Mehr Informationen unter: https://www.iais.fraunhofer.de/de/branchen-themen/themen/intelligente-prozessautomatisierung/gen-ai-robotersteuerung.html

Schlagwort-Archiv: automatica

Robots-Blog besucht Vention auf der automatica 2025. Andrea Alboni im Gespräch mit Sebastian Trella

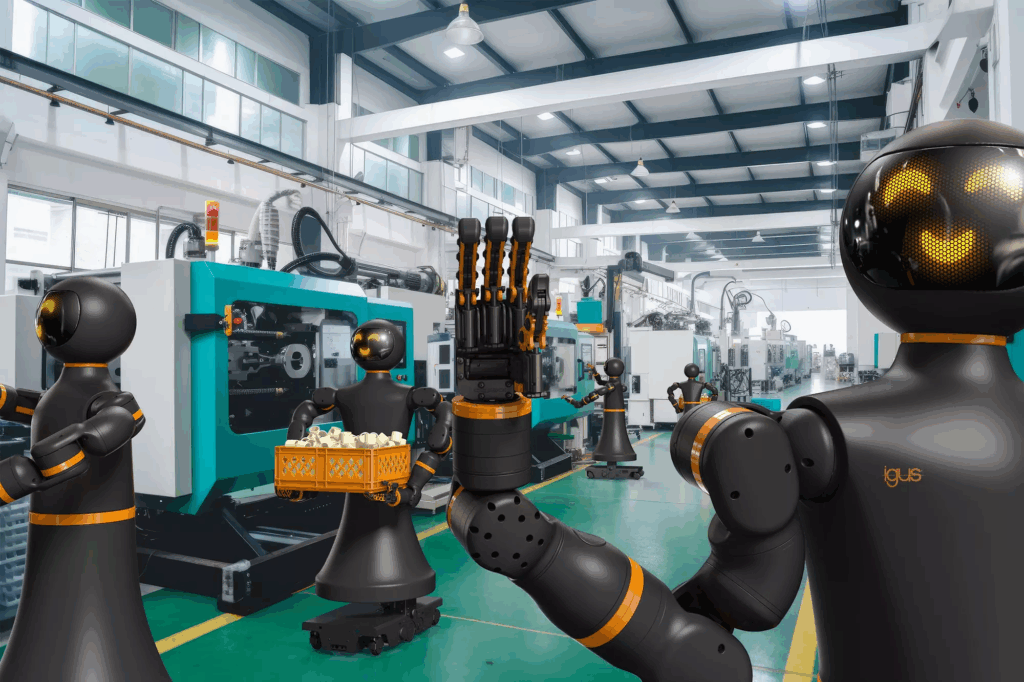

Robots-Blog trifft Alexander Mühlens und igus ersten humanoiden Roboter „Iggy Rob“ auf der automatica

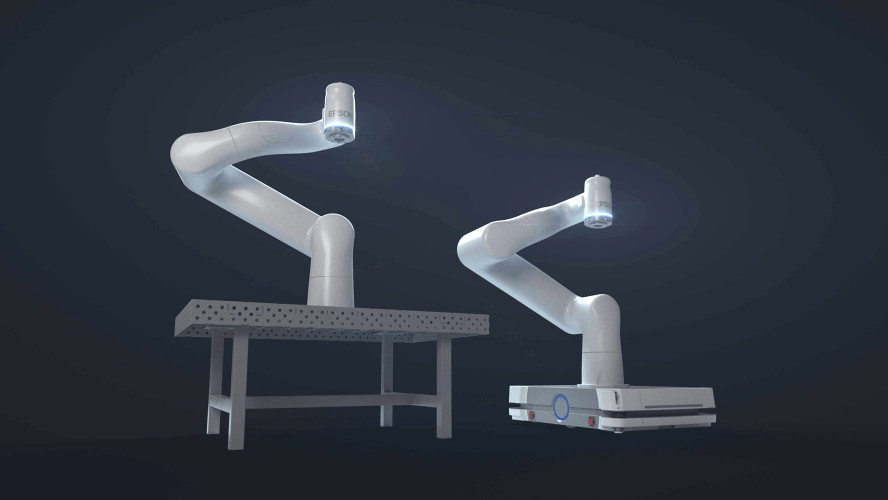

Volker Spanier präsentiert neuen Epson 6-Achs-Roboter Cobot AX6 im Robots-Blog Interview auf automatica 2025

Automatica 2025: Vention erweitert Angebot mit Robotiklösungen von Franka Robotics

MÜNCHEN, 17. Juni 2025 /PRNewswire/ — Vention, Anbieter der weltweit einzigen vollständig integrierten Software- und Hardware-Plattform für industrielle Automatisierung, erweitert sein Robotik-Portfolio um kollaborative Roboter der Franka Robotics GmbH, einer Tochtergesellschaft der in München ansässigen Agile Robots SE.

- Vention hat sein Roboterangebot um kollaborative Roboter der Franka Robotics GmbH erweitert, einem in Deutschland ansässigen Hersteller von Präzisions-Cobots, die in der Forschung und Entwicklung beliebt sind.

- Vention und Franka Robotics zeigen auf der Automatica PCB-Tests mit einem Franka Research 3 (FR3)-Roboter für die präzise und sichere Automatisierung empfindlicher Elektronik.

