Archiv der Kategorie: Events

Robot Operations Group Announces Plan For RobOpsCon 2022

A gathering of the global community of robotics and operations experts will advance the best practices for scaling the use of autonomous robots across industries

MOUNTAIN VIEW, CALIF. (PRWEB) DECEMBER 08, 2021

The Robot Operations Group, a global community of the top experts in scaling the application of advanced robotics, today announced the first-ever RobOpsCon will take place in October 2022 in Silicon Valley. The conference will bring together practitioners and a leading panel of multi-disciplinary speakers across industries, including logistics, supply chain, agriculture, hospitality and healthcare. Additional details will be announced shortly.

The Robot Operations Group, or ROG (pronounced “rogue”) has been meeting virtually for more than two years, with occasional in-person meetings as the pandemic allowed. With almost 150 members based across Europe, Asia, and the Americas, the group’s monthly virtual meetings and RobOps Masters interviews have included renowned experts such as Aaron Prather from FedEx, Lawrence Ibarria of Verdant Robotics and Daniel Theobald, Chief Innovation Officer and founder of Vecna Robotics.

The group’s Robot Operations Manifesto, an open-source document with contributions from many of its members, outlines the best practices for robot operations at scale. With RobOpsCon 2022, the growing community will have an opportunity to meet in person, learn from each other and explore the benefits of robotics in a broad range of applications, from material handling to agriculture to cleaning and sanitization.

“Being part of this community is a great way to realize the value of robotics,” said Florian Pestoni, CEO and co-founder of InOrbit and co-founder of ROG. “There are plenty of online groups and conferences for roboticists to learn how to build a robot, but there wasn’t one for people focused on scaling robots from 5 to 5,000 and beyond. Until now.”

At a recent Association for Advancing Automation (A3) AMR & Logistics conference in Memphis, TN, several ROG members met at an event sponsored by InOrbit and A3. The rapid exchange of ideas, the shared pain points and the different perspectives resulted in a lively discussion. RobOpsCon 2022 aims to take this to the next level.

“I was an active participant in conferences such as LISA, where systems administrators could learn from each other,” said Joe Wieciek, director of technical operations at Outrider and co-founder of ROG. “But when I transitioned from more traditional cloud systems to robotics, I found this was missing. With RobOpsCon 2022, we are continuing that tradition and helping people manage large robot fleets.”

“ROG has always enabled me to connect with innovators in the robot industry at an informal level. It’s not commercial, but the connections have opened a wealth of collaborative opportunities,” said Aldus von der Burg, CEO of Meili Robots and a ROG member based in Copenhagen. “RobOpsCon will be a chance for those in the industry, or even just curious about robot operations, to discuss and learn as a part of a growing and supportive robotics community.”

Participation in ROG’s Meetup group and monthly virtual meetings is free and open to everyone. Tickets for RobOpsCon will be available in June 2022 for the October event.

For more information on RobOpsCon, please visit robops.org/robopscon2022.

About Robot Operations Group

ROG (pronounced „rogue“) is a cross-industry group aimed at developing and sharing best practices to advance the operation of autonomous robots at scale. With almost 150 members and growing rapidly, the group meets monthly online and has published the open-source Robot Operations Manifesto.

Tactile Telerobot by Converge Reaches Finals of $10 Million ANA Avatar XPRIZE

Judges recognize the world’s first haptic robotic system to transmit realistic touch feedback to an operator located anywhere in the world

Converge Robotics Group reached the finals of the $10M ANA Avatar XPRIZE competition for an avatar system that can transport human dexterity to a remote location in real-time.

Converge Robotics Group is an international collaboration between Shadow Robot Company, HaptX, and Tangible Research responsible for developing the Tactile Telerobot, a high-fidelity dexterous telerobot in use in the U.S., U.K., and Asia, and now advanced to the ANA Avatar XPRIZE finals.

