A short video showing Cozmo robot from Anki.

Archiv des Autors: Sebastian Trella

Robomotive Labratories introduces immersive reality robot

Cincinnati-based Entrepreneur launches Kickstarter campaign to bring ‘mimic’ innovation to more people

Cincinnati, OH (Oct.1, 2016) – Robomotive Laboratories is changing the way the world sees robotics with the introduction of their transformative new robot, mimic. Today, the Cincinnati-based small family business launched a new Kickstarter campaign (https://www.kickstarter.com/projects/713401305/mimic-immersion-robot) to help advance the development and production of the new technology.

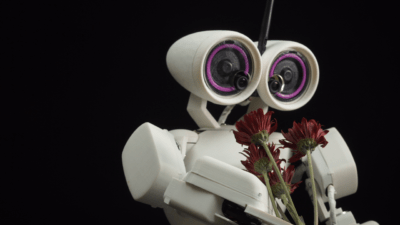

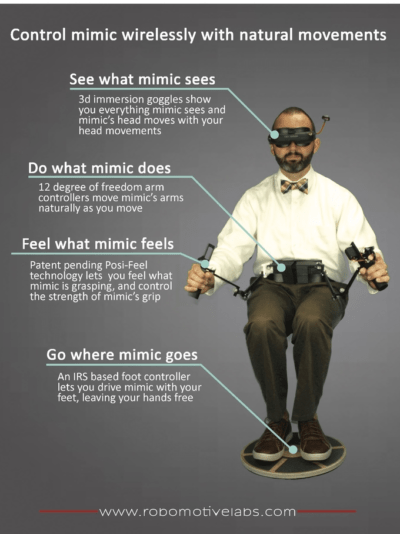

Mimic represents a technological breakthrough in the way people interact with a robot. Through a series of interfaces and controls, the user is transported and able to see what mimic sees, do what mimic does, feel what mimic feels, and go where mimic goes.

“After a successfully-funded Doorbell Phone campaign on Kickstarter, I began to indulge in my love of robotics and introduced the Cortex:Robot Arm controller,” said Brett Pipitone, founder of Robomotive Laboratories. “We continued to develop the technology by adding joints, cameras and motion and soon realized that we had developed something truly unique: The mimic robot was born.”

The key to bringing mimic to life is the mimic arm controller with patent-pending Posi-Feel grip controllers. The user wears a device that allows the seamless control of mimic’s arms and grippers by moving his or her own hands and arms in natural ways while holding two simple handles with trigger style grip controllers. A series of joints, pivots and sensors are built onto the mimic Arm Controller to make this possible.

Mimic can also move around on its own power, controlled by the user with an IRS based foot controller. The user places both feet on the controller and tilts the device forward, back, left, or right to command mimic’s movements in natural, hands free ways.

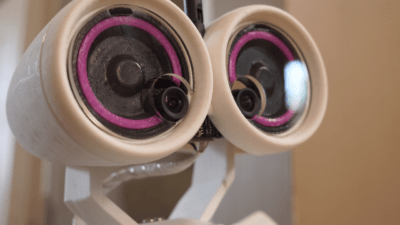

To complete the user’s sense of immersion, immersion goggles receive 3D video from a pair of cameras in mimic’s eyes. Not only does the user see what mimic sees in vibrant 3D, but using a series of sensors and motors the user’s head motion is duplicated by mimic’s head, allowing the user to change view by simply moving his or her head.

This assemblage of new technologies allows the user to see the world from a fresh, new point of view- that of a 12 inch tall, wide-eyed, rotund little robot. In the words of Robomotive Laboratories founder Brett Pipitone „mimic represents a technological breakthrough in think about human interfaces by adapting the robot to the user, rather than the other way around.“

Robomotive Laboratories realized early that a single version of the mimic robot would not fit all users needs, so backers have a choice of four versions of the robot, each design with a different use in mind.

