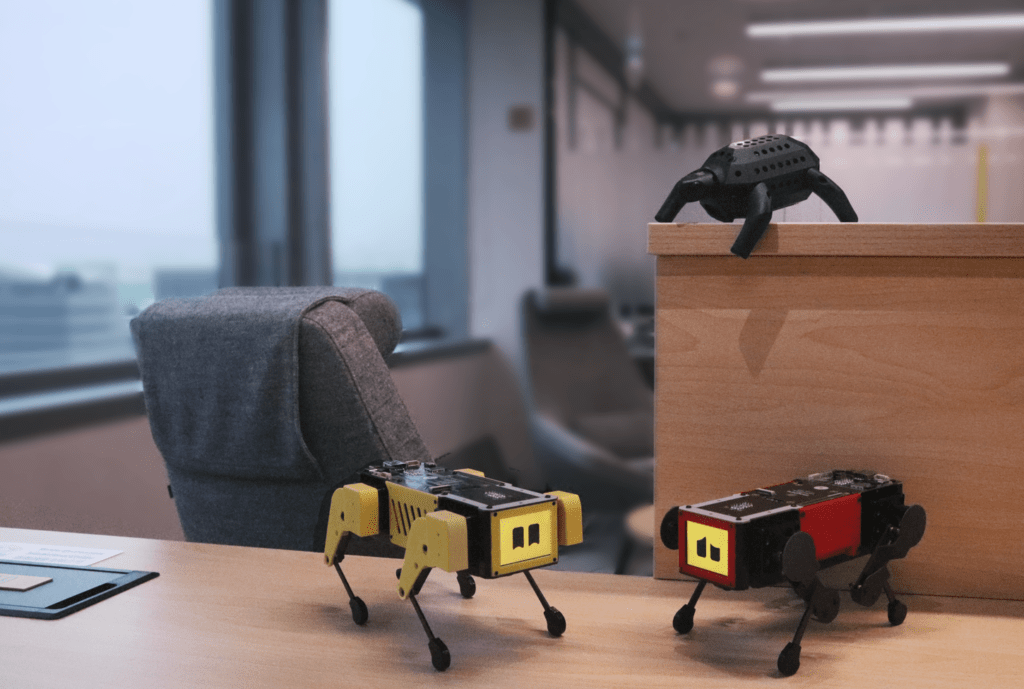

MangDang’s Kickstarter project „MD Robot Kit: Unlock your AI Robot Engineering Dream Job“ aims to promote the creativity and technical know-how of robotics enthusiasts. It offers two main robots, each addressing different needs and interests.

