Schlagwort-Archive: AMR

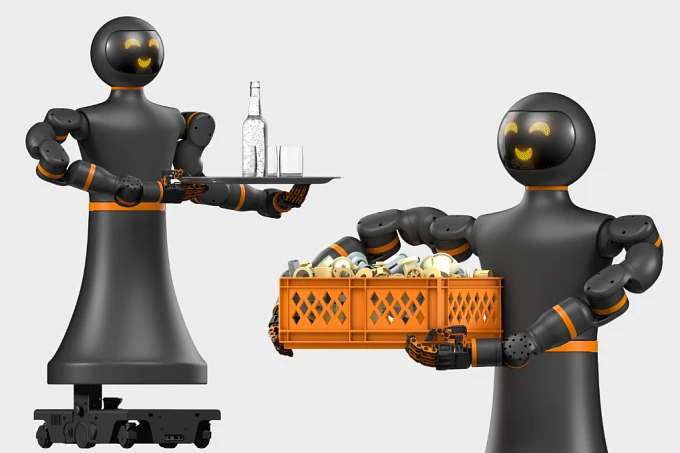

Für unter 50.000 Euro: igus stellt humanoiden Roboter Iggy Rob vor

Zweiarmiger Kunststoffroboter des Kölner Unternehmens unterstützt künftig auf vielfältige Weise – Testphase vor Kauf inbegriffen

Köln, 16. April 2025 – Humanoide Roboter stehen kurz davor, die Industrie kräftig umzukrempeln. Während bisherige Systeme sehr teuer sind, bietet der motion plastics Spezialist igus mit dem Iggy Rob nun seinen ersten humanoiden Roboter als Low-Cost-Lösung an. Für 47.999 Euro unterstützt er in der industriellen Fertigung, bei Transportaufgaben oder im Service. Um Erfahrung mit dem neuen Helfer zu sammeln, ruft igus zum „Test before Invest“ auf. Der Trend zeigt in eine klare Richtung: Schätzungen zufolge könnten bis 2030 20 Millionen humanoide Roboter in der Industrie im Einsatz sein. Die Nachfrage nach der Technologie steigt auch bei europäischen Unternehmen rasant an, das Problem dabei: Humanoide Roboter sind aktuell noch sehr teuer, erste Anwendungsmöglichkeiten müssen vielerorts erst identifiziert werden. Das möchte der Kölner motion plastics Experte igus nun ändern: Mit dem Iggy Rob liefert das Unternehmen einen preisgünstigen humanoiden Roboter, der dank seiner zwei Arme und einem stabilen, rädergetriebenen Unterbau eine Vielzahl von Anwendungen ermöglicht. „Die Welt ist für den Menschen geschaffen, das Potenzial für humanoide Roboter ist deshalb riesig“, erklärt Alexander Mühlens, Leiter Geschäftsbereich Low-Cost-Automation bei igus. Acht Stunden ohne Pause im Einsatz Der Iggy Rob ist rund 1,70 Meter groß und kann sich acht Stunden lang mit nur einer Akkuladung bewegen. Ausgestattet mit einem Lächeln begrüßt er seine Kolleginnen und Kollegen mit zwei ReBeL Cobot Armen und zwei bionischen Händen. Ausgestattet mit einem LIDAR-Sensor und 3D-Kameras zur Objektdetektion navigiert der Roboter problemlos durch sein Umfeld. Zur Steuerung nutzt igus die hauseigene igus Robot Control. Der Roboter ist nach VDE 5050 für das Flottenmanagement zugelassen und besitzt eine CE-Zertifizierung. Ergänzt um eine ROS2-Schnittstelle erfüllt Iggy Rob die Ansprüche an moderne Robotik. AMR schafft die Grundlagen Die Basis von Iggy Rob bildet der Autonome Mobile Roboter (AMR) ReBeL Move. Die mobile Plattform ist dank einer Dreipunktlagerung sehr stabil. igus hat bei seinem humanoiden Roboter bewusst auf Beine verzichtet, da die Infrastruktur für AMRs in vielen Fabriken bereits fortgeschritten ist. Mit einer Traglast von 50 Kilogramm und 100 Kilogramm Zuladung schafft der ReBeL Move die Voraussetzungen für die arbeitsplatzungebundene Bewegung. Der Iggy Rob kann als Serviceroboter am Empfang arbeiten, Transportaufgaben in der Fabrik übernehmen oder in der Kantine Besteck abräumen. igus selbst plant, den Iggy Rob beim Einlegen von Bauteilen in die Spritzgussmaschinen des Unternehmens zu nutzen. „Wir gehen davon aus, dass humanoide Roboter zu Beginn vor allem für industrielle Zwecke interessant sind“, erklärt Alexander Mühlens. Gemeinsame Fortentwicklung: „Test before Invest“ In der Weiterentwicklung des Iggy Robs zählt igus auf seine Kunden. Der Hersteller bietet bereits vor dem Kauf ein „Test before Invest“-Programm an, bei dem die igus Experten die Potenziale vor Ort evaluieren und Einsatzmöglichkeiten am realen Roboter prüfen. Ist der Test überzeugend, so ist der Iggy Rob zu einem im Marktvergleich niedrigen Kaufpreis von 47.999 Euro erhältlich. „Bisher erhältliche humanoide Roboter kosten teils zwei- oder dreimal so viel“, sagt Mühlens. Mehr Informationen zum humanoiden Roboter finden Sie unter: https://www.igus.de/automation/news/humanoider-roboter |

MATRIX Robotics System unveils MATRIX R4 Robo Set in Collaboration with Arduino Education

