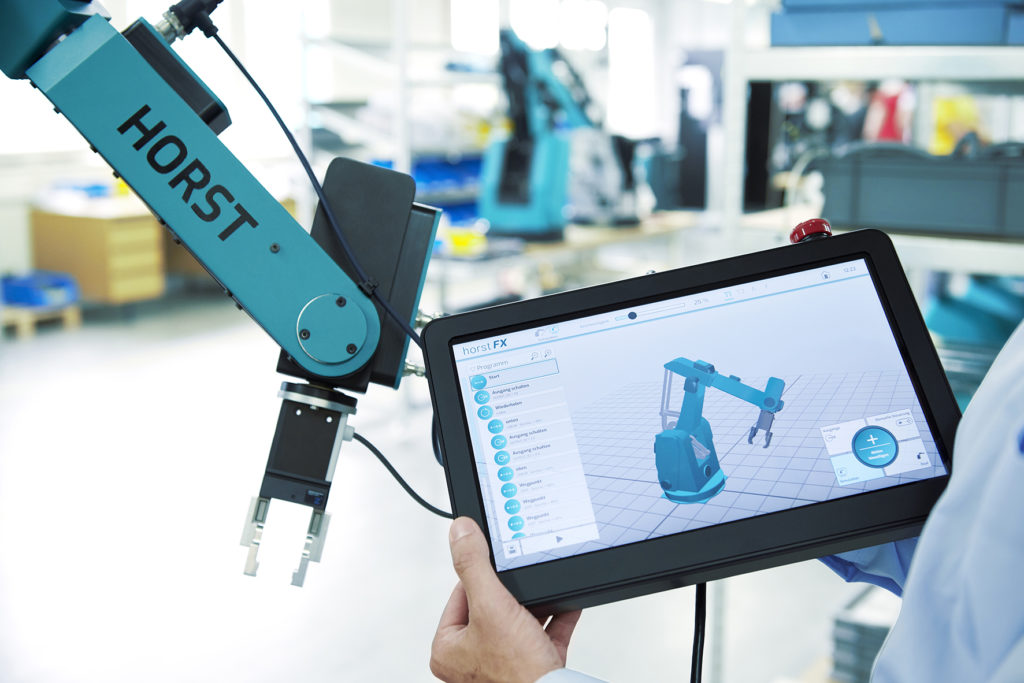

fruitcore robotics presents its new industrial robots HORST600 and HORST1400.

With HORST900, fruitcore robotics launched its affordable robot line with innovative kinematics two years ago. HORST900 now gets two brothers at once: the smaller, fast and precise HORST600 and the larger and more powerful HORST1400 extend the product family. With the expansion of the portfolio the young com- pany, based in Constance, meets the requirements of the market even further.

