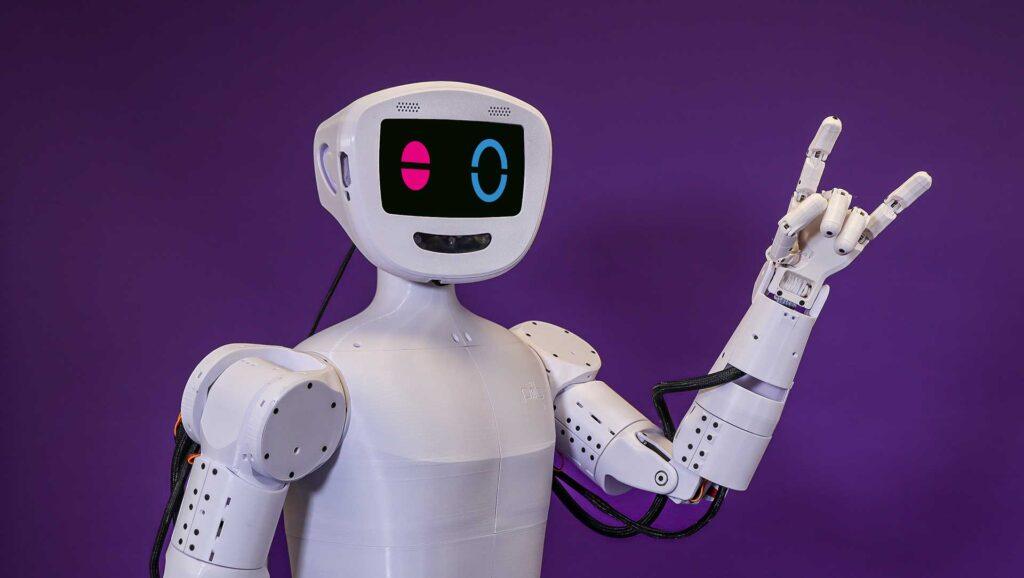

The world of robotics is evolving – and right in the middle of it: pib. This humanoid robot, entirely 3D-printable, has received a prestigious award. The German Design Award 2025 has been granted to the printable intelligent bot, recognizing not only its technological sophistication but also its innovative design. But what makes pib so special?

A Robot for Everyone – and by Everyone

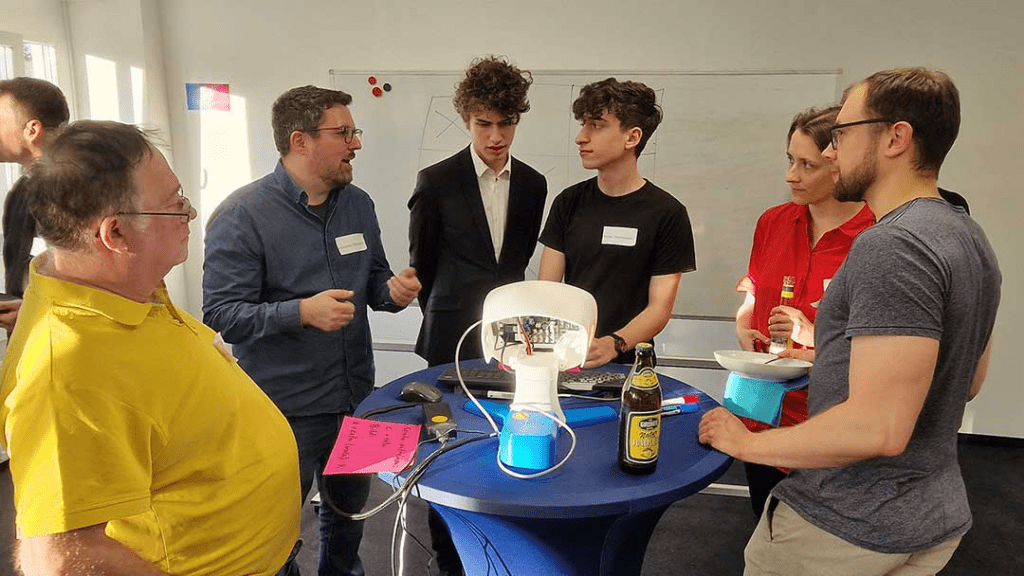

Imagine a robot that anyone can build and program themselves. A robot that isn’t just a technical gadget but an inspiration to create, research, and explore new paths in robotics. That’s exactly what pib is. Its open-source approach has a central goal: to make robotics and AI more accessible while breaking down technological barriers. Whether you’re a tinkerer, a student, or simply a technology enthusiast, pib invites everyone to be part of its ever-growing community.

German Design Award 2025: Recognition for Visionary Product Design

The German Design Award is one of the most prestigious awards for outstanding design. Every year, an international panel of experts honors innovative concepts in product design, communication, and architecture. This year, pib impressed the jury with its “Excellent Product Design” in the category „AI in Product Design Processes“ – a testament to how technology and aesthetics can go hand in hand.

Technology Meets Creativity

pib is more than just a robot – it is a platform for innovative technologies. The project enables curious minds to experiment with 3D printing, robotics, and artificial intelligence in a playful and hands-on way. No prior knowledge is required; anyone can contribute, co-create, and learn. The community plays a crucial role: the newly designed, human-like body that won the German Design Award was developed by a community member using CAD software.