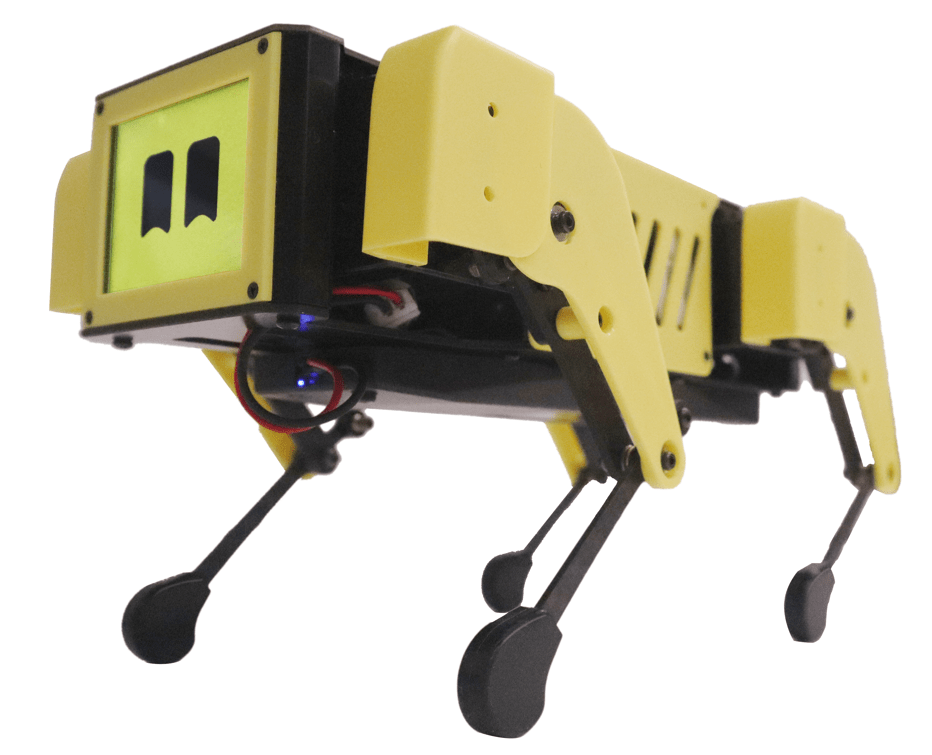

The first robot, the Mini Pupper, is available in several versions, including Mini Pupper 1, Mini Pupper 2, and the 2G and 2GA models. This robot is a low-cost, personal quadruped kit that comes with open-source software. The Mini Pupper supports multimodal generative AI platforms such as OpenAI’s ChatGPT, Google’s Gemini, and AWS’s Claude. It is also compatible with ROS1 and ROS2, which expands its capabilities in the areas of SLAM (Simultaneous Localization and Mapping) and navigation. The integration of OpenCV allows the robot to perform deep learning with cameras. Thanks to the use of Raspberry Pi and Arduino, the Mini Pupper offers high adaptability and expandability, making it ideal for developers who want to realize their own projects.