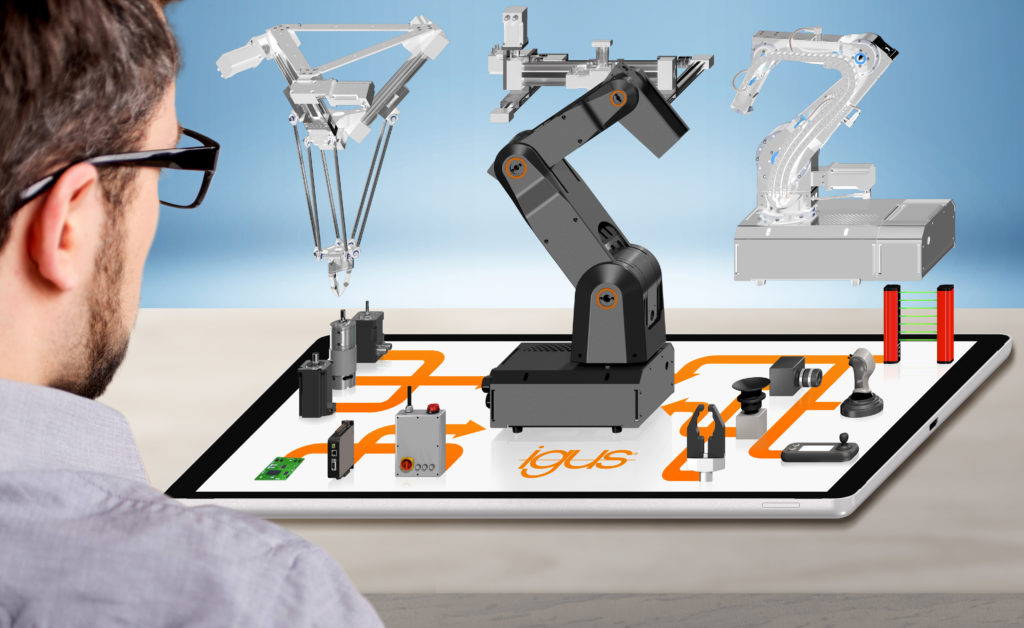

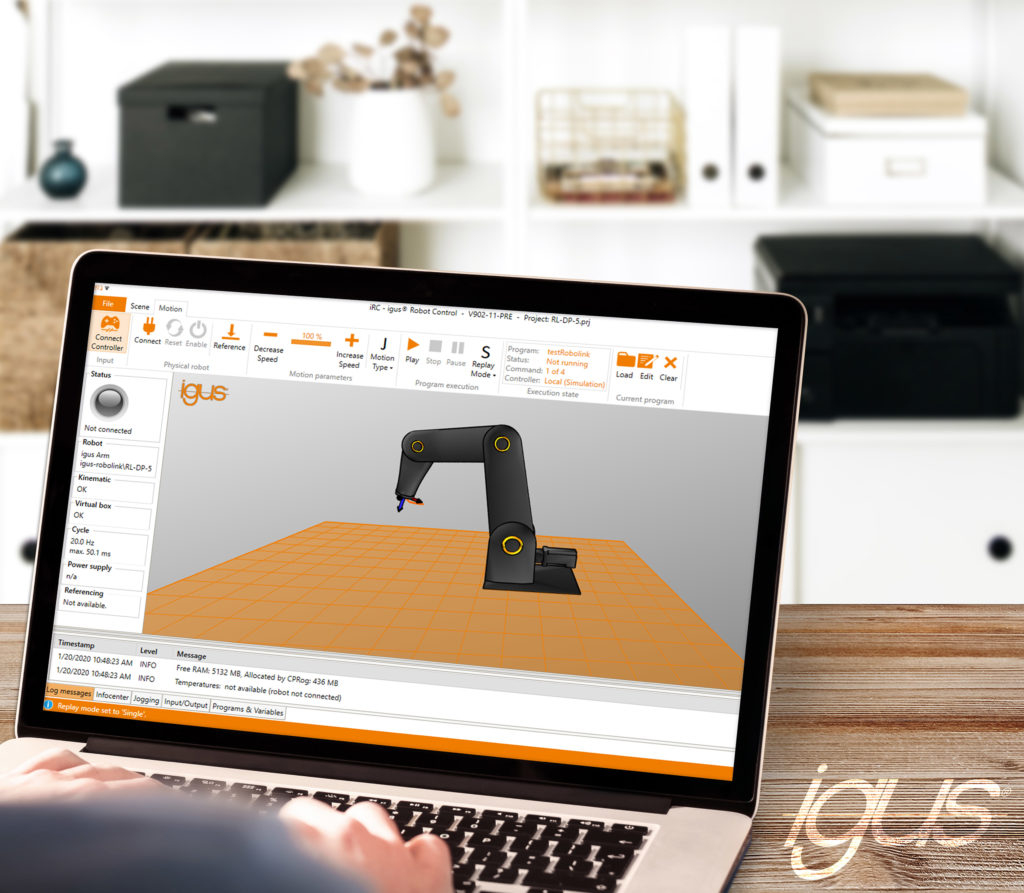

With the two new family members HORST600 and HORST1400, fruitcore robotics presents one industrial robot below and one above the well-established HORST900 in case of range and payload. All fruitcore robotics robot models are easy to operate and offer an unbeatable cost-benefit ratio. Both new family-members are based on the well-proven HORST technology, are Made in Germany and are supplied as a all-in-one solution. All fruitcore robots can be programmed intuitively using the horstFX software developed especially for HORST and the horst- PANEL control unit. The efficient and straightforward communication with external machines and components is made via the safety control system horstCONTROL. The innovative kinematics also show the family resem- blance. But like most brothers, all HORSTs have very different characteristics and strengths.