- Darüber hinaus präsentiert Vention KI-gestütztes Bin-Picking und ein All-in-One-Steuerungssystem für Bewegung, Bildverarbeitung, Sensorik und KI.

- MachineMotion™ AI, Ventions Steuerung der dritten Generation, feiert ihre Europapremiere mit einer KI-gestützten Bin-Picking-Demonstration auf einem ABB GoFa – inklusive intelligenter Teileerkennung und Greifpräzision im Submillimeterbereich.

- Modulare Roboterzellen für Maschinenbestückung und Palettierung werden ebenfalls gezeigt – mit führenden Robotermarken wie Universal Robots und FANUC.

- Besucher von Stand B4.307 erhalten kostenlosen Zugang zu MachineBuilder 101™, dem neuen Zertifikatskurs von Vention zur Planung, Simulation und Inbetriebnahme von Automatisierungslösungen auf der Vention-Plattform.

Franka Robotics hat sich mit seinem beliebten FR3-Roboterarm als führende Plattform in der akademischen Forschung etabliert und ist mittlerweile die bevorzugte Wahl für Doktoranden, KI-Forscher und Robotik-Labore. Mit der Aufnahme von Franka Robotics-Anwendungen in das eigene Portfolio erweitert Vention sein Angebot gezielt, um der starken Nachfrage von Hochschulen, Forschungseinrichtungen und innovationsgetriebenen Unternehmen gerecht zu werden, die bereits im Vention-Ökosystem arbeiten.

Vention präsentiert auf der Automatica 2025 (vom 24. bis 27. Juni) in München erstmalig eine Live-Demonstration mit einem FR3-Roboter von Franka Robotics (Stand B4.307).

„Wir sind stolz, Franka Robotics im Vention-Ökosystem begrüßen zu dürfen“, sagt Francois Giguere, Chief Technology Officer von Vention. „Der sehr gute Ruf von Franka Robotics im akademischen Umfeld passt perfekt zu unserer Mission, die industrielle Automatisierung zugänglicher und intuitiver zu gestalten. Wir freuen uns über die Zusammenarbeit mit einer angesehenen deutschen Marke – Deutschland hat die Geschichte von Vention von Anfang an maßgeblich geprägt, und diese Partnerschaft markiert ein spannendes neues Kapitel auf unserem Weg.“

„Die Partnerschaft mit Vention ermöglicht es uns, die Reichweite unseres Roboters Franka Research 3 einem breiteren Anwenderkreis im akademischen Bereich und in innovativen Anwendungen zugänglich zu machen“, erklärt Henrik Hermann, Vertriebsleiter bei Franka Robotics. „Gemeinsam setzen wir uns dafür ein, innovative, benutzerfreundliche Automatisierungslösungen zu liefern, die unseren Kunden neue Möglichkeiten in der Robotik und KI eröffnen.“

Der FR3 ist ein benutzerfreundlicher, kompakter und leichter (18 kg) Roboterarm mit sieben Freiheitsgraden. Er ist sicher, hochflexibel und damit ideal für Laborumgebungen mit begrenztem Platzangebot. Dank seiner drehmomentgeregelten Gelenke verfügt er über eine Echtzeit-Kraftsensorik, mit der er Kräfte wahrnehmen und darauf reagieren kann. Dies ist entscheidend für die Forschung zur Mensch-Roboter-Interaktion, das Lernen durch Demonstration sowie die Durchführung kontaktintensiver Aufgaben mit empfindlichen Komponenten.

Vention auf der Automatica 2025

Vention zeigt auf der Automatica insgesamt vier Live-Demonstrationen, die die vollständig integrierte Automatisierungsplattform des Unternehmens in der Praxis erlebbar machen – durch die Kombination aus intuitiver Software, modularer Hardware und den KI-gestützten Funktionen von MachineMotion™ AI.

MachineMotion™ KI & NVIDIA-Technologie – Leistungsstarke Bewegungssteuerung

Nach der NVIDIA GTC 2025 und der Automate in den USA stellt Vention seine KI-gestützten Bin-Picking-Demonstration mit einem ABB GoFa CRB 15000 erstmals auf einer europäischen Messe vor. Auf Basis von MachineMotion™ AI, NVIDIA Jetson Computing sowie CUDA-beschleunigten Isaac-Bibliotheken und -Modellen von NVIDIA deckt die Live-Demonstration von Vention fortschrittliche Robotik, KI-basierte Bewegungssteuerung und skalierbare Schulungsszenarien ab – und zeigt, welchen konkreten Mehrwert KI bei der praktischen Implementierung robotergestützter Lösungen in der Fertigung bietet. Die Anwendung erreicht eine Greifgenauigkeit im Submillimeterbereich bei ungeordneten Fertigungsteilen – ideal für High-Mix-/Low-Volume-Produktionsumgebungen.

Modulare Demos für praxisnahe Anwendungen

Im Rahmen Automatica wird Vention den FR3-Arm von Franka Robotics bei Leiterplattentests auf einer Vention-Workstation vorführen und die Präzision und schonende Handhabung für empfindliche Elektronik und feinmotorische Aufgaben demonstrieren.

