Bochum, 16. Oktober 2023 – Die United Robotics Group (URG) und das Fraunhofer-Institut für Produktionstechnik und Automatisierung (IPA) haben im Rahmen ihrer neu geschlossenen technologischen Partnerschaft eine Lizenzvereinbarung unterzeichnet. Inhalt der Vereinbarung ist der Vertrieb und die Weiterentwicklung des Laborroboters KEVIN®, der zukünftig von der URG produziert und vertrieben wird. Mit diesem strategischen Schritt baut die URG ihre Präsenz im Bereich Life Science aus.

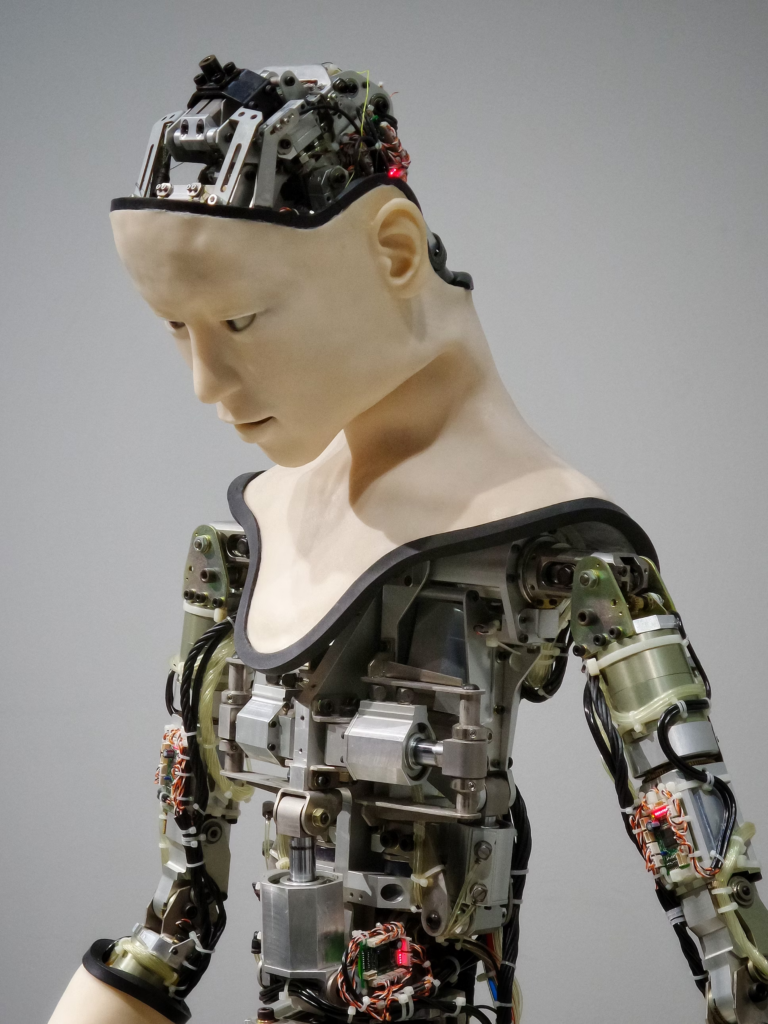

Fraunhofer IPA, Thomas Linkenheil, Co-CEO der URG, Sarah Ostertag, UX & Industrial Design Lead and Product Management und Tobias Brode, Head

of Business Development Lab Automation.

Quelle: Fraunhofer IPA/Foto: Rainer Bez

Zudem erschließen beide Partner wertvolle Synergien für die zukunftsweisende Automatisierung von Laboren – die Forschungs- und Innovationskompetenz des Fraunhofer IPA ergänzt die Robotik-Expertise der URG optimal. Der Laborroboter KEVIN® wurde von der Abteilung für Laborautomatisierung und Bioproduktionstechnik des Fraunhofer IPA entwickelt und mit ersten Testkunden weltweit zur Prototypenreife gebracht. Unter dem Dach der URG soll KEVIN® nun in Serienproduktion gehen. Hierzu erwirbt das Unternehmen eine entsprechende Lizenz zur Nutzung und Weiterentwicklung der Hard- und Software des Roboters.

„Wir freuen uns darüber, dass wir im Rahmen der Zusammenarbeit durch unsere Robotik-Lösungen neue, vielversprechende Perspektiven für die Laborautomation schaffen können. Damit stärken wir unsere Präsenz im Life Science-Bereich – und können gesellschaftlichen Herausforderungen wie dem Fachkräftemangel und dem demografischen Wandel wirksam begegnen,“ erklärt Thomas Linkenheil, Co-CEO der URG.

Mobiler Laborroboter

KEVIN® ist ein autonomer, mobiler Laborroboter. Er automatisiert Prozesse und lässt sich flexibel und intuitiv in Laborinfrastrukturen integrieren. Der Roboter übernimmt repetitive Routineaufgaben. So befördert er Mikrotiterplatten und Racks im SBS-Format, wie etwa Proben oder Consumables zum Nachfüllen. Darüber hinaus kann er Anlagen mit Pipettenspitzen beliefern.

Mit einem Einsatz von KEVIN® rund um die Uhr steigt die Effizienz im Labor. Angesichts des Fachkräftemangels ist eine Entlastung der Belegschaft besonders wichtig, denn so kann sie sich auf besonders wertschöpfende Tätigkeiten konzentrieren.

„Mit der neuen Vereinbarung haben wir der weiteren Entwicklung und Vermarktung von KEVIN® einen entscheidenden Schub verliehen. Automatisierung spielt im Life-Science-Bereich eine zentrale Rolle. Labore können dadurch auf unterschiedliche Bedarfe flexibel reagieren. Umso wichtiger ist es, gemeinsam passende Lösungen für diesen Sektor zu entwickeln“, kommentiert Thomas Bauernhansl, Institutsleiter des Fraunhofer IPA.

Personeller Zuwachs für die URG

Im Zuge der technologischen Partnerschaft zwischen dem Fraunhofer IPA und der URG sowie der Übertragung der Lizenzrechte an KEVIN® kommt es auch zu personellen Veränderungen. So werden Sarah Ostertag und Tobias Brode zur United Robotics Group wechseln. In der URG werden Sarah Ostertag künftig als UX & Industrial Design Lead + Product Management und Tobias Brode als Head of Business Development Lab Automation tätig sein. Beide begleiten KEVIN® von der ersten Idee an bis zum marktreifen Serienprodukt und stärken somit nachhaltig die Expertise im Unternehmen.