- The mimic:maker version comes in kit form for the user to assemble. The kit includes a robot with two arms and grippers, as well as a mimic arm controller. The kit does not include a body, however, so the user can tailor the robot to their needs or to make something new. For even more flexibility, all the electronic inputs and outputs are exposed to be manipulated or utilized by the user, including record and playback through an on board SD card. „The future is being invented in basements, garages, and maker spaces all over the world. That’s where mimic was born, and mimic:maker is a chance for other tinkerers to use and improve it,“ says Pipitone.

- The mimic:play comes as a fully assembled robot, including the 12- degrees-of-freedom arm controller. While mimic:play doesn’t have as many features as some offerings, it’s just as adorable and its simplicity makes it more accessible for some users. Fun features like the mimic arm controller, Posi-Feeel grippers, and on-board SD card are included. As Pipitone suggests, “mimic:play is simpler than the other versions, but still offers intuitive control and a sense of feel. It’s great for younger users or for interactive settings.”

- The mimic:social has all the features of mimic:play, but also adds the IRS based foot controller, 2D camera, and a video receiver to be attached to the user’s television. „People love the concept of interacting from a distance,“ says Pipitone. „It’s great fun to put mimic:social in a room and watch it’s interactions on TV with your friends.“

- The mimic 3D is the most advanced and full featured version offered and includes the mimic arm controller with Posi-Feel grippers, the foot controller, and SD card, in addition to the immersion googles and 3D cameras. With this full suite of features the user can completely loose themselves in mimic’s world. „This robot really transports you to an immersive reality. Everyday things seem huge, and you can interact from an entirely new point of view,“ describes Pipitone. „I can interact with my baby daughter on her level as an equal, while it’s simple enough that my 6 year old son can pick it up and use it. It’s an indescribable experience.“

The implications of the mimic immersive reality robot are great, and users can be a part of it now by backing mimic on Kickstarter. According to Pipitone, „We’ve delivered the personal robot of the future. We’re still working on flying cars and jet packs.“

For more information, please visit: http://www.robomotivelabs.com/.

Maker Faire Berlin toppt Erwartungen – 17.500 begeisterte Besucherinnen und Besucher beim bunten Kreativfestival

Hannover, 3. Oktober 2016 – Die zweite Auflage der Maker Faire Berlin sorgte für einen neuen Besucherrekord. An drei Tagen wurden 17.500 Besucher gezählt, unter ihnen viele Familien mit kleinen Kindern. Und die kamen auf ihre Kosten: An fast allen 200 Ständen konnte sich der Nachwuchs beim Experimentieren, Bauen, Programmieren, Löten, Basteln oder Schmieden ausprobieren.

Das Motto der Maker Faire heißt Selbermachen und die riesigen Hallen des ehemaligen Postbahnhofs, der Station, boten das passende Ambiente dazu: Während sich die Großen bei Vorträgen und Workshops über die schier unzähligen Möglichkeiten der Technikerfindungen und DIY-Ideen bei den rund 900 Makern informierten, hantierten die Kleinen hochkonzentriert und voller Hingabe mit Heißklebepistole, Lötkolben oder mit Hammer und Säge.

„Wer denkt sich so etwas Cooles aus?“ „Also, ich werde später auch mal Erfinder!“ Hörte man den jungen Besuchern zu und beobachtete sie bei den vielen Mitmachaktionen, muss man sich über die Ingenieure von morgen keine Gedanken machen. „Das Konzept der Maker Faire, vor allem den Nachwuchs für Technikbasteleien zu begeistern, ist hier in Berlin voll aufgegangen“, sagt Daniel Rohlfing, Senior-Produktmanager der Maker Faire. Mit rund 15.000 Besuchern rechneten die Veranstalter und die Erwartungen wurden nach drei Tagen Maker Faire sogar übertroffen.