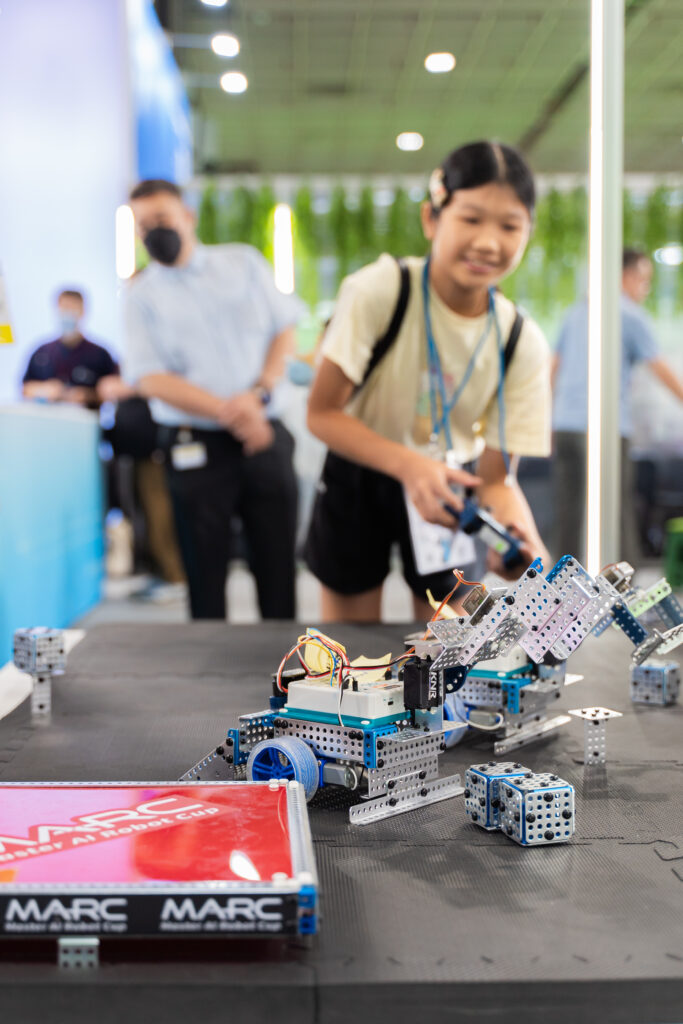

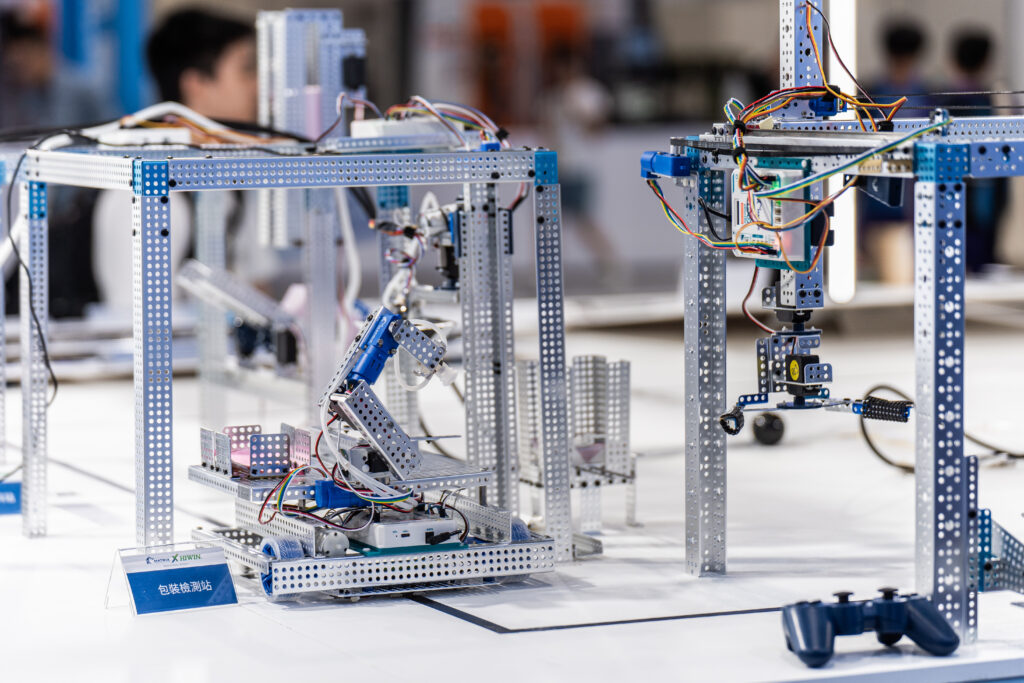

In July, the Taiwanese-based company MATRIX Robotics System marked a significant milestone in educational robotics with the release of its latest product: the MATRIX R4 Robo Set. Developed in partnership with and certified by Arduino Education, this innovative robotics set is built on the UNO R4 WiFi platform, providing users with a sophisticated 12- in 1 robot model and versatile tool to explore and excel in the field of robotics.

The MATRIX R4 Robo Set has been meticulously designed to cater to all ages for versatile projects. The MATRIX R4 offers comprehensive solutions that leverages Arduino’s cutting-edge technology. The set provides endless possibilities for those eager to enhance their robotics skills, whether they are students, hobbyists, or seasoned competitors.

The MATRIX R4 Robo Set includes a versatile controller that supports various applications beyond just robots, but also factory simulations. The controller allows for different projects and scenarios, such as smart factories, by integrating components like the Mvision camera and IoT functionalities. The Smart Factory simulation models a factory inspection process where products are assessed after production. This flexibility enables users to explore and understand a wide range of industrial and technological processes.

The MATRIX R4 RoboSet serves as more than just a tool; it is an educational journey. With educational objectives, it enhances learning programming featuring MATRIXblock and Arduino IDE, introduces foundational computing concepts, making it an ideal starting point for anyone interested in computer science and robotics. Furthermore, with a quick and easy assembly building system, users gain hands-on experience in mechanism design, a crucial skill in robotics.

The R4 set not only lays the foundation for developing hardware and software integration skills but also encourages users to think critically and creatively when tackling real-world robotics challenges. It provides practical applications for problem-solving skills. While controlling a motor with Arduino WiFi can be challenging, especially when managing both the motor and sensors, the R4 set simplifies the process with its easy plug-and-play solution.

One of the standout features of the MATRIX R4 Robo Set is its compatibility with various expansion kits, allowing users to customize and expand up to 12 different robotic creations. For example, the MX300 expansion kit empowers users to build robust and fundamental robots using the MATRIX basic set. The MX300 Expansion Kit is a versatile tool that bridges the gap between theory and practice in small and medium-sized Autonomous Mobile Robots (AMRs). Tailored for students, educators, and enthusiasts, it helps users understand AMR principles and serves as a demonstration robot for the MARC (Master AI Robot Cup) competition, providing participants with a platform to practice and hone their skills in a competitive setting.

Additionally, the MJ2 Wireless Joystick, a key part of the MATRIX ecosystem, uses 2.4G wireless technology to connect over 20 devices simultaneously. Its strong anti-interference and stable signal make it perfect for precision-demanding competitive scenarios.