HORST600: small, fast and precise With HORST600 fruitcore robotics expands its product family with a modular small robot. The smallest HORST is particularly suitable for applications where space is limited and can also be mounted on the wall or ceiling for even more flexibility. With an installation area of 382 x 200 millimetres and a maximum range of 578 millime- tres, HORST600 can move loads of up to three kilograms quickly and precisely – with a repeatability of ± 0.05 mil- limetres. The Industrial robot is available in two different versions: HORST600 is used in industrial environments, for example in metal processing, logistics or in the plastics industry. Typical appications are pick & place applica- tions, palletizing or the loading and unloading of machines. The second version – HORST600 lab („laboratory“) is specially designed for the pharmaceutical and chemical industry as well as laboratorys and research facilities. In addition to the adapted design, this industrial robot is made for the interface requirements of the industry and can be equipped with an appropriate gripper. Specific features and modules also allow easy handling of test tubes or samples. To meet the requirements of the different applications, HORST600 and HORST600 lab are available in two performance classes: the version „fast“ for applications where the cycle time is decisive, and the version“strong“ when the payload is important. Due to the innovative production technology the moving load of HORST600 is very small. The powerful small robot weighs around 23 kilograms. It therefore has different kine- matics than the larger series. The innovative kinematic approach based on four-bar linkage offers its big broth- ers significant stiffness advantages and allows the use of smaller motors and gearboxes, which due to the smaller size of the HORST600 offer no advantages and are therefore not used. The engineers at fruitcore robot- ics focused more on a compact construction when developing HORST600. This construction provides maximum range with the largest possible working space. As with all robots from fruitcore robotics, the modular robot arm is comparatively light and can be easily maintained or repaired.

The encoder technology developed by fruitcore robotics is also used, which in combination with the high-quality drive system guarantees accuracy. With HORST600, fruitcore robotics is also equipping the first robot with the optional playback mode. This allows the operator to guide the robot by hand, which makes programming even easier.

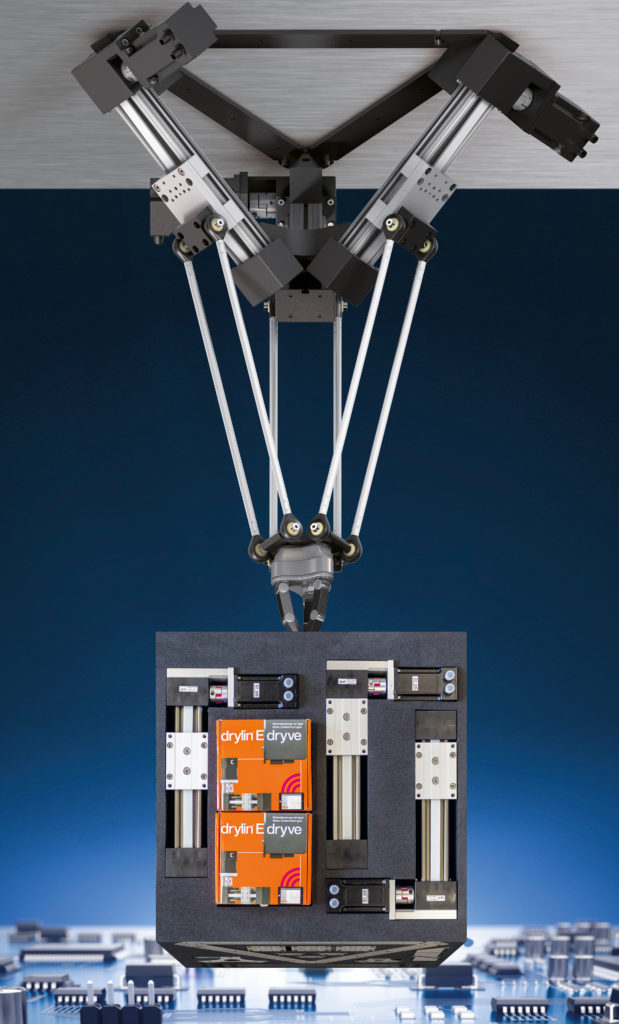

HORST1400: for large payload and range At the top end of the performance scale, in terms of maximum reach and maximum payload, fruitcore robotics introduces its second new robot – HORST1400. It is designed for applications in logistics as well as in the metal or plastics processing industry that require high payloads and ranges or short cycle times.The industrial robot is suitable, for example, for commissioning as well as for loading and unloading machines or mesh boxes. HORST1400 lifts loads of up to ten kilograms and has a maximum range of 1,400 millimetres. The industrial robot HORST1400 is, like its smaller brother HORST900, characterized by its hybrid kinematics based on multiple four- bar linkages, which makes a more efficient use oft the build in motors possible. This makes it possible to use smaller electric motors and gears and still achieve the same quality and dynamics as with conventional robots. The innovative kinematic approach based on four-bar linkage results in a lower overall weight and significantly lower costs.