Bereits am Freitag, dem Schülertag, verwandelte sich die Station in ein großes Kreativlabor. Über 2000 Schülerinnen und Schüler waren mit ihren Lehrkräften unterwegs, um zu sehen, was man mit 3D-Drucker, Fräse oder Laser alles machen kann. Auch die vielen Anwendungen mit den starken Minicomputern, den Arduinos und Raspberry Pis, fanden großen Anklang. Für wahre Begeisterungsstürme sorgten die Robocup-Turniere. Die Jugendlichen fieberten mit den Teams mit und feierten ausgelassen, wenn den kleinen Nao-Robotern ein Tor gelang.

Begehrte Fotomotive waren zudem die Wasteländer, die skurrilen Fahrzeuge im „Mad-Max-Style“, die mit ihrer Show auf dem Außengelände für Aufsehen sorgten. Bestaunt wurden aber auch die kleinen fahrenden R2D2-Droiden, das Endzeitauto oder der Kult-Drumsynthesizer MR-808. Darüber hinaus lud ein ausrangierter Volvo, umgebaut zum Legoauto zum Bebauen ein. Etliche bunte Legoklötzchen in immer neuen Variationen verschönerten das Auto.

Die nächste Maker Faire Berlin findet vom 9. bis 11. Juni 2017 erneut in der Station statt. Interessierte Maker können sich ab sofort mit ihren Projekten bewerben.

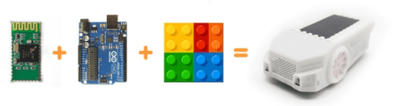

blinkgogo – Wireless program Arduino & Fun Robotic Learning Platform

I just received this information from the blinkgogo team:

“Wireless program Arduino & Fun Robotic Learning Platform. Designed for STEM education, Open Source! APP controlled, based on Arduino, supports Scratch. Let kids Play and Learn! ”

Blinkgogo is a open source fun STEM robotic learning platform based on Arduino. Blinkgogo supports wireless Bluetooth upload, APP controlled, Scratch.

This robot kit has everything you need to get started. You can demonstrate many standard robot functions right out of the box. It’s simple, easy to use and fun.

With Blinkgogo, you can build many standard robots for example Line Following robot, Light Seeking robot, Edge Detection robot, APP control robot.

It comes with 3D printed shell and compatible with LEGO blocks.

Blinkgogo also comes with a hardware expansion board for those who really want to go wild when it comes to trying new things and developing new robotics systems.

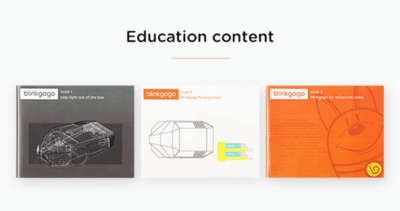

Blinkgogo comes with three step-by-step tutorials to help you learn programming.

- Binkgogo play right out of the box Tutorial: Blinkgogo works right out of the box. You can demonstrate many standard robot functions. You can drive it by controlling it with your phone through it’s Bluetooth capability. Or have it follow a black line.

- Blinkgogo for Beginners Tutorial:Blinkgogo comes with a number of step-by-step tutorials. It is easy to program with the scratch graphical programming language. For the more extreme programmers it also works with C++. And the Arduino IDE programming environment

- Blinkgogo for Advanced Users Tutorial:Blinkgogo offers a lot for advanced users. Blinkgogo comes with a hardware expansion prototyping plate where you can mount servos and many other sensors.

It’s perfect for STEM education:

In the home

Perhaps your home has many toys already. However we believe to prepare for the future children need toys that are made to be modified and programmed. Children need to learn not just to be consumers but to actively participate in the building and modifying of things around them.

In school

Everybody knows that STEM education is important however most robotics platforms do not come with enough easy to use tutorials out of the box to be used by most non-engineers and still have enough flexibility to be still useful to those who excel in programming.

Why we made this kit?