As the field of robotics continues to evolve, MATRIX Robotics System remains at the forefront, providing cutting-edge tools and resources to inspire the next generation of roboticists. The MATRIX R4 Robo Set represents a gateway to a world of innovation, creativity, and competition, equipping users with the skills they need to succeed in the rapidly changing landscape of robotics.

Get yours today

https://www.matrixrobotics.com/matrix-r4-robo-set

By joining the MATRIX Project #DevelopMATRIXR4ROBO program, you’ll:

-Gain Hands-On Experience: Receive a complimentary MA300 sample to explore and integrate into your projects.

-Provide Valuable Feedback: Share your insights and suggestions to help improve future iterations of the MA300.

-Showcase Your Skills: Demonstrate your expertise through application videos and social media promotion.

Sign up today and create like never before!

United Robotics Group presents new modular uLink series for retail, warehouse logistics and production

- At VivaTech 2024, the United Robitics Group (URG) will be showing the new product in action – together with other robots from the URG fleet, which are fully adapted to the needs of retailers.

- uLink is a highly flexible, versatile platform for rapid adaptation and support in logistics and automation.

- uLink is the first URG solution with an open API for seamless integration with operating systems and greater operational flexibility.

Paris/Bochum, May 22, 2024 – At VivaTech in Paris, the United Robotics Group will be presenting its new service robots from the uLink series for the first time, which are characterized by easy integration, flexible customization and individual extensions. They are suitable for use in retail, warehouse logistics and manufacturing. As the European market leader for service robotics solutions, URG is expanding its CobiotX portfolio worldwide with the latest Cobiot for integrated workflows in the aforementioned segments. The modular platform fits seamlessly into the respective workflows and can be expanded with industry-standard accessories. uLink is designed to simplify operations and increase safety and efficiency in various environments. The unique combination of features sets new standards in the industry – from modular design and open API to 3D LiDAR-based navigation and real-time operational data visualization.

uLink is equipped with IDE, SDK and fleet management tools and allows the seamless integration and control of various components such as LiDARS, engines or sensors. Thanks to powerful software functions for configuring and managing robot applications, as well as sensors and accessories, the robot can easily handle various logistics challenges in trade and warehousing, which vary depending on the industry, company size and automation requirements. The uLink accessory interface is also modular, so that the usable area can carry a payload of up to 60 kg. The SEER navigation control allows deliveries in a predefined area of up to 400,000 m².

With the help of the plug-and-play mechanism, other accessories such as a locker for Click & Collect or confidential deliveries, a pegboard for the delivery of tools and spare parts, and trays for transporting stock can be integrated into the platform. In addition, partner integrators can develop new accessories to meet specific requirements.

„The retail and logistics sector has been undergoing a profound transformation for years, related to the growth of e-commerce, automation and the shortage of skilled workers in the value chain. Whether it’s shelf replenishers or water-spiders, i.e. those responsible for inventory in warehouses or production: it is important to support the players and offer solutions that meet their specific needs,“ explains Thomas Linkenheil, Co-CEO of the United Robotics Group. „In a highly competitive sector, consumers want a fast and personalized service. Our new logistics solution enables service providers to offer up-to-date customer service without long searches in the warehouse or tedious processes that can cost time and affect customer business.“

First Cobiot with an open API for connectivity and flexibility

Like all CobiotX solutions from the United Robotics Group, uLink is also equipped with a particularly user-friendly user interface. It is based on the no-code principle and enables users without robotics knowledge to quickly integrate into daily operations. In addition, uLink has an open API platform. This allows the solution to communicate with existing operations and other connected systems such as automatic doors or elevators, and also work with other robots and automated guided vehicles such as AMRs and AGVs.

With the launch of uLink, United Robotics Group is expanding its range of robotics solutions for logistics, warehouse management and industrial manufacturing. The robot is intended to be used in retail and logistics environments such as department stores, supermarkets, warehouses and fulfillment centers, but also factories and production facilities as well as airports and healthcare facilities.

The robot is equipped with 3D LiDAR and PL LiDAR systems for maximum precision in mobility. The platform can immediately register changes in the environment such as certain movements or people or machines and react accordingly. It is connected to an online dashboard that facilitates both workflow management and quick decisions between front- and back-of-house teams.

uLink has a long battery life of up to 14 hours on a single charge. In addition, the solution has an intelligent, wireless charging function that was developed with a well-known German battery manufacturer. This allows it to automatically return to the charging station between individual operations. The robot complies with the highest security and privacy standards, including the EU’s Performance Level D Machinery Directive and GDPR regulations.

uLink, along with United Robotics Group’s logistics and warehouse management fleet, including RBWatcher and MobilePalletizer, will be on display at the company’s VivaTech booth (Hall 1, Booth G18) in Paris from May 22-25.

uLink can be rented via the RaaS (Robot as a Service) model of the United Robotics Group from 699 euros / month or purchased for 19,900 euros.