Darüber hinaus erleben Besucher vollständig integrierte, anpassbare Roboterzellen für:

- 7th Axis Range Extender – für mehr Reichweite und Flexibilität bei Anwendungen wie Maschinenbestückung, Montage und Verpackung.

- Rapid Series Palletizer – aufgebaut auf einer Teleskopsäule und optimiert mit der neuesten Version 4.5 der MachineApp-Software von Vention.

Die Live-Demonstrationen finden in Halle B4, Stand 307 statt.

Weitere Informationen auf Vention.com.

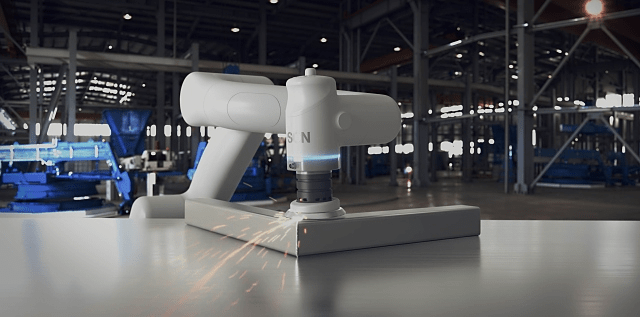

automatica 2025: erster kollaborativer Roboter von Epson

Düsseldorf, 10. Juni 2025 – Epson, ein führender Anbieter von Roboter- und Automatisierungstechnik, stellt auf der automatica 2025 seine erste kollaborative Industrieroboterlösung vor. Diese ermöglicht in Branchen wie Fertigung, Logistik und dem sich schnell entwickelnden Life-Science-Sektor eine wirkungsvolle Interaktion zwischen Mensch und Maschine und steigert so die Effizienz und Produktivität. Die Lösung wird ab Herbst 2025 als erstes kollaboratives Roboter-Komplettpaket von Epson angeboten, welches den neuen, aus Carbon-Leichtbau bestehenden 6-Achs-Roboter AX6-A901S sowie die kompakte Epson RC-A101-Steuerung inklusive dem Programmiersystem AX-Portal umfasst.

„In den stark wachsenden Bereichen Biowissenschaften und pharmazeutische Industrie sind präzise Arbeitsabläufe und ein strenges Hygienemanagement von größter Bedeutung“, erklärt Volker Spanier, Head of Manufacturing Solutions von Epson. „Um auch diese Anforderungen zu erfüllen, ist der neue kollaborative Roboter von Epson reinraumtauglich. Dank seiner präzisen Bewegungen erlaubt die Maschine daher auch in Laboren und pharmazeutischen Einrichtungen die Verrichtung selbst komplizierter Aufgaben.“

Wichtige Produktmerkmale des kollaborativen Roboters AX6-A901S von Epson:

- Ausbalanciertes Design: Der AX6-A901S bewegt eine Nutzlast von bis zu 6 kg bei einer Armlänge von 900 mm. Er besitzt ein besonders leichtes und kompaktes Design, sodass sowohl sein Transport als auch seine Integration in bestehende Produktionslinien sehr einfach sind. Dank der kompakten Abmessungen lässt er sich auch in beengten Umgebungen einsetzen.

- Kompakter und leichter Controller: Der Epson RC-A101-Controller ist für die Installation auf fahrerlosen Transportfahrzeugen (AGVs) und autonomen, mobilen Robotern (AMRs) geeignet. Er hat die Abmessungen B 440 x T 205 x H 135 mm und wiegt weniger als 6 kg. Auch dieses kompakte Design ermöglicht eine sehr platzsparende Installation.

- Kompatibel zu verschiedenen Stromquellen: Der kollaborative Roboter ist mit Stromquellen von 100 bis 230 VAC bzw. 48 VDC kompatibel, sodass er in Umgebungen mit verschiedenen Stromquellen installiert werden kann.

- Reinraumkompatibilität: Der AX6-A901S besitzt die Reinraumklasse 5 nach ISO 14644-1 und die Schutzart IP54. Das glatte Gehäusedesign ohne Schraubenlöcher und scharfe Kanten minimiert die Staubansammlung und damit das Kontaminationsrisiko in Reinraumumgebungen.

- Python-Programmierung: Die Programmierumgebung unterstützt die weit verbreitete Programmiersprache Python. Diese Kompatibilität vereinfacht die Integration in alle F&E-Umgebungen und die Inbetriebnahme. Auch wird so das Erlernen einer neuen Programmiersprache unnötig.

