Archiv der Kategorie: Video

Rise of the Autobots: Fanhome’s Optimus Prime

Fanhome, a well-known collectors‘ company, has just released a new line celebrating Optimus Prime, arguably the most recognizable figure in the Transformers franchise. Fans can now get their hands on a wide variety of high-quality building materials and magazines honoring the courageous leader of the Autobots, thanks to this limited-edition collection. Fanhome provides a quality experience for Transformers fans, from a sturdy backpack to a realistic model and the opportunity to construct one’s own Optimus Prime. Explore the amazing Fanhome Optimus Prime Collection and all it has to offer.

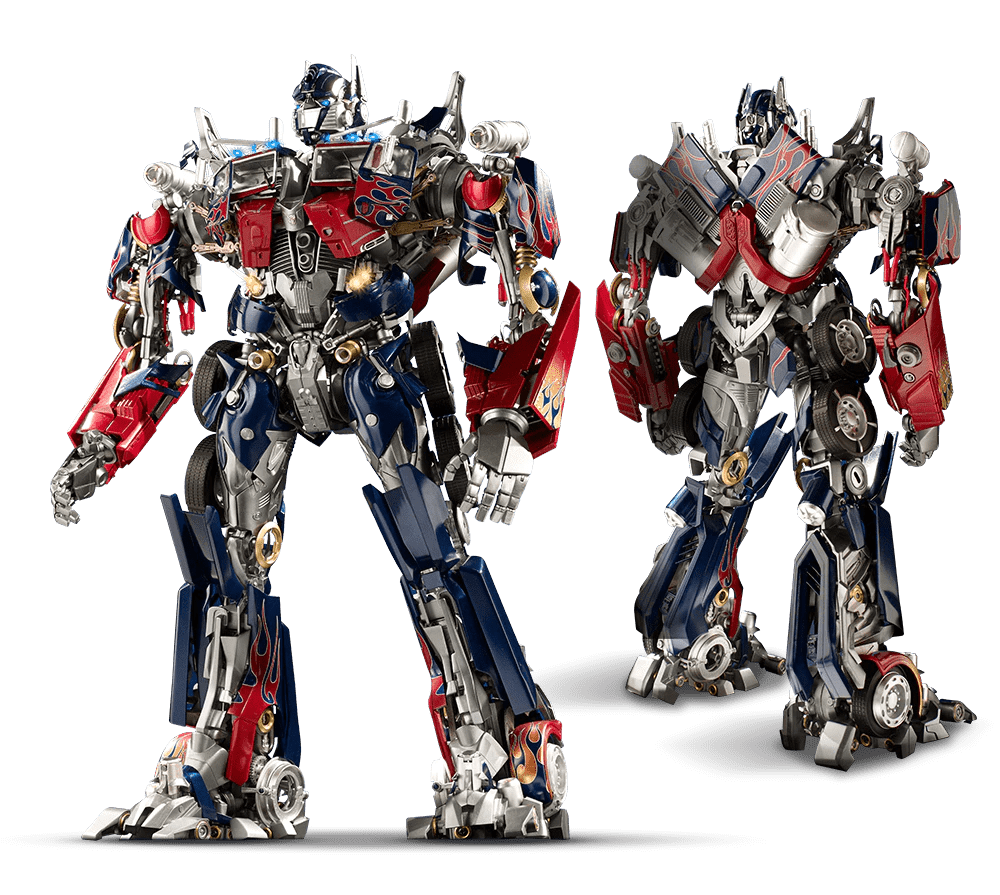

The Legend of Optimus Prime Model: Specifications

The centerpiece of the exceptional Fanhome Optimus Prime Collection, the Legend of Optimus Prime sculpture stands tall at an astounding height of 60 cm. The strength, leadership, and unshakable commitment to justice of Optimus Prime are perfectly captured in this expertly crafted collectible. Get ready to be enthralled as you see Optimus Prime’s magnificent presence come to life.

The Legend of Optimus Prime model was meticulously created and had a level of artistry that is simply amazing. Using metal and ABS plastic combined with high-quality materials offers a long-lasting and accurate portrayal of the legendary Autobot leader. The delicate details are all accurately replicated, providing enthusiasts with an unmatched authentic replica.