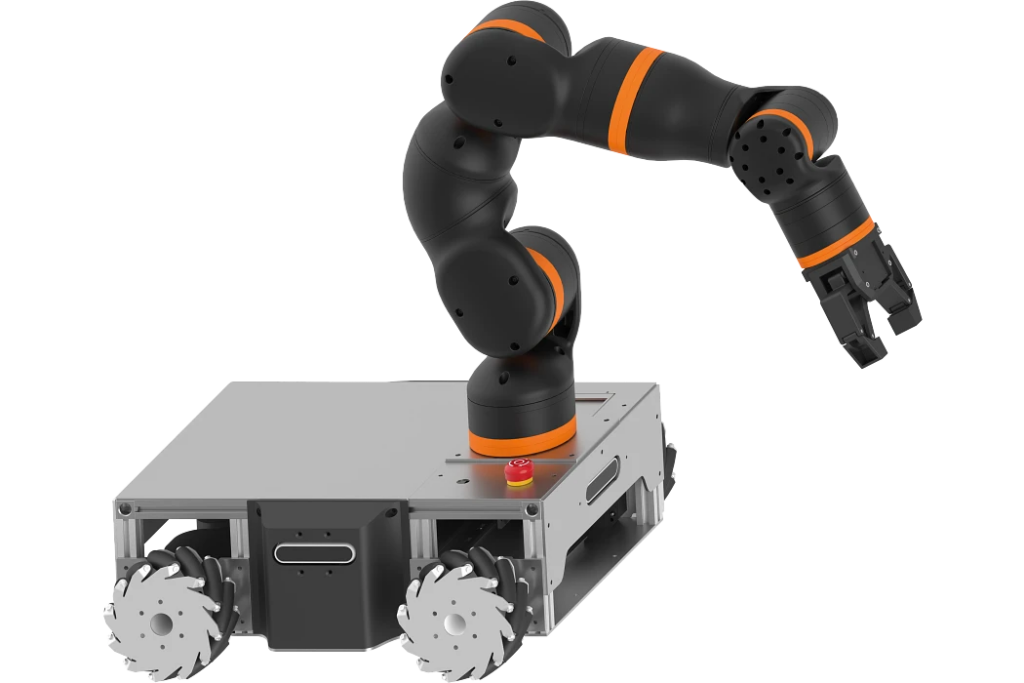

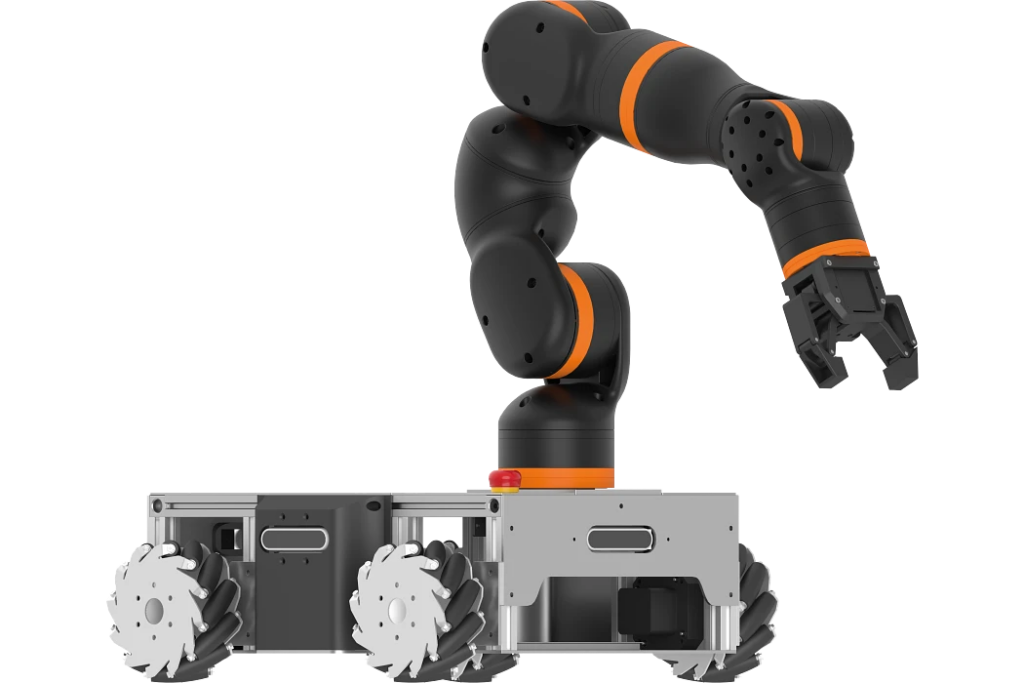

„ReBeLs on Wheels“ make driverless transport systems affordable through modern plastic technology

Cologne/Hanover, April 24, 2024 – Mobile robotics systems are being used in more and more work areas, in e-commerce warehouses as well as in modern restaurants. Conventional models on the market start at around 25,000 euros, while solutions with an integrated robot arm start at around 70,000 euros. However, widespread use in the market is often unaffordable for small and medium-sized enterprises due to the high prices. igus wants to change this with new low-cost robotics offerings and is presenting a series of low-cost mobile plastic robots at the Hannover Messe.

The market for Automated Guided Vehicles (AGV) and Autonomous Mobile Robots (AMR) is booming: The global market for mobile robotics, including service robotics, is currently worth around 20.3 billion US dollars, and experts expect it to almost double by 2028. 1 Mobile robots are particularly common in intralogistics and industrial applications. And even in the catering industry or in hospitals, the smart helpers are increasingly making their rounds. This is also the case at motion plastics specialist igus: For four years now, the plastics experts have been successfully testing AGVs in-house – driverless racks that deliver mail and deliveries to offices, as well as mobile robots in production that move transports and stack-and-turn containers. The experience gained flows directly into the development of a new low-cost automation product line, the „ReBeL on Wheels“. Their goal: to pave the way for small and medium-sized enterprises (SMEs) to use cost-effective mobile robotics.

Mobile ReBeL solutions for education, logistics and service

The basis of any mobile robotics system is the ReBeL. The use of plastic makes the robot particularly affordable at 4,970 euros and, with a dead weight of 8.2 kilograms, the lightest service robot with cobot function in its class. All mechanical components that make up the ReBeL are developed and manufactured by igus without exception. It has a load capacity of 2 kilograms and a reach of 664 millimetres. Various mobile systems are planned in which the ReBeL is centrally integrated: igus is launching an affordable version for the education sector for 14,699 euros – including the robot arm. The ReBeL EduMove equipped with a gripper serves as an autonomous learning platform for educational institutions thanks to open source. It has a modular design and can be flexibly expanded to include additional functions such as lidar, camera technology or slam algorithm. Another variant is an automated guided vehicle system for SMEs. It can carry up to 30 kilograms. With the optional ReBeL, simple A-to-B positioning can be made. It dispenses with expensive sensor technology and instead relies on 3D sensor technology developed in-house. The price is 17,999 euros. In addition, igus will be showcasing a study of a service robot at a low price in Hanover. The ReBeL Butler is suitable for simple but time-consuming pick-up and drop-off services, for example in the hotel and catering industry.