Ever since I was a child I have always wanted to learn how to make electronics. Now that I am an electrical engineer my dreams are now a reality. However in the past when friends and asked if they could do electronics, my only answer was you need to go to school to be an electrical engineer.

Luckily time to change. Thanks to Arduino and other open-source platforms it’s not only possible for my friends to start their own hobby electronics products I can now start teaching my two children Harry and Tina. I have selfishly developed Blinkgogo specifically to teach my children electronics. But due to enthusiasm from my neighbors I have developed Blinkgogo into a product to share with the world. I hope you have as much fun with Blinkgogo as I did developing it and share it with my children.

We are on kickstarter now!

We are now crowdfunding on kickstarter now. We got over 60% funds within 24 hours. Please support us and let more kids can enjoy this all-in-one robotic learning platform!

Website: www.blinkgogo.com

Video: https://www.youtube.com/channel/UCgj2axca16VY3bHaIBzzzuQ

Facebook: https://www.facebook.com/blinkgogorobot/

Twitter: https://twitter.com/BlinkgogoRobot

Google+: https://plus.google.com/u/0/111819239969740793655

Kickstarter link: https://www.kickstarter.com/projects/makerstudio/blinkgogo-wireless-arduino-and-fun-robotics-learni?ref=4a4oio

Trending on Kickstarter: ‘MOTI’ is your personal robotic companion for building healthy habits

SAN FRANCISCO, CALIF. — Emerging from an industry saturated with apps and wearables, San Francisco based startup MOTI (www.moti.io) is seeing tremendous support on Kickstarter, exceeding a goal of $50,000 within the first five days of launching. At 23 days left on the campaign, MOTI has over 700 backers, and has now released additional “stretch goals” for their little robot. These goals include adding a wild card color that backers can vote on, integrations with Fitbit, Evernote, and Google Calendar, as well as a new top secret feature – should the campaign reach $175,000.

Who is this little robot and why is everyone so intrigued by him? First, MOTI is a physically present smart companion for building better habits. The device combines insights from behavioral science, social robotics and human-centered design, and is built to learn and react to human beings’ psychological triggers with the purpose of getting them to start practicing healthy habits (such as jogging, hydrating, meditating, etc). Second, what makes him different is that unlike a standalone app, MOTI’s very physicality, presence, and emotional AI contributes to his ability to effectively influence behavior. Standing at just under three inches tall, MOTI acts as an ever-present environmental queue that is meant to interact with you in the moments and places where you would normally start forming your habit (i.e. your kitchen, your work desk, your yoga space,etc.).

The science and design behind MOTI’s habit-forming influence draws from the habit-loop theory, which explains that in order to build any habit, three things are required: a trigger, a routine, and a reward. To help you form your habit, MOTI supports all three things through a combination of lights, haptics, human-like intonations and other sounds. In order to have the best effect on behavior, MOTI is also designed to form a bond with the user, and his personality is continually adapting to the users’ needs.

“What we found in early research is that apps and wearables rely on data, graphs, and tracking for motivation,” says Kayla Matheus, Inventor and Co-Founder of MOTI. “But we’re human – we need more than just numbers. We need our technology to understand how we work at a psychological and emotional level. That’s why MOTI isn’t another device – he’s your friend, or your cheerleader, or even your mom.”

Live demos are available today at BulletProof Bio-Hacking conference, and customers can now pledge an order for their own MOTI at http://kck.st/2d8NBu2 , on sale for $99 each and available in light grey, dark grey, and turquoise.

About MOTI

MOTI is a behavior change company combining science and design to create transformative products that help people live better lives, one habit at a time. Established March 2015 in New York City, the company is led by Founder and CEO Kayla Matheus (Yale BA’11) and Founder/COO Laura Day (Vanderbilt BE’02, Harvard Business School MBA ‘09). MOTI is an alum of Google 30 Weeks and Highway1 Accelerators. Connect with MOTI via Facebook, Twitter, and Instagram (@habitMOTI) or visit www.moti.io to learn more.