This model stands out for having amazing features that make Optimus Prime come to life. Fans can exhibit Optimus Prime in battle-ready mode thanks to the model’s painstakingly crafted accessories and details, which give an extra level of authenticity. As Optimus Prime’s eyes are illuminated by fascinating LED lights, the model also exudes strength and resolve.

You may buy this Legend of Optimus Prime model with confidence since it is an officially licensed item that demonstrates Fanhome’s dedication to providing Transformers fans with products of the highest caliber and authenticity. It is evidence of the company’s commitment to giving fans memorabilia that accurately reflect the characters they like.

The Legend of Optimus Prime model comes with batteries to make your experience even more pleasurable. As a result, you can dive right into the intriguing world of Transformers.

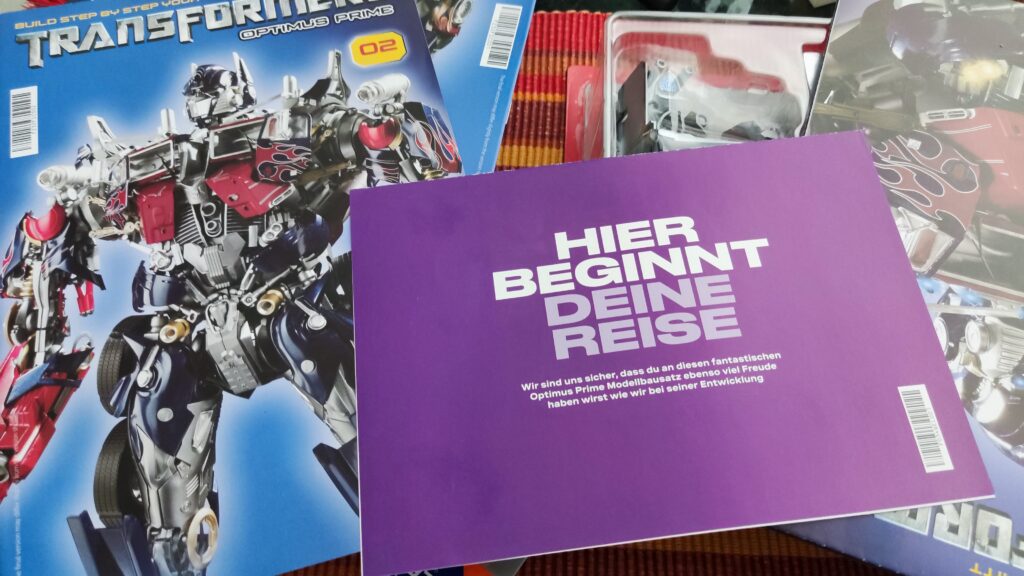

Build Your Own Transformers Optimus Prime

Build your own Transformers Optimus Prime with Fanhome if you want a realistic and exciting experience. Subscribers receive carefully curated packages comprising all the parts and tools needed for assembly as part of a monthly subscription. New construction phases start each month, accompanied by educational periodicals, including interesting articles, directions, and statistics. Fans can fully immerse themselves in the Optimus Prime universe and see their invention come to life thanks to this hands-on method.

Conclusion

For Transformers fans and collectors, Fanhome’s Optimus Prime Collection is a paradise. Fanhome offers a first-rate experience in the process of making your own Optimus Prime. You may embody the courage, heroism, and steadfast dedication that Optimus Prime stands for.. Let the Fanhome Optimus Prime Collection stoke your imagination and whisk you away to the enthralling world of the Transformers as you let loose your inner Autobot.

The Optimus Prime Backpack for the first 1000 subscribers

Any dedicated Transformers fan must own the Optimus Prime backpack. This unique collector backpack, which was made with durability in mind, enables you to show off your support for Optimus Prime and the Autobots. Its robust design features characteristics that fans will immediately recognize, and its solid construction guarantees that it can sustain daily use. The bag combines practicality and fandom in an elegant way thanks to its roomy space and meticulous design. Subscribe now, be one of the first 1000 subscribes and get this unique backpack.

Weltweit abgeschiedenster Roboter automatisiert Wiederaufforstung im Amazonas

Ein Pilotprojekt von ABB Robotics und der US-amerikanischen Non-Profit-Organisation Junglekeepers zeigt auf, welche Rolle Cloudtechnologie für eine schnellere, effizientere und skalierbare Wiederaufforstung spielen kann.