Spanier fasst zusammen: „Epsons Engagement für die Weiterentwicklung der Robotik resultiert in diesem kollaborativen Roboter, der auch sehr komplexe Aufgaben sicher ausführt. Damit erfüllen wir die wachsende Nachfrage der Labor- und Pharmaindustrie und weiteren Branchen. Diese Maschine stellt einen bedeutenden Fortschritt auf dem Weg zur Verbesserung des Epson Angebotes im Bereich der industriellen Automatisierung dar. Unsere Roboter erfüllen dabei auch die strikten Anforderungen des Life-Science-Sektors und gewährleisten Sicherheit und Präzision bei jeder Interaktion zwischen Mensch und Maschine.“

Zu den neuen Robotern gibt es am 24. Juni eine Pressekonferenz am Epson Stand 311 in Halle B5

Weitere Informationen zu den Robotiklösungen von Epson:

automatica 2025 | Epson Europe

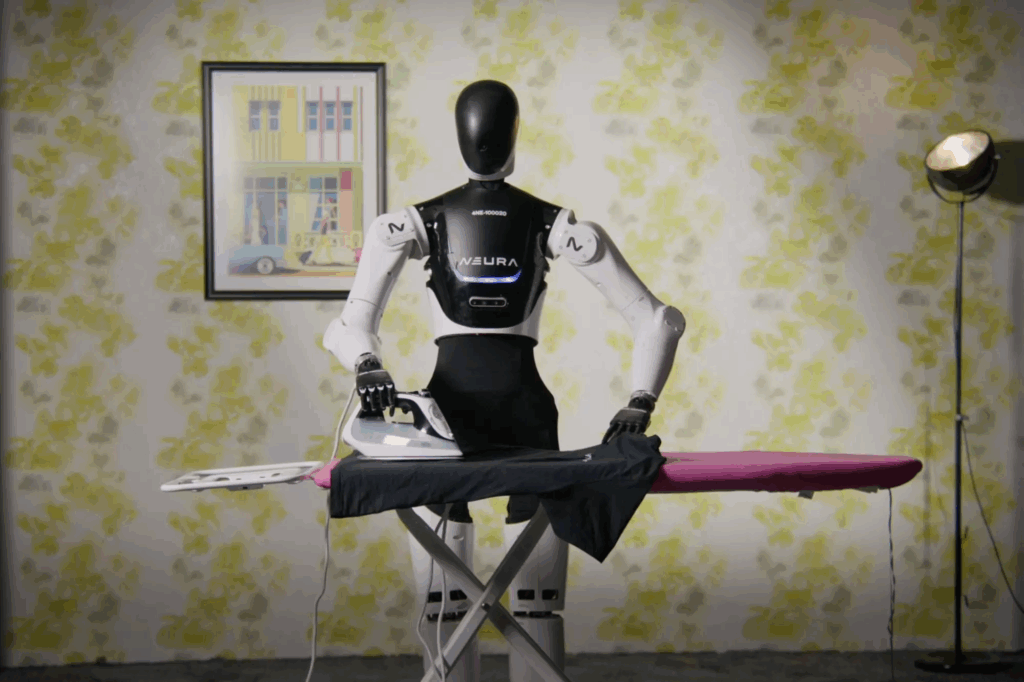

Men in Blech statt Mann am Band: Ambitionierte Ziele für die Massenfertigung von Humanoiden

Die Entwicklung im Bereich humanoider Roboter schreitet mit einer beeindruckenden Dynamik voran. Das Kräftemessen zwischen den USA und China sowie Fortschritte im Bereich der KI, der Batterieentwicklung und der Mechanik befeuern die Performance der Men in Blech. Auf der automatica wird deutlich werden, wie weit diese Entwicklung bereits fortgeschritten ist.

Was die Humanoiden im Reich der Mitte zu leisten im Stande sind, konnten sie jüngst bei einem Halbmarathon in Peking unter Beweis stellen. Auf der gut 21 Kilometer langen Laufstrecke traten rund 20 humanoide Roboter erfolgreich gegen Menschen an. Mit dem Wettlauf hat die Volksrepublik ihr Ziel erreicht, sich als einer der führenden Anbieter menschenähnlicher Roboter zu präsentieren.

