A short unboxing video showing the new Dexter Industries Gigglebot for the BBC Microbit. More information: https://www.gigglebot.io/

Archiv der Kategorie: English

Maker Faire Eindhoven 2018

Free VEX Coding Studio Youtube Webinars

Ready to transition your coding skills to VEX Coding Studio? Carnegie Mellon University is hosting a free, four week webinar series detailing everything you’ll need to know to transition from RobotC!

Be sure to tune in to Carnegie Mellon’s YouTube stream (almost) every Thursday, from September 13th to October 11th for your introduction to VEX Coding Studio. We’ll cover topics such as updating firmware, configuring motors and sensors, and programming with VEX C++ and Modkit. If you have any additional topics that you want covered on-air, be sure to ask beforehand on Twitter @CMUCMRA !

To set your YouTube reminders or to see a detailed weekly outine of these webinars, visit the Carnegie Mellon University Website.

New iRobot® Roomba® i7+ Robot Vacuum Learns a Home’s Floor Plan and Empties Itself

BEDFORD, Mass., Sept. 6, 2018 /PRNewswire/ — Imagine a robot vacuum that not only remembers a home’s floor plan and cleans specific rooms by name – but also automatically empties itself. iRobot Corp. (NASDAQ: IRBT), the leader in consumer robots, today announced the Roomba® i7+ robot vacuum with Clean Base™ Automatic Dirt Disposal. The Roomba i7+ brings a new level of intelligence and automation to robotic vacuum cleaners with the ability to learn, map and adapt to a home’s floor plan. Introducing Imprint™ Smart Mapping, the Roomba i7+ remembers multiple floor plans and room names so users can customize cleaning jobs and direct the robot to clean specific rooms by voice1 or via the iRobot HOME App. When the Roomba i7+ robot vacuum is finished cleaning, it empties its own dust bin into the Clean Base™, which holds 30 bins of dirt, allowing customers to forget about vacuuming for weeks at a time.

Experience the interactive Multichannel News Release here: https://www.multivu.com/players/English/8234051-irobot-roomba-i7-plus/

„With the ability to learn, adapt to and remember a home’s floor plan, and the introduction of automatic dirt disposal, the iRobot Roomba i7+ represents the most advanced robotic vacuum ever built,“ said Colin Angle, chairman and CEO of iRobot. „This robot delivers on the original vision we had when we embarked on the journey to build a vacuuming robot almost 20 years ago.“

Knows your home’s floor plan. Understands your command.

Ushering in a new era of consumer robots, the Roomba i7+ allows customers to clean specific rooms in the home. Using Imprint™ Smart Mapping, the Roomba i7+ gets to know the home’s floor plan, giving customers total control to choose which rooms are cleaned and when. The robot learns every room – remembering up to 10 different floor plans – so users can carry their robot to another floor or a separate home, where the robot will recognize its location and clean as instructed. iRobot’s patented iAdapt® 3.0 Navigation with vSLAM® technology helps the Roomba i7+ seamlessly and efficiently navigate the home by keeping track of where it’s been and where it has yet to clean. The Roomba i7+ also adapts to changing home environments, so it always knows the best way to clean.

The Roomba i7+ works with Alexa™ enabled devices and the Google Assistant, and is the only robot vacuum that lets users clean specific rooms by name with a voice command1. For example, just say, „Alexa, ask Roomba to clean my kitchen,“ or „Hey Google, clean the living room,“ and the Roomba i7+ will efficiently find its way to the appropriate room to clean. Once finished, the robot will return to its base to charge and automatically empty its contents when paired with the Clean Base™ Automatic Dirt Disposal.

Empties on its own.

The iRobot Roomba® i7+ robot vacuum takes convenience to a whole new level with the first-of-its-kind Clean Base™ Automatic Dirt Disposal, which automatically empties the contents of the Roomba i7+ dust bin into the Clean Base. Doubling as the robot’s charging station, the Clean Base takes the dirty work out of vacuuming, storing debris in an enclosed bag, and trapping dirt and dust so it can’t escape into the air. When the bag is full, the user is notified via the iRobot HOME App. Then they simply pull it out of the Clean Base and replace with a new one. The bag can hold 30 bins of debris, so users don’t have to think about vacuuming for weeks at a time.

