Archiv der Kategorie: Video

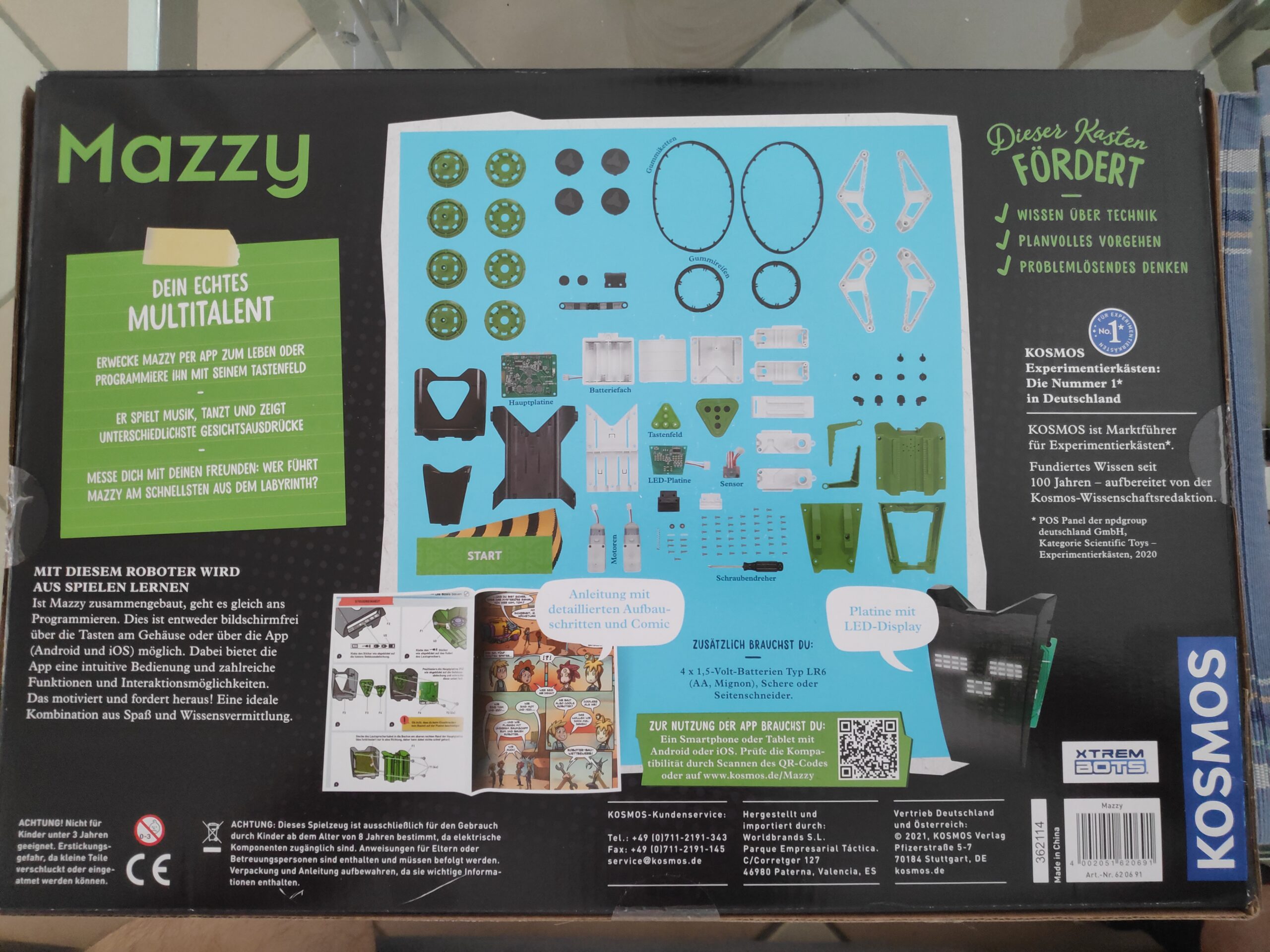

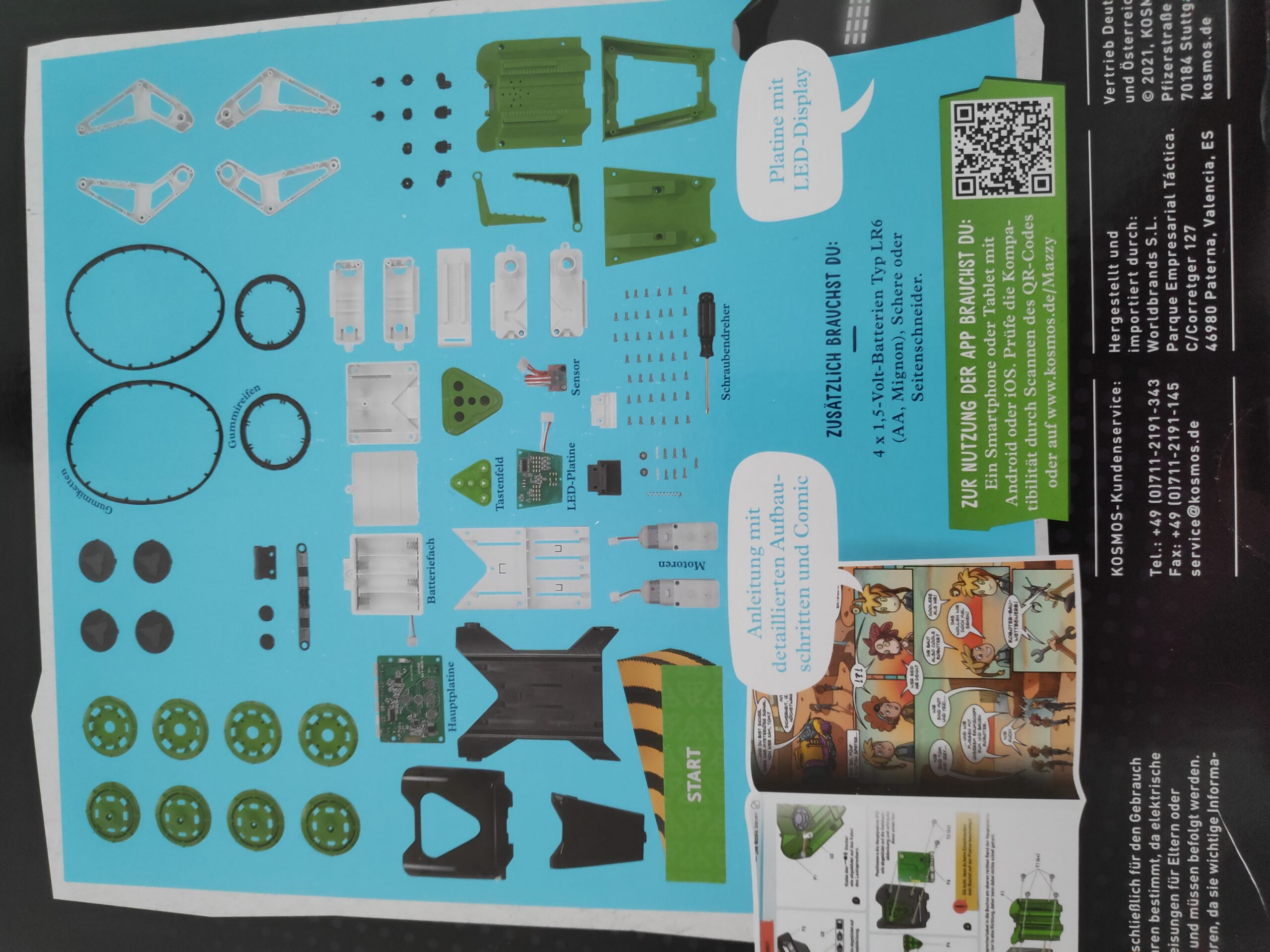

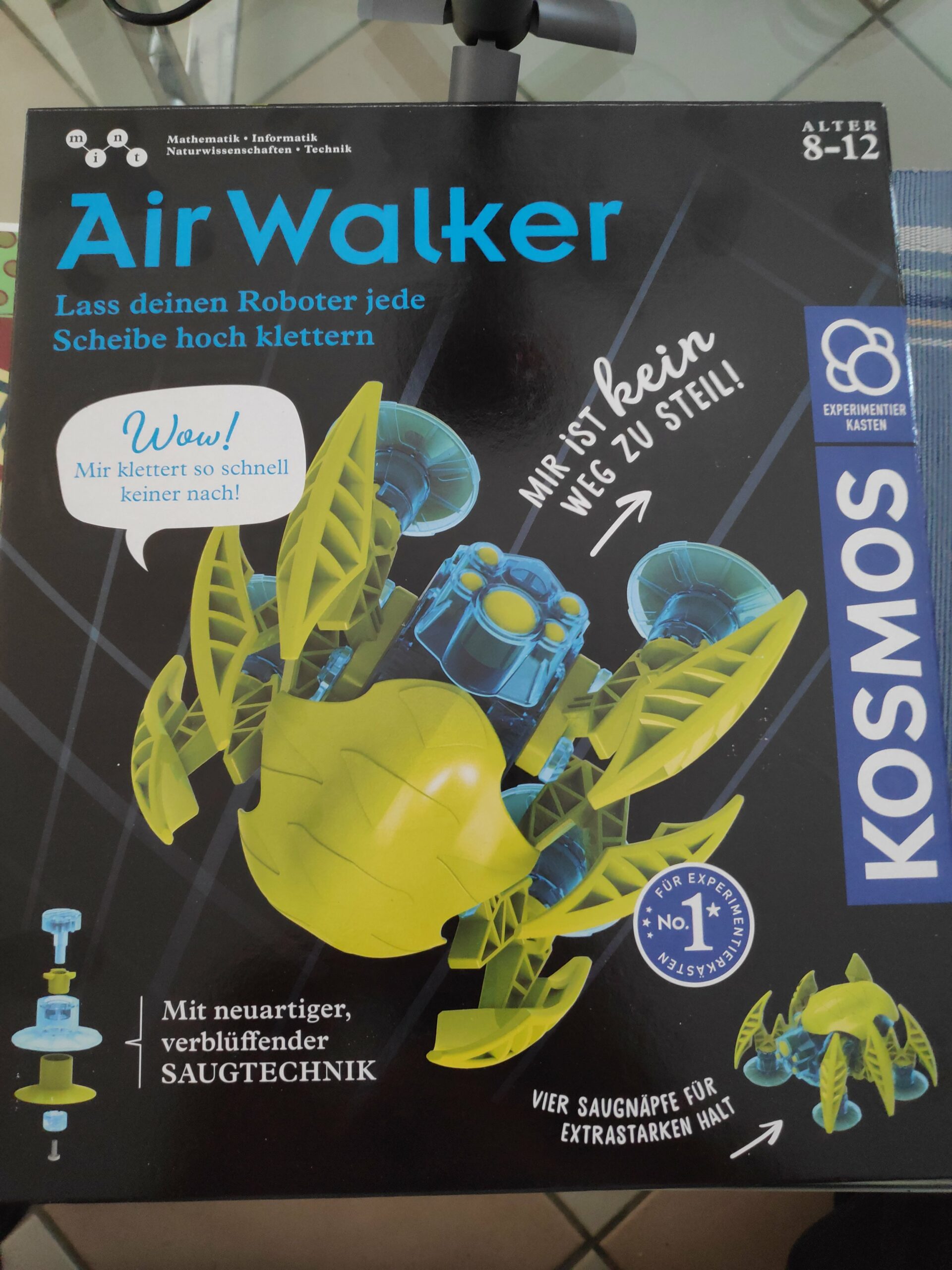

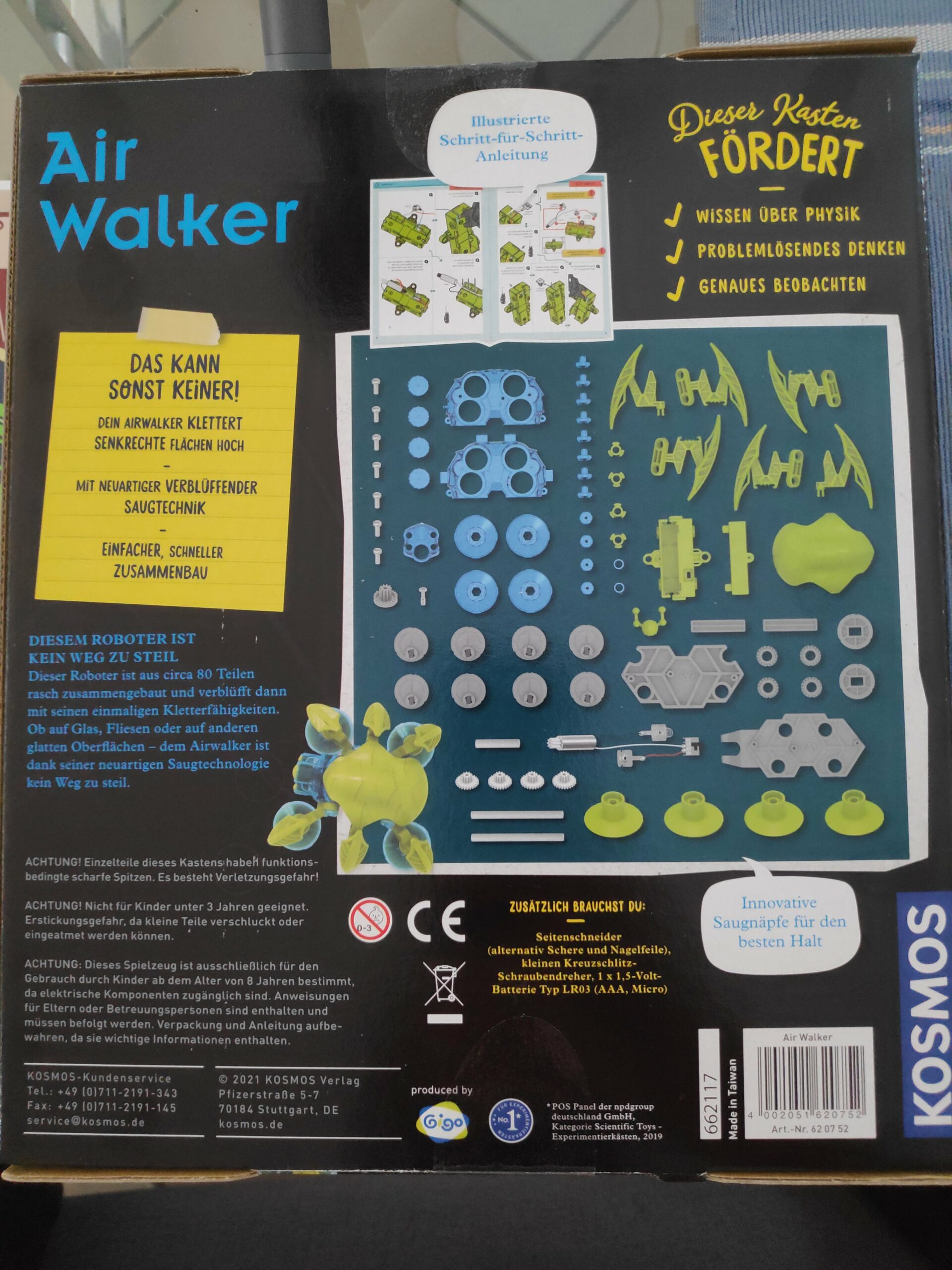

Kosmos Air Walker climbing robot STEM kit

