Es ist wieder Maker-Zeit: Am dritten August-Wochenende, am 19. und 20. August, treffen sich wieder die Macher von morgen im HCC, um ihre spannenden Ideen und beeindruckenden Erfindungen vorzustellen. „The Iron Horse“, ein riesiges aus Eisenplatten konstruiertes Pferd, auf dem eine Ballerina tanzt, ist der Top-Act auf der Maker Faire Hannover. Die spanische Theatergruppe Antigua i Barbuda ist mit dem Pferd zum ersten Mal Gast auf dem etwas anderen Familienfestival, das sich als bunter Mix aus Messe, Wissensplattform und Jahrmarkt versteht. Zu dem Event erwarten die Veranstalter rund 1.000 Maker, 200 Stände und 15.000 Besucher.

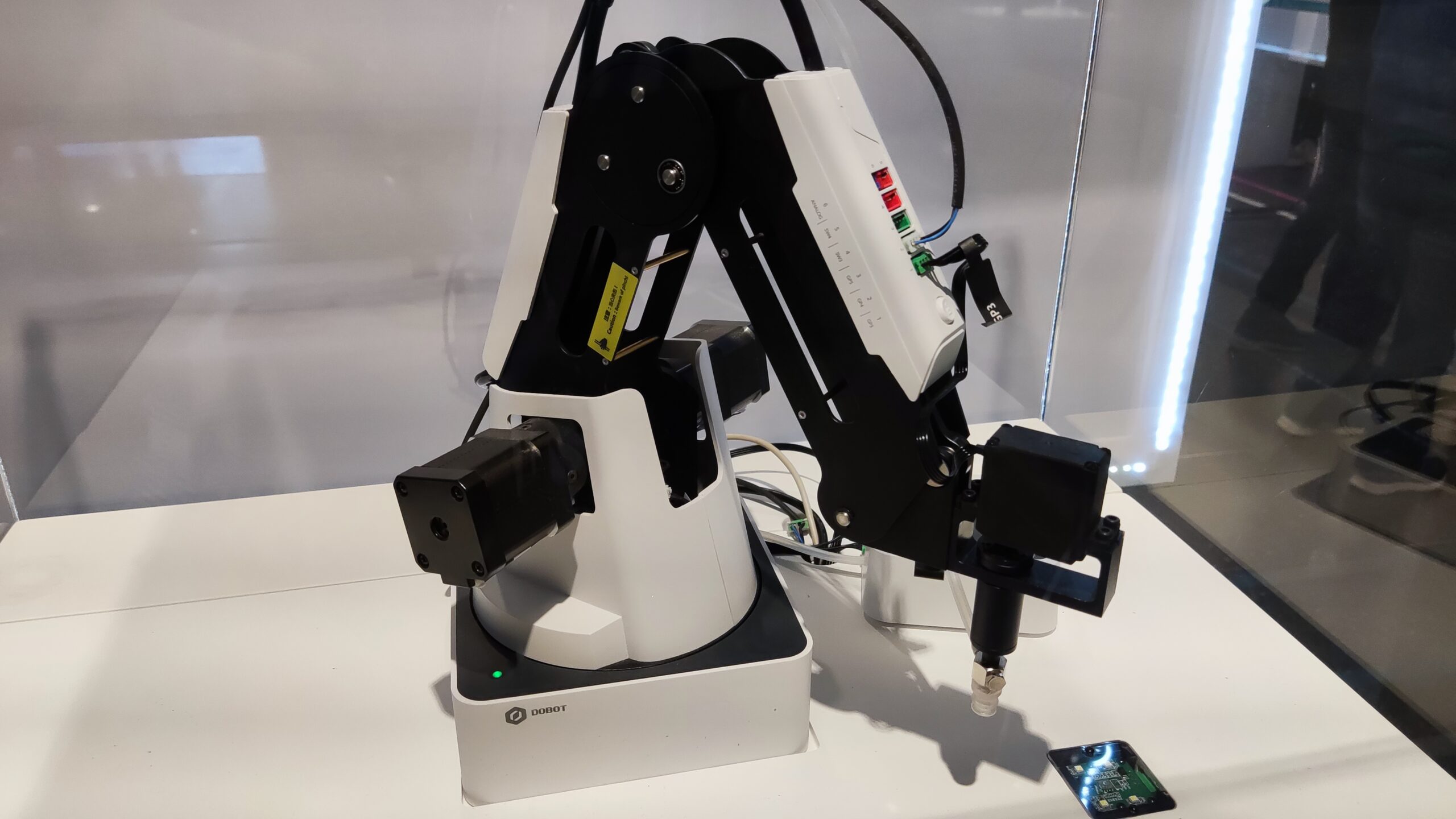

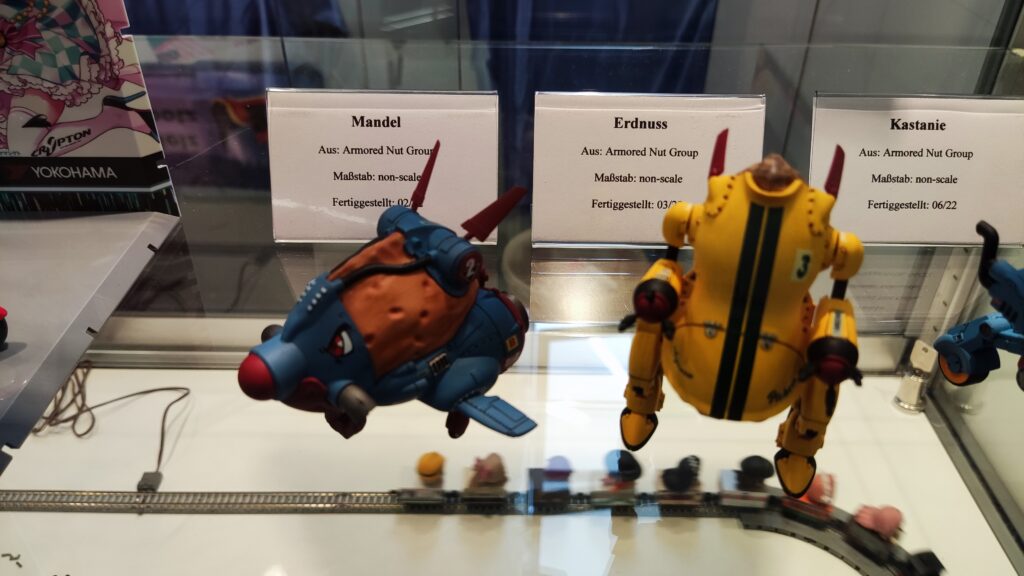

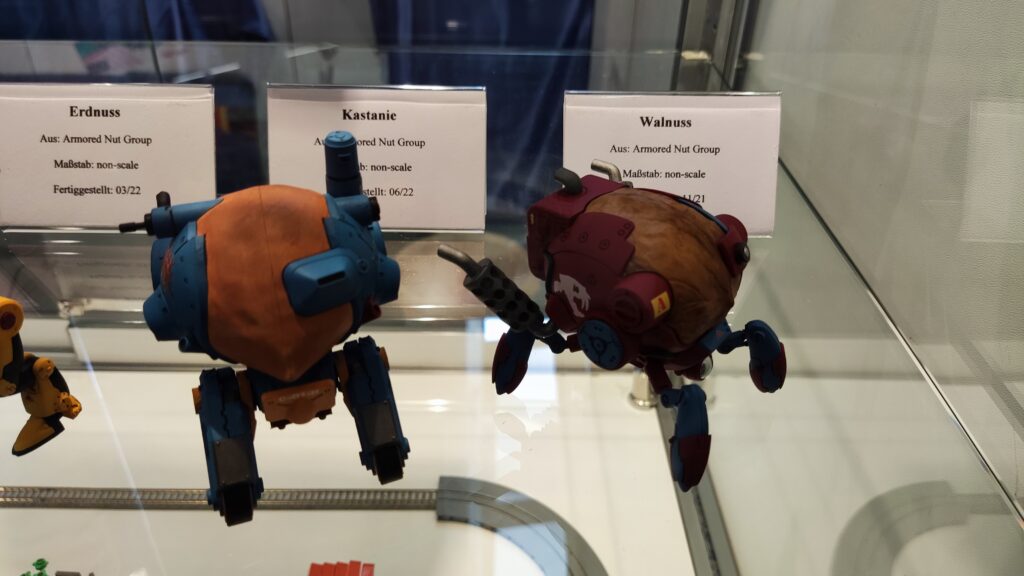

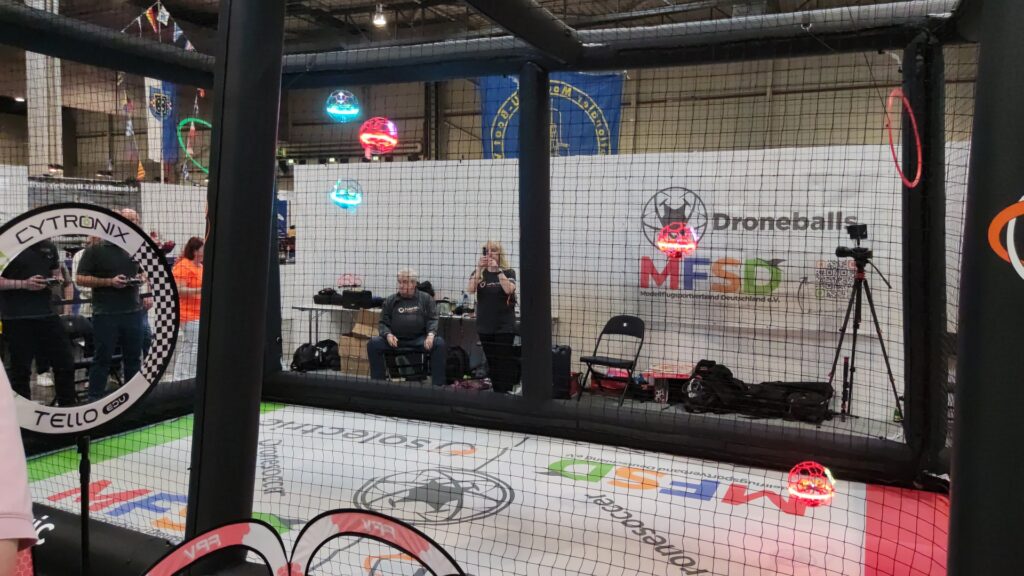

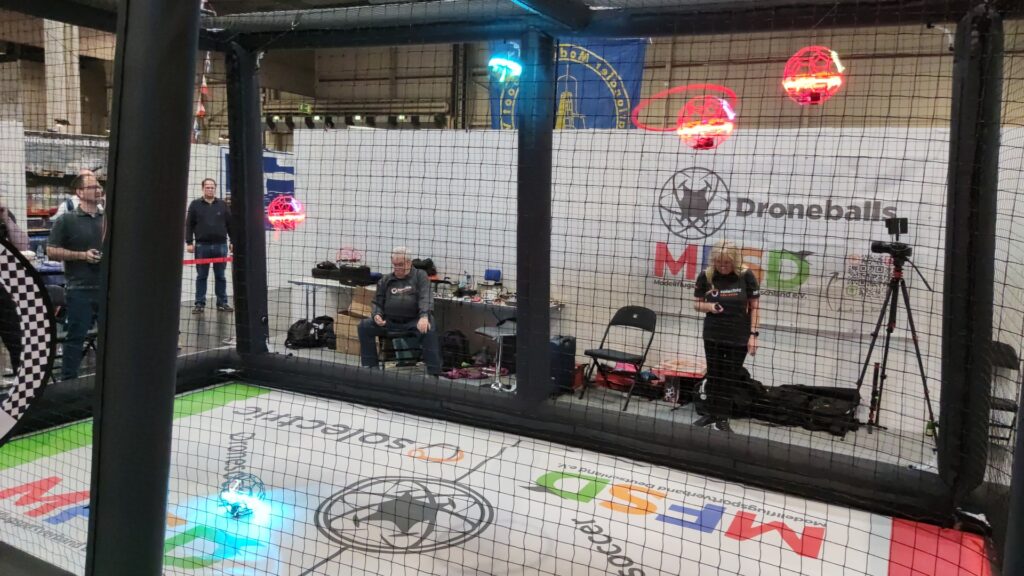