A lighthouse project on wheels

The goal of all these developments is the lighthouse project, a mobile robot with integrated HMI and vision that could even tidy up an office on its own. „With this project, we are pursuing a bottom-to-top strategy, in which certain components such as safety laser scanners are not included in the basic package in order to keep the price low,“ explains Alexander Mühlens, authorized signatory and head of the low-cost automation business unit at igus. „Nevertheless, it ensures that the solution can be retrofitted for industrial requirements.“ Among other things, igus is presenting an affordable gripper with a large stroke and travel this year, which offers a high degree of flexibility when gripping different geometries. Alexander Mühlens: „The areas of application for this targeted low-cost AMR are extremely diverse and go far beyond simple transport tasks. They encompass a huge range of applications in various areas of life, such as cleaning tasks or serving coffee directly at the workplace.“

Auf der Überholspur: Mobile Roboter von igus senken Kosten für den Mittelstand

„ReBeLs on Wheels“ machen durch moderne Kunststofftechnologie Fahrerlose Transportsysteme erschwinglich

Köln/Hannover, 24. April 2024 – Mobile Robotiksysteme kommen in immer mehr Arbeitsbereichen zum Einsatz, in E-Commerce-Lagerhallen ebenso wie in modernen Restaurants. Herkömmliche Modelle auf dem Markt starten bei etwa 25.000 Euro, Lösungen mit integriertem Roboterarm liegen bei rund 70.000 Euro. Ein flächendeckender Einsatz im Markt ist allerdings aufgrund der hohen Preise für kleine und mittlere Unternehmen häufig unerschwinglich. igus will das mit neuen Low-Cost-Robotik-Angeboten ändern und stellt zur Hannover Messe eine Serie günstiger mobiler Kunststoff-Roboter vor.

Der Markt für Automated Guided Vehicles (AGV) und Autonome Mobile Robots (AMR) boomt: Aktuell beträgt der globale Markt der mobilen Robotik inklusive Servicerobotik rund 20,3 Milliarden US-Dollar, bis 2028 erwarten Experten nahezu eine Verdoppelung.1 Besonders verbreitet sind mobile Roboter in der Intralogistik und in industriellen Anwendungsbereichen. Und selbst in der Gastronomie oder in Krankenhäusern drehen die smarten Helfer vermehrt ihre Runden. Auch beim motion plastics Spezialisten igus: Seit vier Jahren testen die Kunststoff-Experten bereits erfolgreich AGVs im eigenen Haus – fahrerlose Regale, die Post und Lieferungen in Büros ausfahren sowie mobile Roboter in der Fertigung, die Transporte und Drehstapelbehälter bewegen. Die gewonnenen Erfahrungen fließen direkt in die Entwicklung einer neuen Low-Cost-Automation-Produktlinie ein, den „ReBeL on Wheels”. Ihr Ziel: kleinen und mittleren Unternehmen (KMU) den Weg in eine kostengünstige mobile Robotik zu ebnen.

Mobile ReBeL Lösungen für Bildung, Logistik und Service

Die Basis eines jeglichen mobilen Robotik-Systems ist der ReBeL. Der Einsatz von Kunststoff macht den Roboter mit 4.970 Euro besonders günstig und mit 8,2 Kilogramm Eigengewicht zum leichtesten Serviceroboter mit Cobot-Funktion in seiner Klasse. Alle mechanischen Bauteile, aus denen sich der ReBeL zusammensetzt, sind ausnahmslos von igus entwickelt und gefertigt. Seine Traglast beträgt 2 Kilogramm und er besitzt eine Reichweite von 664 Millimetern. Geplant sind verschiedene fahrende Systeme, in die der ReBeL zentral integriert ist: So startet igus mit einer erschwinglichen Variante für den Bildungssektor für 14.699 Euro – inklusive des Roboterarms. Der mit einem Greifer ausgestattete ReBeL EduMove dient dank Open Source als autonome Lernplattform für Bildungseinrichtungen. Er ist modular aufgebaut und lässt sich flexibel um weitere Funktionen wie Lidar, Kameratechnik oder Slam-Algorithmus erweitern. Eine weitere Variante ist ein Fahrerloses Transportsystem für KMU. Es kann bis zu 30 Kilogramm transportieren. Mit dem optionalen ReBeL lassen sich einfache A zu B Positionierungen vornehmen. Es verzichtet dabei auf teure Sensorik und setzt stattdessen auf eine eigenentwickelte 3D-Sensortechnik. Der Preis liegt bei 17.999 Euro. Darüber hinaus zeigt igus in Hannover die Studie eines Serviceroboters zum kleinen Preis. Der ReBeL Butler eignet sich für einfache, aber zeitaufwendige Hol-und-Bring-Dienste, beispielsweise im Hotel- und Gastrogewerbe.

Ein Leuchtturmprojekt auf Rädern

Das Ziel all dieser Entwicklungen ist das Leuchtturmprojekt, ein mobiler Roboter mit integriertem HMI und Vision, der sogar eigenständig ein Büro aufräumen könnte. „Mit diesem Projekt verfolgen wir eine Bottom-to-Top-Strategie, bei der bestimmte Bauteile wie Sicherheits-Laserscanner nicht im Grundpaket enthalten sind, um den Preis niedrig zu halten“, macht Alexander Mühlens, Prokurist und Leiter des Geschäftsbereichs Low-Cost-Automation bei igus, deutlich. „Dennoch ist sichergestellt, dass die Lösung für industrielle Anforderungen nachgerüstet werden kann.“ Unter anderem stellt igus in diesem Jahr einen erschwinglichen Greifer mit großem Hub und Verfahrweg vor, der hohe Flexibilität beim Greifen unterschiedlicher Geometrien bietet. Alexander Mühlens: „Die Einsatzgebiete dieses angestrebten Low-Cost-AMRs sind äußerst vielfältig und gehen über einfache Transportaufgaben weit hinaus. Sie umfassen eine riesige Bandbreite an Anwendungen in verschiedenen Lebensbereichen, wie Reinigungsaufgaben oder die Ausgabe von Kaffee direkt am Arbeitsplatz.“

AGILOX introduces new ODM robot

AGILOX expands its product portfolio with an intelligent dolly mover

After AGILOX ONE and AGILOX OCF, now comes AGILOX ODM. The company, which specializes in logistics robots, is adding an autonomous dolly mover to its range of intelligent transport systems controlled by swarm intelligence. AGILOX is thus targeting a completely new area of application: the transport of small load carriers.

AGILOX is expanding its range of Autonomous Mobile Robots (AMRs) with the new Omnidirectional Dolly Mover AGILOX ODM. While the AGILOX ONE is equipped with a scissor lift and the AGILOX OCF has a free lift for load handling, the AGILOX ODM is built on the principle of a dolly mover. This means it can accept loads with a maximum weight of 300 kg to a maximum lifting height of 250 mm and transport them to their destination. The intelligent AMR concept with AGILOX X-SWARM technology thus opens up new areas of application and other industry segments because small load carriers (such as totes), which the new AGILOX ODM is designed to transport, are widely used, especially in the electronics and pharmaceutical industries.