„iRobot is addressing a long-standing customer call by giving Roomba the ability to empty its own bin after each cleaning,“ said Christian Cerda, COO of iRobot. „This enhances the customer experience by eliminating the dusty and dirty mess often associated with emptying vacuum canisters. With the ability to remember the home, clean specific rooms and empty itself when its finished, the Roomba i7+ with Clean Base Automatic Dirt Disposal quite literally frees customers from every aspect of vacuuming – from start to finish – for weeks at a time.“

Introducing the Roomba® e5 Robot Vacuum.

iRobot also introduced the Roomba® e5 robot vacuum. Starting at $449, customers can enjoy the luxury of automated cleaning at a more accessible price. The Roomba® e5 is packed with innovative technologies that work together for a clean home every day. It starts with the premium 3-Stage Cleaning System and Dual Multi-Surface Rubber Brushes. The specially designed Edge-Sweeping Brush focuses on dirt that accumulates around edges and corners. Smart navigation and Dirt Detect™ technology work together to cover a floor and focus on the areas that need it most. And because it’s Wi-Fi® connected, users can control and schedule cleanings on the Roomba e5 with the iRobot HOME App, or using their voice when paired with Alexa™ enabled devices or the Google Assistant.

Powerful performance, intelligent clean.

iRobot is the only leading robot vacuum brand with robots that have two Multi-Surface Rubber Brushes that work together to effectively clean both carpets and hard floors2. The Roomba i7+ and Roomba e5 robots will automatically adjust the height of the cleaning head so the two brushes can directly engage with the floor. One brush loosens and agitates dirt and the other moves in the opposite direction to extract and pull dirt in. And instead of bristles, which can bend and miss dirt, the flexible rubber brushes hug the floor to clean everything from small particles, like dust and dirt, to hair and large debris.

Featuring a low-profile design to clean under furniture and along toe kicks, the Roomba i7+ and Roomba e5 robots use a High-Efficiency Filter to capture 99 percent of pollen, mold, dust mites, and cat and dog allergens.

Leveraging Dirt Detect™ Technology – an iRobot patented feature – the Roomba i7+ and Roomba e5 robots are always looking for the places that need the most attention. Sensors in the robot recognize particularly dirty areas, such as sand near a doorway entrance, and prompt the robot to clean them more thoroughly. Once the Roomba i7+ robot is finished cleaning, users can view Clean Map™ reports in the iRobot HOME App to see where the robot cleaned and other details3.

Pricing and Availability

The Roomba i7+ robot vacuum with Clean Base™ Automatic Dirt Disposal is available for pre-sale immediately in the U.S. and Canada starting at $949 USD on www.irobot.com, with shipments beginning Wednesday, September 12. The Roomba i7+ will be available at select retailers beginning in October. The Roomba i7 robot vacuum can also be purchased without the Clean Base™ starting at $699 USD on www.irobot.com. The Clean Base™ Automatic Dirt Disposal sold separately will retail for $299 USD. Additional Dirt Disposal Bags can be purchased for $14.99 for a pack of three bags. The Roomba i7+ with Clean Base™ Automatic Dirt Disposal is expected to be available in certain international markets in Q1 2019.

The Roomba e5 robot vacuum starts at $449 USD and will be available on www.irobot.com in the U.S. and Canada beginning Wednesday, September 12.

Sony Announces Limited First Litter Edition Release of aibo in U.S.

NEW YORK, Aug. 23, 2018 /PRNewswire/ — Sony Electronics Inc. today revealed plans to offer a special First Litter Edition of its acclaimed aibo autonomous robotic „puppy“ companion in the United States. Following the recent reintroduction of aibo in Japan, Sony’s First Litter Edition for the U.S. will be a limited, all-in-one aibo bundle that includes the aibo1, a three-year AI Cloud Plan2, a fun assortment of aibo toys, and an individually numbered commemorative dog tag.