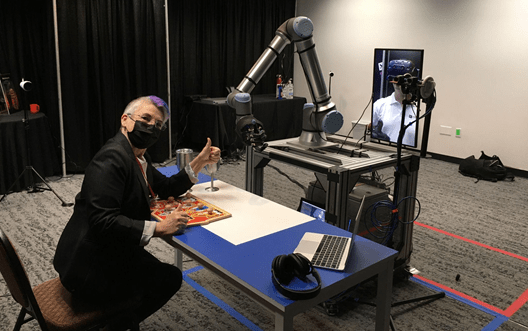

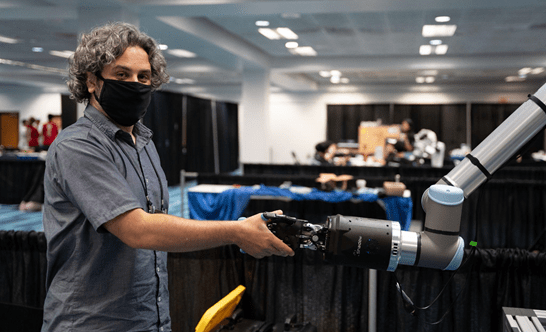

The Tactile Telerobot features Shadow Robot’s Dexterous Hands, HaptX Gloves DK2 with true-contact haptics, SynTouch’s biomimetic tactile sensors, and Universal Robots robotic arms to allow an operator to perform complex human tasks instantaneously across the globe such as handling objects in laboratories or workshops. The Tactile Telerobot mimics your movements, displaying human-like and reactive behaviours. Users can feel what the robot hands are touching, making it possible to connect humanity across vast distances like never before.

The groundbreaking technology of the Tactile Telerobot has been described as “weirdly natural” by Amazon founder Jeff Bezos, who added, “The tactile feedback is really tremendous.” The Telerobot’s most recent improvements for the XPRIZE Semifinals, hosted in Miami, include the use of high-fidelity audio and visual technology and other safety and usability improvements. It meets the competition’s criteria for a non-autonomous Avatar System with which an operator can see, hear, and interact within a remote environment in a manner that feels as if they are truly there.

Rich Walker, Managing Director of the Shadow Robot Company, said, “We’re coming up to Shadow’s 25th anniversary as a company and what a way to lead up to it by reaching the finals for a four-year global competition! The Shadow Dexterous Hands have been a sought-after product among the research community ever since we formally registered as a company. What the Hands can achieve today, on their own and as part of the Tactile Telerobot, is truly revolutionary and it’ll only get better.”

“Lifelike touch feedback is a critical component of transporting human presence,” said Jake Rubin, founder and CEO of HaptX. “The Tactile Telerobot demonstrates the difference that true-contact haptics makes in the field of robotic teleoperation, and we’re delighted for HaptX and our partners in Converge Robotics Group to receive this recognition from the ANA Avatar XPRIZE judges.”

“I’m proud of the accomplishments of our international and interdisciplinary team,” said Jeremy Fishel, founder and CTO of Tangible Research and Converge’s XPRIZE team lead. “We’ve brought together experts in robotic dexterity and haptics with the amazing technology of our partners and collaborators to do amazing things.”

In the XPRIZE Semifinals, the Converge Robotics Group debuted their collaboration with Voysys, a company that specialises in high-quality, low-latency video communication for the teleoperation of vehicles and machines.

„The combination of the Voysys video pipeline with ultra-low latency, the HaptX Gloves DK2, and the sensitive robot hand from Shadow Robot truly revolutionizes telepresence and makes remote working possible for a whole range of new industries,“ said Magnus Persson, CEO of Voysys.

“Advancing to the ANA Avatar XPRIZE finals alongside excellent competition is a significant milestone in this journey,” said the Converge Robotics Group in a statement “We look forward to showing how our Telerobot system can be used by ordinary people in amazing ways, making engineering jobs safer, reducing the need for global travel (and CO2 emissions) and letting us spend more time at home with our loved ones.”

MAKER LEARN FESTIVAL

FREE E-LEARNING ARRIVES TO YOUR HOME OR OFFICE FROM 8 TO 12 NOVEMBER BY MAKER FAIRE ROME

Over 50 webinars, talks, online and free workshops about all the innovation topics offered by our makers and partners: check out the complete list of webinars and choose the one that suits you the most!