Robodonien 2016 Photos

- SAMSUNG

- SAMSUNG

- SAMSUNG

- SAMSUNG

- SAMSUNG

- SAMSUNG

- SAMSUNG

- SAMSUNG

- SAMSUNG

Robodonien 2016 in 360°

People Power Announces World’s First iOS and Android Enabled Smartphone Security Camera Robot – Presence 360

Breathe New Life Into an Unused Phone With the Intelligent Motion-Sensing Smartphone Robot That Can Automatically Keep an Eye on the Most Important Locations in Your Home

DALLAS, TX–(Marketwired – Sep 13, 2016) – People Power, a services enablement company providing apps, cloud and mobile services for the Internet of Things (IoT), today announces Presence 360, the world’s first 360-degree smartphone security camera robot that reveals existing blind spots in home security. Presence 360 integrates with People Power’s free Presence app, which reimagines spare smart devices into remotely monitored video cameras and has already sent more than 80 million Presence Video Alerts worldwide. By downloading the Presence app on an unused smartphone and cradling that device in Presence 360’s adjustable arms, users can monitor their homes and loved ones in 360-degrees, control viewing angles remotely and automatically receive motion detected video alerts when they’re away from home. People Power will be demoing Presence 360 at the CEDIA Expo 2016, September 15-17, 2016, at booth 4171.

Traditional security cameras are costly and only let you see a single static view, which leaves users blind to anything outside of the camera’s visual range. Presence 360’s full pan-and-tilt and 360-degree rotation allows users to look all around. Users can customize how long the camera remains at each vantage point too. Set Presence 360 to automatically pan to the front door for 15 seconds, the kitchen window or any other area of the home. Presence 360 cycles through those vantage points automatically to search for intruders or activity — recording video the instant motion is detected. When motion is detected, a Presence Video Alert of the activity is sent straight to the user’s smartphone as well as to their trusted circle of family and friends.

“In an era where technology is helping workers make impressive strides in productivity, we still find a big need for technology that lets consumers know what’s happening at home when they can’t be there,” said Gene Wang, CEO and co-founder of People Power. “Unless you’ve budgeted for a complicated and expensive home surveillance system, you may never know what’s happening until it’s too late. By revealing those nagging blind spots, Presence 360 brings people peace of mind, and is paving the way for a new era of lifestyle security.”

The Presence Security Pack extends the value of Presence 360. It works through the Presence app and combines entry, motion, water, humidity, temperature and touch sensors to create a whole home monitoring solution.

Also announced today is a significant performance increase to the Android version of Presence, which comes as a result of a conscientious refactoring of the popular mobile application. Android users will experience an increase in performance 3 times greater with the new version of Presence, available today in the Google Play Store.

Presence 360 is compatible with iOS and Android smartphones. To pre-order Presence 360, visit https://www.indiegogo.com/projects/presence-360-smartphone-security-camera-robot-99-app#/.

About People Power

Founded in 2009, People Power Company is an award-winning software company with a successful legacy in mobile and cloud technology. The People Power IoT Suite enables rapid connection, engagement, delivery and management of IoT products and services for services providers, manufacturers and consumers searching for connected lifestyle enhancements. Its ready-made cloud and mobile software stacks connect people with networked devices to humanize the Internet of Things. Services from concept through commercial release enabled by People Power are available as white-labeled solutions for customers around the world. For more information, visit www.peoplepowerco.com

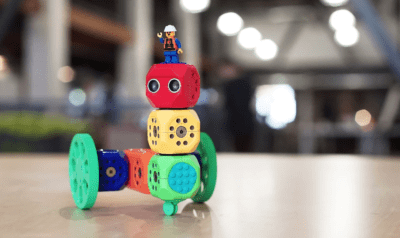

Robo Wunderkind raises $500,000 and announces a new mobile application

Vienna, Austria, Sept. 20, 2016 — The Vienna-based hardware startup Robo Wunderkind, which develops modular programmable robots for young children, announced today a $500,000 funding round with participation from Arkley VC as lead investor, business angel Juergen Habichler, and the Austrian Federal Promotional Bank (AWS). The funding will go into the widening of their retail reach and the expansion into new markets. The plan is to build a worldwide distribution system and to give young customers from everywhere a chance to learn coding and robotics in a fun and simple way.