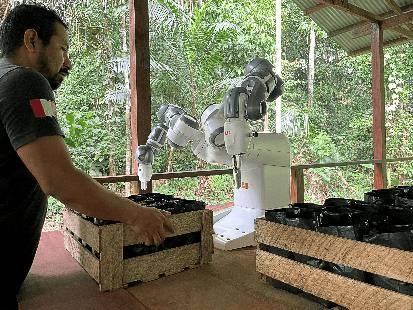

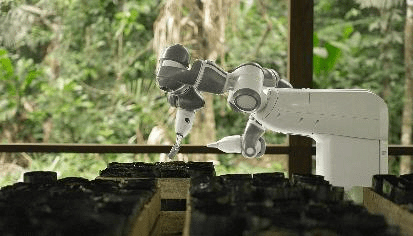

ABB Robotics unterstützt Junglekeepers bei ihrem Vorhaben, rund 22.000 Hektar Amazonas-Regenwald zu schützen und die Entwaldung umzukehren. In einer bislang einzigartigen Demonstration automatisiert der kollaborative Roboter (Cobot) YuMi von ABB Pflanzarbeiten an einem Forschungs- und Versuchsstandort mitten im Dschungel. Dabei beschleunigt er das Verfahren erheblich, so dass die Freiwilligen von Junglekeepers ihre wertvolle Zeit und Ressourcen für bedeutendere Arbeiten einsetzen können.

Mit Hilfe der RobotStudio Cloud-Technologie von ABB simulieren, optimieren und realisieren ABB-Experten die Programmierung für YuMis Tätigkeiten im Regenwald vom 12.000 Kilometer entfernten Västerås in Schweden aus und ermöglichen damit den abgeschiedensten Robotereinsatz der Welt.

„Die Zusammenarbeit von ABB und Junglekeepers zeigt, dass Roboter- und Cloudtechnologien eine zentrale Rolle bei der Bekämpfung der Entwaldung spielen können. Letztere zählt zu den Hauptverursachern des Klimawandels“, sagt Sami Atiya, Leiter des Geschäftsbereichs Robotik & Fertigungsautomation von ABB. „Unser Pilotprojekt mit dem abgeschiedensten Robotereinsatz der Welt ermöglicht die Automatisierung stark repetitiver Aufgaben. So haben die Ranger mehr Zeit für wirkungsvollere Arbeiten im Regenwald und können das Land, auf dem sie leben, besser schützen.“

In einem Forschungs- und Versuchslabor in einer abgeschiedenen Region im peruanischen Amazonasgebiet wurde ein YuMi-Cobot installiert, um zentrale Aufgaben bei der Einpflanzung von Saatgut zu automatisieren – bisher eine rein manuelle Tätigkeit. Der Cobot gräbt ein Loch in die Erde, legt das Saatgut ein, verdichtet die Erde darüber und markiert die Stelle mit einem farbigen Etikett. Mit dem Einsatz von YuMi kann Junglekeepers täglich eine Fläche von zwei Fußballfeldern wieder bepflanzen. Dank der Automatisierung können die Freiwilligen von Junglekeepers ihre wertvolle Zeit und Ressourcen für wirkungsvollere Arbeiten einsetzen. Dazu gehören etwa Patrouillen zur Abschreckung illegaler Holzfäller, die Aufklärung der lokalen Bevölkerung über den Erhalt des Regenwaldes und das Einpflanzen von jungen Bäumen.

Die vollständig abgelegene und autonome Cobot-Installation löst ein weiteres Problem: Menschen zu finden, die für einen längeren Zeitraum an diesem abgelegenen Ort im Dschungel arbeiten wollen. Nach der ersten Installation kann YuMi seine Aufgaben selbstständig ausführen und muss sich nur bei Bedarf einer Fehlerbehebung unterziehen.

„Wir haben bisher 20 Prozent des gesamten Amazonas-Regenwaldes verloren, und ohne den Einsatz von Technologie kommen wir beim Naturschutz nicht mehr weiter“, erklärt Moshin Kazmi, Mitgründer von Junglekeepers. „YuMi vor Ort zu haben ist eine ausgezeichnete Möglichkeit, unsere Ranger mit neuen Arbeitsweisen vertraut zu machen. Er beschleunigt und erweitert unsere Aktivitäten und bringt unsere Mission voran.“

Die Zerstörung des Amazonas-Regenwaldes durch menschliche Eingriffe wie Abholzung und Brandrodung zur Gewinnung von Flächen für die Landwirtschaft trägt erheblich zu den verheerenden Auswirkungen des Klimawandels bei. Seit 1985 wurden schätzungsweise mehr als 870.000 km² des Amazonas-Regenwaldes gerodet – eine Fläche, die größer ist als Frankreich, das Vereinigte Königreich und Belgien zusammen.1 Da bereits mehrere Milliarden Bäume verschwunden sind, erwärmt sich die Region schnell.