Participating is simple: you just need to register for the event of your choosing and then you will receive an alert just before it starts. All webinars are held on Zoom: make sure you got the app on your device.

MAKER LEARN FESTIVAL: E-LEARNING FOR EVERYBODY

Maker Learn Festival is truly for everyone.

A few examples? If you are a professional, an entrepreneur, a startupper, take look at the webinars dedicated to the world of entrepreneurship with specific focus on digital and robotics, artificial intelligence, digital manufacturing and 3D printing, transition 4.0, PNRR and incentives for SMEs . Eg check the selection for the fabrication topic here.

And that’s not all, an entire section is dedicated to innovation born within the Italian universities and there is no shortage of webinars and specific workshops for students and young people!

„Academic“ events: select the „Universities“ tag and discover all the workshops and talks organized by some of the most important Italian universities, including the University of Pisa, La Sapienza University of Rome, the University of Studies Roma Tre, the Polytechnic of Bari.

Appointments for students and teenagers: dedicated contents from robotics to experiments to be done in the classroom or at home along with the parents.

And if you want to, you can specifically select the topics of your interest, browse by topics such as art, robotics, artificial intelligence … the offer is very wide!

Come and discover all the innovation you need on the Maker Learn Festival, from 8 to 12 November!

WHAT IS MAKER LEARN FESTIVAL

Maker Learn is the project of Maker Faire Rome and PID Punto Impresa Digitale, for continuous training, a web gateway in which you can find free training opportunities throughout the year covering the most diverse topics. Maker Learn Festival is the natural continuation of Maker Faire Rome, the event that was held from 8 to 10 October. With Maker Learn Festival we celebrate the continuous training by concentrating over 50 different courses in one week. By participating in the Maker Learn Festival, you can experience firsthand the benefits that “life long learning” can offer you.

Oxford University’s Robotics Institute Win Prestigious International Exploration Challenge

Robotics researchers from the Oxford Universities Robotics Institute, have contributed to the winning team, Team CERBERUS, at the DARPA Subterranean Challenge – coming away with the top prize of $2m. The finals of the competition concluded on Friday in an underground cavern in Louisville, Kentucky with 8 international teams going head-to-head.

Underground settings present significant challenges for civilian first responders, with unknow hazards and conditions that can vary drastically or change quickly. The DARPA Subterranean or „SubT“ Challenge was established to stimulate new approaches to rapidly map, navigate, and search underground environments during time-sensitive disaster response scenarios.

The challenge took place over three years and was designed to push the boundaries of autonomous robotic technology. The task was to explore an underground environment and to locate objects such as mannequins – simulating injured humans, – backpacks, phones and tools.

‘We are delighted to have done so well. Contributing to CERBERUS has really accelerated our research. After 3 years of preparation, it was fantastic to test it in the DARPA’s complex underground maze’. Said Prof. Maurice Fallon, lead of the Oxford University team.

Points were awarded when an object was correctly located. Challenges included locomotion over rough terrain, accurate mapping, and coordination of the robot team by a single operator from outside the test location. The test location blended aspects of cave, tunnel and urban subways and was often unlit, filled with smoke or on a steep slope.

CERBERUS*, deployed a team of four quadruped robots, called ANYmals, as well as autonomous aerial vehicles in the competition organized by the US Government research agency DARPA.

‘In the underground environment there are so many challenges from lighting and communications to the slipperiness of terrain itself. This demanded a whole range of breakthroughs by our team’. Said Dr. Marco Camurri, Senior researcher, Oxford University.

In the end CERBERUS tied with a team from CSIRO – a research lab based in Brisbane, Australia – winning only on a tiebreaker. Other teams included representatives from top universities such as University of Colorado, Boulder (in 3rd place), Carnegie Mellon University, Massachusetts Institute of Technology (MIT) and Jet Propulsion Laboratory (part of NASA).

It is envisaged that the technologies will impact on disaster response, environmental monitoring, industrial inspection, and construction sectors.