First introduced in 1999, the latest design of aibo is the sixth generation of Sony’s beloved companion robot. Unlike previous versions, it pairs cutting-edge robotics with a new, cloud-connected artificial intelligence (AI) engine and advanced image sensors, giving aibo the ability to learn and recognize faces. As aibo interacts with people over time, it develops its own unique personality through everyday interactions, enabling it to remember what actions make its owner happy and form a deep bond with members of the household.

No two aibo companion robots are the same. Each owner’s approach to raising their aibo shapes its personality, behavior and knowledge, creating a unique environment for growth. In fact, aibo is able to learn new tricks through owners‘ interactions, experiences with changing seasons and different events. Not content to sit and wait to be beckoned, aibo will actively seek out its owners and can recognize their faces. It can also detect words of praise and smiles, as well as react to being petted or scratched on the head.

„This is truly a one-of-a-kind product designed to connect with its owners on an emotional level,“ said Mike Fasulo, president and chief operating officer of Sony Electronics North America. „aibo’s charming personality, dog-like behaviors and ability to intelligently interact with family members help to create a personal bond. Bringing aibo back to the U.S. reflects Sony’s broader commitment to provide consumers with products that not only entertain them, but also enrich their lives.“

To create such a loveable, expressive and life-like robo-puppy, Sony integrated a wide range of sensors, cameras and actuators to bring aibo to life. Ultra-compact 1- and 2-axis actuators give aibo’s body the freedom to move along a total of 22 axes. Its adaptable behavior is made possible through deep learning AI technology in the form of built-in sensors that can detect and analyze sounds and images. aibo’s whimsical body language is expressed through a combination of eye, ear, and tail movements, as well as different voice sounds. In addition, two OLED displays are utilized for aibo’s eyes and give the appearance of blinking and closing, allowing for diverse, nuanced expressions.

Like any pup, aibo enjoys playing with a variety of toys. Sony’s First Litter Edition aibo will arrive with a pink ball, an „aibone,“ paw pads and charging station. Users can also take their aibo experience to the next level with the „My aibo1 2“ app. In addition to accessing system settings and owner information, the app’s handy user interface allows owners to check out and share their aibo’s pictures, as well as add „tricks“ to its repertoire. The app is packed with fun-filled features—even for people who don’t have an aibo of their own.

The three-year AI Cloud Plan2 included in the First Litter Edition bundle enables aibo to upload its day-to-day life experiences to Sony’s leading-edge AI engine. This database of memories is accessed to form each aibo’s unique personality, which grows and evolves over time. The aibo AI Cloud Plan also enables users to enjoy the full range of aibo features via Wi-Fi connection at home or a mobile connection on the go.

Sony’s latest generation aibo is one of the products of the Company’s broader commitment to technology innovation, particularly in the areas of AI, robotics and image sensing. This commitment has enabled Sony to achieve other innovations in these areas, such as its Neural Network Console, an integrated software development environment for creating deep learning programs for artificial intelligence; Sony’s recent agreement with Carnegie Mellon University to collaborate on artificial intelligence and robotics research; and the introduction of a compact CMOS image sensor with resolution rivaling SLR cameras.

By looking for new ways to bring joy to people’s lives through technology innovation, such as with aibo, Sony is staying true to its philosophy of Kando – creating an emotional connection with Sony’s customers. Similarly, the company has designed aibo’s packaging from 50 percent post-consumer recycled plastic as a reflection of its commitment to environmental sustainability.

aibo First Litter Edition with accessory bundle and three-year AI Cloud Plan will be available for purchase in September 2018 at a suggested retail price of $2,899, with delivery in time for the holidays. Additional details will be announced in the coming weeks. To get the latest aibo updates via email and find additional information on fun aibo features and accessories, visit us.aibo.com

aibo will be exhibited at Sony Square NYC from August 24th to October 14th. The exhibit is open to the public and is the only place to experience aibo before it goes on sale.