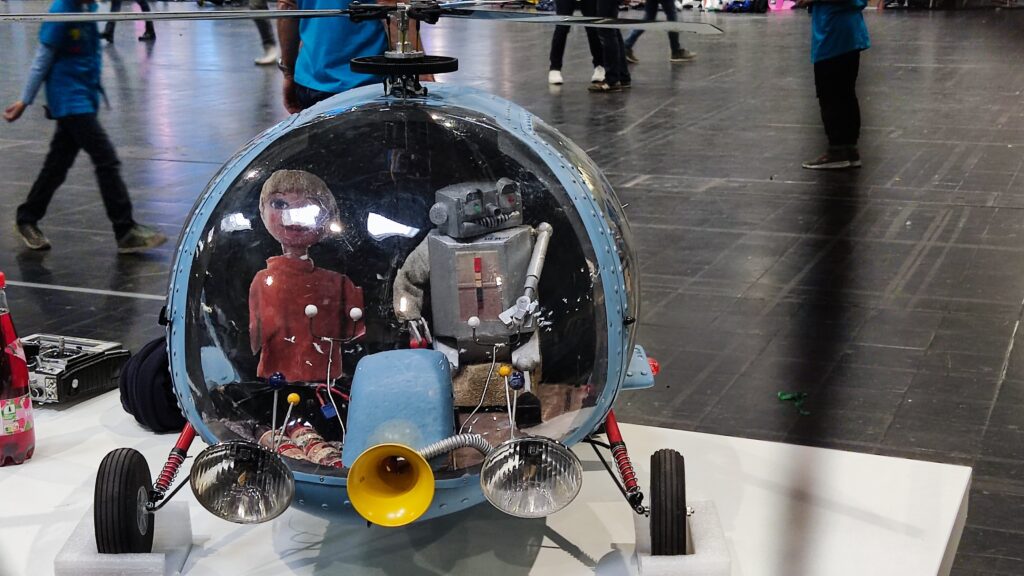

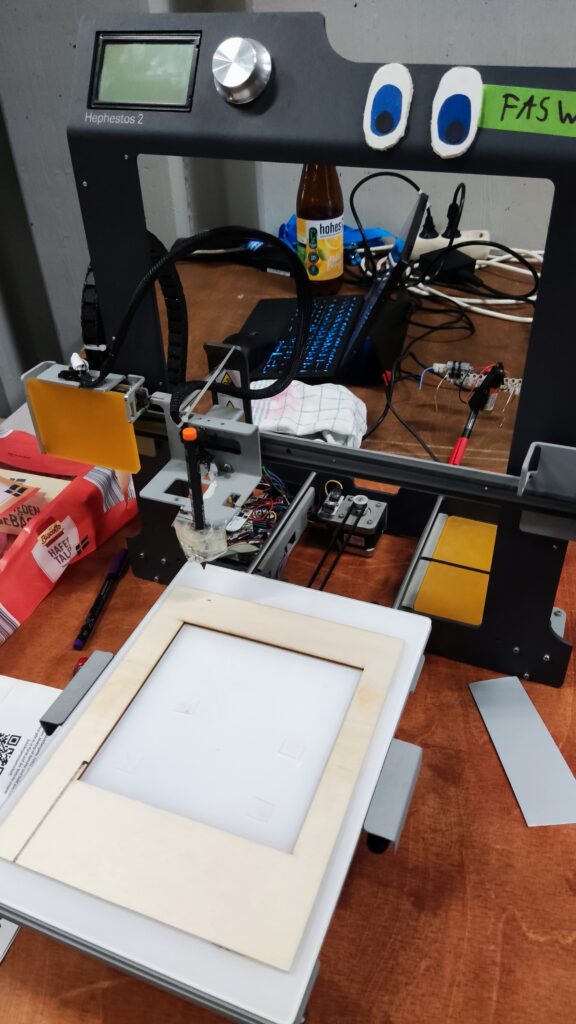

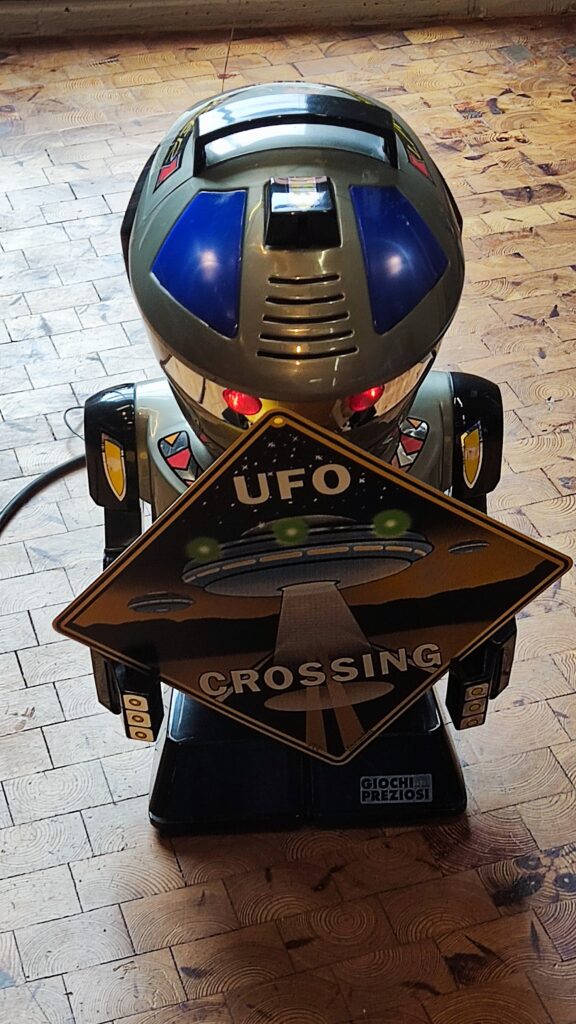

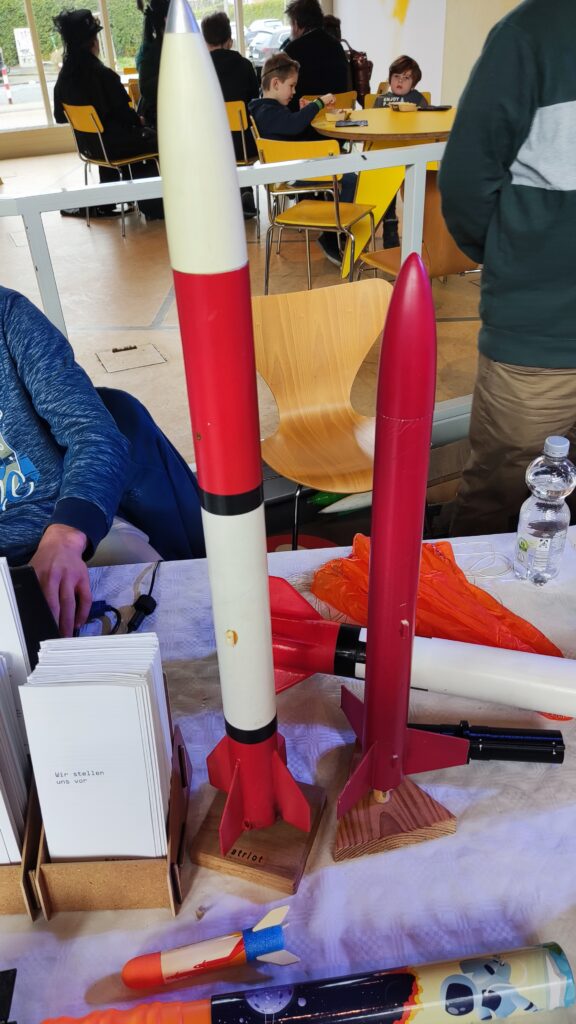

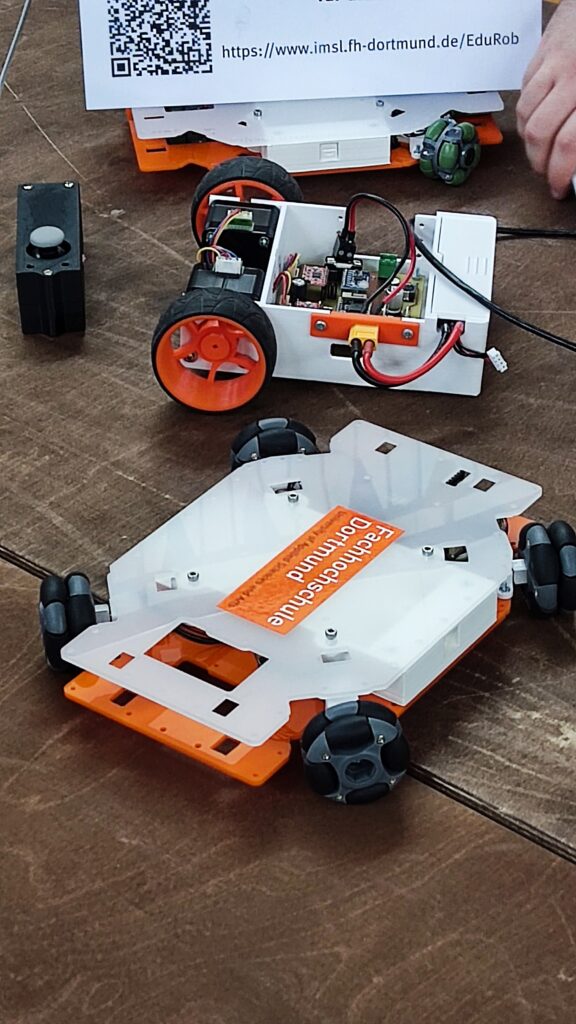

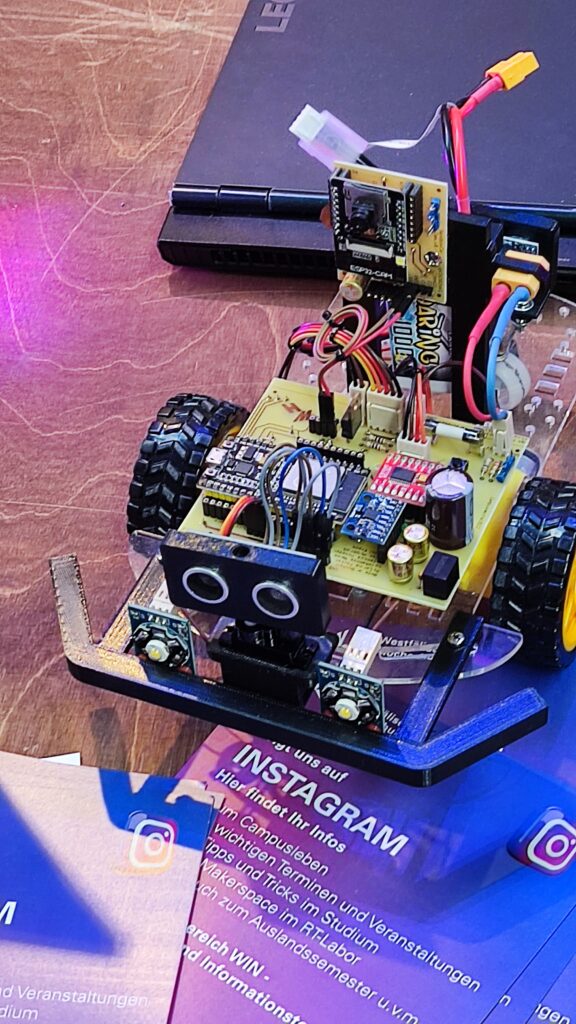