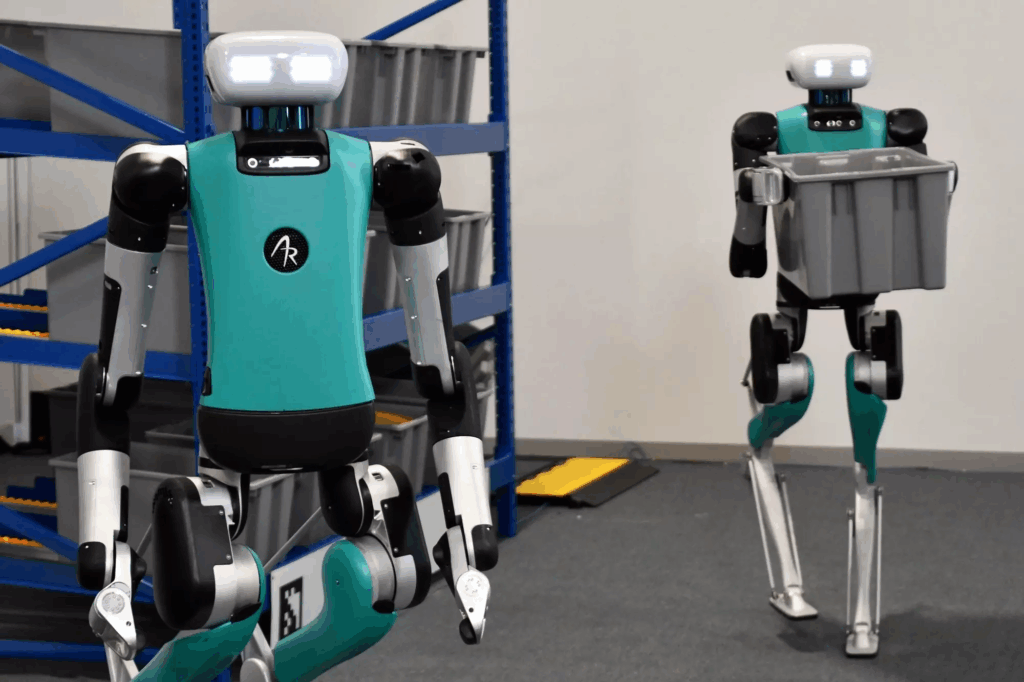

Zwei Beine ermöglichen maximale Flexibilität und Mobilität

Aber gerade ein Halbmarathon führt zwangsläufig zu einer oft gestellten Frage: Warum haben Humanoide Beine? Wäre es nicht effizienter, Radantriebe zu nutzen? Weshalb die meisten Humanoiden dennoch mit zwei Beinen ausgestattet sind, erklärt Jonathan Hurst, Chief Robot Officer bei Agility Robotics: „Zweibeinige Roboter sind für die Koexistenz mit dem Menschen konzipiert und bieten eine Vielseitigkeit und Mobilität, die über das hinausgeht, was Radantriebe leisten können. Durch den Einsatz von Beinen können sich Humanoide an komplexe Umgebungen anpassen, Treppen steigen, Bordsteine überwinden und ein breites Aufgabenspektrum erfüllen.“ Digit, der Humanoide von Agility, ist bereits in vielen Applikationen vorwiegend in Logistikzentren im Einsatz wie beispielsweise bei amazon und GXO Logistics. Mit einer Körpergröße von 1,75 m und einem Gewicht von etwa 64 kg kann Digit komplexe Aufgaben wie das Heben von Lasten mit einem Gewicht von bis zu 16 kg ausführen. Und dank fortschrittlicher Sensorik, darunter LIDAR und Kameras, kann er auch selbstständig navigieren. Über Digit und die Frage, wie Humanoide Lücken in der Automatisierungskette schließen können, spricht auch Melonee Wise, Chief Product Officer bei Agility Robotics, auf dem automatica Forum in Halle A5. Anwendungsorientiert referiert direkt im Anschluss Carolin Richter, Head of Next Generation Robotics bei der BMW Group, über die Erfahrungen des Unternehmens mit konkreten Praxiseinsätzen von Humanoiden.

USA mit Vorreiterrolle in der Technologieentwicklung

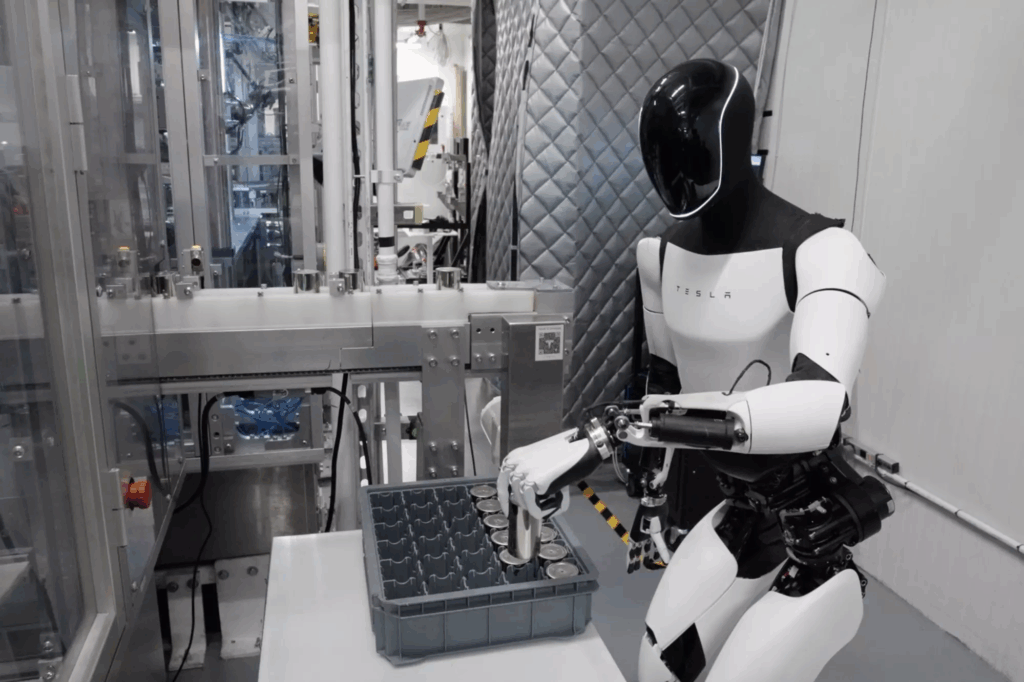

Wie Digit kommen weitere hochentwickelte Humanoide aus den USA, darunter Atlas von Boston Dynamics, Optimus von Tesla, Figure 01 und 02 von Figure AI und Apollo von Apptronik. Sie alle arbeiten bereits in Piloteinsätzen in der Automobilindustrie. „Wir entwickeln die fortschrittlichsten und leistungsfähigsten humanoiden Roboter der Welt, die den Menschen auf sinnvolle und revolutionäre Weise zur Seite stehen“, sagt Jeff Cardenas, CEO und Mitbegründer von Apptronik. Aber viel Kapital und potente Mitstreiter sind nötig, um diese Entwicklungen voranzutreiben. Gerade konnte Apptronik eine Finanzierungsrunde von mehr als 350 Millionen Dollar abschließen. Kooperationen mit der NASA, NVIDIA, Google DeepMind und auf der Anwenderseite mit Mercedes-Benz und GXO Logistics sollen sicherstellen, dass Apptronik in diesem Zukunftsmarkt weiter ganz vorne mitspielen wird.

