Der Preis für Automatisierungslösungen mit einem schnellen Return-On-Invest geht in die 2. Runde

Köln, 9. September 2021 – Sie automatisieren die Verpackung, sortieren Waren und helfen bei gefährlichen Aufgaben im Arbeitsalltag: kostengünstige Robotik- und Automatisierungslösungen von igus. Die kreativsten Anwendungen zeichnet der motion plastics Spezialist auch 2022 wieder mit dem ROIBOT Award aus. Gesucht werden Projekte, die mithilfe von igus Low Cost Automation und drylin Antriebsachsen einen schnellen Return-on-Invest erzielen konnten. Die Gewinner erhalten ein frei wählbares Robotik-Paket von dem Marktplatz RBTX.com im Wert von bis zu 5.000 Euro.

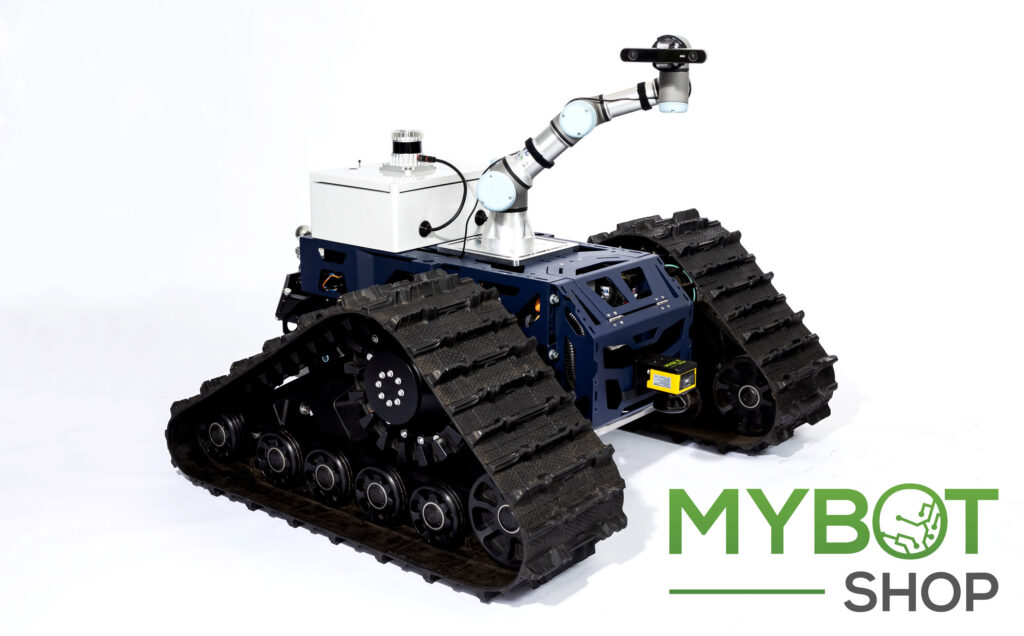

Über 70 Bewerbungen aus aller Welt gingen im letzten Jahr für den ROIBOT Award 2019/2020 ein. Der Preis kürt Automatisierungsprojekte, die kostengünstige Robotik- und Automatisierungslösungen von igus einsetzen. Die Sieger aus Salzburg (Österreich) durften sich dabei über ein Preisgeld von 5.000 Euro freuen. Die Studenten konstruierten ein mobiles Robotersystem mit Greifer, um gefährliche Handling-Aufgaben zum Beispiel im Handwerksbereich aus der Entfernung umzusetzen. Dazu kommt ein mit Sensorik ausgestatteter Handschuh zum Einsatz, der eine intuitive Steuerung durch Gesten ermöglicht und das mit Feedback. Für den kostengünstigen und wartungsfreien robolink D-Gelenkarm von igus entwickelten die Ingenieure ein Antriebssystem, ein Akkusystem sowie ein mechanisches Gerüst. Das Projekt überzeugte die Fachjury und gewann den ersten Platz. Den zweiten Platz belegte das Pick & Place-System für den Healthcare Sektor von Apostore. Es besteht aus einer Roboterzelle und einem Versorgungssystem für die zuführende Schüttgut-Ware. Den dritten Platz erreichte die deutsche Firma Superwurm. Die Regenwurmzüchter entwickelten mithilfe von igus Low Cost Automation eine Anlage, die Würmer automatisiert abzählt und in Dosen verpackt.

ROIBOT Award geht 2022 in die nächste Runde

Der ROIBOT Wettbewerb sucht auch jetzt wieder weltweit nach bereits bestehenden Low Cost Automation Anwendungen, die zu einem schnellen Return-on-Investment geführt haben. Zum Einsatz können sowohl robolink Gelenkarmroboter, drylin Delta-Roboter, kartesische Roboter sowie drylin Antriebstechnik von igus kommen. Eine Fachjury bewertet die Konzepte. Eine spannende Einreichung, die sich durch Kreativität und einem Optimierungsgedanken auszeichnen, führt zu einer hohen Bewertung. Der Gewinner erhält ein frei konfigurierbares Robotik-Paket im Wert von 5.000 Euro, der zweite Platz kann sich für 2.500 Euro und der dritte Platz für 1.000 Euro Automatisierungslösungen auf RBTX.com aussuchen. Einsendeschluss ist der 30. April 2022. Die Preisverleihung erfolgt durch igus auf der automatica 2022 in München, der Leitmesse für intelligente Automation und Robotik. Auf der Website igus.de/roibot-anmeldung können sich die Teilnehmer bewerben.

Schauen Sie sich jetzt die Gewinner vom ROIBOT Award 2019/2020 an: https://youtu.be/HAvJHEvj-pU