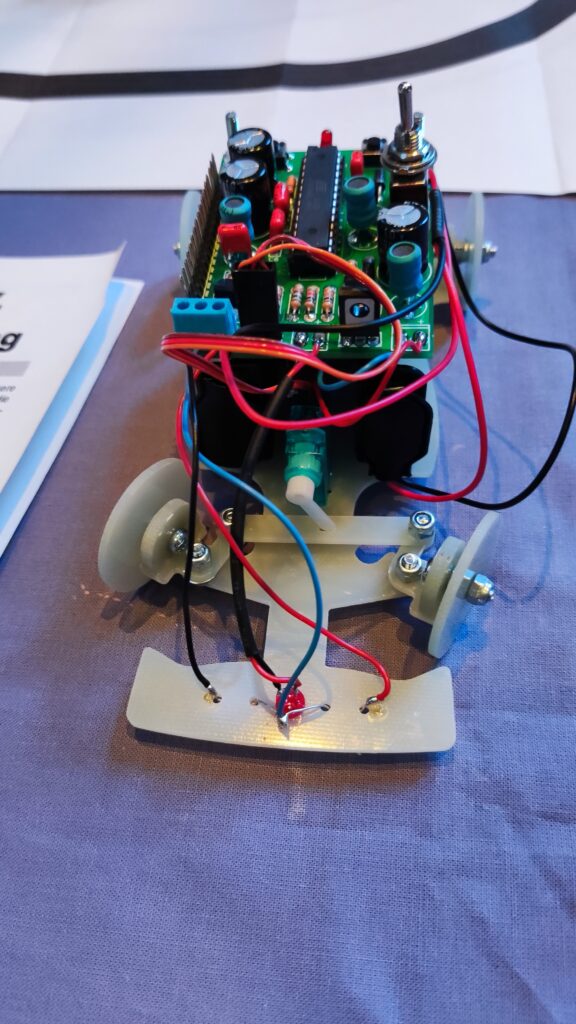

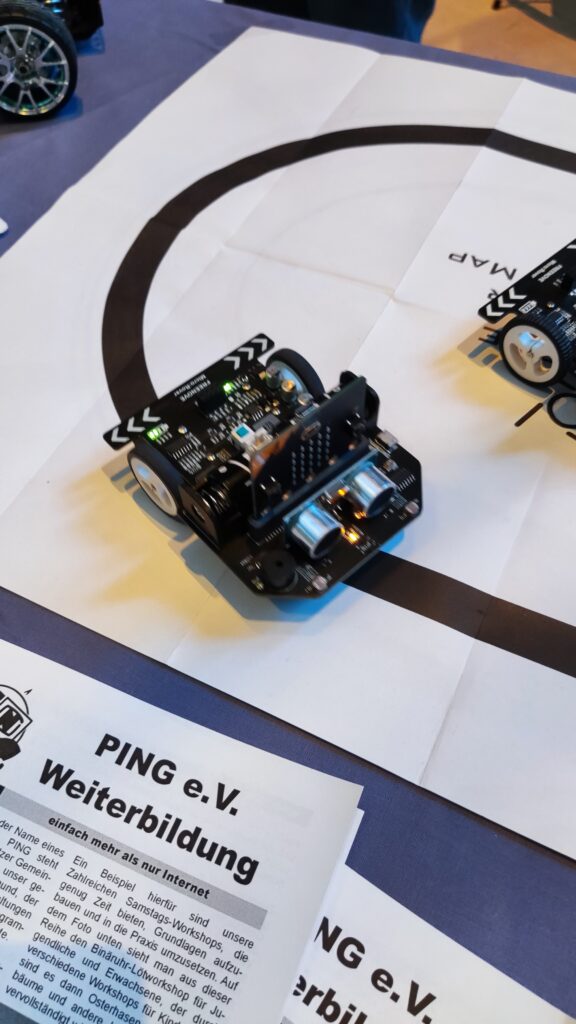

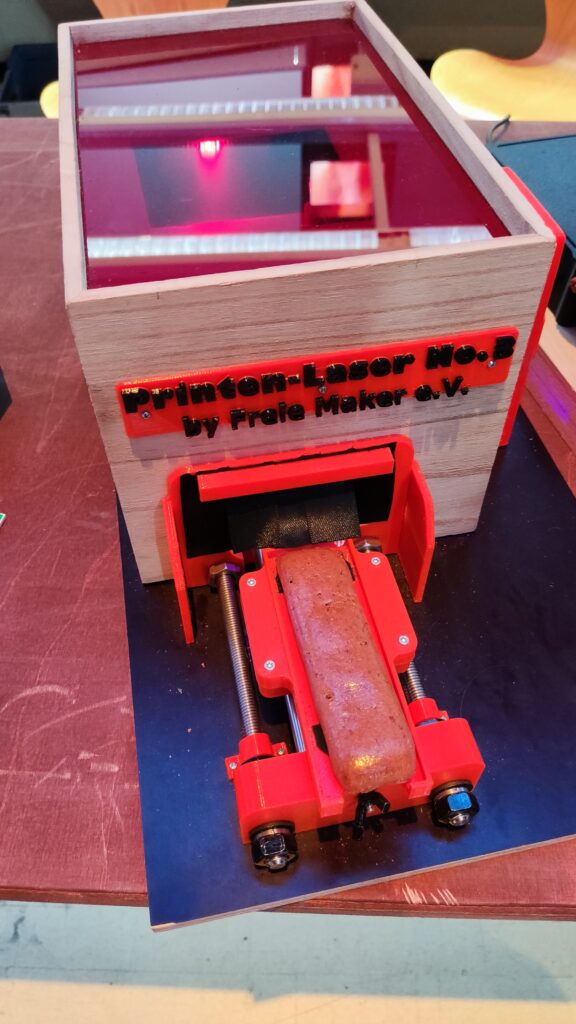

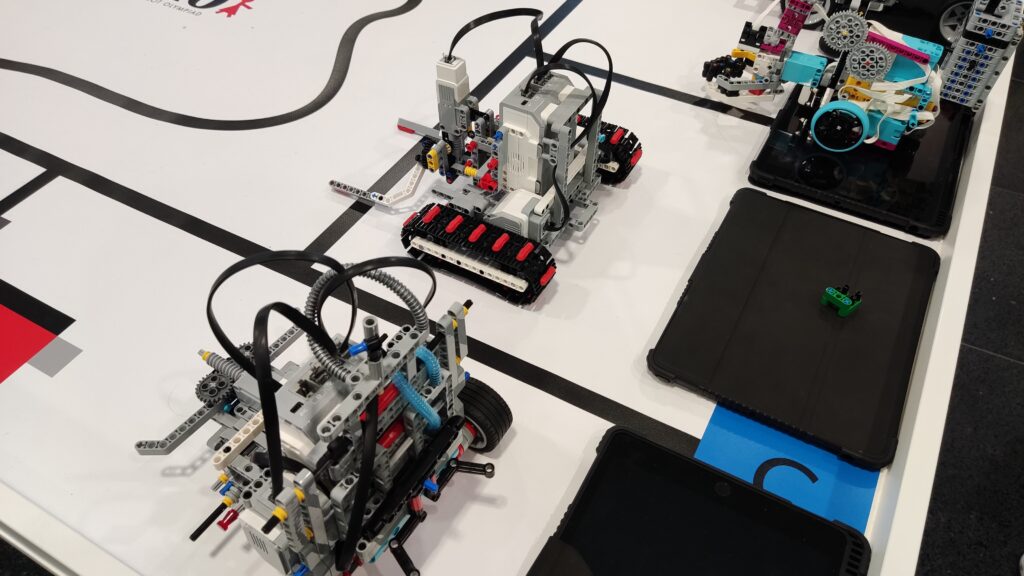

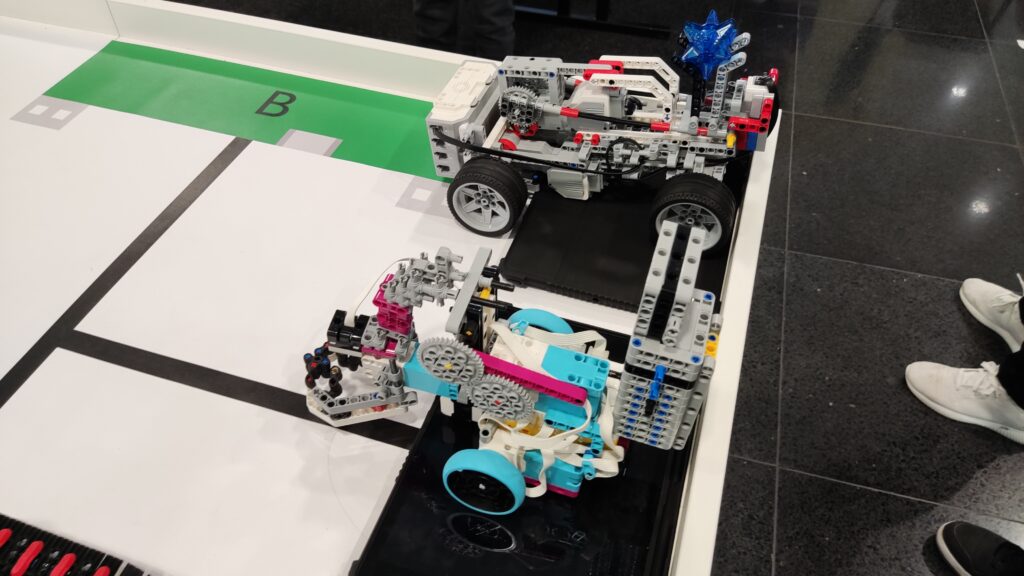

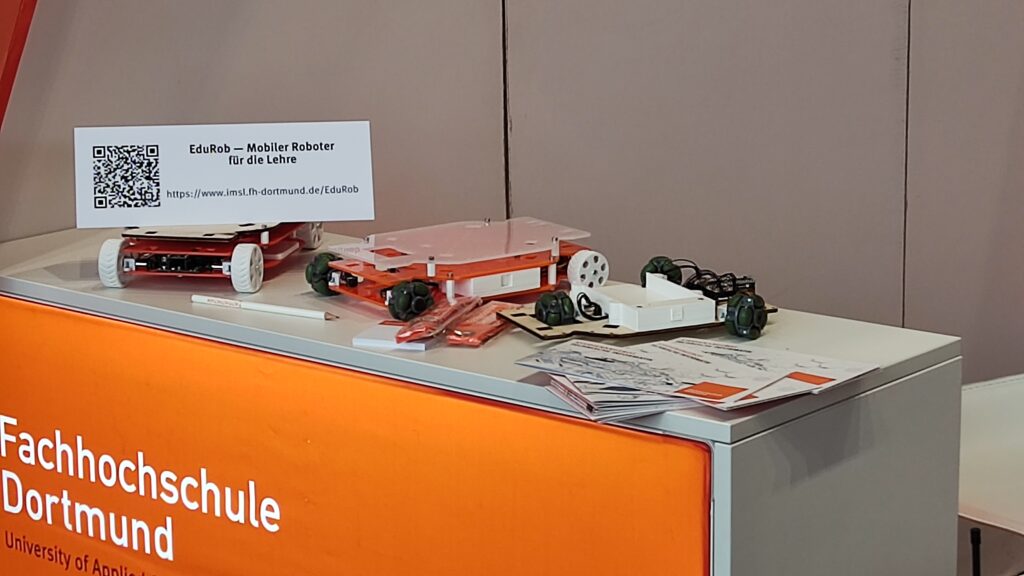

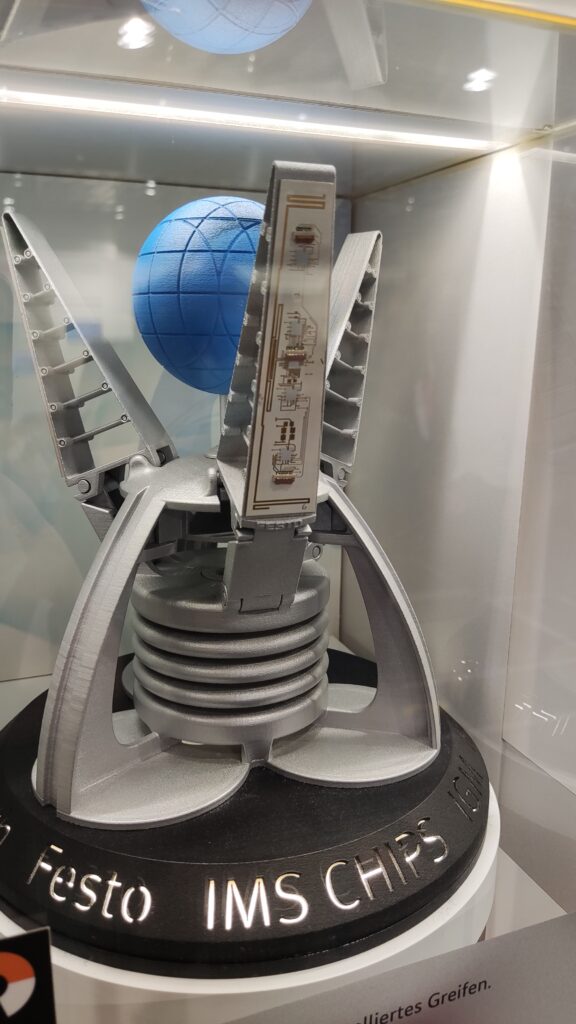