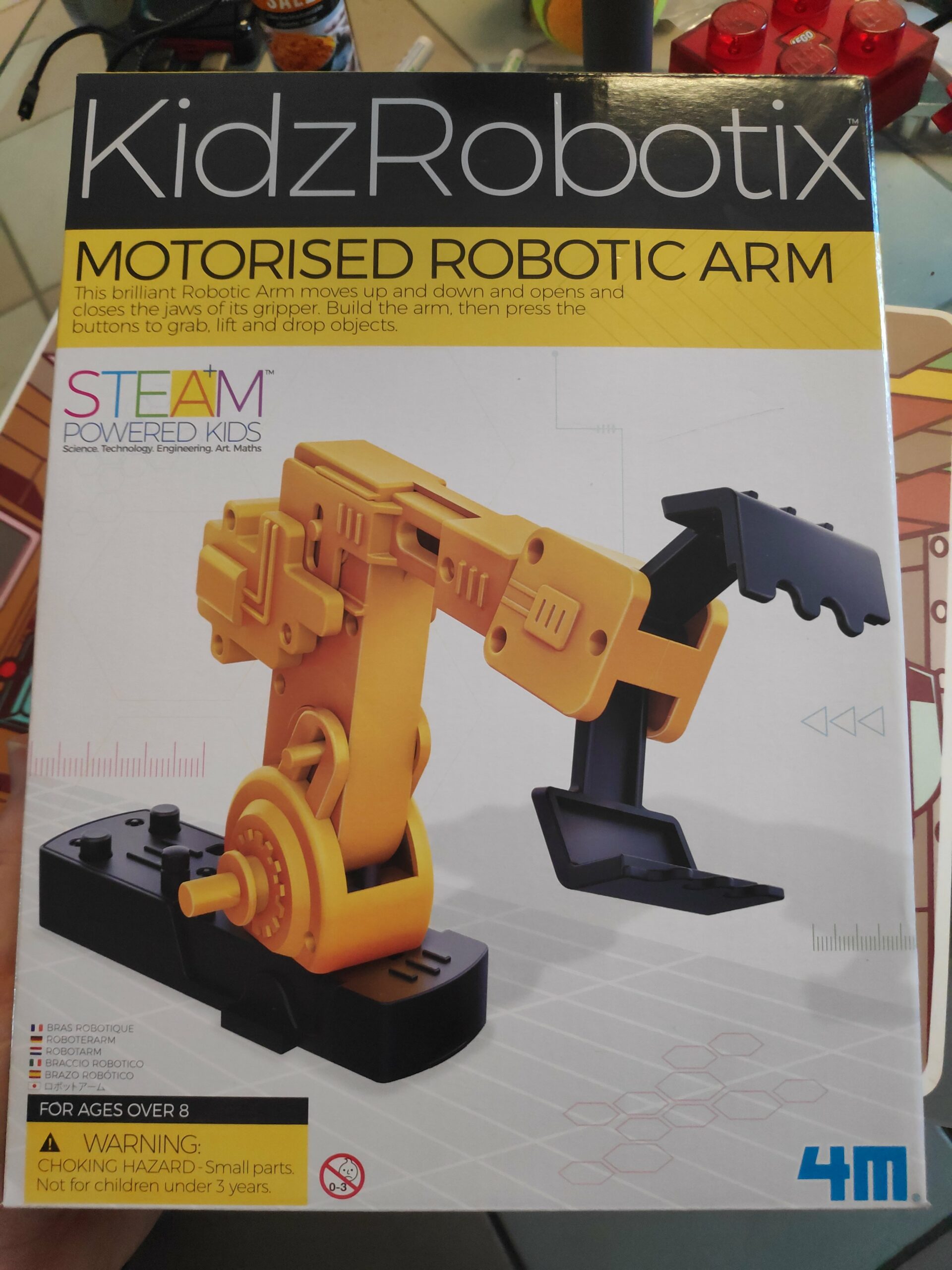

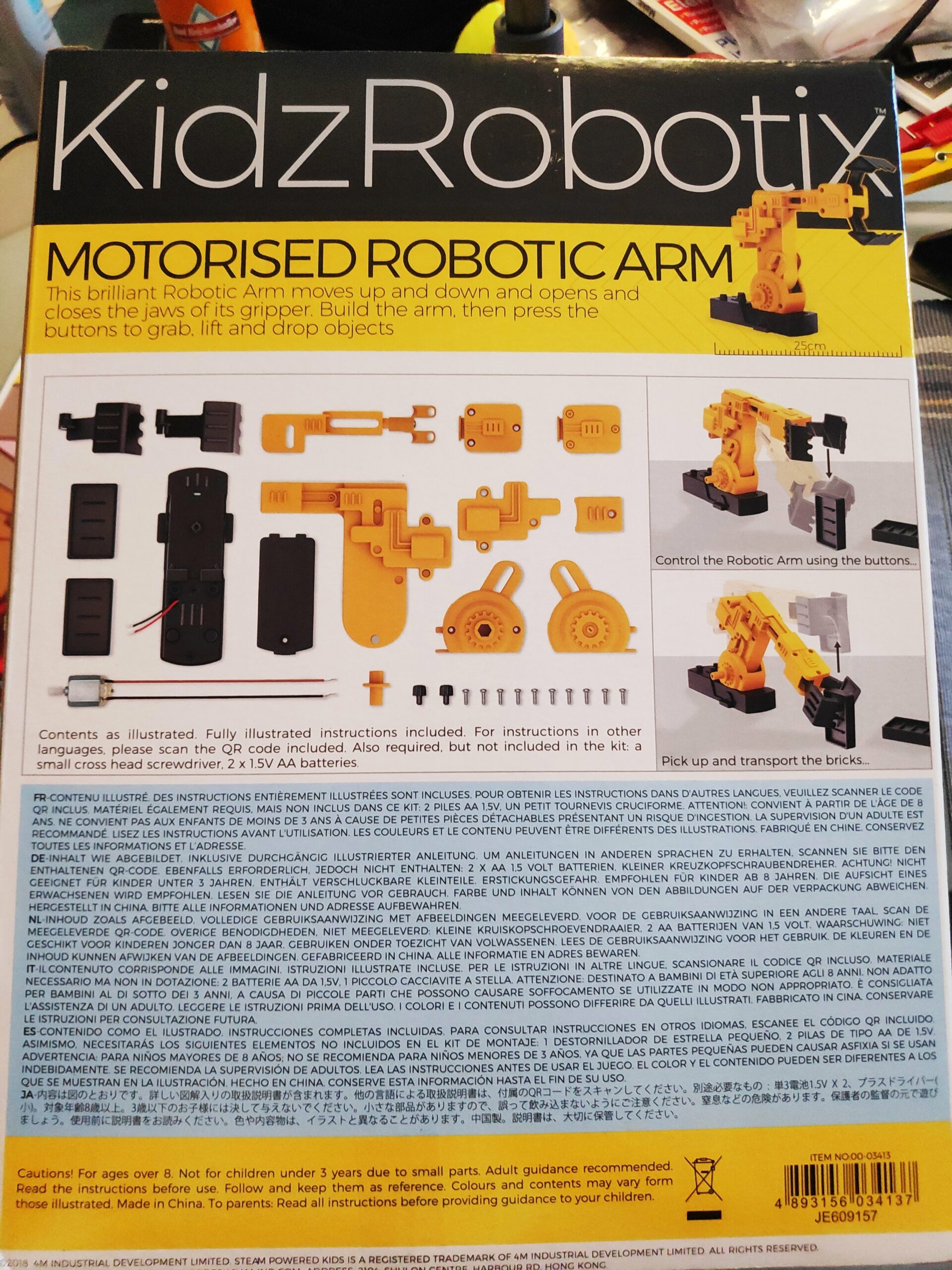

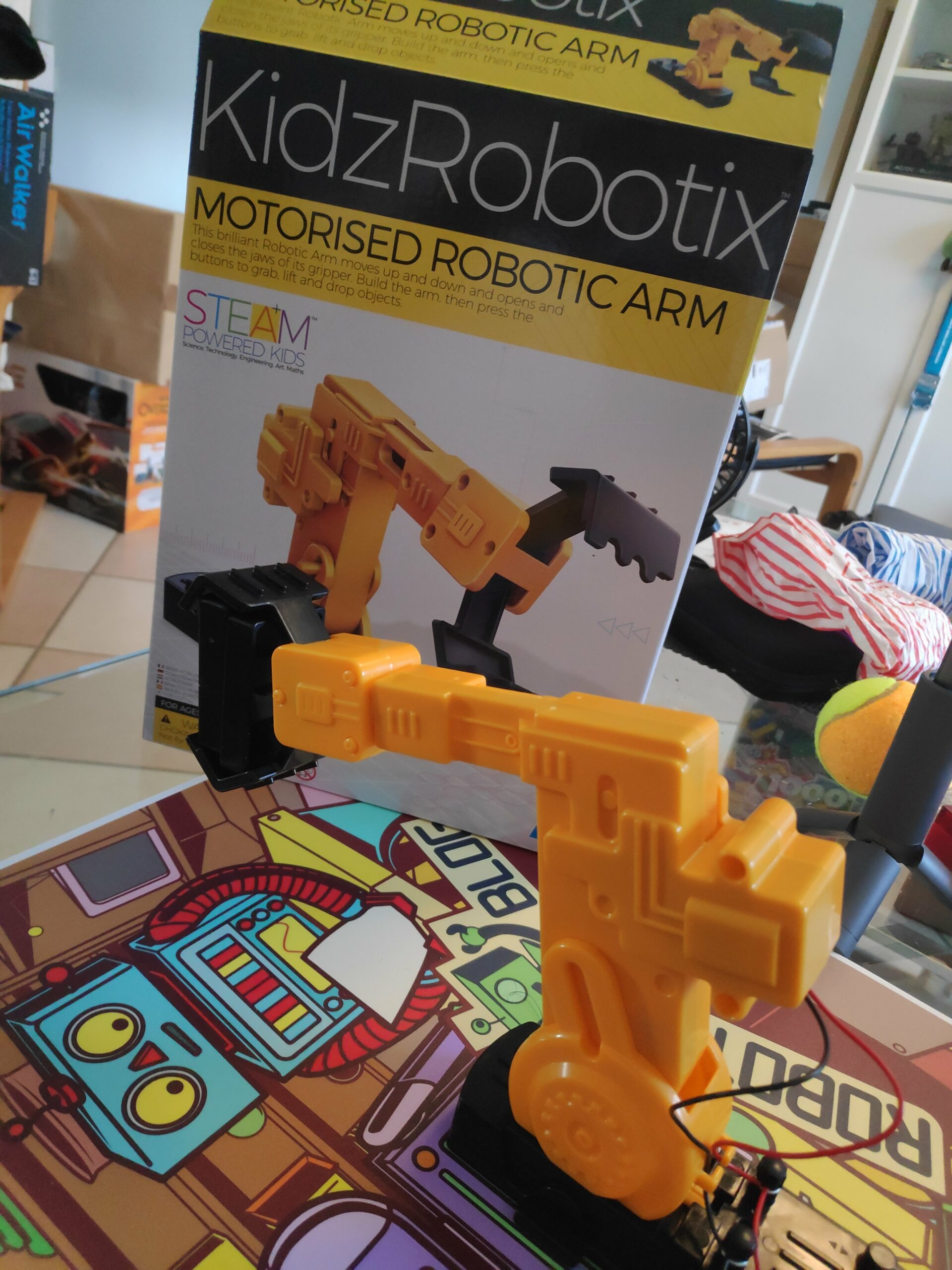

4M KidzRobotix Motorised Robotic Arm

4M KidzRobotix Fridge Robot

This robot can climb up your fridge

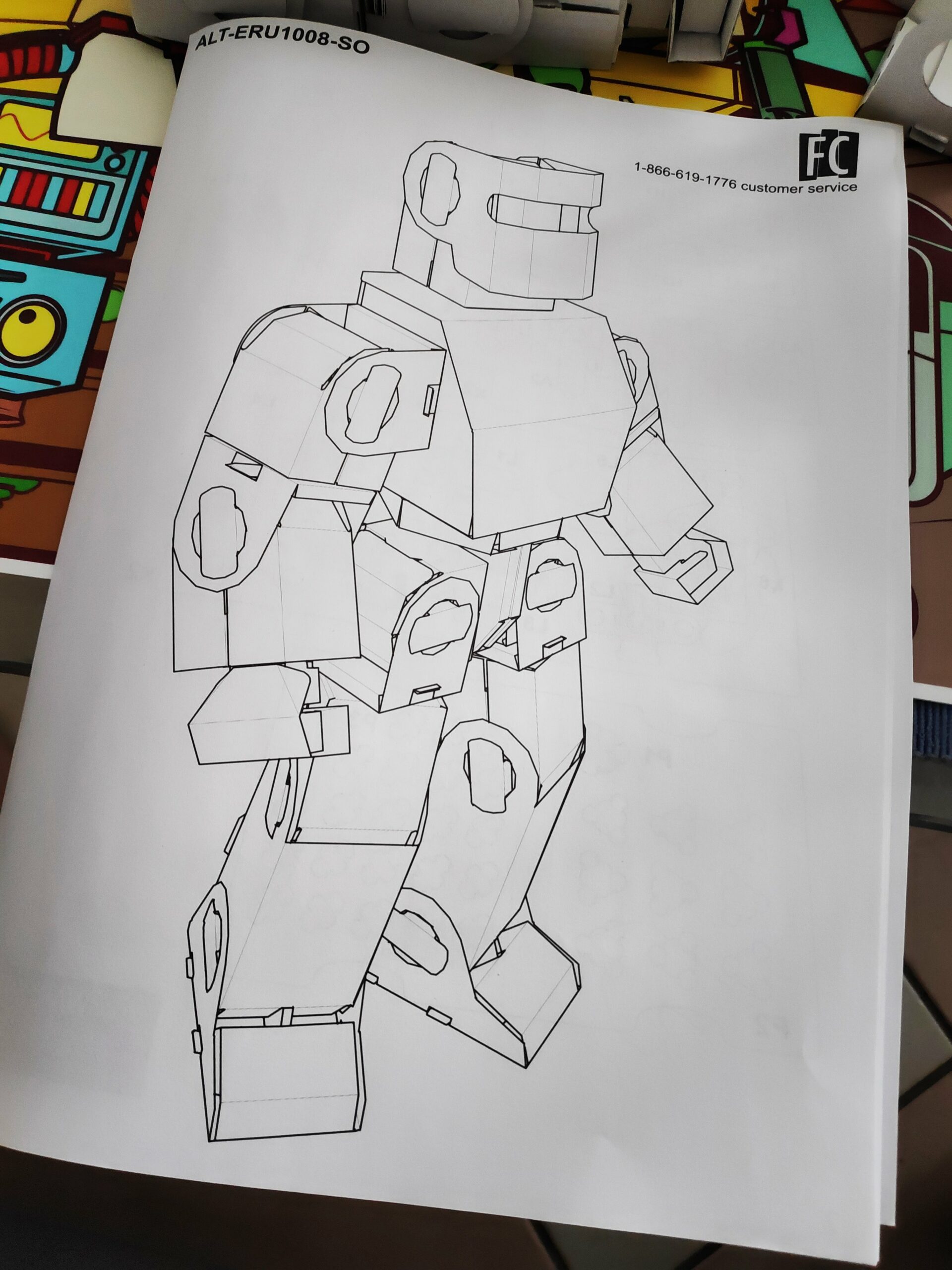