ROIBOT 2022: igus sucht nach spannenden Anwendungen mit kostengünstiger Robotik

Der Preis für Automatisierungslösungen mit einem schnellen Return-On-Invest geht in die 2. Runde

Köln, 9. September 2021 – Sie automatisieren die Verpackung, sortieren Waren und helfen bei gefährlichen Aufgaben im Arbeitsalltag: kostengünstige Robotik- und Automatisierungslösungen von igus. Die kreativsten Anwendungen zeichnet der motion plastics Spezialist auch 2022 wieder mit dem ROIBOT Award aus. Gesucht werden Projekte, die mithilfe von igus Low Cost Automation und drylin Antriebsachsen einen schnellen Return-on-Invest erzielen konnten. Die Gewinner erhalten ein frei wählbares Robotik-Paket von dem Marktplatz RBTX.com im Wert von bis zu 5.000 Euro.

Über 70 Bewerbungen aus aller Welt gingen im letzten Jahr für den ROIBOT Award 2019/2020 ein. Der Preis kürt Automatisierungsprojekte, die kostengünstige Robotik- und Automatisierungslösungen von igus einsetzen. Die Sieger aus Salzburg (Österreich) durften sich dabei über ein Preisgeld von 5.000 Euro freuen. Die Studenten konstruierten ein mobiles Robotersystem mit Greifer, um gefährliche Handling-Aufgaben zum Beispiel im Handwerksbereich aus der Entfernung umzusetzen. Dazu kommt ein mit Sensorik ausgestatteter Handschuh zum Einsatz, der eine intuitive Steuerung durch Gesten ermöglicht und das mit Feedback. Für den kostengünstigen und wartungsfreien robolink D-Gelenkarm von igus entwickelten die Ingenieure ein Antriebssystem, ein Akkusystem sowie ein mechanisches Gerüst. Das Projekt überzeugte die Fachjury und gewann den ersten Platz. Den zweiten Platz belegte das Pick & Place-System für den Healthcare Sektor von Apostore. Es besteht aus einer Roboterzelle und einem Versorgungssystem für die zuführende Schüttgut-Ware. Den dritten Platz erreichte die deutsche Firma Superwurm. Die Regenwurmzüchter entwickelten mithilfe von igus Low Cost Automation eine Anlage, die Würmer automatisiert abzählt und in Dosen verpackt.

ROIBOT Award geht 2022 in die nächste Runde

Der ROIBOT Wettbewerb sucht auch jetzt wieder weltweit nach bereits bestehenden Low Cost Automation Anwendungen, die zu einem schnellen Return-on-Investment geführt haben. Zum Einsatz können sowohl robolink Gelenkarmroboter, drylin Delta-Roboter, kartesische Roboter sowie drylin Antriebstechnik von igus kommen. Eine Fachjury bewertet die Konzepte. Eine spannende Einreichung, die sich durch Kreativität und einem Optimierungsgedanken auszeichnen, führt zu einer hohen Bewertung. Der Gewinner erhält ein frei konfigurierbares Robotik-Paket im Wert von 5.000 Euro, der zweite Platz kann sich für 2.500 Euro und der dritte Platz für 1.000 Euro Automatisierungslösungen auf RBTX.com aussuchen. Einsendeschluss ist der 30. April 2022. Die Preisverleihung erfolgt durch igus auf der automatica 2022 in München, der Leitmesse für intelligente Automation und Robotik. Auf der Website igus.de/roibot-anmeldung können sich die Teilnehmer bewerben.