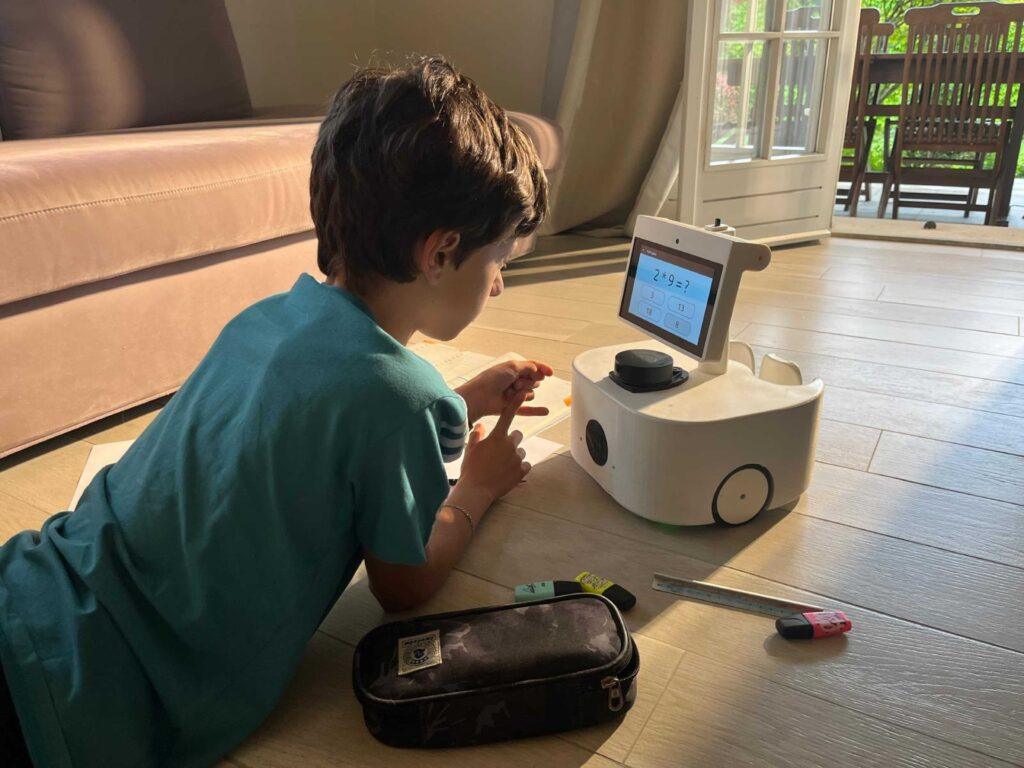

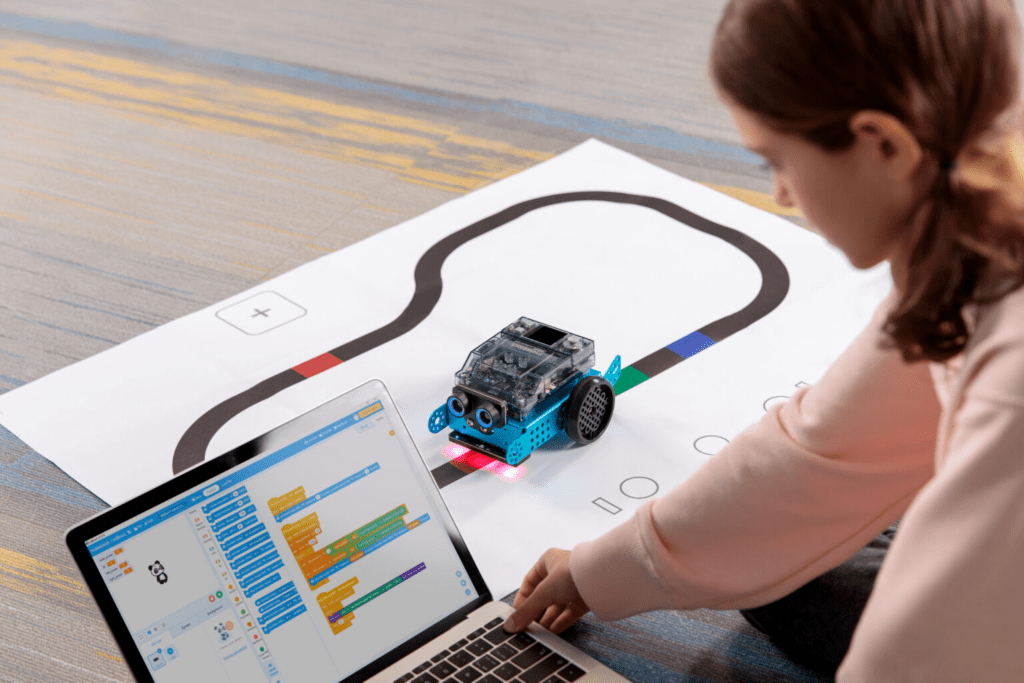

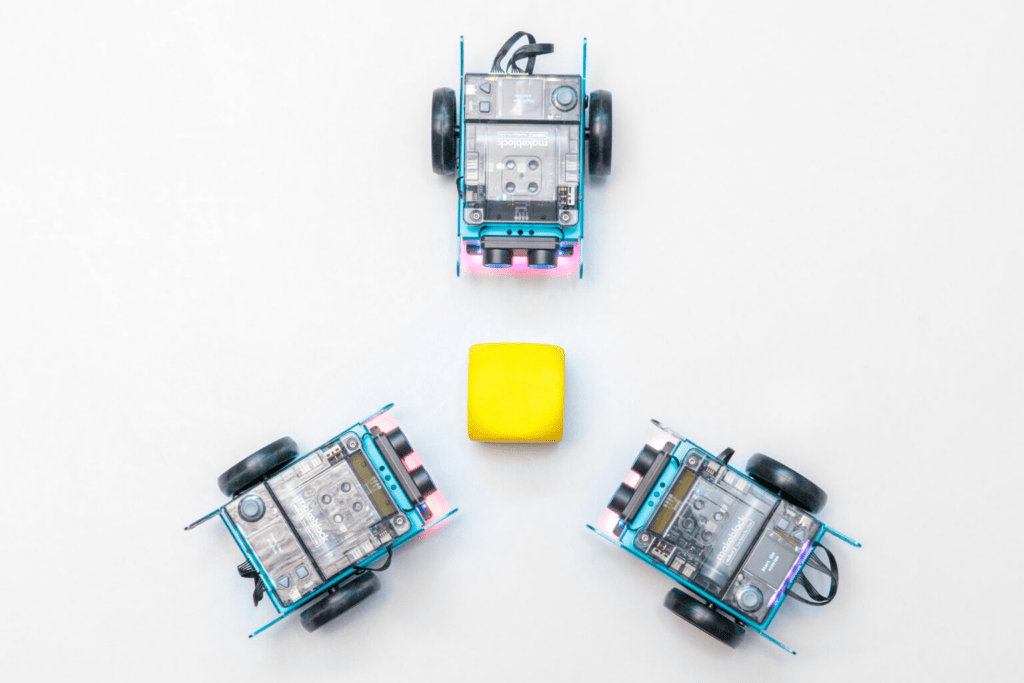

The second robot presented is the Turtle Robot, which will be available soon. This robot is specifically aimed at schools, homeschooling families, and robot enthusiasts. While detailed specifications have not yet been fully released, it is clear that the Turtle Robot also aims to support learning and creativity in the field of robotics.