About Sony Electronics Inc.

Sony Electronics is a subsidiary of Sony Corporation of America and an affiliate of Sony Corporation (Japan), one of the most comprehensive entertainment companies in the world, with a portfolio that encompasses electronics, music, motion pictures, mobile, gaming and financial services. Headquartered in San Diego, California, Sony Electronics is a leader in electronics for the consumer and professional markets. Operations include research and development, engineering, sales, marketing, distribution and customer service. Sony Electronics creates products that innovate and inspire generations, such as the award-winning Alpha Interchangeable Lens Cameras and revolutionary high-resolution audio products. Sony is also a leading manufacturer of end-to-end solutions from 4K professional broadcast and A/V equipment to industry leading 4K Ultra HD TVs. Visit www.sony.com/news for more information.

__________________________________

1 „My aibo“ will be available at Google Play and the App Store from the day on which the aibo is shipped. A web browser version is also available at the same time. Network services, content, and the operating system and software of this Product may be subject to individual terms and conditions and changed, interrupted or discontinued at any time and may require fees, registration and credit card information.

2 aibo and aibo AI Cloud Plan subscription required to fully enjoy all features of „My aibo.“ App

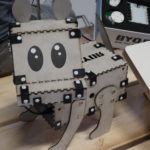

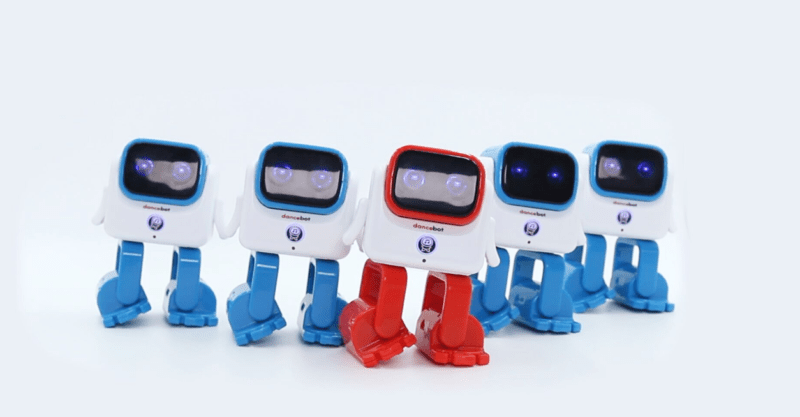

World’s first smart dancing robot speaker, dancebot, gets funded just 2 hours from launch

Expressive robot speaker connects with any Bluetooth-capable device and converts any type of audio played in real time into motion using intelligent algorithm to drive the feet of the robot using bionics technology.

HOUSTON – Aplus Drones is pleased to announce the launch of Dancebot, a smart dancing robot speaker designed with intelligent algorithm technology, today on Kickstarter. Dancebot reached its funding goal of $10,000 in just 2 hours.

Dancebot is the world’s first smart dancing robot speaker. Connect your device to Dancebot via Bluetooth and use it as a speaker. Dancebot will move to the audio it plays.

Aplus Drones has developed an algorithm to analyse audio input on the fly to string together movements that best express the sound played through Dancebot. It moves to the rhythm and tempo of music in its adorable expression of the songs. It taps its feet and jives to upbeat tunes. It slides in silky sleek movements to bring out the sexy in slow pieces.

Dancebot is designed with two joints in each leg. A motor drives each joint through 360 degrees of motion. Aplus Drones engineers have been creating a database of movements Dancebot is capable of. The variation of speed and degree of motion at each joint creates multiple permutations of possible moves that can be achieved with the four joints. The large library of movements and on-the-fly analysis means Dancebot has a different dance routine each time it jives to the same song.

The movement expressed by Dancebot depends on the audio it plays. Besides playing music, Dancebot can be used to play audiobooks, videos, podcasts or even voice messages.

This makes Dancebot the perfect companion for children. Play a children’s audiobook or nursery rhymes with Dancebot and it will move to the narration of the story and dance along to the nursery rhymes. Dancebot’s animated movements makes learning more engaging and a whole a lot more fun.