„Der Amazonas ist in Gefahr. Um ihn zu retten, müssen wir Technologie, Wissenschaft und lokales Wissen bündeln, andernfalls wird es zu spät sein. Der Regenwald kann gerettet werden, aber wir müssen alle diese Elemente zusammenführen, um wirklich etwas zu bewirken“, betont Dennis del Castillo Torres, Director of Forest Management Research am Peruvian Amazon Research Institute. „Es ist sehr wichtig, Spitzentechnologie und Naturschutz zu vereinen. Es gibt viele Technologien, die wir für den Erhalt des Waldes nutzen können. Dieser Roboter kann die Wiederaufforstung beschleunigen, muss aber sehr gezielt eingesetzt werden. Wir sollten ihn in stark entwaldeten Gebieten zur Beschleunigung der Neubepflanzung nutzen.“

Das Pilotprojekt wird durch die RobotStudio Cloud-Technologie von ABB unterstützt, die Teams auf der ganzen Welt ermöglicht, in Echtzeit zusammenzuarbeiten. Diese innovative Art der Fernprogrammierung ermöglicht ein neues Maß an Flexibilität und sofortiger Optimierung, was die Effizienz und Resilienz steigert und Zeitverluste bei der Bepflanzung verhindert. Gestützt auf mehr als 25 Jahre Erfahrung in der Offline-Programmierung bietet RobotStudio branchenführende digitale Technologie und gewährleistet eine 99-prozentige Übereinstimmung zwischen Simulation und Realität. So können Anwender den Zeitaufwand für Tests von Roboterlösungen um 50 Prozent reduzieren und Produktionsunterbrechungen vollständig vermeiden.

Das Pilotprojekt von ABB Robotics im Amazonasgebiet unterstützt das Ziel der Division, mit intelligenten Roboter- und Automatisierungslösungen zu einer nachhaltigen Transformation beizutragen und Unternehmen zu helfen, ihre Produktivität zu steigern, Abfallmengen zu verringern und die Effizienz zu maximieren. 2022 arbeitete ABB Robotics mit der gemeinnützigen Organisation und dem globalen Netzwerk Parley for the Oceans zusammen, das sich gegen die Plastikverschmutzung und Zerstörung der Weltmeere einsetzt. ABB Roboter stellten per additivem 3D-Druck personalisierte Designobjekte aus recyceltem Parley Ocean Plastic® her.

Auf Wunsch von Junglekeepers wird das Pilotprojekt mit RobotStudio Cloud und YuMi im Regenwald über rund sechs Wochen laufen (im Mai und Juni 2023). Nach Abschluss des Pilotprogramms wird ABB Möglichkeiten zur weiteren Unterstützung von Junglekeepers ausloten. Außerdem will das Unternehmen prüfen, wie seine Roboterlösungen und Cloudtechnologien die nachhaltige Transformation zusätzlich maßgeblich fördern können.

