue robolink macht sich die Vorteile von zwei Materialien zunutze: Edelstahl und Hochleistungskunststoffe. Dabei bestehen die Verbindungselemente, erstmalig bei einem igus Roboter, aus rostfreiem V2 oder V4 Edelstahl und die Gelenke aus den bewährten schmiermittelfreien Tribopolymeren. Der Anwender benötigt keine teure zusätzliche Abdeckung, denn durch den Verzicht auf eine Schmierung in den Gelenken kann sich kein Fett auswaschen und in die Umwelt gelangen. Der neue robolink erfüllt mindestens die Schutzklasse IP44 und ist damit beständig gegen Spritzwasser. Er hat kann bis zu drei Kilogramm tragen, besitzt mit fünf Achsen eine Reichweite von 790 Millimetern und setzt 7 Picks die Minute um. Durch den Einsatz von Motoren mit Encodern der Schutzklasse IP65 lässt sich der Roboter problemlos auch zur Inspektion im Außenbereich einsetzen. Weitere Anwendungsszenarien sind zum Beispiel in der Lebensmittel- und Getränkeindustrie, im Bereich Chemie und Pharma oder auch der Tank- und Behälterreinigung möglich.

Sehen Sie jetzt den spritzwassergeschützten robolink mit Alexander Mühlens im Video: https://youtu.be/WXm8gO6QxWQ

GrubTech and Wobot.ai join forces in the automation and digitization of restaurant & cloud kitchen operations

9th November 2020, Dubai, United Arab Emirates: GrubTech, the UAE-based tech start-up that is taking the foodservice industry by storm with the introduction of the world’s most technologically advanced digital commerce tool for restaurant and cloud kitchen owners, and India-based AI-powered video analytics powerhouse Wobot.ai are proud to announce a global strategic collaboration. The partnership brings together GrubTech’s native technology expertise in the foodservice landscape and Wobot’s state-of-the-art platform to curate an optimum experience for restaurateurs and cloud kitchen operators globally.

In this age of the technological revolution, rapidly evolving technology is expected to provide much-needed tailwinds to the foodservice business, as tech enablement is no longer a luxury, but a necessity to survive and succeed. The alliance between GrubTech and Wobot.ai establishes a comprehensive solution for restaurants and cloud kitchens, encompassing the digitization of everything from order capture and operations to compliance management and marketing.

GrubTech’s integration with food aggregators, points of sale and third party logistics providers, eliminates the need for the manual, error-prone and often cumbersome entry of orders into siloed solutions. Rather, it digitizes the order lifecycle, providing comprehensive visibility over sales and operations and resulting in reduced costs, increased efficiencies and shortened food preparation and delivery times, i.e. from click to doorbell in far less time.

„GrubTech provides restaurants, cloud kitchens and virtual brands with the first end-to-end management system, automating manual processes in order to drive operational efficiencies and improve the customer experience. Wobot’s AI-powered insights & business intelligence tools create a perfect synergy with our platform, setting us on course to completely revolutionise the global foodservice industry. We look forward to helping to drive future fit and profitable operations for our customers, as they strive to win in this ever-changing landscape” said Mohamed Al Fayed, Co-Founder and CEO of GrubTech.

Wobot.ai today powers 10,000+ units globally, helping them reduce their risk of non-compliance, cost of monitoring, and increases their customer NPS with its computer vision technology.

Mr Adit Chhabra, CEO of Wobot added „Our vision with the Wobot-GrubTech alliance is to create a seamless workplace optimized to deliver operational excellence in the hospitality industry with our combined technology platforms. Our service offerings tailored specifically for restaurants and cloud kitchens, offers the unmatched capability to deliver massive value for these businesses. Wobot’s platform monitors health, safety & operational checklists & helps you ascertain if you meet global foodservice industry standards“.

GrubTech’s solution is highly scalable and easily deployable remotely, and the company is in advanced discussions to deploy across a number of large enterprises and SME’s across the MENA region and beyond into SE Asia, and Europe. The agreement with Wobot.ai will significantly enhance the offering, as with heightened food safety requirements and increased restrictions resulting from the COVID-19 pandemic, countries are frequently updating their compliance legislation creating an urgent need for an effective and multi-purpose operations platform.