Deutschland mit Aufholbedarf bei humanoider Robotik

Zwar spielt Deutschland auf dem Weltmarkt für Humanoide keine Schlüsselrolle, dennoch belegt die automatica, dass es auch hier vielversprechende Entwicklungen gibt. Denn neben dem 4NE-1 von Neura Robotics, der bereits 2023 auf der automatica debütierte, werden dieses Jahr weitere Humanoide den Weg nach München finden. Einer von ihnen kommt aus Köln und hört auf den Namen „Iggy Rob“. Igus bietet seinen ersten humanoiden Roboter für knapp unter 50.000 Euro an. Möglich wird dies nach Herstellerangaben durch die Kombination aus hauseigenen Komponenten wie den ReBeL Cobots für die Roboterarme und der mobilen Basis ReBeL Move. Sein Einsatzspektrum reicht von der Assistenzrobotik über Fabrikautomation bis hin zu Bildung und Forschung. Igus will Iggy Rob im eigenen Unternehmen für die Automation von Spritzgießmaschinen nutzen.

© Messe München GmbH

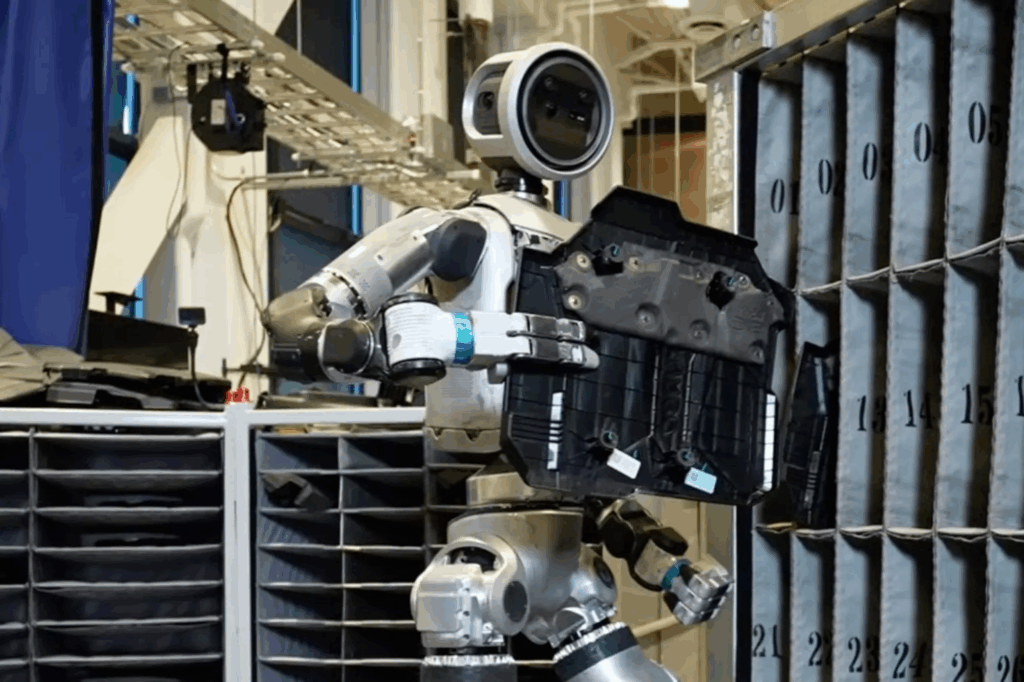

Mit Spannung erwartet wird auch der Messeauftritt des Instituts für Robotik und Mechatronik des Deutschen Zentrums für Luft- und Raumfahrt. Hier forscht man intensiv an der Weiterentwicklung in der humanoiden Robotik. Die jüngsten Ergebnisse werden auf der automatica zu sehen sein. Aufhorchen lässt auch die jüngst geschlossene Kooperation des Instituts mit Siemens. „Diese strategische Partnerschaft ist ein weiteres Beispiel für Transfer von Robotiktechnologien aus der Raumfahrt in industrielle Anwendungen“, sagt Institutsleiter Alin Albu-Schäffer. „Die enge Vernetzung mit führenden deutschen Industriepartnern wie Siemens ist essenziell, um die Wettbewerbsfähigkeit der europäischen Robotik auch in der Zukunft, angesichts der rasanten Entwicklungen in USA und China, zu sichern.“