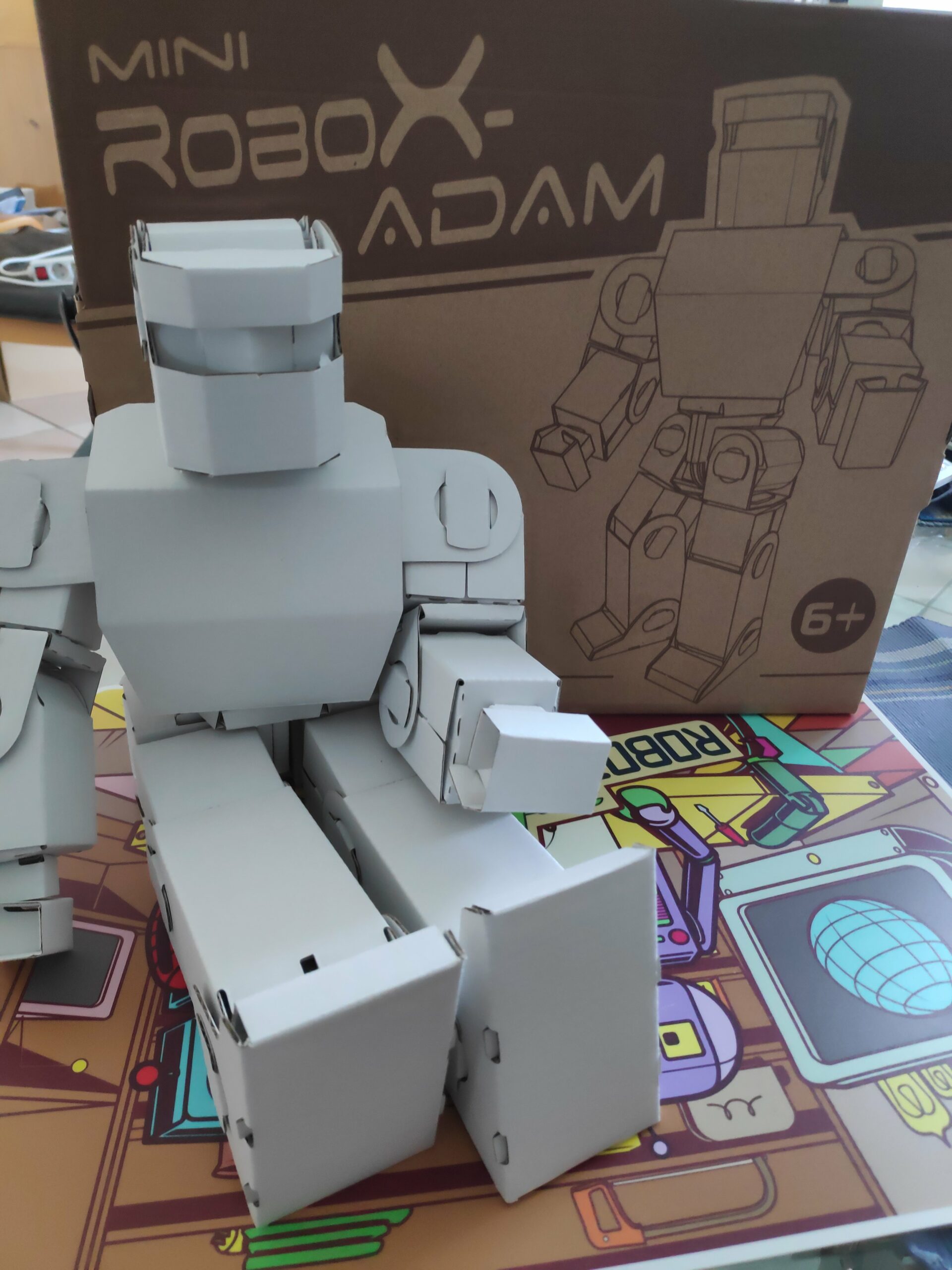

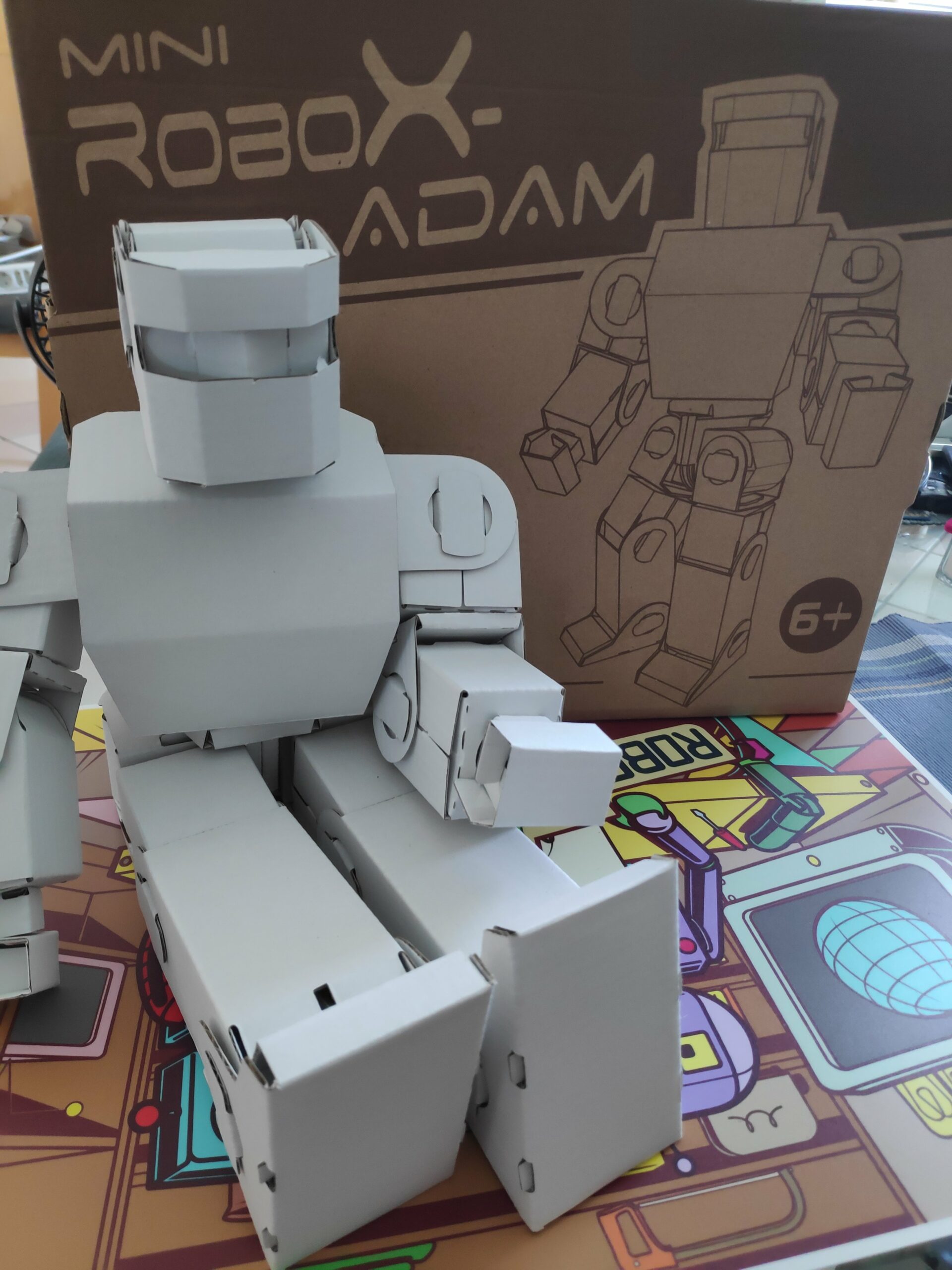

Mini RoboX-Adam Cardboard Robot

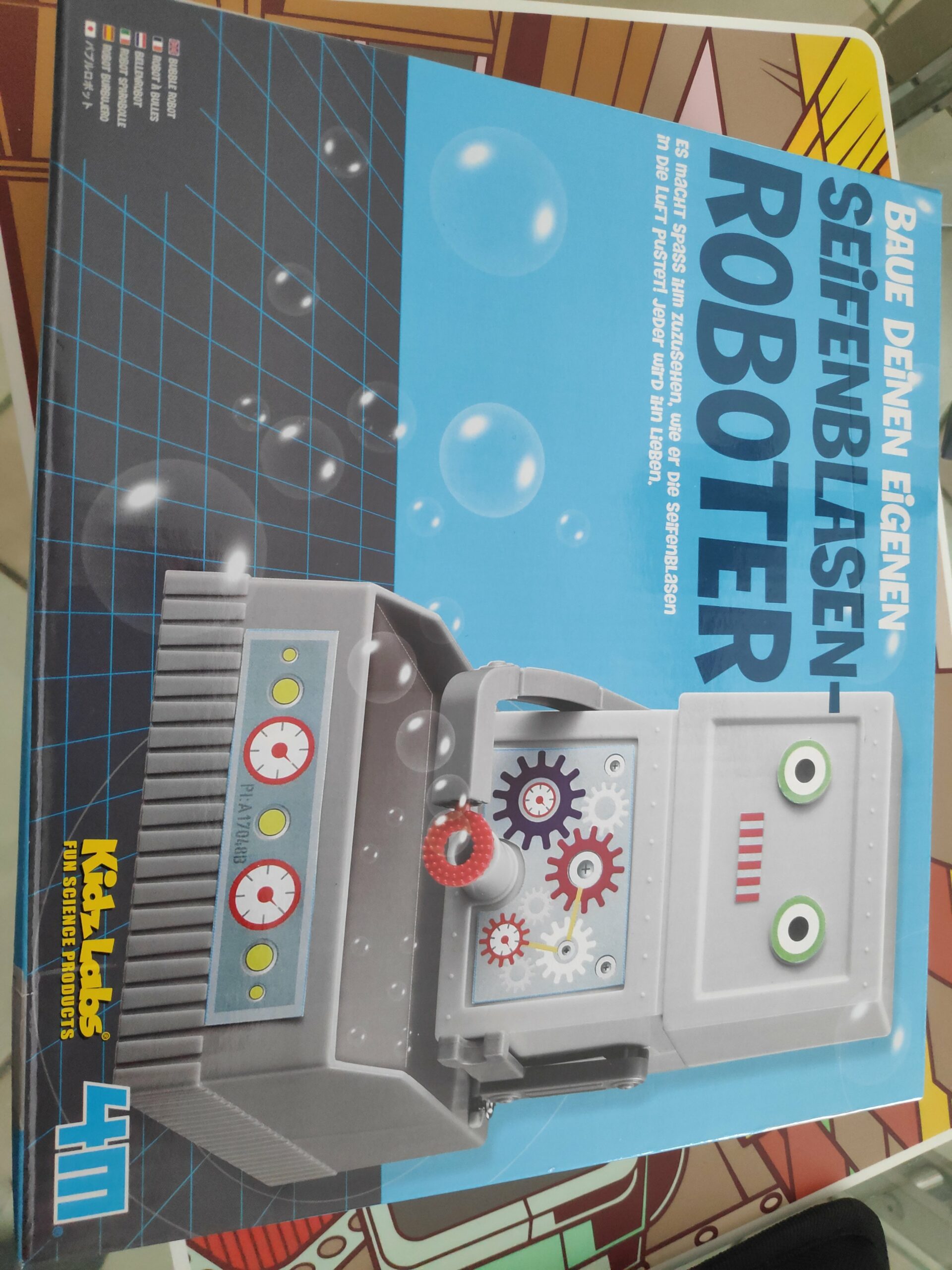

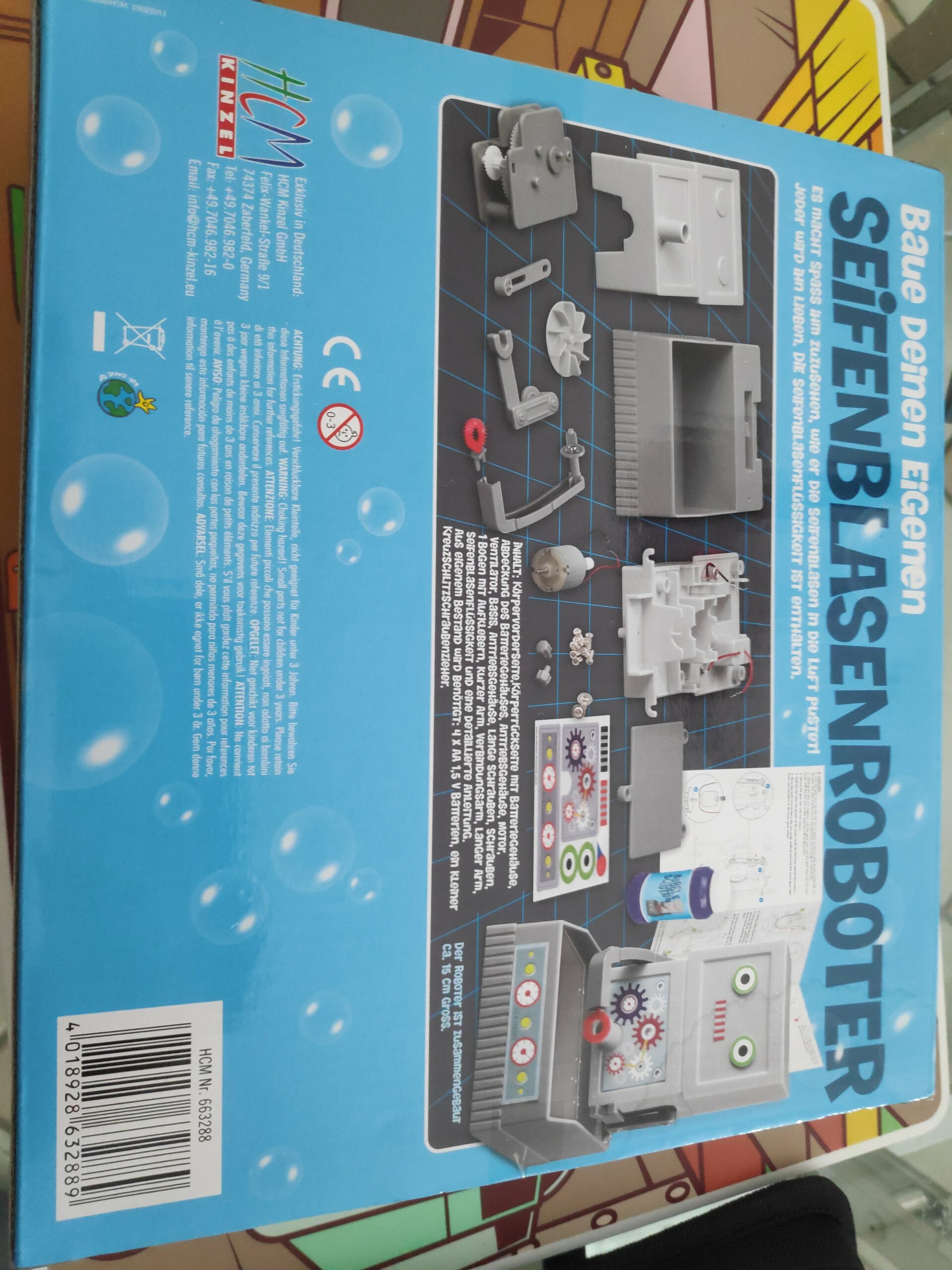

4M KidzLabs Seifenblasen-Roboter

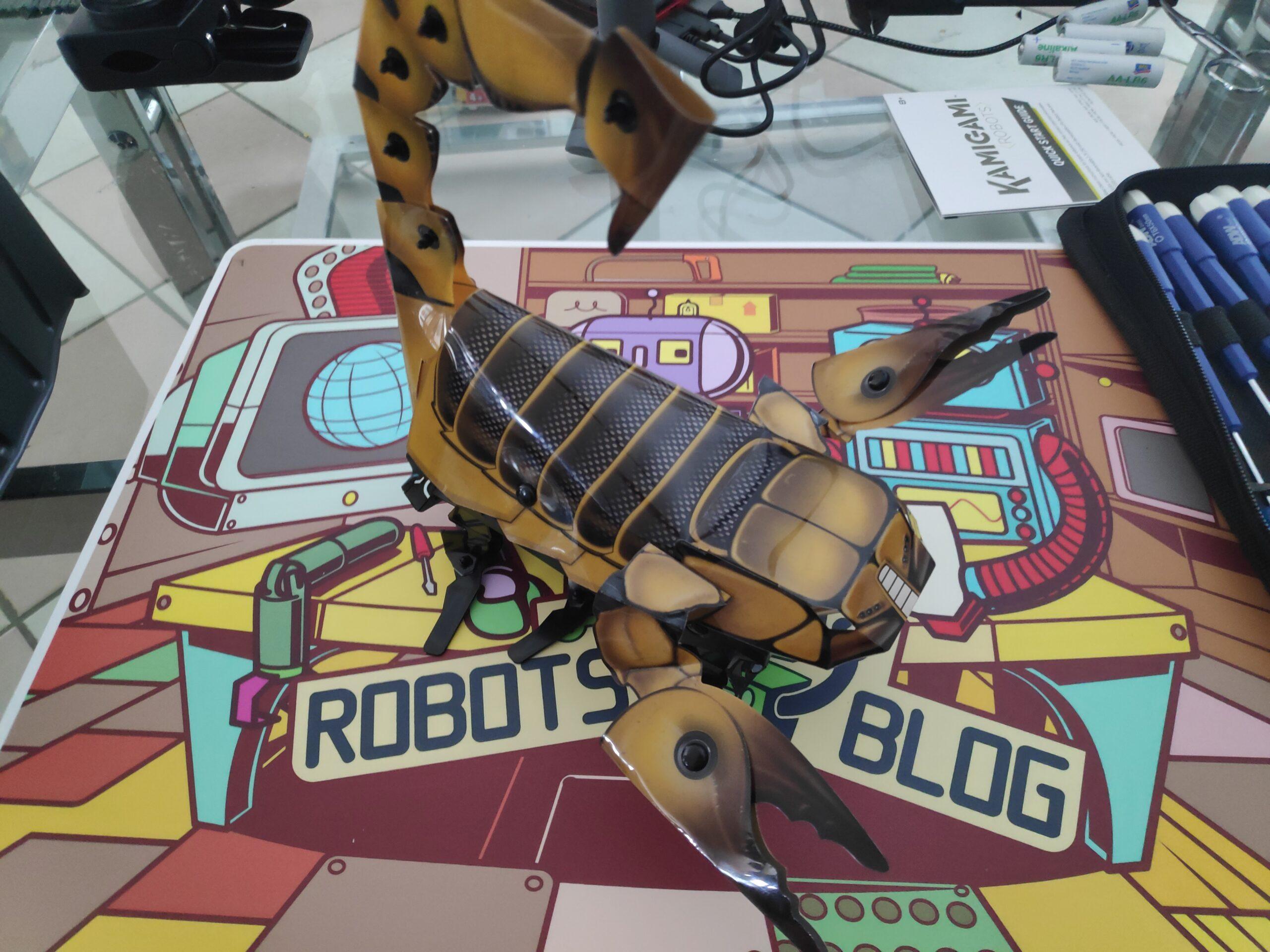