The startup sound for Dancebot can be customized into a personalised message, making it ideal as a gift.

For more information or to purchase Dancebot at a special discount during crowdfunding, visit the Dancebot Kickstarter campaign page.

About Aplus Drones

Aplus Drones is an entrepreneurial technology company focusing on artificial intelligence and robotic technology development. The company provides award-winning product design, product development, manufacturing, marketing, logistics and shipping services. Full control over the whole supply chain makes Aplus a one-stop solution for clients.

About Dancebot

Dancebot is a smart dancing robot speaker that is a fun audio companion. It moves to the rhythm and tempo of the audio played through it. Play music, audiobooks, podcasts, videos or even voice messages

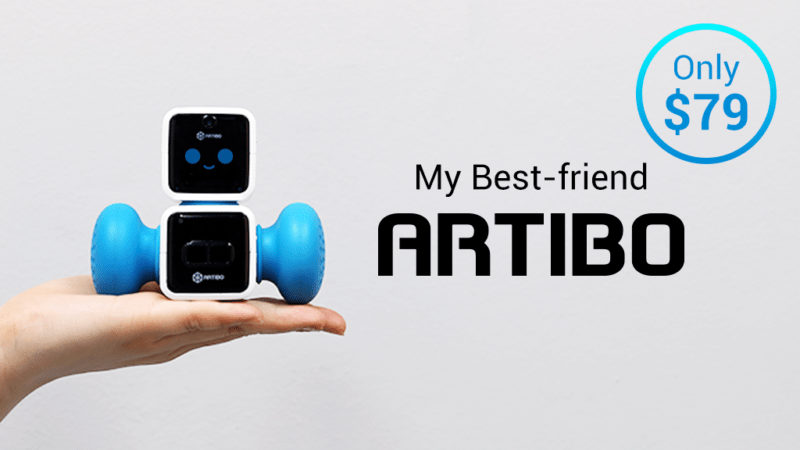

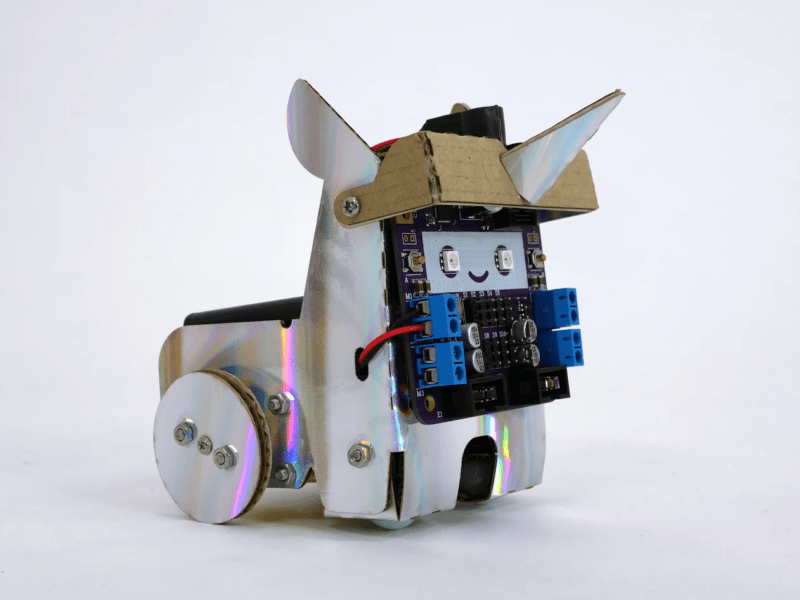

My Best-friend ARTIBO

Introducing Cubroid’s second robot project: ARTIBO! Cubroid originally launched in 2017 with its AI educational Coding Blocks and is back with a new robot for coders, non-coders, kids and adults all alike. Only having been showcased at trade fairs such as The International Consumer Electronics Show (CES) and The Mobile World Congress (MWC) so far, Cubroid will now make Artibo available to general consumers.