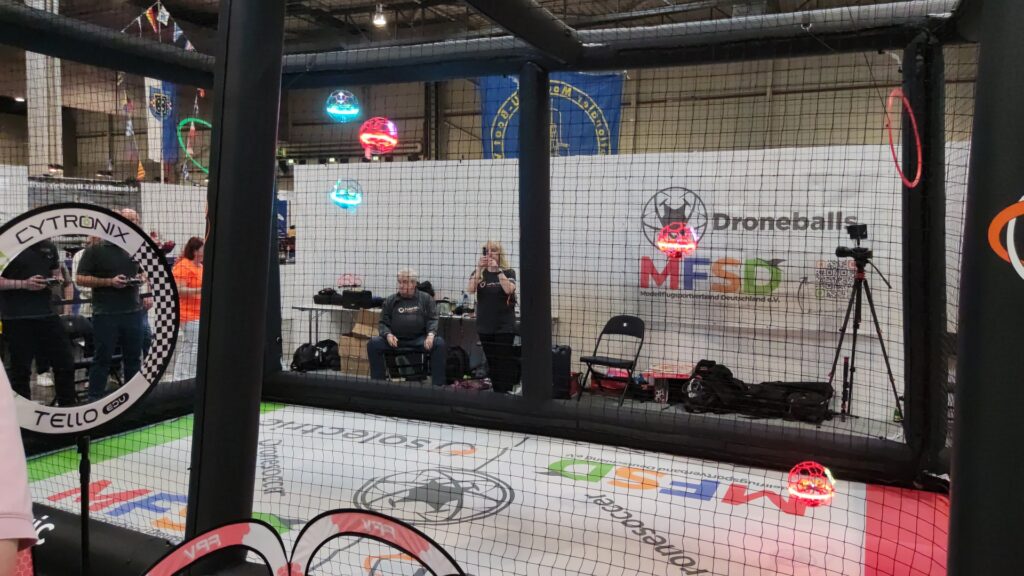

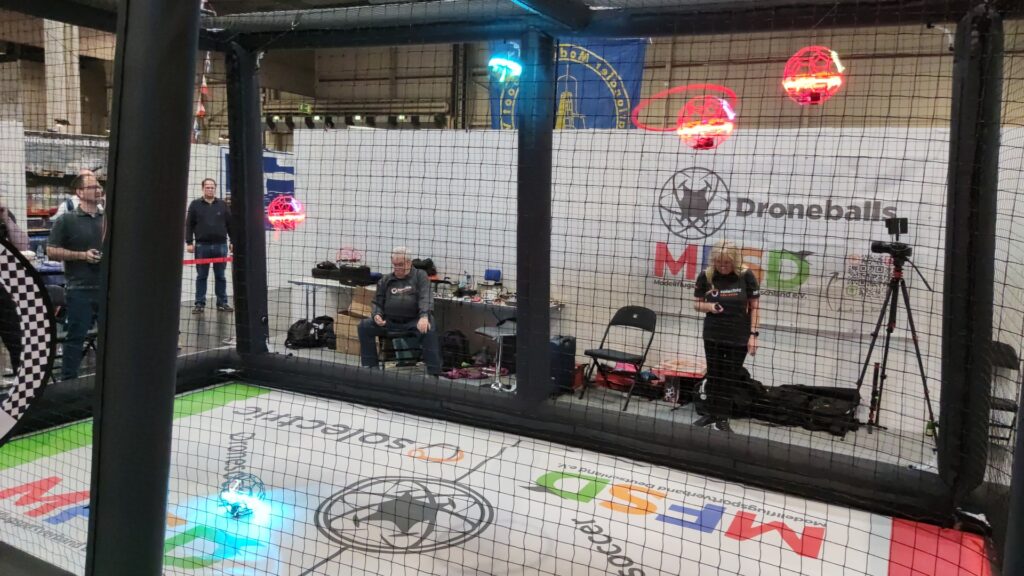

Logistics and Automation 2023 Dortmund

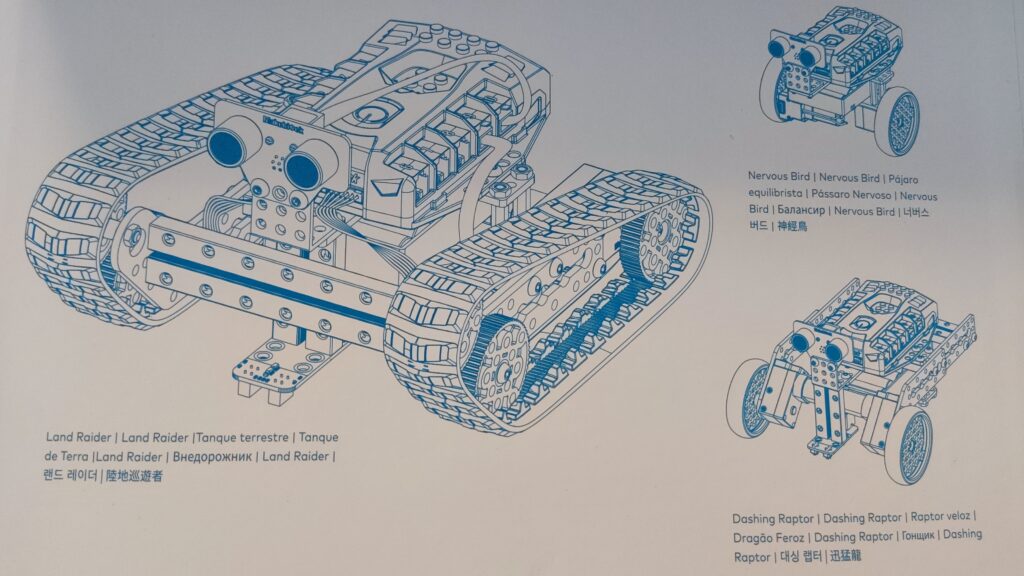

Makeblock mBot Ranger – 3in1 robot building kit

The Makeblock mBot Ranger is a 3-in-1 robot building kit designed for kids aged 10 years that teaches building and programming robots in a fun and exciting way.

Features

1. Three different robot configurations

- The mBot Ranger can be configured into three different robots: a robot tank, a three-wheeled racing car, and a self-balancing car. This allows kids to learn about different types of robots and how they work.

2. Programmable

- The mBot Ranger is programmable using the mBlock software, which is based on Scratch 2.0. This allows kids to learn coding and programming skills in a fun and interactive way.

3. Easy to build

- The kit is solidly built, mostly metal, and has easy-to-understand architecture. It comes with the tools to build several different iterations and lots of add-ons for customization.

4. Hands-on learning

- The mBot Ranger combines building and programming, functionality and hands-on learning. This allows kids to learn by doing and to see the results of their work in action.