Schauen Sie sich jetzt die Gewinner vom ROIBOT Award 2019/2020 an: https://youtu.be/HAvJHEvj-pU

Robotik zum Anfassen: Universal Robots begrüßt MCI | Die Unternehmerische Hochschule® als autorisiertes Trainingszentrum

Innsbruck / München, 25. August 2021 – Praxisnahe Robotik-Schulungen für Österreich: Seit Mai 2021 ist das Innsbrucker Zentrum für Produktion, Robotik & Automatisierung ein autorisiertes Trainingszentrum von Universal Robots (UR). Das Zentrum ist eine gemeinsame Initiative der Unternehmerischen Hochschule® und der Industriellenvereinigung (IV) Tirol. Der Cobot-Marktführer aus dem dänischen Odense möchte mit dem Trainingsangebot vor Ort den Zugang zur Automatisierung für KMUs in Österreich noch einfacher gestalten. Voraussetzungen für die Autorisierung waren neben der geeigneten Schulungshardware auch zertifizierte, fachlich und didaktisch erfahrene Trainer.

„Unsere Schulungen ermöglichen allen Teilnehmern fundiertes Robotik-Wissen. Von den Basics der Programmierung in den Core Schulungen bis hin zur Umsetzung einer komplexen Cobot-Anwendung: In allen Trainings setzen wir auf praxisnahe Wissensvermittlung und höchste Qualität“, erklärt Benjamin Massow, Leiter des Zentrums für Produktion, Robotik & Automatisierung.

Trainingszentrum in Tirol: Internationale Qualität, regionaler Support

„Wir freuen uns sehr, dass Unternehmen in Österreich jetzt dank unserer Kooperation ein hochqualifizierter lokaler Ansprechpartner für Robotik-Schulungen zur Seite steht“, sagt Andrea Alboni, General Manager Western Europe bei Universal Robots. „Um an einer Schulung von UR teilzunehmen, müssen sie ihre qualifizierten Fachkräfte nicht bis nach Wien oder ins Ausland schicken. So sind diese im Notfall schnell zurück in der Firma und können sich dennoch ein fundiertes Robotik-Wissen aufbauen.“

„Bei null starten“: Neue Kurse im Herbst und Winter

Interessierte können sich demnächst ein eigenes Urteil bilden und dafür an einem der zahlreichen Workshops teilnehmen. So bietet das Trainingszentrum im Herbst und Winter 2021 neue UR-Kurse an. Auf dem Programm stehen dann unter anderem Core Schulungen sowie Unboxing Workshops, bei denen die Robotersysteme ausgepackt, getestet und programmiert werden. Benjamin Massow weiß, was die Teilnehmer hierbei erwartet: „Anwender/innen gehen in diesen Kurs ohne die geringsten Vorkenntnisse, und einen halben Tag später haben sie erste Ideen für die eigene Cobot-Anwendung.“

MCI und Universal Robots – Partnerschaft für Industrie 4.0

Universal Robots und das Zentrum für Robotik, Produktion & Automatisierung am MCI in Innsbruck kooperieren bereits seit 2020. Ziel ist es, Unternehmen bei der Implementierung neuer Technologien zu unterstützen. Unternehmen und Studierenden soll aufgezeigt werden, welche Möglichkeiten innovative Technologien und methodische Vorgehensweisen innerhalb der smarten Produktion bieten. Die Partner setzen dieses Vorhaben gemeinsam mit Schmachtl, einem österreichischen Distributor von Universal Robots, um, und halten dafür auf dem Campus des MCI Veranstaltungen, Workshops und Seminare ab. Darüber hinaus sind gemeinsame Forschungsprojekte geplant, in denen die Unternehmen kollaborierende Roboter von UR nutzen können.

Kurzinterview mit Carsten Busch von DENSO

Sebastian Trella von Robots-Blog konnte ein kurzes Interview mit Carsten Busch von DENSO führen. Im Interview erfahrt ihr mehr über den DENSO COBOTTA.

Robots-Blog: Wer bist du und was ist deine Aufgabe bei DENSO?

Carsten: Mein Name ist Carsten Busch und ich bin der Product & Business Development Manager für Cobots (kollaborative Roboter)

Robots-Blog: Was macht DENSO?

Carsten: DENSO ist zum einen der weltweit zweitgrößte Automobilzulieferer (Tier1). Neben weiteren Geschäftsbereichen, wie Wärmepumpen, zentralen Klimaanlagen etc. ist DENSO auch Entwickler und Hersteller von Industrierobotern – und hierin marktführend in dem Bereich der kompakten Roboter.

