In July, the Taiwanese-based company MATRIX Robotics System marked a significant milestone in educational robotics with the release of its latest product: the MATRIX R4 Robo Set. Developed in partnership with and certified by Arduino Education, this innovative robotics set is built on the UNO R4 WiFi platform, providing users with a sophisticated 12- in 1 robot model and versatile tool to explore and excel in the field of robotics.

The MATRIX R4 Robo Set has been meticulously designed to cater to all ages for versatile projects. The MATRIX R4 offers comprehensive solutions that leverages Arduino’s cutting-edge technology. The set provides endless possibilities for those eager to enhance their robotics skills, whether they are students, hobbyists, or seasoned competitors.

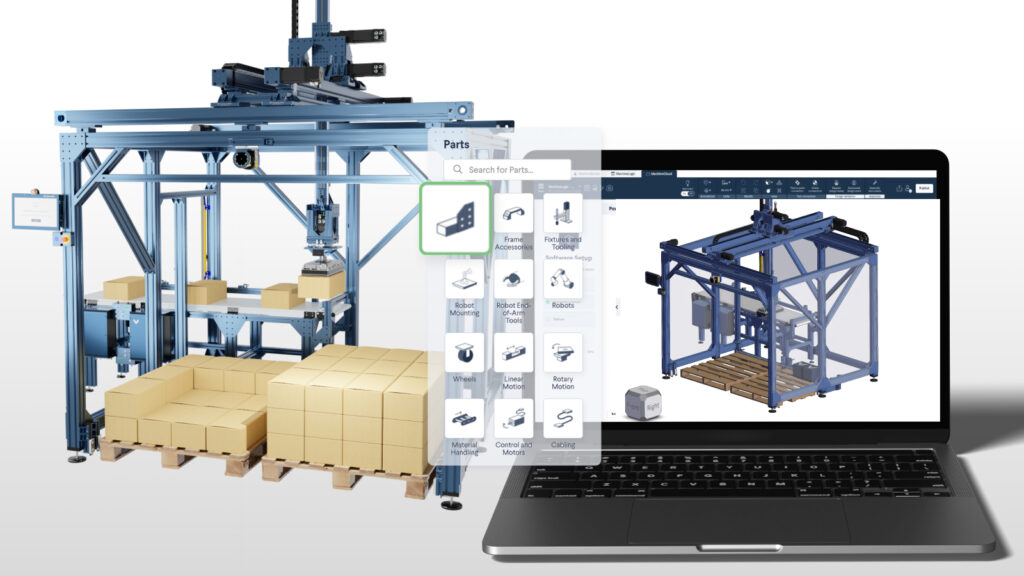

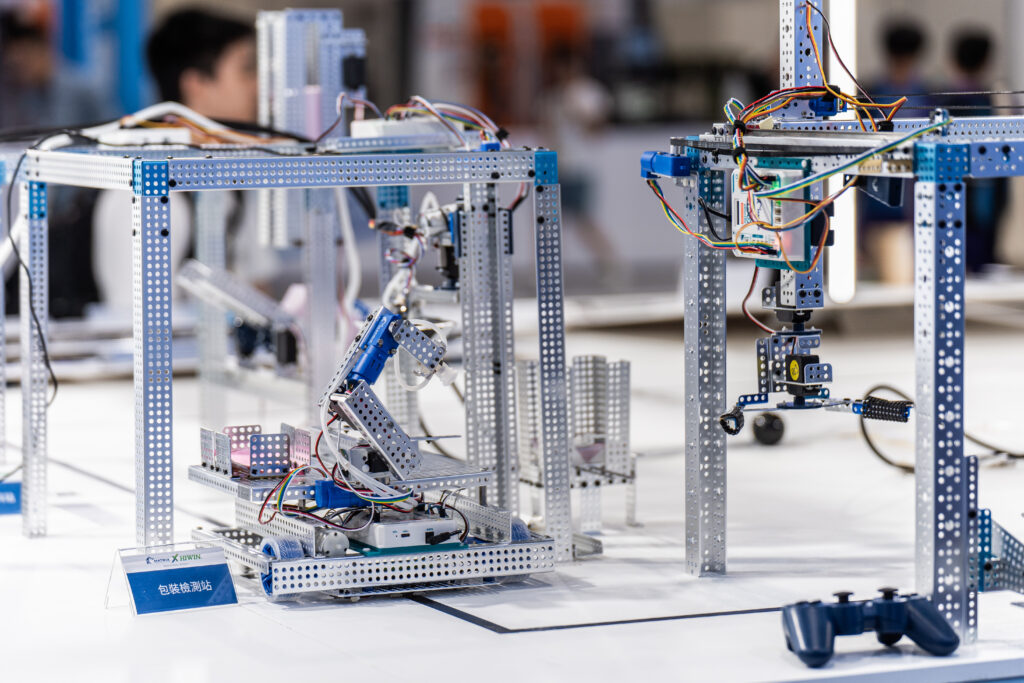

The MATRIX R4 Robo Set includes a versatile controller that supports various applications beyond just robots, but also factory simulations. The controller allows for different projects and scenarios, such as smart factories, by integrating components like the Mvision camera and IoT functionalities. The Smart Factory simulation models a factory inspection process where products are assessed after production. This flexibility enables users to explore and understand a wide range of industrial and technological processes.