Caja Robotics will bring fulfillment robotics to Sela Logistics

Israeli-based Caja Robotics, which offers a unique robotic order fulfillment solution, announced an important achievement of partnering with one of the leading Israeli 3PLs. Caja Robotics will upgrade a logistics center operated by Sela Logistics installing Caja’s innovative robotic solution.

Caja Robotics is a goods-to-person solution for unit picking that significantly increases order fulfillment productivity and storage capacity of a warehouse. The system employs two types of robots that collaborate with each other to share tasks and can adapt to any existing warehouse infrastructure. The robotic system is powered by software based in the cloud, that uses advanced algorithms, artificial intelligence, machine and deep learning for navigation, fleet management, and inventory optimization.

Sela Logistics Ltd. is a leading supplier of general logistics solutions, one of the top players in the logistics field in Israel. The company provides its clients with a full range of services and owns seven logistics centers spanning an overall area of over 1.2 million square feet. The company’s clients include: Nike, Adidas, Levi’s, Diesel, Hugo Boss, and more.

„As a company striving to lead and innovate in our field, we welcome the commencement of cooperation with Caja Robotics, which offers a flexible, advanced and uniquely suitable solution for our clients, enabling us to continue to provide the best service possible,“ said Johnatan Grinbaum, CEO of Sela Logistics.

Caja’s robotic solution was selected by Sela Logistics to be implemented within a multi-staged automatization process at its logistics centers. In the initial stage, a fleet of dozens of robots will be incorporated, while at later stages operations will be expanded to include additional Sela Logistics activities. Caja Robotics will soon begin supplying the logistics center with a solution that includes two types of robots combined with unique software developed by Caja. Caja’s solution is already fully operational, at the logistics center of Bergen Logistics in New Jersey, handling the daily fulfillment for thousands of orders from the New York metropolitan area.

„Over the past few years the field of logistics has experienced major growth, due to the ever-increasing participation of new populations in the world of online purchases. This process has led companies that manage the supply chain to search constantly for solutions that support their suitability to this new, developing world,“ said Dr. Ilan Cohen, CEO of Caja Robotics. „We are pleased that a leading company in the field has chosen to substantially integrate automatization and robotics processes, and we view them as strategic partners. It is already clear that as the years go by, giant warehouses and logistic centers will not be able to rely solely on logistics workers, and there will be a need to integrate robots and smart systems in logistic processes. We anticipate that the recent increase in logistic activities will boost interest in the products the company develops.“

About Caja Robotics:

Caja Robotics was founded in 2014, with the vision to lead the transition to automated warehouses with smart systems and flexible robotics that pick-up order efficiency, lift storage capacity and optimize employees‘ workplaces. Caja’s team of visionary software and robotics experts is continuously striving to elevate warehouse operations through robotic fulfillment. Learn more at https://www.cajarobotics.com/.

One America Works Highlights Thriving Robotics Industry in Pittsburgh Through Virtual Recruitment Event

SAN FRANCISCO (PRWEB) OCTOBER 27, 2020

To help continue to expand the Steel City’s world-class robotics and engineering expertise, One America Works, an organization that bridges the divide between Silicon Valley and emerging tech hubs across the U.S., is convening more than a dozen of the top robotics companies for its second Pittsburgh-based virtual recruitment event on November 13th, to help fill more than 100 available jobs. With high quality technical and business positions available, this event will showcase the opportunities available in Pittsburgh and attract both local talent and national talent looking to relocate from higher cost cities like San Francisco, Seattle, Boston and New York City to work in an emerging innovative tech hub with lower cost of living, higher quality of life and lots of professional opportunity.

What: Virtual Recruiting Event for Pittsburgh-Based Robotics Positions

When: November 13th from 11 am – 4 pm ET

Participants will be assigned a specific time slot to meet companies one-on-one.

Where: Register at https://oneamericaworks.org/robotics_recruiting_event/ by November 8th

“As we continue to see tech workers willingness to move away from traditional tech hub coastal cities in favor of mid-sized regional cities, Pittsburgh has become a key destination for top talent considering relocating, thanks to its thriving innovation driven culture, high quality of life and affordable cost of living,” said Patrick McKenna, founder of One America Works. “The city has established itself as a clear leader within the highly skilled robotics industry with both Big Tech and startups committing to the Steel City, in collaboration with the local talent and research resources available through the top-tier universities.”