Robots-Blog: Hast du viel mit Robotern zu tun im Beruf/im Alltag?

Carsten: Als Product & Business Development Manger habe ich quasi non-stopp mit der Robotertechnik zu tun – und es macht mir noch immer jeden Tag Spaß.

Robots-Blog: Welcher Roboter aus Wissenschaft, Film oder Fernsehen ist dein Lieblingsroboter und warum?

Carsten: Verschiedene Kinofilme wie Star Wars‘ R2D2 oder Nr. 5 lebt haben mich begeistert. Der Film „I, Robot“ von Regisseurs Alex Proyas nach dem Buch von Isaak Assimov hat mich sehr bewegt, da hier die Grenzen der Robotics deutlich aufgezeigt wurden.

Robots-Blog: Und welcher ist dein Lieblingsroboter aus eurem Produktsortiment?

Carsten: Das ist unser kollaborativer Roboter „COBOTTA“. Er ist ein sehr kompakter, leichter Cobot, der durch seine intuitiven Apps und seine im Arm integrierte Steuerung, integrierten Greifer und Kamera, extrem vielseitig einsetzbar ist (zudem Gewinner des German Design Award 2019)

Robots-Blog: Was macht den COBOTTA so besonders und für wen ist er gedacht?

Carsten: Mit einem Eigengewicht (inklusive integrierter Steuerung) von nur 4kg ist COBOTTA extrem portable und auch auf mobilen Plattformen (AGV/ARM) perfekt einsetzbar. Durch die intuitiven Apps können Applikationen auch ohne Programmierkenntnisse in wenigen Minuten erstellt werden – inklusive Greifen and Kameraintegration. Außerdem kann COBOTTA durch die offene Plattform auch mittels diverser Hochsprachen programmiert werden oder auch von ROS basierten Systemen direkt gesteuert werden. Durch sein sicheres Design und die TÜV geprüfte funktionale Sicherheit ist COBOTTA perfekt für die Mensch-Roboter-Kollaboration geeignet.

Robots-Blog: Welche Automatisierungsaufgaben hast du schon mit dem Cobotta gelöst?

Carsten: Wie schon erwähnt ist COBOTTA sehr vielseitig einsetzbar: Montage- und Handhabungsaufgaben in der Elektronikindustrie z.B. Teileprüfung, Labeln, Be-/Entladevorgänge, Klebeapplikationen, etc. Laborassistent in der Life Science Industrie z.B. Mikrotiterplatten und Proben-Handhabung, Zentrifugen Be-/Endladung, Pipettieren, etc. oder in der Ausbildung sowohl in der Schule/Berufsschule und an Universitäten. Sogar ein bekannter Magier hat COBOTTA in seine Zaubershow mit eingebunden!

Robots-Blog: Was kostet mich so eine Unterstützung durch einen Roboter?

Carsten: Ein COBOTTA startet schon ab weniger als 15.000 Euro.

Robots-Blog: Muss ich dafür Programmieren können?

Carsten: Für einfachere Pick&Place Anwendungen inkl. Kameraeinbindung zur Teileerkennung kann mit der COBOTTA World App eine Applikation intuitiv und ohne Roboterkenntnisse in wenigen Minuten erstellt werden – Kinderleicht!

Robots-Blog: Was würdest du gerne in Zukunft automatisieren?

Carsten: Unterstützung von pflegebedürftigen Menschen durch Roboter z.B. Hilfe beim Aufstehen, Anreichen etc.

Igus Robolink RL-DP-5 Installation

Today I installed my new igus low cost Automation robotarm. This still counts as common computer peripheral, right? …Right?