Details of the new AGILOX ODM

With the AGILOX ODM, AGILOX has brought new thinking to the concept of Automated Guided Vehicles: The compact vehicle travels autonomously and navigates freely on the production floor or in the warehouse, perfectly ensuring the in-house material flow. Just like AGILOX ONE and AGILOX OCF, AGILOX ODM uses an omnidirectional drive concept. This allows it to travel transversely into rack aisles as well as turn on the spot, enabling it to maneuver even in the tightest of spaces. The lithium iron phosphate (LiFePO4) accumulator ensures short charge times and long operating cycles.

“AGILOX is a brand that has built a strong foundation with the AGILOX ONE and the AGILOX OCF. With the new AGILOX ODM, we remain true to our brand DNA while simultaneously targeting the transport of small load carriers to support our growth plan to become the world’s leading AMR provider,” says Georg Kirchmayr, CEO of AGILOX Services GmbH.

The AGILOX advantage

With the new AGILOX ODM, customers can benefit from all the advantages of same proven X-SWARM technology as in AGILOX ONE and AGILOX OCF: the unique advantages of an (intra-)logistics solution designed from the ground up.

Since AGILOX AMRs have no need for a central control system and can orient to the existing contours with millimeter precision, this eliminates time-consuming and costly modifications to the existing infrastructure. Autonomous route-finding also enables the vehicles to avoid obstacles unaided. If it is not possible to get past the detected obstacle due its size or the available clearance, the AMRs calculate a new route within seconds to reach their destination as quickly as possible. For customers, this means maximum freedom in their existing processes, because they do not have to adapt to the Autonomous Mobile Robot system. Instead, the system adapts to the customer’s processes. Furthermore, fully autonomous routing ensures a safe workflow – even in mixed operations.

Plug & Perform commissioning of the intelligent intralogistics solutions and the absence of a master computer or navigation aids also saves AGILOX customers from doing tedious alteration work in advance. Once the logistics robots have been put into operation, they organize themselves according to the (decentralized) principle of swarm intelligence, i.e. they exchange information several times a second to enable the entire fleet to calculate the most efficient route and prevent potential deadlocks before these can occur. The customer thus benefits from a system that constantly runs smoothly, with no downtime. Time-consuming coordination of vehicles by the customer is also a thing of the past thanks to AGILOX X-SWARM technology. For the customer, this means flexibility, because it lets them expand the vehicles‘ area of operation within just a few minutes. It also means that it is very easy to relocate an AGILOX AMR to be used temporarily in other areas of the company areas or its subsidiaries. Since AGILOX vehicles can also communicate with other machines or the building infrastructure by means of IO boxes, even rolling doors or multiple floors are no problem for the AMRs. So, this too means that customers enjoy maximum flexibility in the organization of their production processes.

Another major advantage comes from mixed operation of the AGILOX fleet in a “swarm”. The smaller AGILOX ONE and ODM series vehicles can then, for example, feed the assembly workstations or e-Kanban racks, while the AGILOX OCF vehicles transport the pallets. This can easily be done because AGILOX AMRs all use the same control and WiFi infrastructure.

Kivnon brings perfect Pallet Stacking to Logistics & Automation 2022

Kivnon will be presenting its most advanced and safest AGV/AMR Forklift at the event

21 September 2022, Barcelona: Kivnon, an international group specializing in automation and mobile robotics, is attending Logistics & Automation in Spain and will be showcasing it’s safe and versatile K55 AGV/AMR Forklift Pallet Stacker. Putting the emphasis on forklift safety, Kivnon K55 is equipped with advanced safety features to guarantee safe operations as it collaborates, moves, and reacts in a facility.

The Kivnon K55 is designed to move and stack palletized loads at low heights and performs cyclic or conditioned routes while interacting with other AGVs/AMRs, machines, systems, and people, making it a highly effective and safe solution. The model incorporates safety scanners that allow the vehicle to ensure 360-degree safety and operate seamlessly in shared spaces. The fork sensors help assess the possibility of correct loading or unloading of the pallet, keeping the transported goods safe.

Thierry Delmas, Managing Director at Kivnon, says, “AGVs/AMRs are revolutionizing internal logistics. The rising forklift safety challenge is of deep concern, and with the K55 we have taken a step forward to address the global issue. The Kivnon range is designed to ensure safe and reliable operations and to optimize operational efficiency.“

During the event, which runs from 26 – 27 October at IFEMA, Madrid, Kivnon will demonstrate the capabilities of the K55 Pallet Stacker. The vehicle can autonomously transport palletized loads of up 1,000 kg and lift them to heights of up to 1 meter. The vehicle is capable of performing cyclical or conditional circuits and interacting with other AGVs/AMRs, machines, and systems. Highly adaptable, the K55 is perfect for any open-bottom or euro-pallet storage application, receipt and dispatch of goods, and internal material transport. Its use will optimize safety, storage space, and process efficiency.

A robust industrial product, the K55 provides the reliability required to ensure continuity of production process and flexibility to adapt to specific application needs, with an online battery charging system that can function 24/7 with opportunity charges.

Delmas continues, “The Logistics and Automation show is an important networking event where customers can learn about the latest technologies and innovations. We pride ourselves on innovation and are excited to have this opportunity to showcase the capabilities of our products. In addition to the K55, our robust portfolio also includes twister units, car and heavy load tractors, low-height vehicles, and cart pullers, meeting multiple application needs”

The efficiency and precision of Kivnon AGVs/AMRs will be on display and Kivnon robotics experts will be available throughout the show to answer questions and arrange consultations at booth #3F43.

To register for the show, please visit https://www.logisticsautomationmadrid.com/en/

About Kivnon:

Kivnon offers a wide range of autonomous vehicles (AGVs/AMRs) and accessories for transporting goods, using magnetic navigation or mapping technologies that adapt to any environment and industry. The company offers an integrated solution with a wide range of mobile robotics solutions automating different applications within the automotive, food and beverage, logistics and warehousing, manufacturing, and aeronautics industries.

Kivnon products are characterized by their robustness, safety, precision, and high quality. A user-friendly design philosophy creates a pleasant, simple to install, and intuitive work experience.

Learn more about Kivnon mobile robots (AGVs/AMRs) here.