Currently robots trendy among those with interest in such technology. However, going forward, robots will have a huge influence on people’s daily lives as a whole. “We put our best effort forward to make everyone who is interested in robotics have an opportunity to easily enjoy this robot. That’s why being well-designed and functional is key in how Artibo was created” says CEO and Founder, Mark Shin.

Artibo is your very own AI best-friend, designed to make daily life that much more simple. An at-home assistant that is small enough to fit anywhere and also efficient enough to go anywhere you go.

Artibo comes with an AI block (which houses the camera, microphone, speaker and LED screen), a motor block, a connector block (to join the AI and motor block) and silicon wheels.

When all the pieces are connected, Artibo stands at approximately 97mm tall and weighs less than a pound (240g) – with the AI block weighing less than half a pound

With separate (but buildable) parts, you can separate the AI block and place it on your desk while you work or connect all the parts and have Artibo follow you from one room to the next. With Artibo, buying multiple to have one in every room is unnecessary.

The features you would like your Artibo to display are customizable from a list of features such as walkie-talkie, scheduler, music, voice recognition, and many more. Each feature having a corresponding display that is shown on the LED screen.

Keeping with the core of what Cubroid does, you can also code Artibo for even more personable interactions and functionality. Kids can also continue their coding education from coding with Cubroid Coding Block to now coding with Artibo.

On Kickstarter preorder of Artibo will be available from July 31st 2018 to September 30th 2018. With Super Early Bird prices starting as low as US$79. Artibo’s prices are set so low to give as many people as possible the opportunity to afford and experience such a robot. After achieving the set goal, Cubroid estimates manufacturing and delivery to be completed by the end of November 2018. We proudly introduce you to your own AI robot: Artibo!

https://www.kickstarter.com/projects/cubroid/my-best-friend-artibo

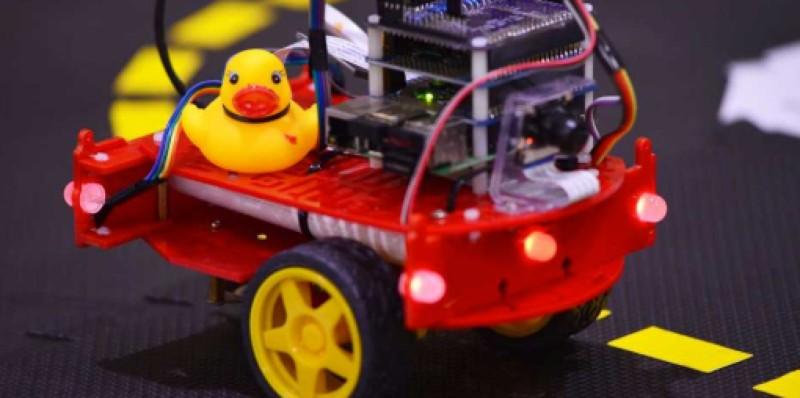

The Duckietown Foundation announces the AI Driving Olympics (AI-DO), a self-driving car competition to debut at NIPS 2018

The Duckietown Foundation is excited to announce the The AI Driving Olympics, a new competition focused around AI for self-driving cars. The first edition of the AI Driving Olympics 2018 will take place December 7, 2018, at Neural Information Processing Systems (NIPS), the premiere machine learning conference, in Montréal. This is the first competition with real robots that will take place at a machine learning conference.

The competition will use the Duckietown platform, a miniature self-driving car platform used for autonomy education and research. The Duckietown project originated at MIT in 2016 and is now used by many institutions worldwide.

The AI Driving Olympics is presented in collaboration with 6 academic institutions: ETH Zürich (Switzerland), Université de Montréal (Canada), National Chiao Tung University (Taiwan), Toyota Technological Institute at Chicago (USA), Tsinghua University (China) and Georgia Tech (USA), as well as two industry co-organizers: nuTonomy (a self-driving car company) and Amazon Web Services (AWS).