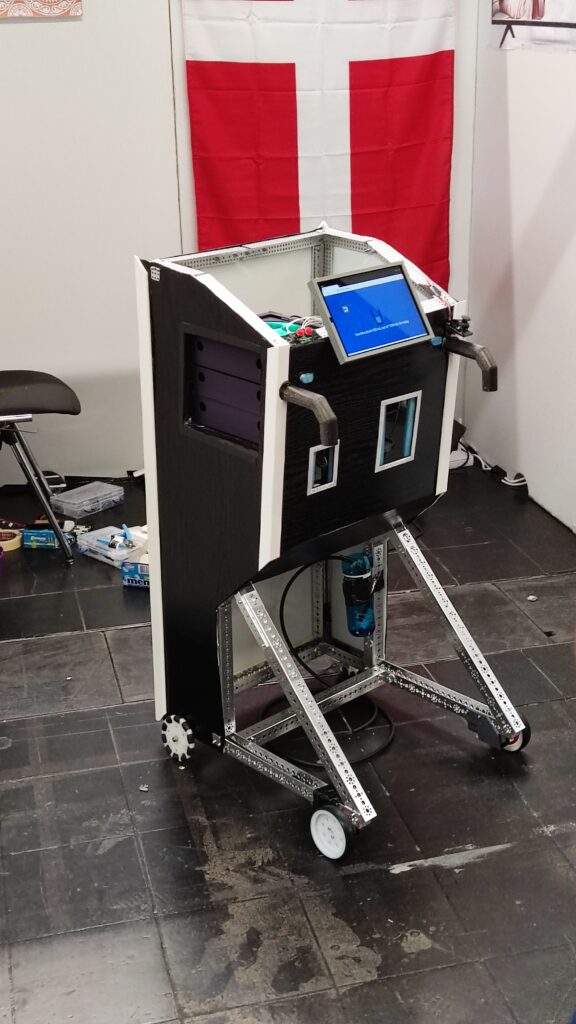

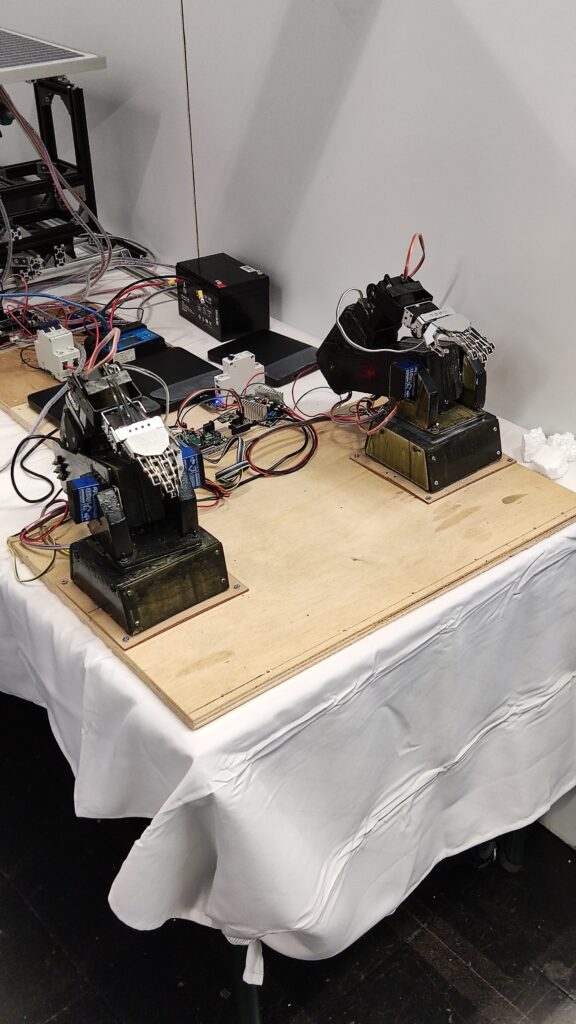

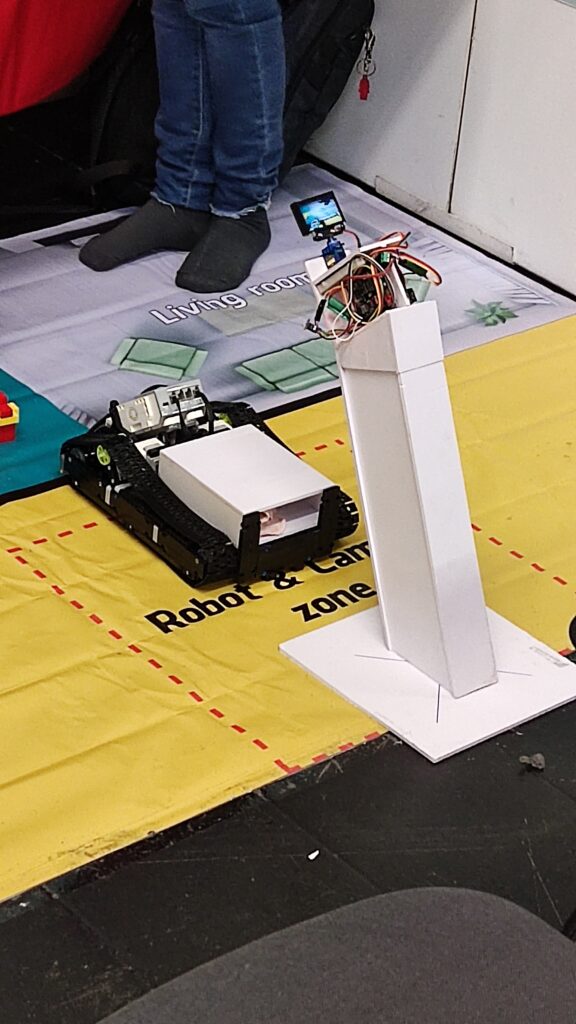

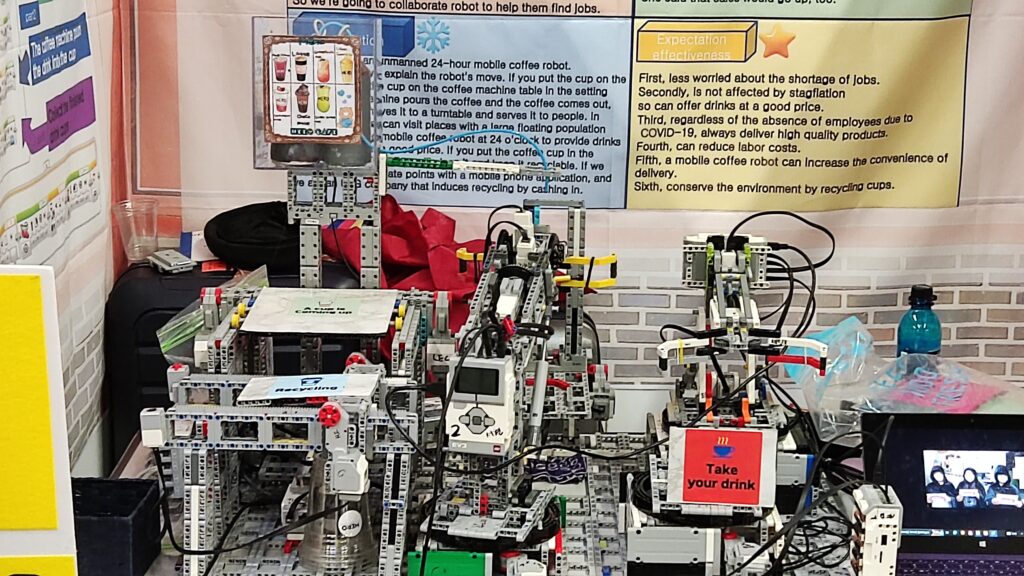

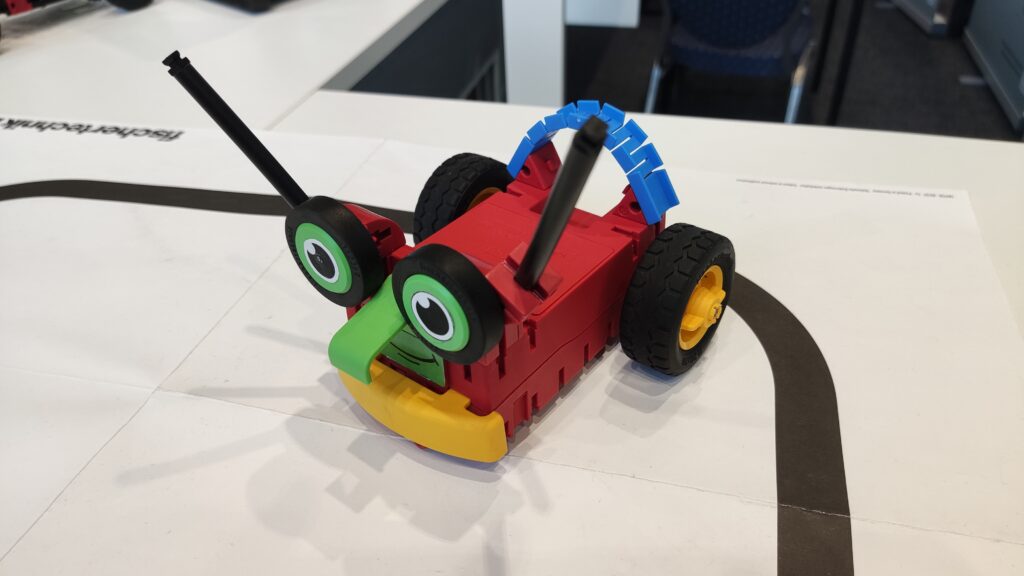

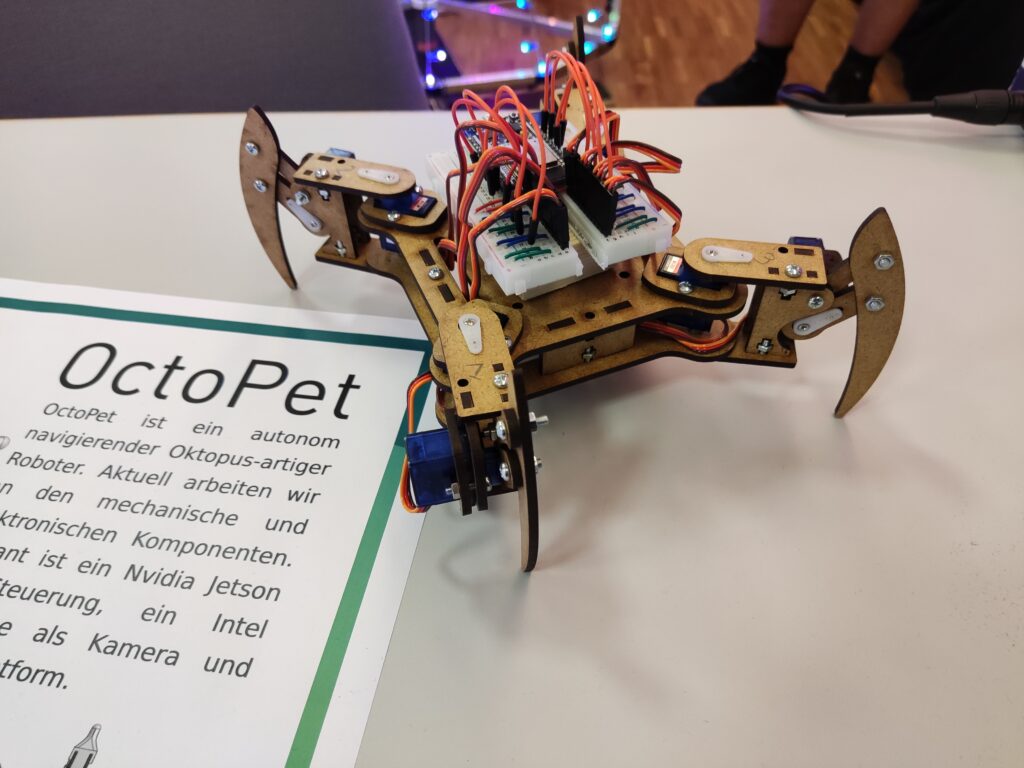

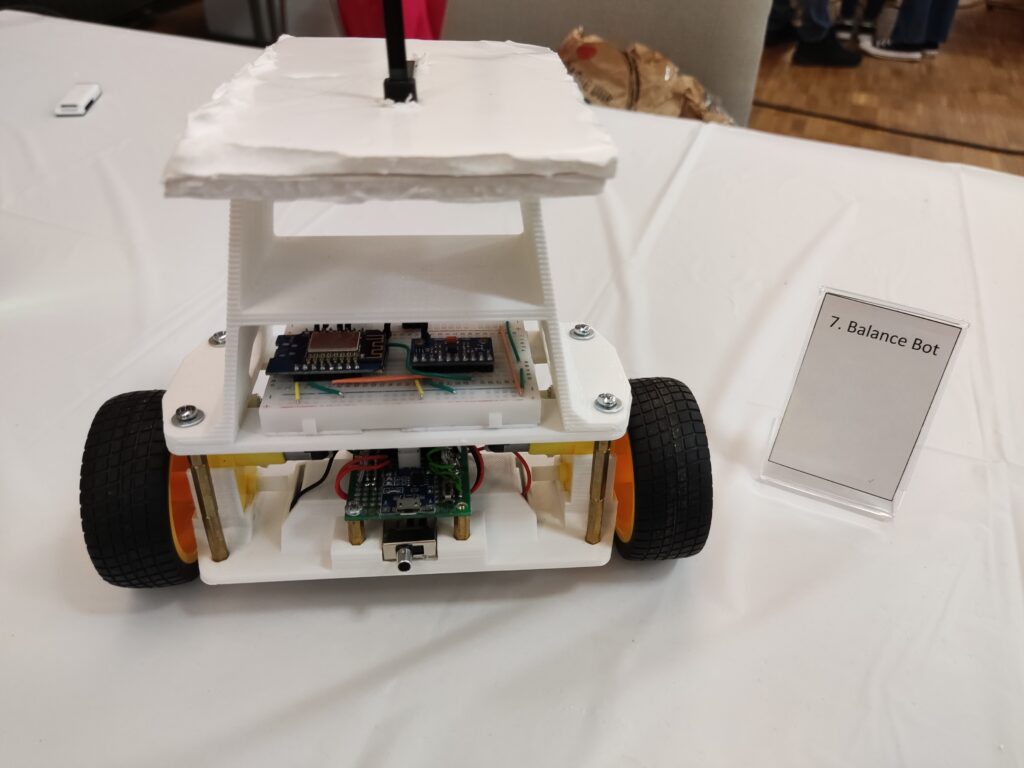