The MATRIX R4 RoboSet serves as more than just a tool; it is an educational journey. With educational objectives, it enhances learning programming featuring MATRIXblock and Arduino IDE, introduces foundational computing concepts, making it an ideal starting point for anyone interested in computer science and robotics. Furthermore, with a quick and easy assembly building system, users gain hands-on experience in mechanism design, a crucial skill in robotics.

The R4 set not only lays the foundation for developing hardware and software integration skills but also encourages users to think critically and creatively when tackling real-world robotics challenges. It provides practical applications for problem-solving skills. While controlling a motor with Arduino WiFi can be challenging, especially when managing both the motor and sensors, the R4 set simplifies the process with its easy plug-and-play solution.

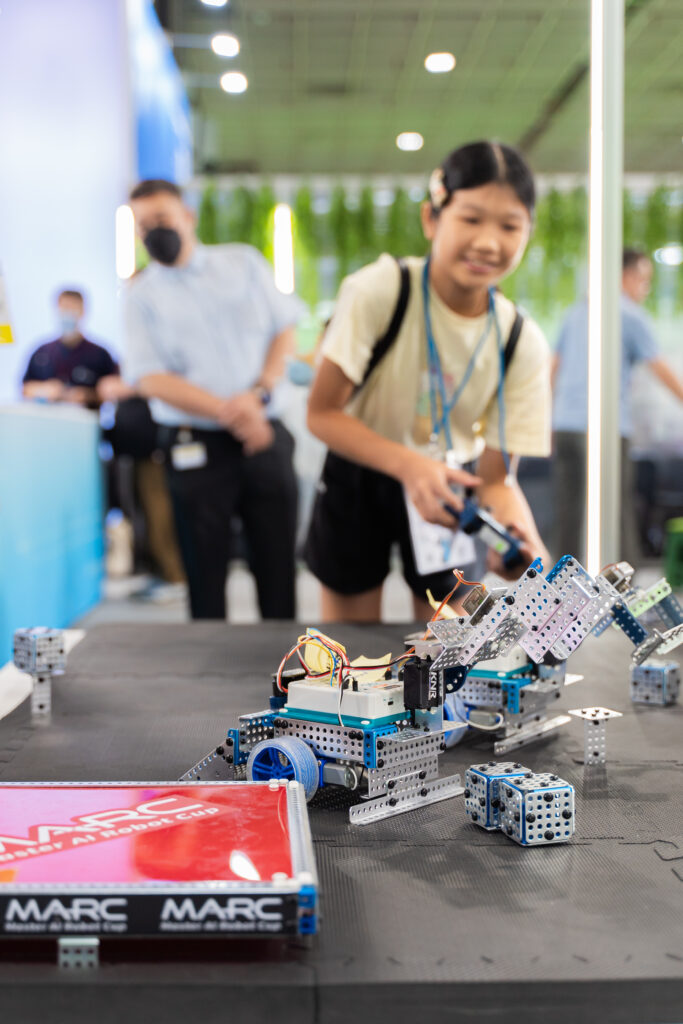

One of the standout features of the MATRIX R4 Robo Set is its compatibility with various expansion kits, allowing users to customize and expand up to 12 different robotic creations. For example, the MX300 expansion kit empowers users to build robust and fundamental robots using the MATRIX basic set. The MX300 Expansion Kit is a versatile tool that bridges the gap between theory and practice in small and medium-sized Autonomous Mobile Robots (AMRs). Tailored for students, educators, and enthusiasts, it helps users understand AMR principles and serves as a demonstration robot for the MARC (Master AI Robot Cup) competition, providing participants with a platform to practice and hone their skills in a competitive setting.

Additionally, the MJ2 Wireless Joystick, a key part of the MATRIX ecosystem, uses 2.4G wireless technology to connect over 20 devices simultaneously. Its strong anti-interference and stable signal make it perfect for precision-demanding competitive scenarios.

As the field of robotics continues to evolve, MATRIX Robotics System remains at the forefront, providing cutting-edge tools and resources to inspire the next generation of roboticists. The MATRIX R4 Robo Set represents a gateway to a world of innovation, creativity, and competition, equipping users with the skills they need to succeed in the rapidly changing landscape of robotics.

Get yours today

https://www.matrixrobotics.com/matrix-r4-robo-set

By joining the MATRIX Project #DevelopMATRIXR4ROBO program, you’ll:

-Gain Hands-On Experience: Receive a complimentary MA300 sample to explore and integrate into your projects.

-Provide Valuable Feedback: Share your insights and suggestions to help improve future iterations of the MA300.

-Showcase Your Skills: Demonstrate your expertise through application videos and social media promotion.

Sign up today and create like never before!