Founded by Patrick McKenna – an entrepreneur and investor with experience co-founding, operating and investing in several highly successful technology companies – One America Works is bridging the divide in America by spearheading connections between high-growth companies looking to expand and emerging regions across the U.S. that provide high-quality talent and investment opportunities. And this concept is gaining momentum as it creates hundreds of jobs in emerging hubs around the country. Through a successful 2019 pilot program in Pittsburgh, One America Works is responsible for creating over 250 jobs and filling nearly 80 positions over the course of six months. The 501c3 non-profit is leveraging a grant from RK Mellon Foundation to expand into new emerging tech cities this year. To showcase well-paying innovation jobs in the Steel City and across the Heartland, One America Works has hosted a series of popular virtual recruitment events across America this year in Columbus, Indianapolis and Pittsburgh.

„Over the last decade, Pittsburgh has seen a revitalization, due in part to the success of the local tech scene in the region. The city has been able to reinvent itself as an emerging tech hub while still remaining an affordable and vibrant area,” said Joel Reed, Executive Director, [Pittsburgh Robotics Networ k. “There are many exciting, innovative robotics companies that have come as a result of the local talent and research resources that make this city such an amazing place to live, play and work.“

Employers attending the fair to hire for Pittsburgh-based robotics talent include IAM Robotics, Honeywell, Locomation, NREC, Qinetiq, Agility Robotics, RE2 Robotics, Near Earth Autonomy, CapSen Robotics, ESTAT Actuation, Komodo Analytics, SKA, Neya Systems, Bloomfield Robotics and more.

About One America Works

One America Works is a non-profit organization that connects growth companies and talented people across the country, bringing the country together around common goals and values. Founded by entrepreneur and investor Patrick McKenna in 2018, One America Works addresses the geographic economic divide across America by introducing innovative technology companies to new sources of talent located in middle American cities, to bring more people in more places into the modern economy. For more about One America Works, visit oneamericaworks.org or follow the organization on LinkedIn or Twitter.

About the Pittsburgh Robotics Network (PRN)

The Pittsburgh Robotics Network (PRN) represents the companies and leaders who make up the Pittsburgh robotics ecosystem, which is anchored by Carnegie Mellon University (CMU) and driven by 100+ robotics organizations, including the worldwide leaders in autonomous vehicle development. It is the PRN’s mission to accelerate the adoption of robotic solutions by bridging this large and dynamic community to the world. We do this by making connections, expanding our collective knowledge, and positively influencing the development and adoption of robotic and artificial intelligence (AI) technologies.