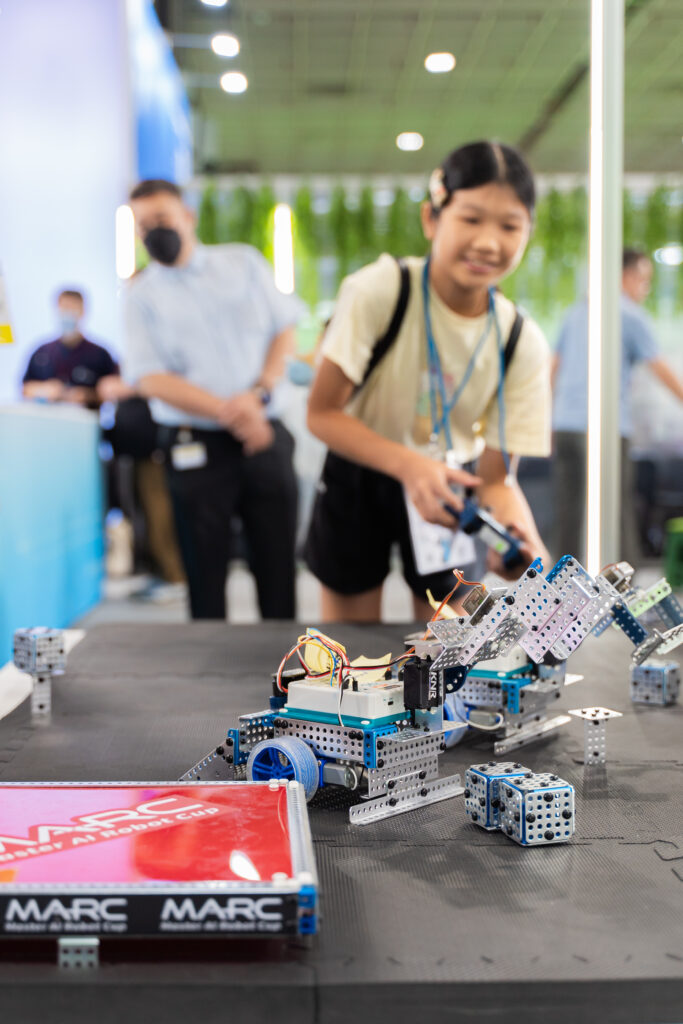

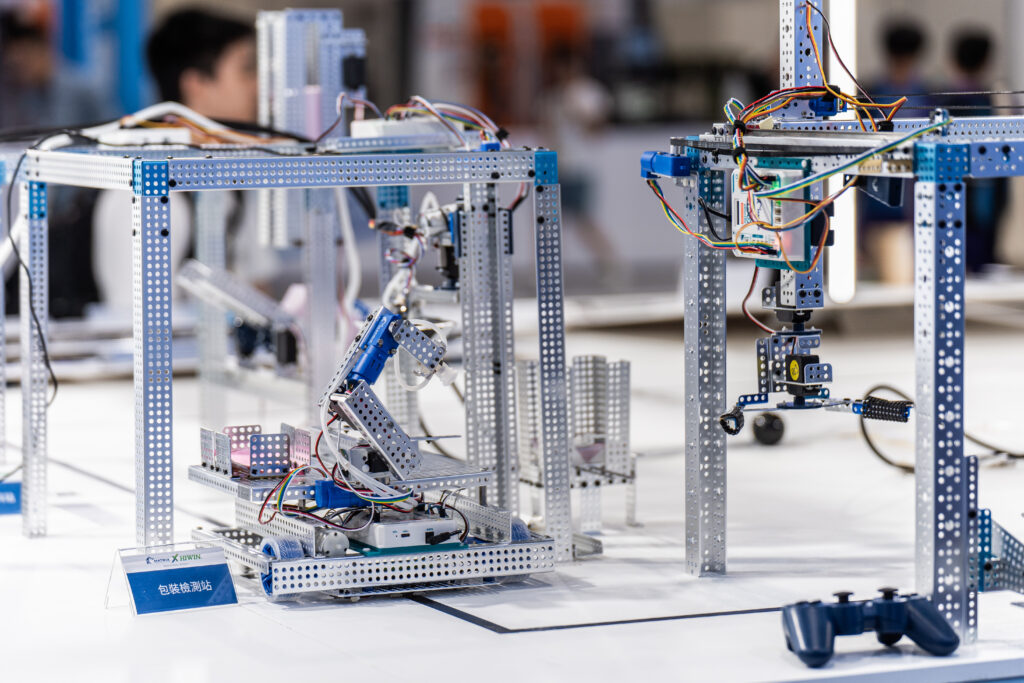

The campaign itself has set a funding goal of 9000€ and has clearly exceeded it with a sum of just under 19000€, which corresponds to over 200% of the original goal. The campaign runs from September 5, 2024 to October 5, 2024 and has attracted 80 supporters so far. A standout feature of the MD Robot Kits is their open-source nature, which allows users to assemble the robots in less than an hour. This makes them particularly accessible to a wide range of audiences, ranging from educational institutions to DIY enthusiasts. The project is designed not only to impart technical knowledge, but also to promote the joy of creating and customizing robots.