Humanoide Roboter: ein gigantischer Wachstumsmarkt

Tesla sieht sich mit seinem humanoiden Roboter Optimus als Technologieführer. Dieser bewegt sich elegant, ist schnell und besitzt eine hochflexible Fünffinger-Hand. Musk hält Einsätze im Haushalt oder in der Kinderbetreuung bald für möglich und auch Goldman Sachs sieht für den weltweiten Markt für Humanoide hohes Potential. Demnach könnte dieser bis 2035 auf 38 Milliarden US-Dollar steigen. Neben US-amerikanischen Unternehmen verfolgt auch die Volksrepublik ambitionierte Ziele und will innerhalb der nächsten drei Jahre zum Weltmarktführer im Bereich humanoider Roboter aufsteigen. Mittelfristig sollen in China fünf Prozent aller Jobs von Humanoiden übernommen lassen. Das würde dem Einsatz von rund 35 Millionen Einheiten entsprechen. Bereits heute sind in Chinas Unternehmen Humanoide von Unitree, AgiBot, Engine AI, Fourier oder Ubtech in unterschiedlichen Applikationen und Branchen im Einsatz.

Branchenprimus Unitree bringt als einer der ersten Hersteller weltweit mit dem G1 einen kleinen Humanoiden zum spektakulär niedrigen Preis auf den Markt. So soll die Basisversion des 1,3 Meter großen und 35 kg leichten G1 in China nur 16.000 Euro kosten, hierzulande werden dann daraus wohl eher knapp 30.000 Euro. Und je nach Ausbaustufe kann sich dieser Preis schnell mehr als verdoppeln. Das Interesse am G1 ist groß, wie Unitree-Marketingmanagerin Qian Yuqi verrät: „Es gibt bereits Bestellungen aus dem In- und Ausland. Zunächst dürften vor allem wissenschaftliche Forschungseinrichtungen unseren Roboter einsetzen, aber auch Industriebetriebe können sich vorstellen, G1 für einfache Arbeiten zu nutzen.“

Die Entwicklung zeigt: Die Zeit für Humanoide und damit für eine neue Ära der Automation ist gekommen. Dank KI sind sie bereits jetzt in der Lage, einen Teil der Aufgaben zu übernehmen, die bislang Menschen vorbehalten waren. Die automatica verspricht spannenden Einblicke, was Humanoide zu leisten im Stande sind und wie ihr Einsatz die Arbeitswelt beeinflussen kann.

Robots-Blog.com at Automatica 2023

fruitcore robotics mit Neuheit horstCUBE plug & play auf der automatica 2022

fruitcore robotics aus Konstanz zeigt auf der automatica 2022 sein Robotik-Angebot rund um die drei einfach zu bedienenden und auch für kleine und mittlere Unternehmen erschwinglichen Digital Robots HORST. Im Mittelpunkt des Messeauftritts steht die neue Komplettlösung horstCUBE plug & play für die flexible Teilevereinzelung. Auf der Leitmesse für intelligente Automation und Robotik in München präsentieren Aussteller:innen vom 21. bis 24. Juni ihre Vision einer neuen Generation von smarten Robotern. Dass diese auch für sehr viele Mittelständler interessant werden, belegt eine aktuelle Umfrage: 46 Prozent der Unternehmen mit 50-500 Mitarbeiter:innen wollen sich Roboter ins Haus holen. fruitcore robotics stellt in Halle B4 am Stand 400 aus.

Mit seinen drei HORST-Systemen bringt fruitcore robotics das Potenzial der Robotik in alle Bereiche der Wirtschaft, weit über die Produktionsstraßen im Automobilbereich hinaus. Die Neuheit horstCUBE plug & play senkt die Einstiegshürden zur Automatisierung und Digitalisierung für kleine und mittlere Unternehmen nun weiter. Anwender:innen können die Komplettlösung direkt einsetzen, um ihre flexible Teilevereinzelung von Schüttgut mittels Kameraerkennung und Bauteilvereinzeler schnell und effizient zu automatisieren. Die Komplettlösung basiert auf der Roboterplattform horstCUBE und ist bereits mit allen Komponenten ausgestattet, die für diese Anwendung notwendig sind. Weitere Prozessschritte, wie Teile-Ausgabe, Teile-Prüfung, Teile-Sortierung oder Teile-Beschriftung können einfach und ohne großen Zeitaufwand umgesetzt werden. horstCUBE wird von fruitcore robotics auch als Einzelprodukt angeboten, denn die flexible Roboterplattform bietet die optimale Basis, um verschiedenste Anwendungen mit den Robotern von fruitcore robotics einfach und sicher zu realisieren.

Steuerung und Software wichtige Bestandteile der HORST-Systeme

Mit HORST-Systemen können ganze Anwendungen wie beispielsweise horstCUBE plug & play intuitiv und einfach gesteuert werden. Verschiedenste Komponenten wie Greifer, CNC-Anlagen oder Sicherheitssysteme werden zentral mit der Bediensoftware horstFX intelligent und stärker als in der Branche üblich vernetzt. „Roboter sind längst sehr viel mehr als nur ein Stück nützlicher Hardware“, so Jens Riegger, CEO und Mitgründer von fruitcore robotics. „Der Großteil der Wertschöpfung lässt sich über intelligente Software erzielen, Roboter werden zu Digital Robots. Jede Person, die ein Smartphone bedienen kann, ist auch in der Lage unsere HORST-Systeme über ihre Software horstFX samt digitalem Zwilling zu bedienen. Damit werden unsere Digital Robots gerade auch für den Mittelstand immer interessanter – auch, weil wir sie zu einem bezahlbaren Preis anbieten können.“