Service Robots Record: Sales Worldwide Up 32%

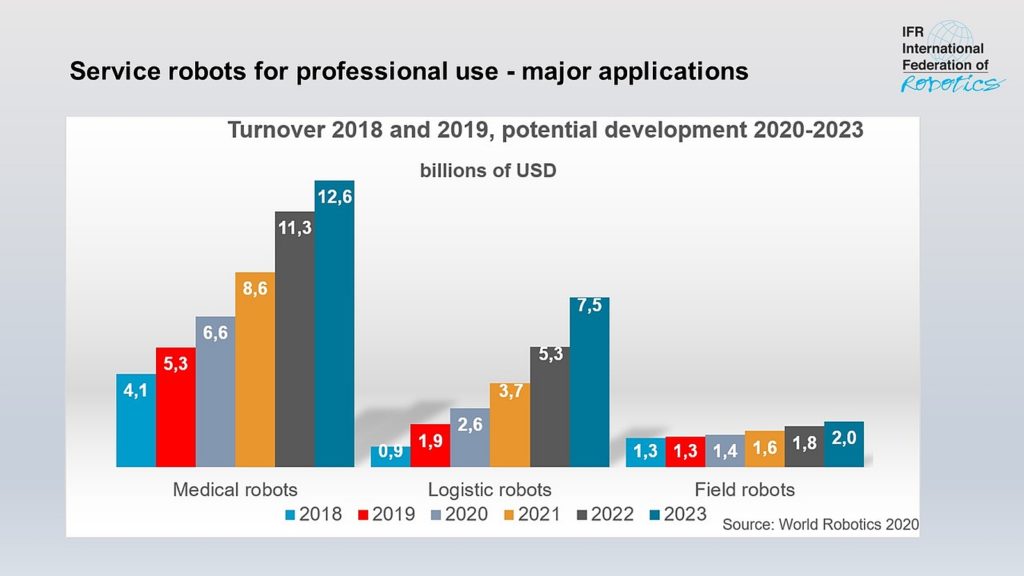

| • Logistics Robots up 110% • Medical Robots up 28% |

| Frankfurt, October 28th, 2020 – Sales value of professional service robots increased by 32% to 11.2 billion U.S. dollars worldwide (2018-2019). The COVID-19 pandemic will further boost the market. High demand for robotics disinfection solutions, robotic logistics solutions in factories and warehouses or robots for home delivery are examples of this trend. This is according to World Robotics 2020 – Service Robots report, presented by the International Federation of Robotics (IFR). In terms of value, the sales of medical robotics accounts for 47% of the total professional service robot turnover in 2019. This was mainly driven by robotic surgery systems, which are the most expensive type in the segment. Sales hit a new record of 5.3 billion U.S. dollars – up 28%. By 2022, medical robot sales have the potential to more than double by reaching 11.3 billion U.S. dollars. About 90% of medical robots are from American and European suppliers. Professional Service Robots – logistics The market value of logistics robots sold or leased was up 110% to 1.9 billion U.S. dollars. Almost all of the logistics turnover was generated with robots for indoor use. Autonomous mobile robots have initially been used in warehouses but with digitalization of production, they are also part of today’s smart factory. Therefore, a continued strong turnover growth of 40% or more per year seems possible. “The investment in service robots for logistics in manufacturing processes is amortized rapidly,” says IFR President Milton Guerry. “Assuming 24 hour operation, the investment in service robots for logistics may be repaid within 2‐3 years and often much quicker. Given a 15 year lifetime, operating costs are around 5% of the annual investment. Highly developed systems often provide operational availability in the 98% plus range.” The trending Robotics-as-a-Service (RaaS) business models lower the hurdle for customers to automate with robots. The benefit is not to invest in hardware, so the companies have no fixed capital, no fixed costs and no need for robot operators. The use of logistics systems in non-manufacturing industries has been strongly driven by warehouse solutions for major e-commerce companies. A strong potential can also be found in hospitals running their logistics with the help of professional service robots. In the segment of professional service robotics, about 90% of the sampled logistics robots were produced in Europe and North America – about 10% in Asia. Professional Service Robots – field The segment of field robotics consists of robots for agriculture, dairy, livestock farming and other field applications. Sales value increased by 3% to USD 1.3 billion U.S. dollars. The Covid-19 pandemic might have an impact for further supply of such robots. Travel restrictions for workers from Eastern Europe for instance, who usually travel to Western Europe in harvest season, caused a shortage of labour supply. Farmers might compensate this with the use of field robots. Sales value growth rates of more than 30% for agricultural robots seem possible. Personal and Domestic Service Robots Service robots for personal and domestic use, which are produced for a mass market, are mainly in the areas of household robots. This include vacuuming and floor cleaning robots, lawn-mowing robots or entertainment robots. The total number of service robots for personal and domestic use increased by 34% to more than 23.2 million units sold in 2019. The value was up 20% to 5.7 billion U.S. dollars. Unit prices for the two major segments, robot vacuums and toy robots, have been declining in recent years. Today, basic robot vacuums are already available for less than 100 U.S. dollars. 75% of the sampled domestic service robots – vacuum and floor cleaners, lawn mowers and other domestic robots – were produced by American companies in 2019. Asian companies had a share of 19% – European companies of 6%. A growing market is the use of assistance robots for elderly or handicapped persons. The estimated sales value increased by 17% to 91 million U.S. dollars. Numerous national research projects in many countries focus on this huge future market for service robots. In contrast to most entertainment robots, these robots are high-tech products. “We expect sales of both professional and personal service robots will continue to increase strongly,” says Milton Guerry, President of the International Federation of Robotics. |