5. Control from smartphone or tablet

- The mBot Ranger can be controlled from a smartphone or tablet using Bluetooth if you don’t like to program. This allows kids control their robot from a distance.

6. Great for entry-level coding lessons

- The mBot Ranger is a great entry-level coding robot kit. It is straightforward and simple to build and control, making it a great choice for kids who are just starting to learn about coding and robotics.

These features make it a versatile and educational tool for teaching kids about robotics and coding.

Hardware

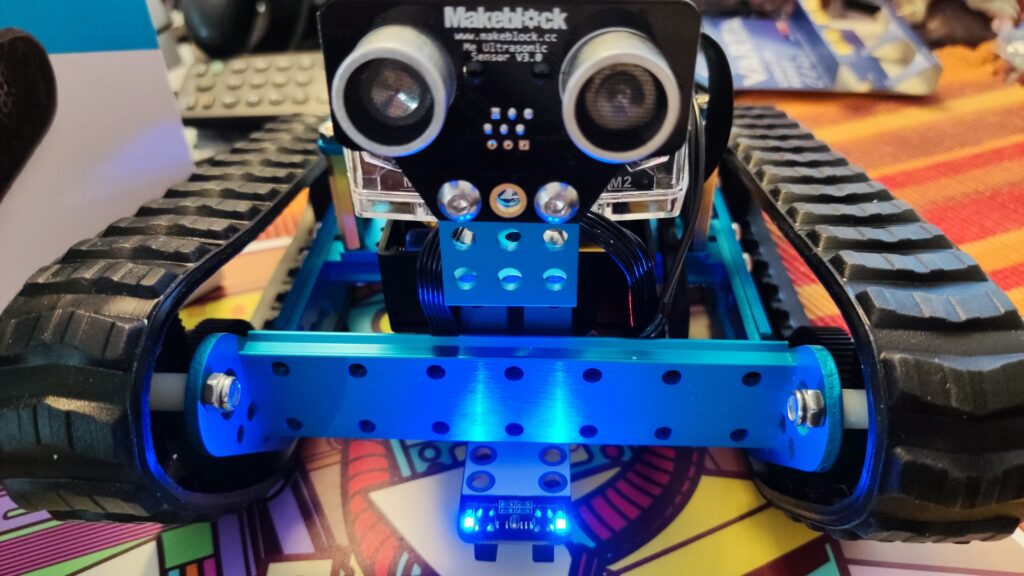

The Makeblock mBot Ranger is an educational robot with powder-coated metal parts and an Arduino compatible mainboard called the Me Auriga. Overall, the Makeblock mBot Ranger comes with a range of hardware and sensors that allow it to navigate, detect obstacles, follow lines, respond to light, and be controlled remotely. Here are some of the hardware and sensors in the kit:

1. Me Auriga mainboard

- The Me Auriga mainboard is an Arduino-compatible board that provides a wide range of features and interfaces.