Find the latest News on robots, drones, AI, robotic toys and gadgets at robots-blog.com. Follow us on our Blog, Instagram, Facebook, Twitter or our other sites. Share your robotics ideas and products with us. #robots #robot #omgrobots #roboter #robotic #mycollection #collector #robotsblog #collection #botsofinstagram #bot #robotics #robotik #gadget #gadgets #drone #robotsofinstagram #instabots #photooftheday #picoftheday #followforfollow #instadaily #werbung #igus #rbtx #lowcostautomation #robotarm #robolink #automation #showyourdesk

Vielfältige DIY-Projekte auf der Maker Faire digital

Hannover, 8. Juni 2021 — Die digitale Maker Faire Hannover am 18. Juni 2021 von 11 bis 16 Uhr bietet jede Menge Inspiration und neues Wissen aus der Maker-Community. Die Teilnahme ist nach vorheriger Registrierung kostenlos.

„Wir freuen uns über die große Resonanz. 90 Makerinnen und Maker haben sich angemeldet und stellen ihre spannenden Erfindungen oder Projekte vor und laden zum Wissensaustausch und Netzwerken ein“, erklärt Kristina Fischer, Projektleiterin der Maker Faire. “Damit können wir einen bunten Querschnitt der Maker-Szene abbilden.”

Einer der Maker ist Michael Schulz. Er stellt in einem der virtuellen Ausstellungsbereiche „Mickey’s Flightdeck“ vor, ein originalgetreues Boeing-737-800-Cockpit. Seine Leidenschaft für Flugsimulatoren teilt der Wedemärker mit 4200 Followern auf seinem YouTube-Kanal und nun auch auf der Maker Faire.

Der Stuttgarter Ingenieur Guido Burger präsentiert seine selbst gebaute CO2-Ampel, die über die Luftqualität in geschlossenen Räumen informiert. Das Bauen und Programmieren seiner DIY-Variante kann in unterschiedlichste Schulfächer integriert werden.

Johannes Střelka-Petz ist der Erfinder der einzigartigen Braille-Tastatur „Oskar“. „Oskar“ ist ein Open-Source-Programm, das mit acht Tasten funktioniert und es ermöglicht, viermal schneller und zweimal genauer zu schreiben als herkömmliche Tastaturen für sehbehinderte und blinde Menschen.

Auch Teilnehmende und Gewinner*innen des Jugend-forscht-Wettbewerbs zeigen ihre Projekte auf der Maker Faire: Jennifer Schott, Schülerin des Marion-Dönhoff-Gymnasiums, stellt ein selbst konstruiertes Elektrolyse-Verfahren vor. Es gelang der Nienburgerin, eine Low-Cost-Anlage zur Gewinnung von Wasserstoff-Knallgas zu entwickeln. Caroline Musin, Amelie Aulinger und Georg Delp aus Rosenheim haben sich den Stomabeutel-Alarm ausgedacht. Dieser Alarm informiert Patient*innen oder die zuständigen Pfleger*innen rechtzeitig vor dem Überlaufen des Beutels.

Der Nonprofit-Verein selfm.aid betreibt die Skills Factory auf Samos in Griechenland und ist ebenfalls zu Gast auf der Maker Faire. Gegründet wurde die selfm.aid-Initiative von der aus Hochfelden in der Schweiz stammenden Sozialarbeiterin Julia Minder und dem gelernten Maurer Simon Bader.

Welchen Zweck muss Kleidung in unserer hoch-digitalisierten Welt erfüllen? Dieser Frage gehen Fashion-Designerin Nicole Scheller und Informatiker Marcel Göbe vom Leipziger Fashion Label nach, sie präsentieren eine technisch orientierte Modekollektion, die die Privatsphäre der Träger*innen schützen soll.

Weitere Maker sind unter anderem Michael Hack, der die Online-Veranstaltung für den Launch der „The German Kurbelkiste“ nutzt, und das IANUS Peace Lab, das Strategien für ein friedliches Miteinander entwickelt hat. Darüber hinaus stellt die Make-Redaktion spannende Projekte aus dem Magazin vor und ist über den Live-Chat für alle Maker und die, die es werden wollen, ansprechbar. Coole, überzeugende DIY-Ideen bekommen hier die Chance auf Veröffentlichung und sollen andere inspirieren.

Informationen zu Ausstellenden, Projekten und dem weiteren Programm gibt es unter https://maker-faire.de/hannover/

Interessierte können sich hier kostenlos registrieren.