Dash Robotics/Mattel Kamigami Robots „Scarrax“ Scorpion

Dash Robotics/Mattel Kamigami Robots „Scarrax“. Find the latest News on robots drones AI robotic toys and gadgets at robots-blog.com. Follow us on our Blog Instagram Facebook Twitter or our other sites. Share your robotics ideas and products with us. #robots #robot #omgrobots #roboter #robotic #mycollection #collector #robotsblog #collection #botsofinstagram #bot #robotics #robotik #gadget #gadgets #toy #toys #drone #robotsofinstagram #instabots #photooftheday #picoftheday #followforfollow #instadaily #kamigami #origami #mattel #scorpion #insect #mattel #toyrobot

Sleepy Robot wants just 5 more minutes

When it’s too early in the morning and your robot refuses to work because it wants to snooze some more…

#igus #robolink #robot #robots #automation #lowcostautomation #snooze #morning #video #fun #sleep #just5moreminutes #tired #wakeup #robotsblog. Find the latest News on robots drones AI robotic toys and gadgets at robots-blog.com. Follow us on our Blog Instagram Facebook Twitter or our other sites. Share your robotics ideas and products with us. #robots #robot #omgrobots #roboter #robotic #mycollection #collector #robotsblog #collection #botsofinstagram #bot #robotics #robotik #gadget #gadgets