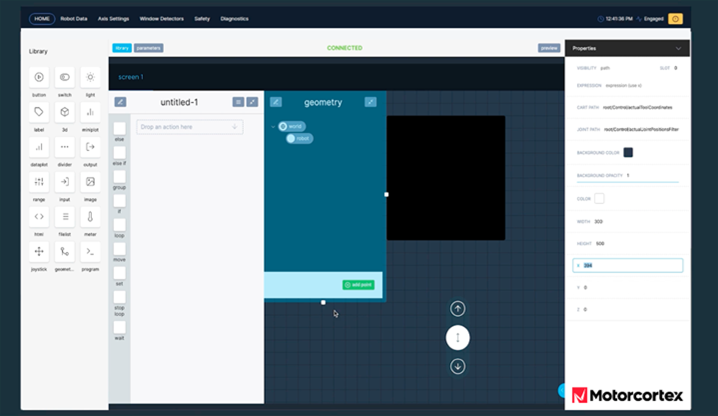

Robotersteuerung schnell und einfach in der Cloud programmiert –

Synapticon macht MOTORCORTEX als Online-Version verfügbar

Böblingen, den 04.08.2022 – Auch in der Welt des Maschinenbaus und der Robotik hat sich Software in den vergangenen Jahren zum entscheidenden Erfolgsfaktor entwickelt. Sowohl die Art und Weise wie Robotersteuerungen entwickelt werden als auch ihre Leistungsfähigkeit in der Praxis sind für die Hersteller von Industrierobotern von großer Bedeutung. Vor diesem Hintergrund hat Synapticon mit MOTORCORTEX.io nun eine bahnbrechende Lösung im SaaS (Software as a Service) Modell vorgestellt. Sie ermöglicht es sehr leistungsfähige, 100% individuelle Robotersteuerungen komfortabel in der Cloud zu entwickeln, auf Steuerungen im Feld bereitzustellen und über einen digitalen Zwilling zu testen. In der Serienproduktion des Roboters bzw. Automatisierungsprodukts kann die individuelle Steuerungs-Software dann in Masse bereitgestellt und auch offline betrieben werden. Dafür können neben Industrie-PCs auch Embedded-Module bis hin zu einem Raspberry Pi eingesetzt werden.

„Die Automatisierung hat in den vergangenen Jahren nochmals deutlich an Fahrt aufgenommen. Tragende Elemente sind dabei unter anderem fahrerlose Transportsysteme (AGV/AMR) sowie Cobots und Leichtbauroboter. Diese Systeme stellen nicht nur neue Herausforderungen an die Hardware, sondern auch an die Software, speziell wenn es um Themen wie Navigation, Sicherheit und das Erlernen von Abläufen geht“, erklärt Nikolai Ensslen, CEO und Gründer von Synapticon. „Die große Herausforderung ist nun für viele Hersteller: Sie müssen ihren Kunden Lösungen anbieten, die preislich attraktiv und immer auf dem neuesten Stand der Technik sind. Die Unternehmen sollen also in der Lage sein, individuelle Steuerungssoftware für ihre Systeme schnell und kosteneffizient zu entwickeln. Hierfür haben wir mit MOTORCORTEX nun eine Lösung im Angebot, die am Markt einmalig ist und welche die Entwicklungszeit von Robotersteuerungen drastisch verkürzt.“

Echtzeit-Steuerungsanwendungen in der Cloud erstellen und auf Offline-Steuerungen deployen sowie aus der Ferne warten

MOTORCORTEX umfasst ein ganzes Paket an Apps bzw. Templates und Tools zum Entwerfen, Steuern, Analysieren und Bereitstellen von industriellen Automatisierungsanwendungen. Dazu gehört beispielsweise auch ein Widget für die einfache grafische Programmierung (“no code”) von Robotern, was im Bereich der Cobots zum Standard wird. Die Plattform für individuelle Roboter- und Maschinensteuerungen ist mit modernster Softwaretechnologie implementiert, erfüllt alle Anforderungen der Automation der Zukunft und ist zugleich hoch leistungsfähig und skalierbar.

Das integrierte Linux-basierte und ressourcenoptimierte Betriebssystem bietet Echtzeitsteuerung von industrieller Hardware über EtherCAT, wie z.B. auf Synapticon SOMANET basierende Antriebsachsen und eine sehr leistungsstarke Kommunikationsschicht für Anwendungen auf höherer Ebene, wie z. B. eine Benutzeroberfläche oder Datenanalysetools. MOTORCORTEX ermöglicht Hochgeschwindigkeits-Streaming-Kommunikation direkt zum Webbrowser ohne Zwischenserver, was in der Industrie eine Wende darstellt. Es ist jetzt möglich, reaktionsschnelle Webanwendungen für eine extrem reibungslose Interaktion mit Maschinen zu erstellen. Die Lösung bietet offene APIs für alle wichtigen Programmiersprachen wie Javascript, Python und C++. Diese offene Architektur bietet viel mehr Freiheiten als aktuelle industrielle Steuerungssysteme und ermöglicht echte Industrie 4.0-Anwendungen mit nur wenigen Codezeilen. Die Kommunikation mit umgebenden bzw. höher liegenden Steuerungseinheiten wird über OPC UA unterstützt.

„Die Nutzung von MOTORCORTEX ist so einfach wie das Einrichten einer einfachen Webseite. Mit etwas Konfigurationsarbeit und ein paar Zeilen Code können sich Entwickler von jedem Webbrowser aus direkt und sicher mit ihrer Maschine verbinden und schnell Daten austauschen. Kein anderes industrielles Steuerungssystem ist so einfach und flexibel für anspruchsvolle und moderne Steuerungsaufgaben einzurichten“, erklärt Nikolai Ensslen. „Anwendungen, die auf MOTORCORTEX basieren, teilen alle ihre Daten automatisch in der darunterliegenden Echtzeitdatenbank, so dass externe Anwendungen oder Dienste einfach und sicher auf die Daten zugreifen können.“

Entwicklung beschleunigt, Kosten gesenkt

Erste Projekte mit Kunden zeigen, dass es Entwicklern mit MOTORCORTEX in der Cloud gelingt, den Entwicklungsprozess von Software um bis zu 90% zu reduzieren. Zugleich sinken tatsächlich die Kosten für die Softwareentwicklung deutlich, da MOTORCORTEX auf ein einfaches Lizenzmodell ohne zusätzliche Kosten für Wartung und Weiterentwicklung setzt. Da MOTORCORTEX zudem vollkommen Hardware-unabhängig ist, bleibt es den Entwicklern freigestellt, welche Hardware-Komponenten sie für die Entwicklung ihrer Steuerungssoftware nutzen. Ideale Resultate und höchste Effizienz verspricht dabei die Kombination der MOTORCORTEX-Software mit den SOMANET-Servoantrieben aus dem Motion Control-Portfolio von Synapticon.