- It is the brain of the robot and allows it to be programmed and controlled.

- The Me Auriga board integrates various sensors, including a gyro sensor, temperature sensor, sound sensor, and ultrasonic sensor

2. Ultrasonic sensor

- The mBot Ranger comes with an ultrasonic sensor that can detect obstacles and measure distances.

- This allows the robot to navigate and avoid obstacles.

3. Line follower sensor

- The kit also includes a line follower sensor that can detect and follow lines on the ground.

- This allows the robot to follow a path and stay on course.

4. Light sensor

- The mBot Ranger has a light sensor that can detect light intensity.

- This allows the robot to respond to changes in light and to adjust its behavior accordingly.

5. Infrared receiver

- The kit includes an infrared receiver that allows the robot to receive signals from a remote control.

- This allows the robot to be controlled from a distance.

6. Gyro sensor

- The gyro sensor can be used to determine the movement and posture of the robot.

- It can be used to make a self-balancing robot.

7. Temperature sensor

- The temperature sensor can be used to measure the temperature of the environment.

- It can be used to create a robot that responds to changes in temperature.

8. Sound sensor

- The sound sensor can be used to detect sound intensity.

- It can be used to create a robot that responds to sound, such as a robot that moves towards a loud noise.

Conclusion

mBot Ranger is a solidly built kit, mostly metal, with easy-to-understand architecture. It comes with the tools to build several different iterations and lots of add-ons for customization. The user manual is excellent and lists out all the components in the kit. The mBlock interface is pretty intuitive, especially if kids have already used Scratch or another block-based language, so kids are likely to be able to work out how to program the Ranger through exploration. Overall, the Makeblock mBot Ranger is easy to use and a great tool for teaching kids about robotics, coding, and hands-on learning.

The Makeblock mBot Ranger is an excellent piece of DIY kit for kids to build different types of robots, write code, and control them from a smartphone or tablet. It is a great tool for teaching kids about robotics, coding, and hands-on learning.

mbot Ranger and more MakeBlock products can be found here.

Robots-Blog at Interpack 2023

#DeutschlandDigital Exhibition at Haus der Geschichte Bonn

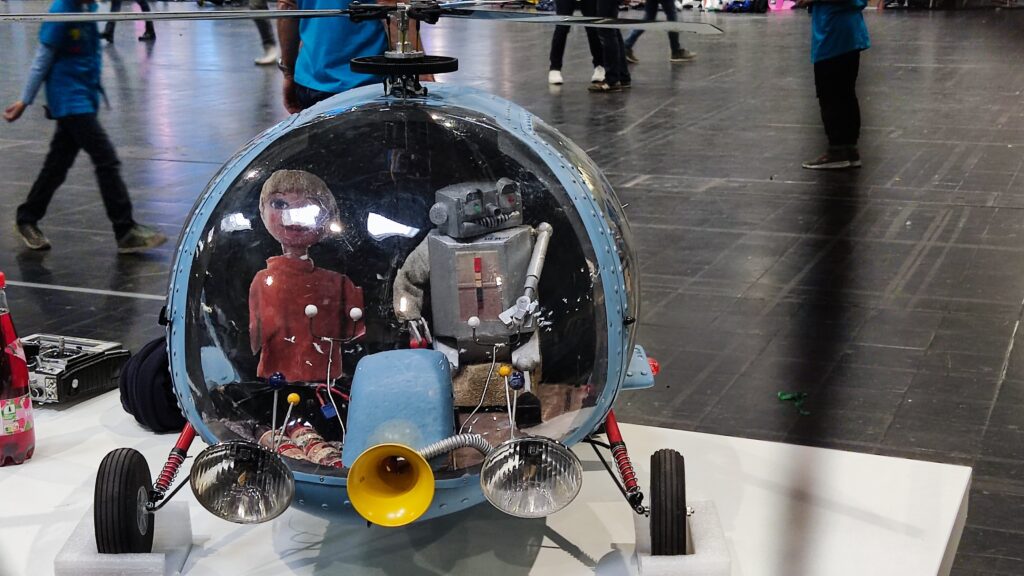

Intermodellbau 2023 Dortmund

LEGO 40619 BrickHeadz Wall-e and Eve

Igus Inside Experience. Two days of low cost automation Innovations.