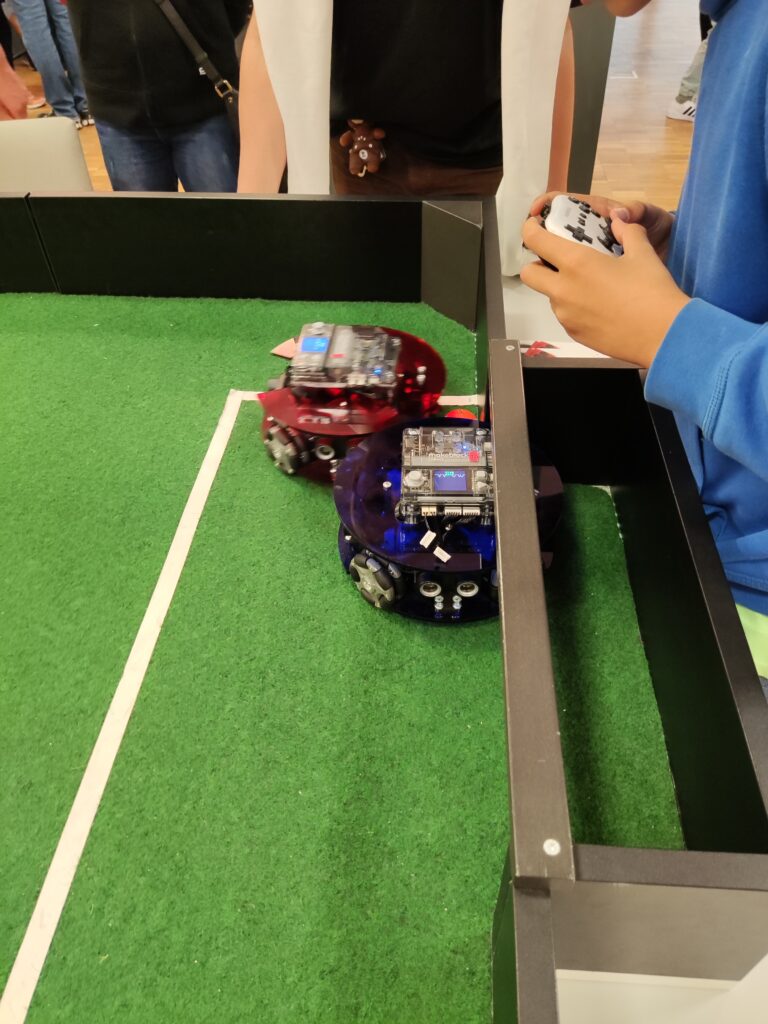

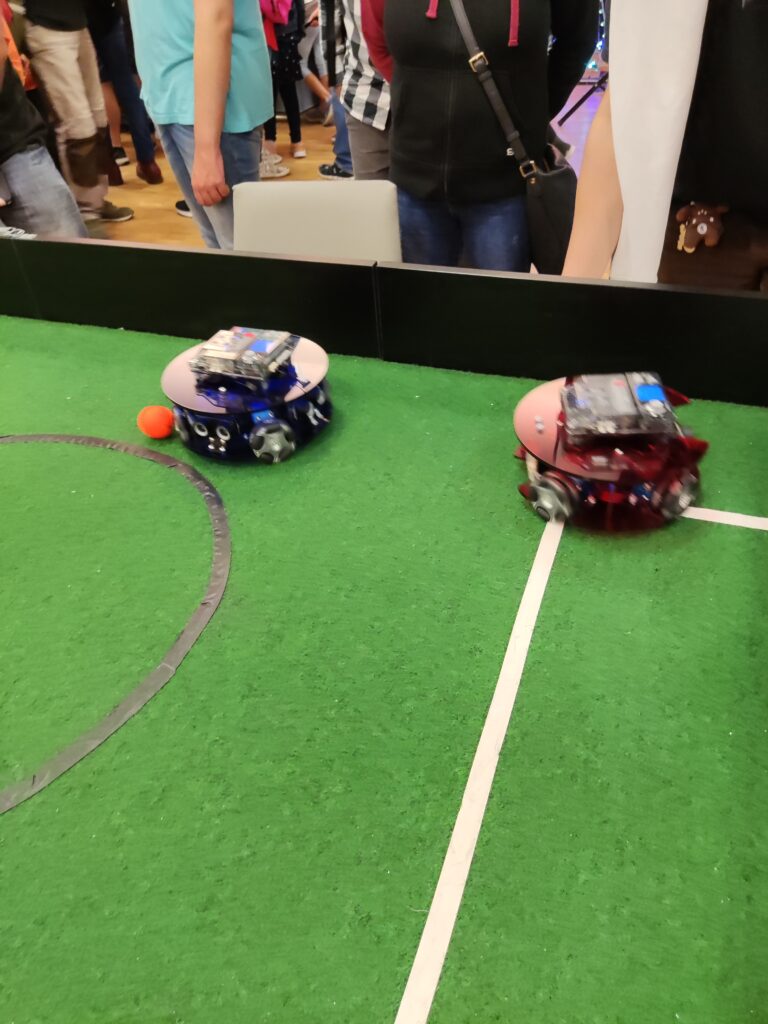

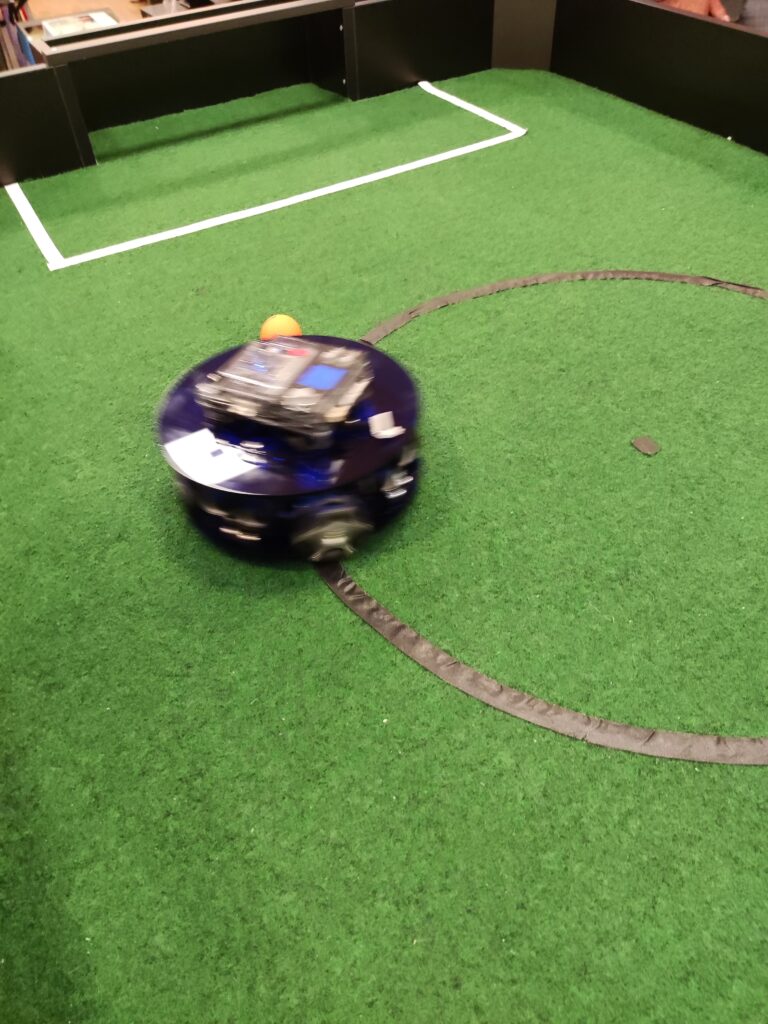

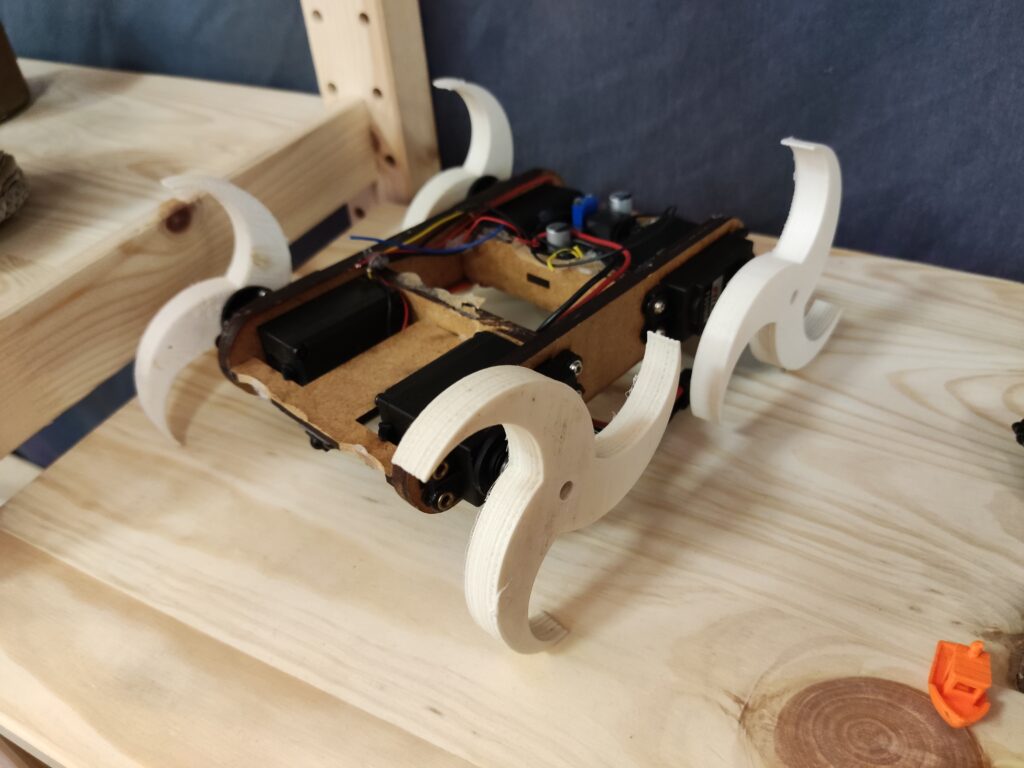

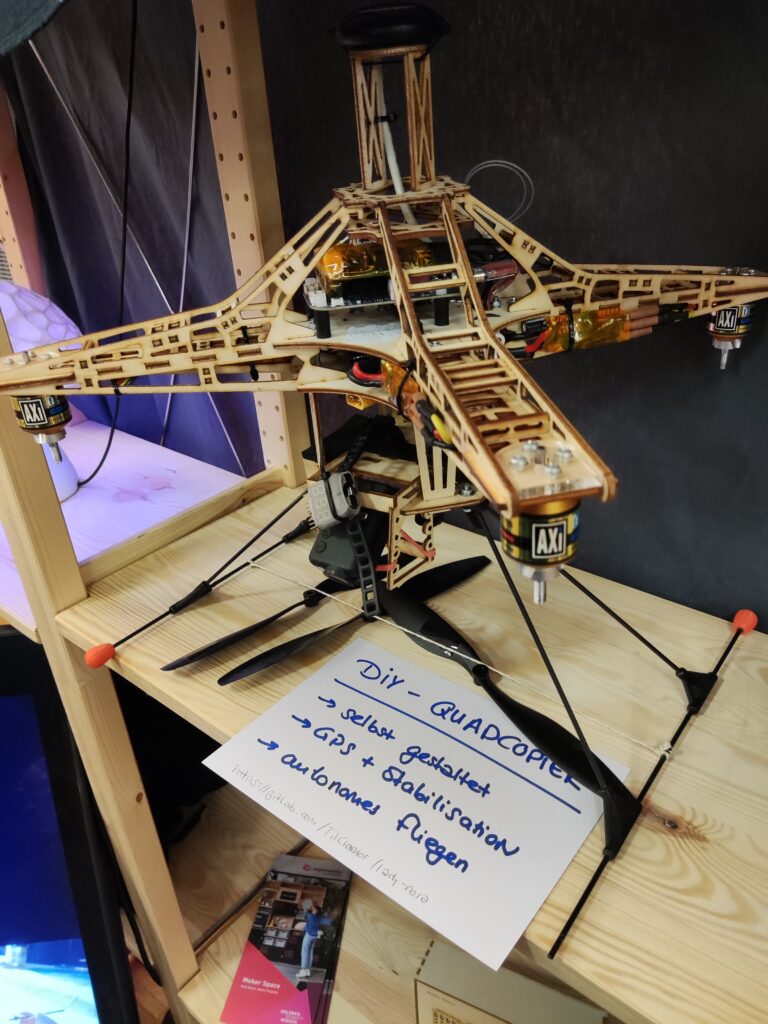

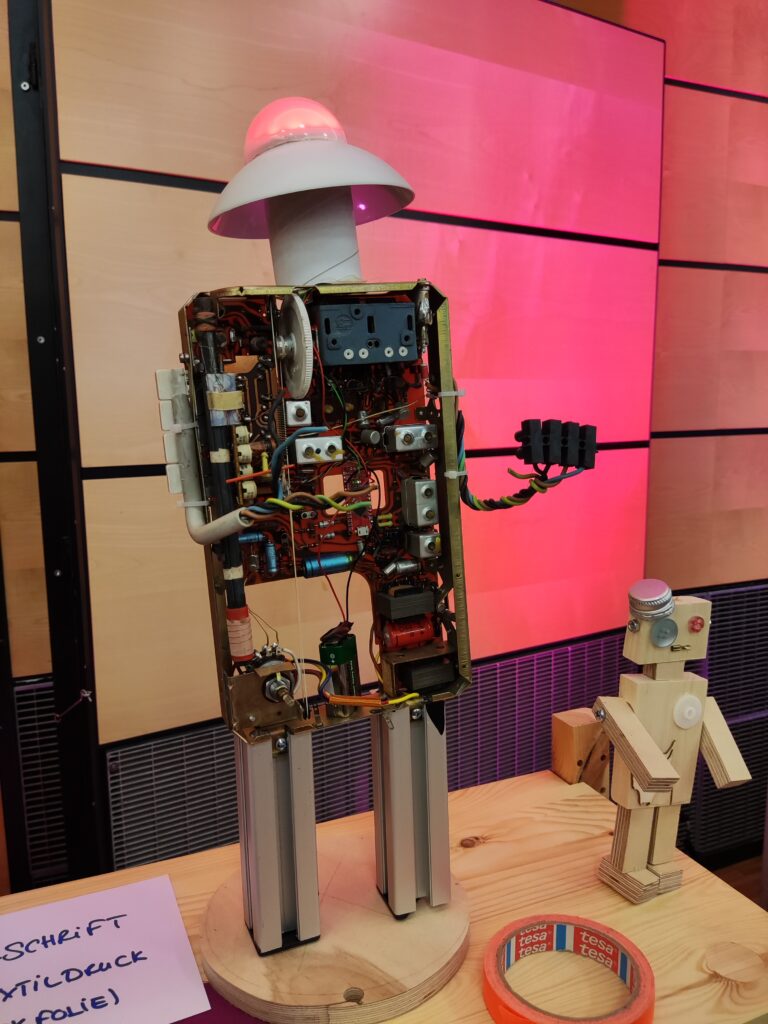