Jürgen Baier, founder of pib, is thrilled about the recognition: „We are proud that pib has won the German Design Award! For us, this confirms that we are on the right path to making robotics and AI more accessible and tangible for everyone. It’s great to see that our vision of inspiring people to create and explore resonates so well.“

Learning with pib: Schools and Media Centers Adopt the Humanoid Robot

But it’s not just the maker community that’s excited about pib. More than 35 schools and media centers are already using it as an innovative learning platform. Students and teachers alike are leveraging this humanoid robot to explore future technologies in an interactive, hands-on manner. The focus goes beyond technical skills to include creative problem-solving and teamwork. By bringing knowledge to life, pib makes robotics and AI tangible – opening doors to the careers of tomorrow.

Open Source and Limitless Possibilities

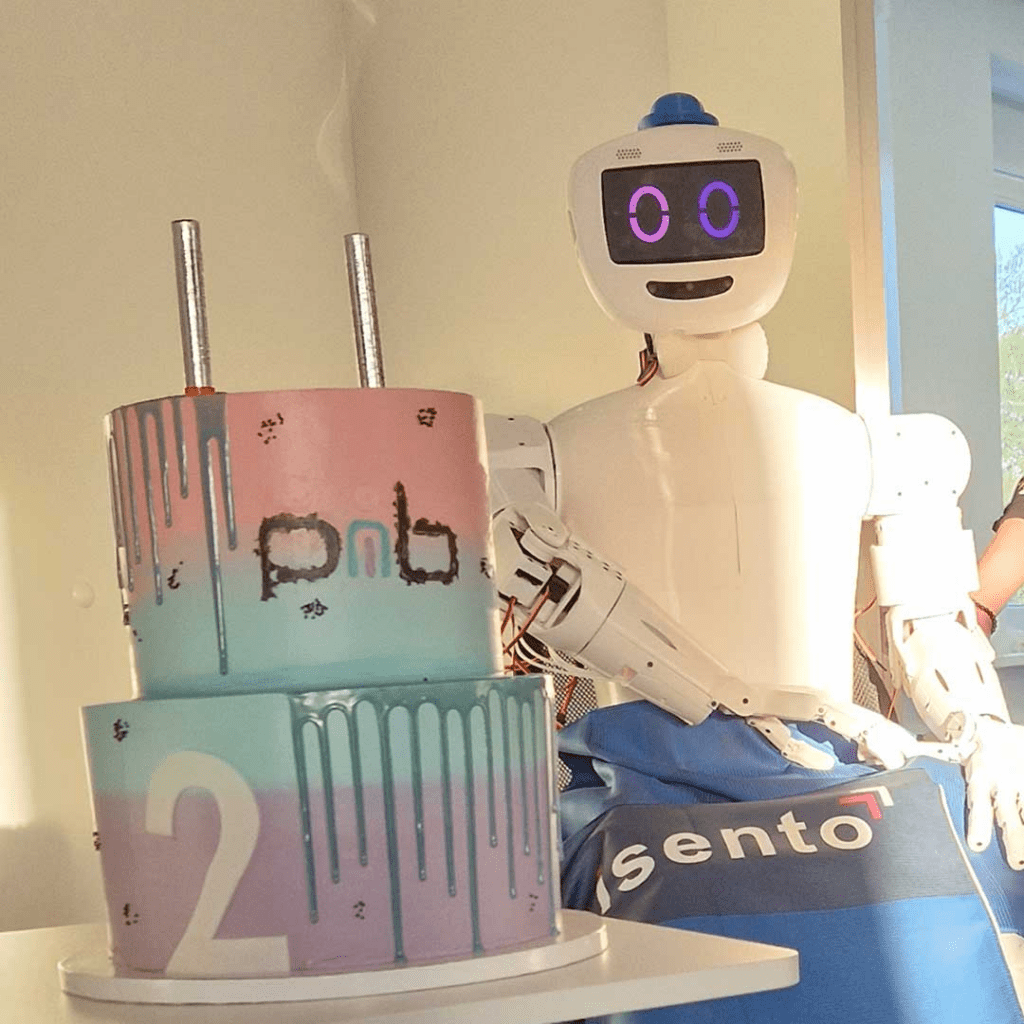

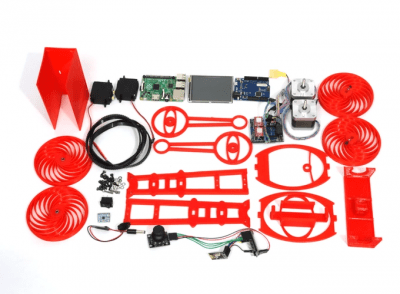

Behind pib stands isento GmbH, a Nuremberg-based company specializing in software development and AI solutions. However, the robot thrives not only due to the work of isento employees but also through the contributions of its community. 3D printing files, detailed assembly instructions, programming code, AI skills, and a knowledge database are all freely available online – an open invitation to help shape the future of robotics.

Winning the German Design Award is a well-deserved honor for pib. But for this project, the award means much more: it is motivation to push the boundaries of what’s possible with open-source robotics even further. So if you’ve ever wondered how to create your own humanoid robot – pib has the answer.