The startup already raised $250,000 from backers from 58 countries on Kickstarter in October 2015 and by now collaborated with more than 50 schools around the globe to bring Robo Wunderkind to the classroom. Its vision is to revolutionize the way children interact with technologies through developing educational hardware and software products.

Piotr Wasowski, Managing Partner of Arkley VC:

“I expect Robo Wunderkind to transform how our kids interact with technology. Even very young children will be able to learn the basic principles of programming, which are vital for their future careers and for understanding the world around them.”

Juergen Habichler, Business Angel:

“Robo Wunderkind is the future of education. I have been looking for a long time to find a visionary team, which combines robotics with education. I strongly believe that Robo Wunderkind has the potential to become the education platform for kids, students as well as adults.“

Today, the startup is also announcing its new application to remote control electronic devices: the Robo Play App. Its simple programming interface will allow users to easily create personalized virtual dashboards to control the robots they will build with Robo Wunderkind modules, remotely via Bluetooth or Wifi. In the next step, the team is going to make the Robo Play App compatible with other Internet of Things (IoT) devices, such as cameras, lights, motion and light sensors.

Rustem Akishbekov, co-founder and CEO at Robo Wunderkind:

“In the beginning, we wanted to create an interface that will allow even a 5-year old to control our robotics kit. Eventually, we created a platform that will allow us to expand our target audience and reach older users. With our app, everyone will be able to control their IoT devices with the help of a very intuitive and customizable app. The way our robots prepare young kids for the digital world of the 21st century, our app will open the world of IoT devices to everyone.”

Yuri Levin, Chief Design Officer:

“With the help of our user-friendly and intuitive design, we are making interaction with IoT devices seamless and accessible for the wider audience.”

Robo Play App is free and will work on both Android and iOS devices. It will be compatible with all Robo Wunderkind kits, which are already available for pre-orders on their website with shipping planned for later this year.

About Robo Wunderkind

Robo Wunderkind was founded by Rustem Akishbekov, who brought Anna Iarotska and Yuri Levin on board in 2013. The company is based in Vienna, Austria, and maintains an office in Shenzhen, China. In the last three years, the founders have gathered a team of passionate engineers and designers dedicated to the vision of making coding and robotics accessible to everyone. Their first product is an educational robot that syncs with intuitive mobile applications to help children understand the basics of programming. Robo Wunderkind was part of the world’s first and largest hardware accelerator HAX in 2014 and Finalist of TechCrunch Disrupt SF Startup Battlefield in 2015.

Giant Cardboard Robots

I just received this message from the „Giant Cardboard Robots“-Team:

Are you in need of inspiration for your kid’s next Halloween Costume? Check out Giant Cardboard Robots, a project that makes Kid-Sized Giant Cardboard Robot Arms a reality.

At Giant Cardboard Robots, we have been making and selling adult size giant cardboard robot arms for the past several years, and now we have put together an offering especially for the junior giant robots among us.

Our Kickstarter rewards include DIY kits for cardboard robot arms in both the kid and adult sizes, plans to allow crafters to make their own robot arms from cardboard they have laying around, as well as some truly unique corrugated creations ranging from a giant robot pirate hook to a wearable giant cardboard jack-o-lantern head.

We have launched a Kickstarter campaign that will run until September 30 and has been picked by Kickstarter itself as a „Project We Love“.

More information: http://kck.st/2bqTqjP