MOTORCORTEX hat nicht den Anspruch, der eigenen Softwareentwicklung von Roboterherstellern oder innovativen Steuerungslösungen von Drittanbietern, etwa zum einfachen Teachen von Robotern oder für die Integration von Bildverarbeitung und KI, zuvor zu kommen bzw. diese zu ersetzen. Die Plattform soll vielmehr als solide Grundlage für diese dienen und die Entwickler in der Basis entlasten.

„MOTORCORTEX versteht sich, ebenso wie die SOMANET-Elektroniken, als im Endprodukt versteckte Infrastruktur. Sie soll ein leistungsfähiges, zuverlässiges Fundament für die modernsten und innovativsten Robotersteuerungen zur Verfügung stellen. Wir sehen uns als Technologie- und Infrastrukturpartner der besten Innovatoren in Robotik und Automation,” fasst Nikolai Ensslen zusammen. „Ich bin mir sicher, dass wie in vielen anderen Industriebereichen zukünftig Software auch in der Robotik zu einem wesentlichen und kritischen Unterscheidungsmerkmal wird. Mit MOTORCORTEX geben wir Unternehmen hierfür die beste Plattform in die Hand, so dass diese sich auf die relevanten Innovationen für Ihre Kunden und die Differenzierung von ihrem Wettbewerb konzentrieren können.“

Mehr Informationen unter www.synapticon.com

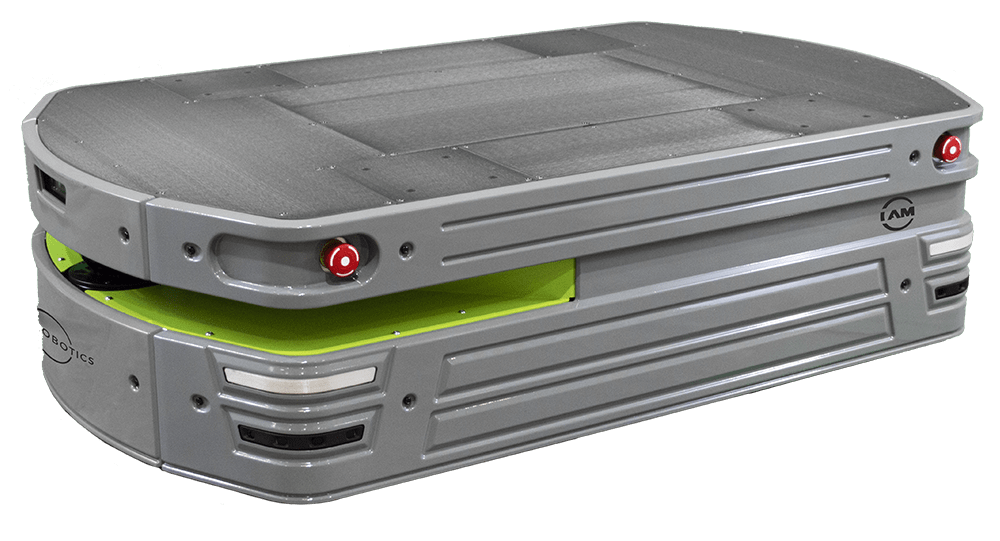

IAM Robotics Introduces Groundbreaking Mid-size AMR

Pittsburgh, PA, March 31 – IAM Robotics is breaking boundaries in the midline autonomous mobile robot (AMR) market with its new robot, Bolt™. Making its debut April 12, 2021 at ProMat DX, Bolt gives you the power to do more in material handling—faster, longer, and farther.

Packed with high-tech features, Bolt is built to thrive in warehouse and manufacturing environments. It elevates productivity and efficiency to new heights and stands out as an autonomous mobility solution for more than just a few reasons:

● Adaptability – Bolt allows you to retrofit various tops to serve your needs, from piece-picking arms to pallet movers. Choose from standard solutions or customize a unique top. No other AMR has this flexibility.

● Smarter Safety – Bolt uses 360-degree vision and a combination of state-of-the-art sensors and direct-drive wheel motors to ensure complete safety. Direct-drive wheel technology means Bolt’s entire body acts as a bump sensor. And for this to work, Bolt offers the same type of power-force-torque limiting as collaborative robot arms.

● Unmatched Power and Efficiency – Bolt is powerful, with a battery 3.5X the size of similar AMRs and 20-hour runtime that exceeds any other AMR. The patented hot swap battery makes it easy for one person to change in ten seconds or less. Plus, with a best-in-class 661-pound payload capacity, customers never compromise.

Bolt is completely autonomous, is compatible with conveyor and material handling systems, and scales easily for any size application.

Founder and CEO, Tom Galuzzo, reflected on developing the robot. “When we built our AMR, we thought, ‘How can we make this the most powerful, flexible, and collaborative solution?’ Bolt expands on our AMMR, Swift™, by turning its base into a standalone AMR. We applied what we learned with Swift, honing in on battery power and direct-drive wheels to ensure Bolt has the power to operate safely and efficiently—even with top modules attached.” He continued, “Bolt is already opening new doors for IAM Robotics because it introduces us to a faster-growing market with general AMRs.”

IAM Robotics knows AMRs are in high demand because of their benefits to businesses over existing automation and human labor. AMRs have a low barrier to entry because they’re relatively affordable, and they deploy in as quickly as a matter of weeks—so businesses can hit the ground running. But they’re also flexible. AMRs provide the power of autonomous mobility, so you’re not limited by stationary conveyors, and they’re designed to collaborate with and complement human workers and existing automation. Bolt is certainly no different, doing all this and more.

For more information about Bolt, explore the product online or get in touch with IAM Robotics to discuss specific applications.

###

About IAM Robotics

IAM Robotics is the future of material handling. Our mobile robotics platform powers operational excellence in an on-demand world.

We are dedicated to building adaptable and safe robotics solutions that seamlessly integrate into any operational environment. Our team of robotics engineers and supply chain veterans work closely with partners to model, simulate, and configure optimal solutions that keep their businesses competitive.

IAM Robotics was founded in 2012 and is proudly based in Pittsburgh, Pennsylvania. The company is home to over 50 employees and supports customers worldwide.

To learn more, please visit iamrobotics.com.