About the competition: The competition comprises 4 challenges of increasing complexity: 1) Road following on an empty road; 2) Road following with obstacles; 3) Point to point navigation in a city network with other vehicles; and 4) Fleet planning for a full autonomous mobility on demand system.

Competitors will have access to a suite of professional development tools (simulators, logs, baseline implementations). Real environments called “Robotariums” will be remotely accessible for evaluation. The highest scoring entries in the robotariums will be run during the live event at NIPS 2018 to determine the overall winners.

Scientific goals: The competition aims at directing academic research towards the hard problems of embodied AI, such as modularity of learning processes, and learning in simulation while deploying in reality.

Social goals: The competition also promotes the democratization of AI and robotics research by using an inexpensive platform, and offering a common infrastructure available through the use of remote testing facilities. Competitors can also build or acquire their own testing facility (Duckiebots and a Duckietowns), through either open-source DIY instructions, or as rewards obtained in our kickstarter campaign (https://www.kickstarter.com/projects/163162211/duckietown-a-playful-road-to-learning-robotics-and?ref=dwrnb2)

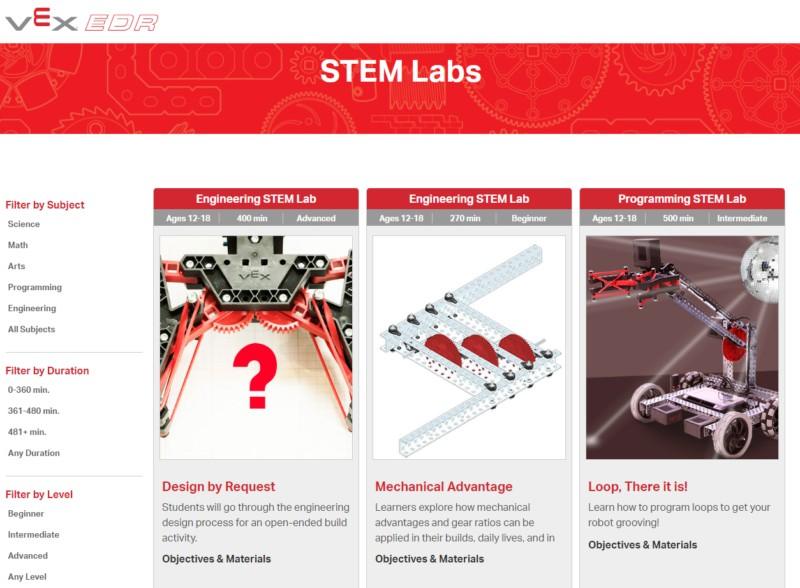

Transform your classroom with VEX EDR

Careers in STEM are on the rise!

Give your students the tools they need to succeed:

With more schools adopting robotics as a platform to enhance STEM and Computer Science courses, teachers need a solution to seamlessly integrate curriculum, programming software, and hardware into the classroom.

STEM Labs

Our scaffolded, standards-matched STEM Labs

can be adapted to fit any classroom

STEM Labs are hands-on activities, which include diverse builds, games, and competitions, that align with education standards while also showing real-world applications of concepts.

These activities give students the opportunity to communicate and collaborate with their classmates. Every STEM Lab has multiple approaches to solving a problem, allowing students to experiment with creative design solutions.

For many teachers, figuring out how to implement concepts into maths, design & technology, engineering and computer science subjects can be difficult. Our STEM Labs allow for easy implementation with minimal preparation time. Each STEM Lab can be used on multiple platforms and includes easy-to-follow build instructions.