1. Mini Pupper:

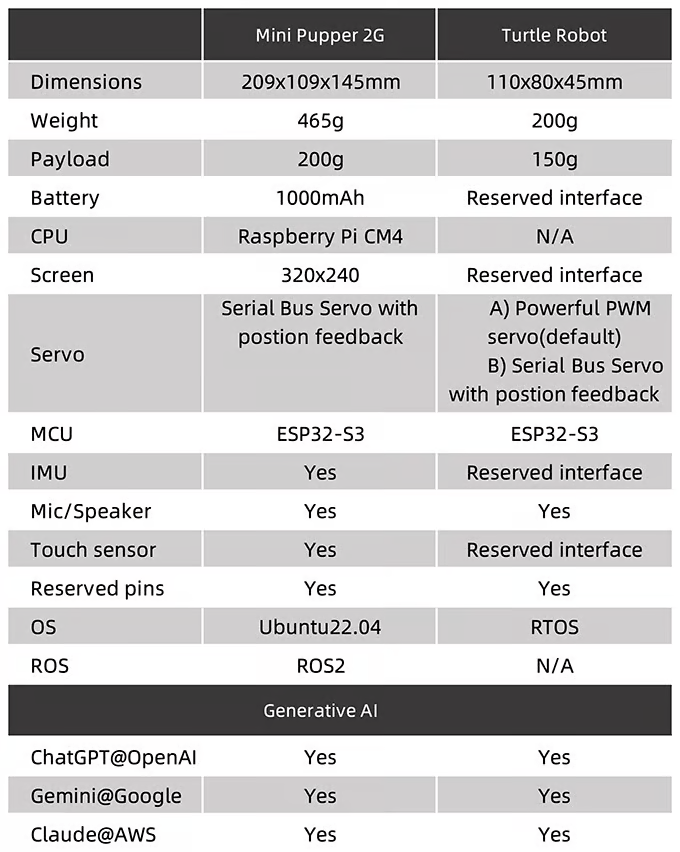

- Versions: Mini Pupper 1 (2021), Mini Pupper 2 (2022), Mini Pupper 2G & 2GA.

- Design: A low-cost, personal quadruped kit with open-source software.

- Features: Supports multimodal generative AI such as OpenAI’s ChatGPT, Google’s Gemini, and AWS’s Claude. It is compatible with ROS1 and ROS2 for SLAM & navigation and is based on OpenCV for deep learning with cameras.

- Extensibility: Uses Raspberry Pi and Arduino, which allows for high adaptability.

- Open-source platform: The Mini Pupper supports the Robot Operating System (ROS) and offers features such as SLAM (Simultaneous Localization and Mapping) and navigation. It is equipped with lidar and camera sensors that allow it to map its surroundings and move autonomously

- Technical specifications: The robot has 12 degrees of freedom, made possible by advanced servo motors. These motors provide feedback on acceleration and force, which allows precise control.

- Hardware and expandability: The Mini Pupper uses the Raspberry Pi 4B or the Raspberry Pi Compute Module 4 as the central processing unit and is equipped with an ESP32 as a microcontroller. It has an IPS display with a resolution of 240 x 320 pixels, a microphone, speakers and a touch sensor.

- Adaptability: Thanks to its open-source nature, the Mini Pupper can be modified deeply. Users can add their own modules and customize the robot for different projects, such as tracking objects in space.

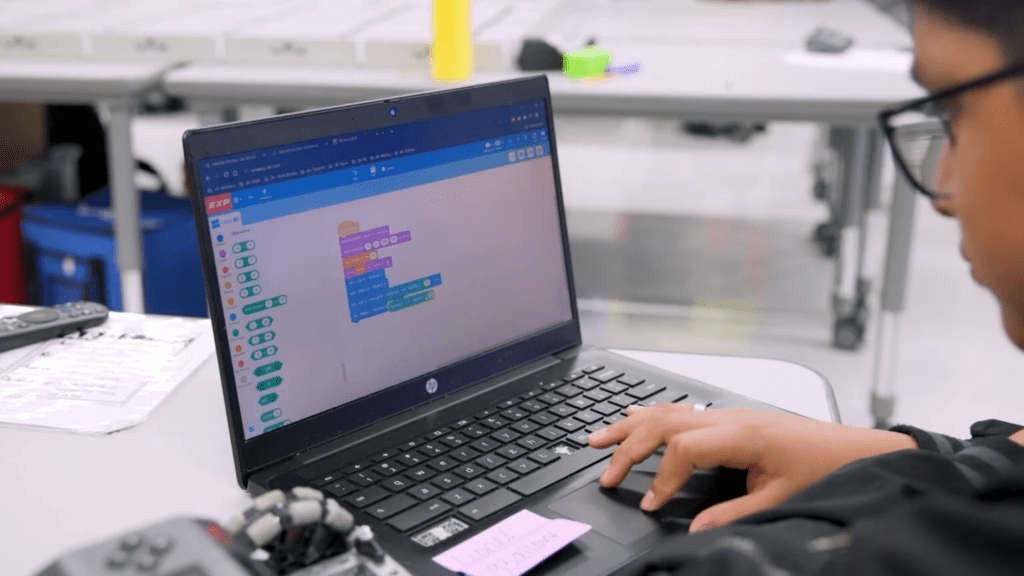

- Education and community: The Mini Pupper is ideal for schools and homeschooling families. It comes with comprehensive guidance and resources to help you get started with robotics. Users can become part of a global community to share ideas and get support.