Eine neue Kategorie etabliert sich

Digital Robots vereinen modernste Robotik-Hardware mit intelligenter und intuitiver Software. Sie lassen sich einfach und ohne Vorkenntnisse mittels grafischer Bedienkonzepte einrichten und bedienen. Updates und Upgrades erhalten sie over-the-air, wodurch ihr Nutzen über die Lebensdauer ausgeweitet werden kann. Digital Robots bieten einen einfachen und schnellen Einstieg in die Automatisierung und Digitalisierung, der sich im Idealfall schnell amortisiert. Drei Aspekte zeichnen Digital Robots insbesondere aus: die intuitive Bedienung samt digitalem Zwilling, eine IIoT-Plattform, über die der digitale Zwilling des Roboters mit seiner direkten Umgebung verbunden werden kann sowie offene Schnittstellen, die eine Einbindung in Systeme erlauben, die weit über die direkte Umgebung hinaus gehen, z.B. ERP-Systeme.

Umfrage im Mittelstand: Nachfrage, Hoffnungen, Tipps fürs Management

Fast die Hälfte der deutschen Mittelständler (46 % in Betrieben mit 50-500 Mitarbeiter:innen) plant, sich Roboter ins Haus zu holen, 14 Prozent haben schon welche. Das hat eine Umfrage unter mehr als 1.000 deutschen Fach- und Führungskräften ergeben*. Die Mehrheit (66 %) sagt, dass es nun „höchste Zeit“ sei, dass auch manuelle Arbeit bei Digitalisierungsplänen priorisiert würde. Viele Fachkräfte erhoffen sich Verbesserungen im Alltag, zum Beispiel eine Verringerung der repetitiven Tätigkeiten, Qualitätsverbesserungen oder die Aussicht, weniger mit gefährlichen Substanzen arbeiten zu müssen. Fast ein Drittel sagt zudem, ihr Job würde interessanter werden (27 %) und sie würden Stolz empfinden, mit High Tech zu arbeiten (26 %). Begleitmaßnahmen der Einführung: Am wichtigsten sind den Befragten Trainings und Upskilling-Programme (34 %) sowie Mitsprache, welche Aufgaben an Roboter übergeben werden (29 %).

* Methodik

fruitcore robotics beauftragte die Marktforscher von Sapio Research mit der Befragung von Fach- und Führungskräften in Deutschland. 1005 Fach- und Führungskräfte aus Deutschland nahmen an der Umfrage teil. Die Auswahl fokussierte sich auf Fach- und Führungskräfte, die nicht vorwiegend im Büro arbeiten, sondern v.a. manuelle Arbeit verrichten oder manuelle Arbeit planen und/oder beaufsichtigen. Bei mehr als 30 Prozent der Befragten in Deutschland (322 Personen) handelt es sich um Produktionsleiter:innen. Die Umfrage wurde Anfang April 2022 durchgeführt.

Robothon® – The Grand Challenge 2022 // Call for Teams

Dear Robothon® Community!

We, the Munich Institute of Robotics and Machine Intelligence (MIRMI) of the Technical University of Munich (TUM), in collaboration with Messe München

and automatica have launched successfully a new high-tech platform calledmunich_i in 2021, an event bringing together the world’s leading thought leaders and personalities from AI and robotics.

munich_i will take place again at the next automatica from June 21-24, 2022 in Munich, therefore

Robothon®, the international competition to develop skills in robot manipulations, will also go into the second round!!

Robothon® – The Grand Challenge Series focuses on pressing and unsolved challenges of our time and was 2021 held digitally in the run-up to the automatica sprint

with 9 international teams and a renowned Grand Challenge Jury. As a highlight, it ended with the Award Ceremony on June 22, 2021

with 4 winning teams, a total prize money of € 22,500, great recognition and an expansion of our community.

Are you a motivated robotics enthusiast looking for new challenges?

CALL FOR TEAMS is open until March 31, 2022!!

Apply HERE!

KEY FACTS:

- Robothon® will once again will be held digitally from April 29 to June 1, 2022

- Special highlight: the Award Ceremony will take place on-site on June 21, 2022, during automatica at the Messe München!

HOW IT WORKS:

- Robothon® againwill focus on single-arm robot manipulation

- The Grand Challenge 2022: disassembly and sorting of e-waste

- The competition is free of charge

- Up to 20 selected teams can participate (2-4 members)

- All roboticists (academic and young professionals) are encouraged to apply

- Teams will need to provide their own robot to complete the challenge remotely

- Each team will receive an internet connected competition task board by mail

- The processing period of 1 month starts from receipt of the competition scorecard

- Team performances will be evaluated by the Grand Challenge Jury

- Prize money awaits the finalists!

HAVEN’T SIGNED UP YET? Apply as a team until March 31, 2022, and visit our website www.robothon-grand-challenge.com to learn more.

Know someone who should participate? Please help spread the word!

Feel free to email us with any questions at [email protected].

With kind regards,

The Robothon® Team

Barbara Schilling & Peter So (Technical Leader)