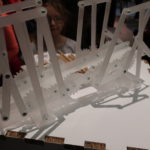

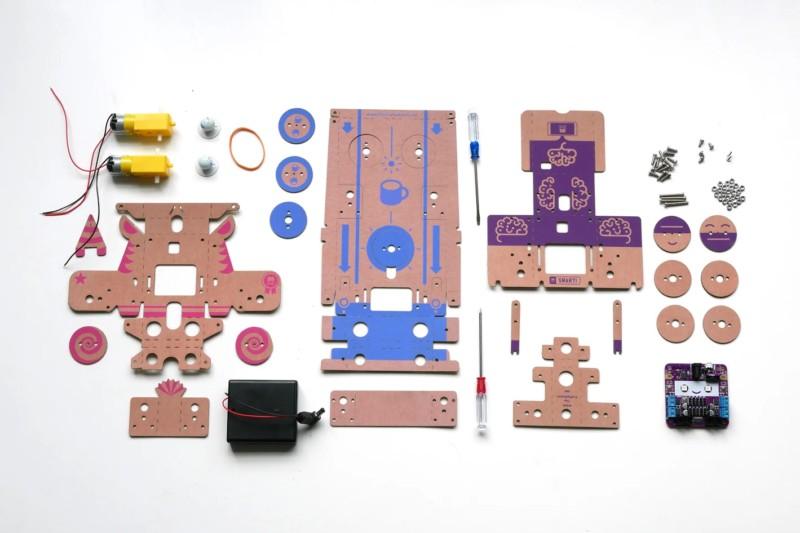

Smartibot launches the world’s first A.I. enabled cardboard robot

London, England – June 26th 2018 – The Crafty Robot today launches its new robot kit Smartibot which is aimed at letting users get hands-on experience with A.I. and get creative through building their own robot out of anything, even a potato. Created by product designer Ross Atkin, who is part of a team of inventors in the BBC’s flagship technology program ‘The Big Life Fix’, Smartobots are available for pre-order on Kickstarter from £30 ($40).

https://www.kickstarter.com/projects/460355237/338515758?ref=1k04h4&token=994114b3

Smartibot takes The Crafty Robot’s ‘build a robot out of anything’ ethos and adds the latest A.I. technology and smartphone connectivity. This allows you to build robots that can recognise and respond to objects they can see such as people, animals and vehicles, or be driven around the home and office using your smartphone as a remote control.

Smartibot comes with cleverly designed cardboard parts, and can be re-used to easily create new robots out of almost anything from porcelain to parsnips. The first three cardboard robot designs include;

- A.I. Bot: The fun robot that can chase you, your pets or toy vehicles around the room.

- Teabot: Which can carry two full drinks around the room, giving you a fun way to deliver your favourite person their beverage of choice.

- Unicorn: It’s a freakin’ Unicorn!

Working with two groups of London-based craftspeople who use traditional processes, Smartibot has grown from a simple robot to something more. Artists at Turning Earth Studios have been able to craft robots using various clay and ceramic techniques whilst regulars at Wild and Woolly Yarn Shop have found knitting a series of robots was more their style. In an East London Makerspace, Machines Room, Smartibot robots have been made using the less traditional materials including potatoes and other vegetables in order to pit them against each other in a race and arena combat in the inaugural ‘Botato Wars’.

“I build technology for a living and I know that the best way to avoid being replaced by a robot is to be the person making the robot” explained Ross Atkin. “We believe building your own robot should be affordable, easy to understand and exciting for everyone. Because of this we created Smartibot in order to allow everyone the opportunity to experiment with the latest A.I. technology in a fun and inventive way.”

Unlike most education technology products, Smartibot allows you to learn all of the disciplines required to create new inventions, from coding and machine learning, to mechanical design and development through iteration.

Akram Hussein, Smartibot software lead, said “What I love about Smartibot is it allows me share my love of technology and machine learning with my young nephews in a way that is both fun but educational. I’m hopefully they will be excited to pursue STEM careers and believe Smartibot is just the right level to get them started in learning how robots and programming work.”

About The Crafty Robot

The Crafty Robot is a technology education brand, founded by Ross Atkin that has manufactured and sold cardboard robots since 2015 when it was successfully Kickstarted and delivered to over 1,600 backers.

Ross, a London based designer and engineer specialising in internet of things and smart city products, and is part of a team of eight inventors who create one off pieces of technology to solve problems for disabled individuals in the primetime BBC2 TV program ‘The Big Life Fix’.

The Crafty Robot is focused on allowing people to get creative with technology in the most fun and accessible ways possible.