- Price and availability: As part of the Kickstarter campaign, the Mini Pupper will be offered in different versions, with the base model costing around 479 euros. Delivery is scheduled to begin in February, with supporters aware of the financial risk of crowdfunding campaigns.

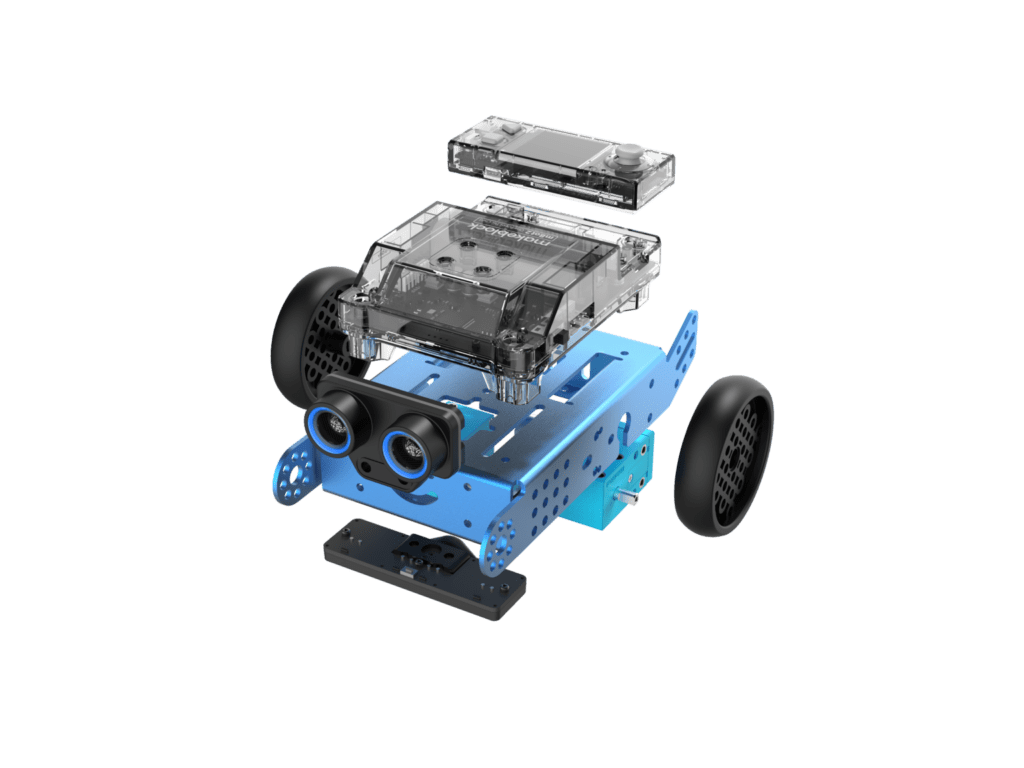

2. Turtle Robot:

- Open-source project: The Turtle Robot is based on Arduino and is an open-source project that supports the integration of generative AI. This allows users to customize and expand the robot.

- Affordability: The Turtle Robot is a low-cost learning platform for multimodal generative AI and comes at an introductory price of 60% off $99. This makes it particularly attractive to educational institutions and DIY enthusiasts.

- Ease of use: The robot is designed to be set up and put into operation within a week. This makes it easier for beginners to start learning and experimenting quickly.

- Support and resources: MangDang offers comprehensive support across multiple channels, as well as access to all code and design files via a GitHub repository. Users can print the STL design files and contribute their own ideas.

- Multimodal Generative AI: The Turtle Robot uses advanced AI technologies that enable continuous voice interactions. The AI can remember previous conversations and give personalized answers based on them.

- Application examples: There are two Arduino projects that can be used with the Turtle Robot: one for testing individual functions and another that performs all functions via voice control.

- Availability: The Turtle Robot was available as part of the Kickstarter campaign until October 2024 and will be available in an online store after that.