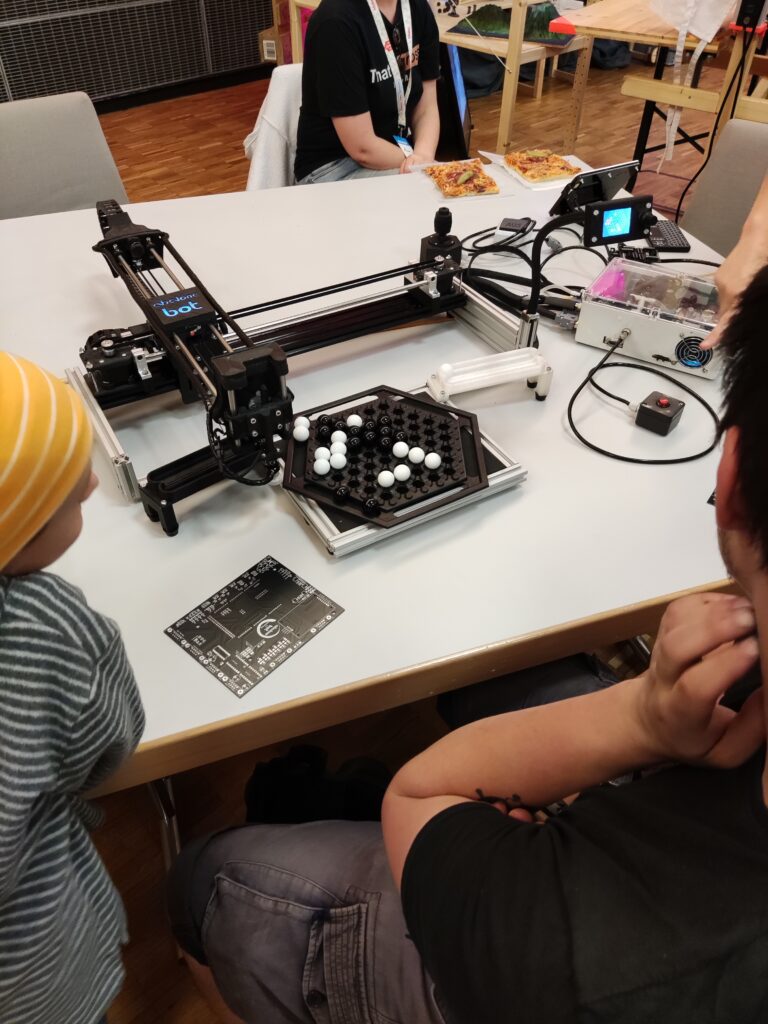

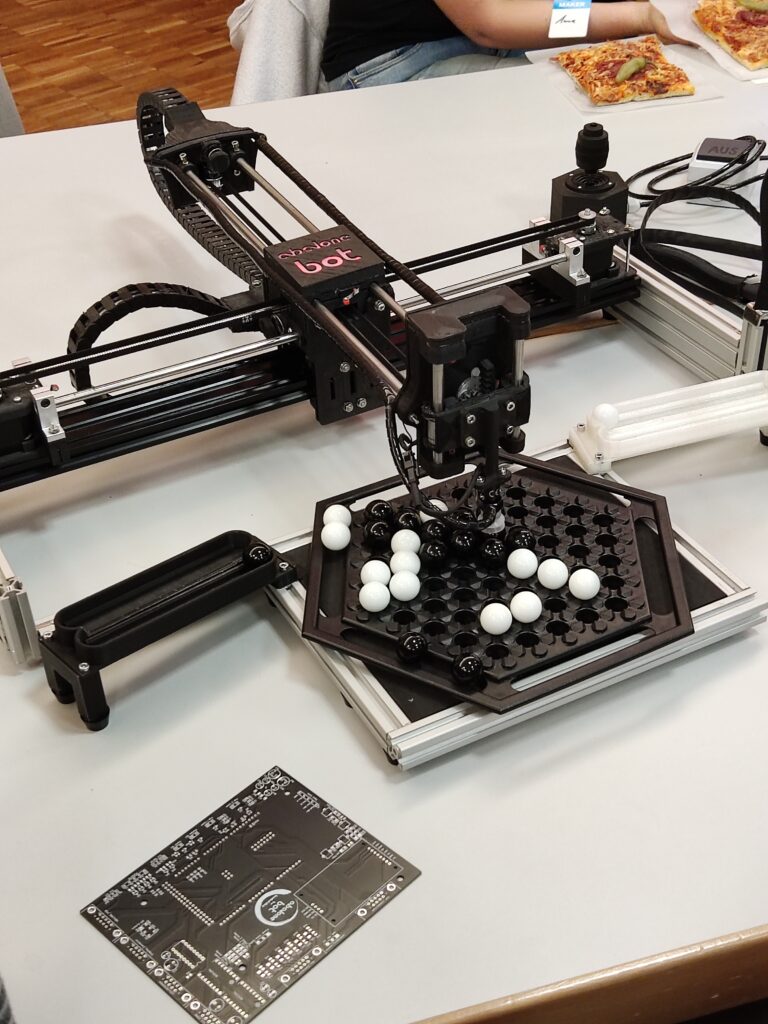

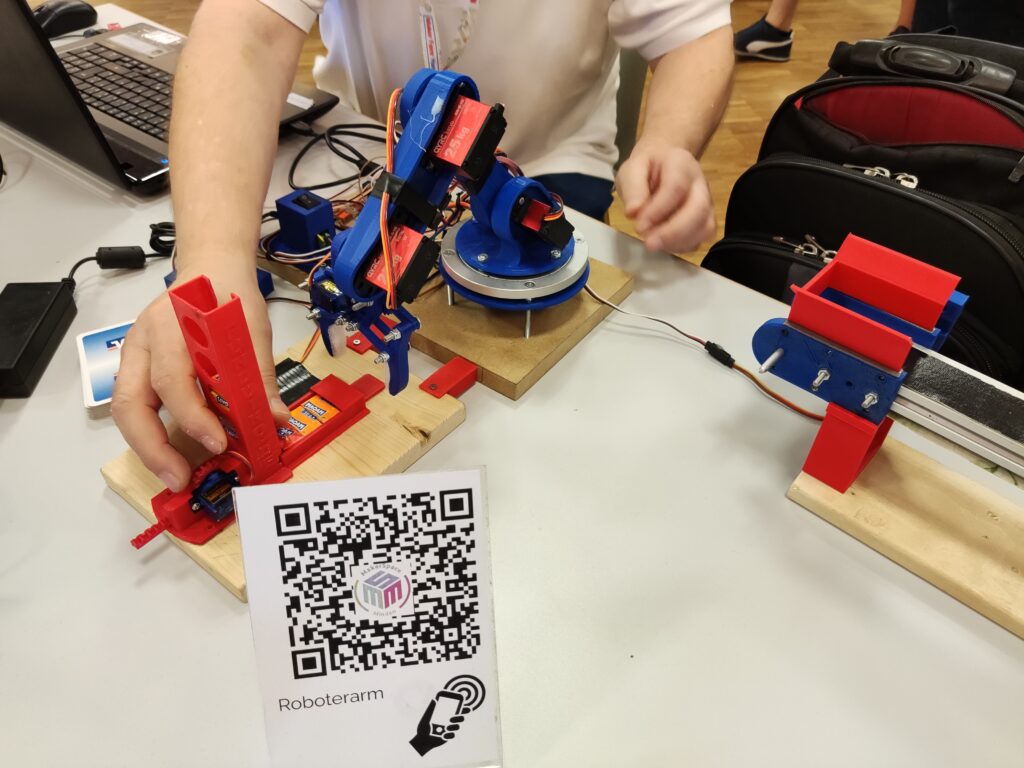

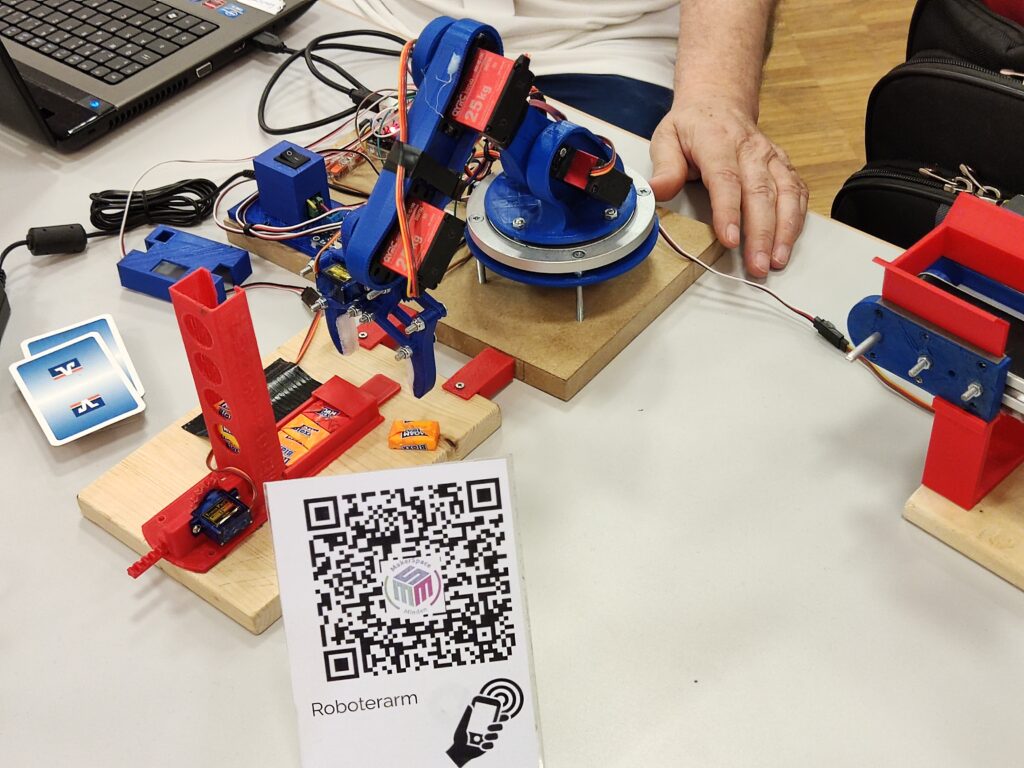

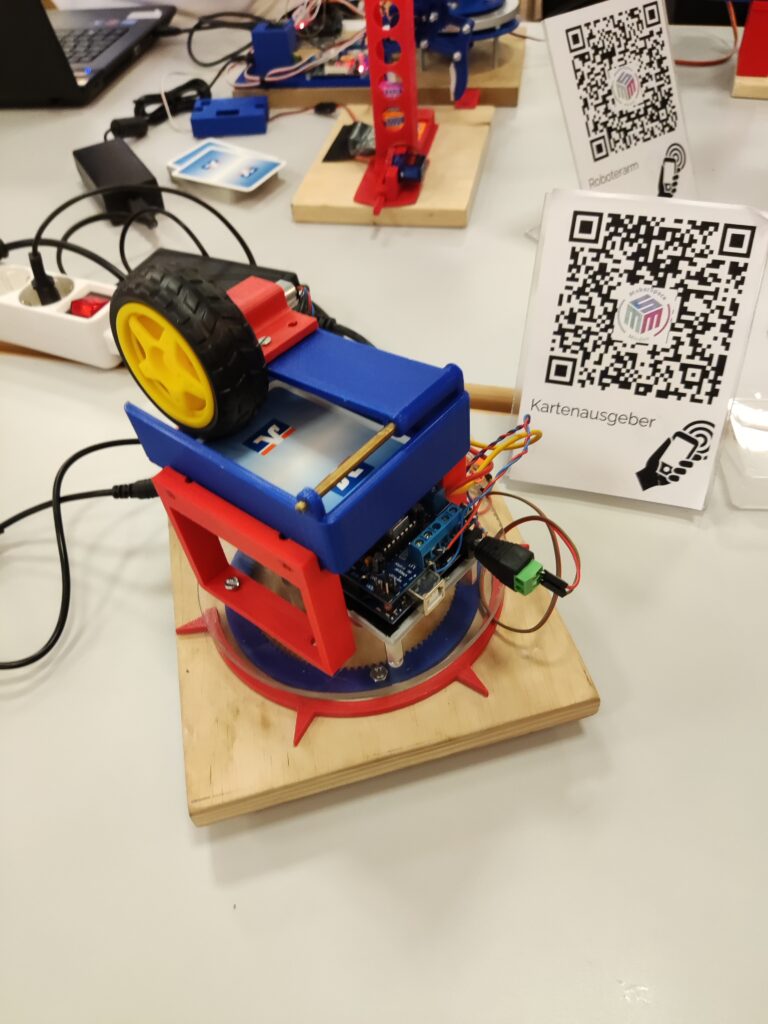

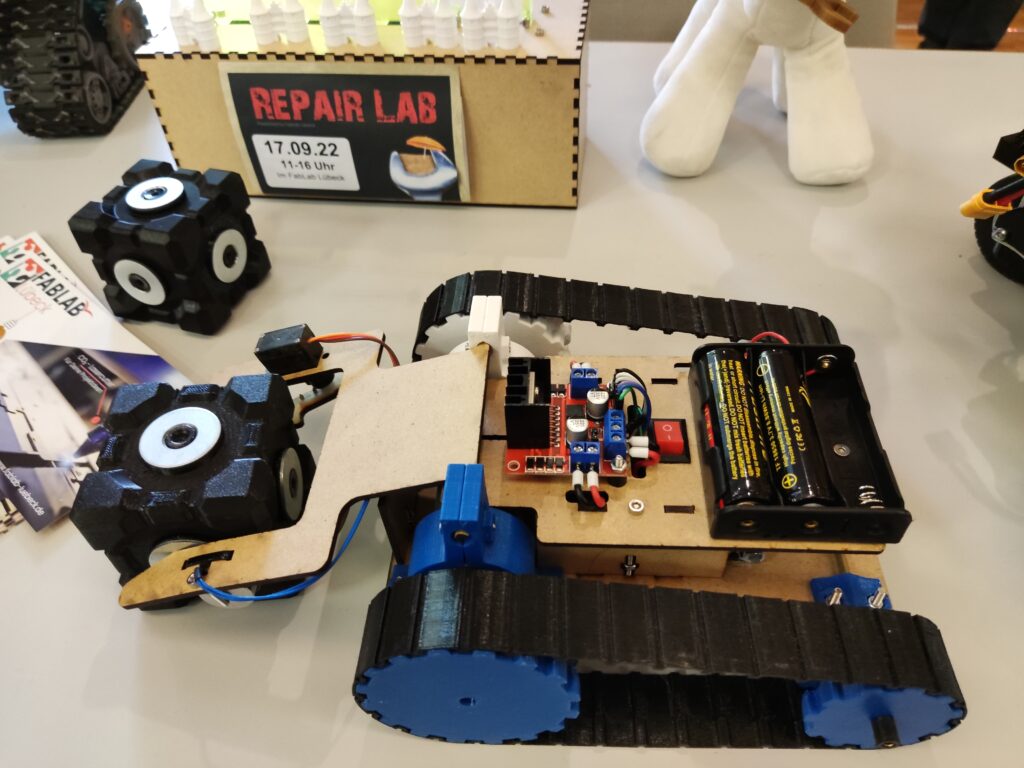

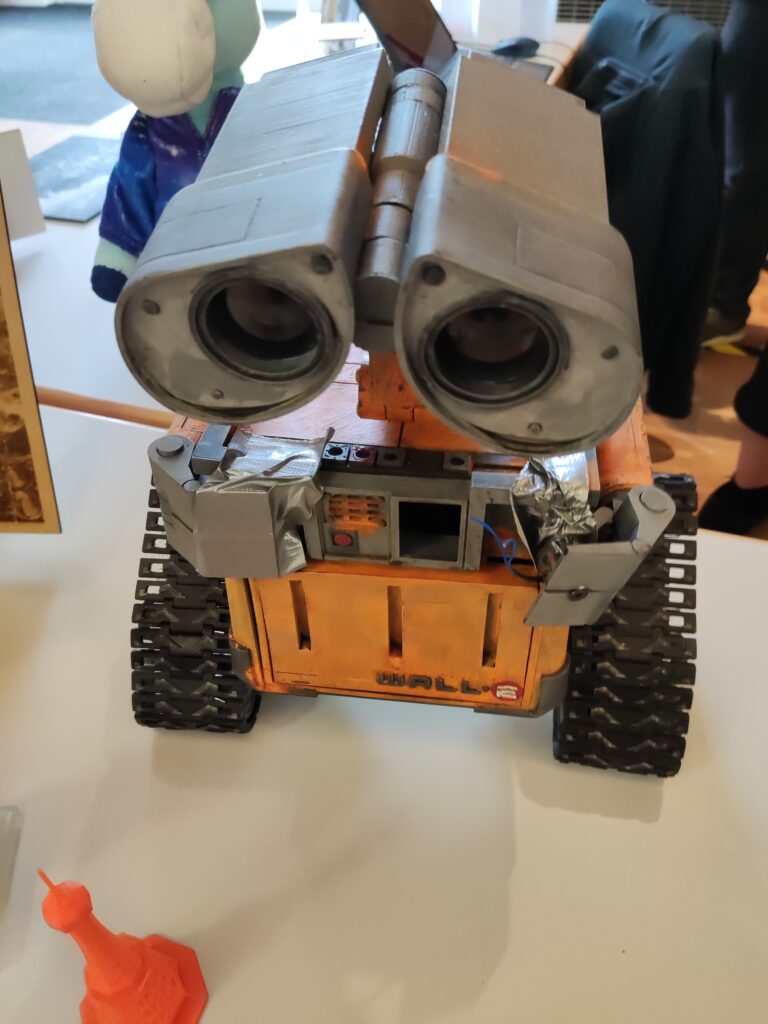

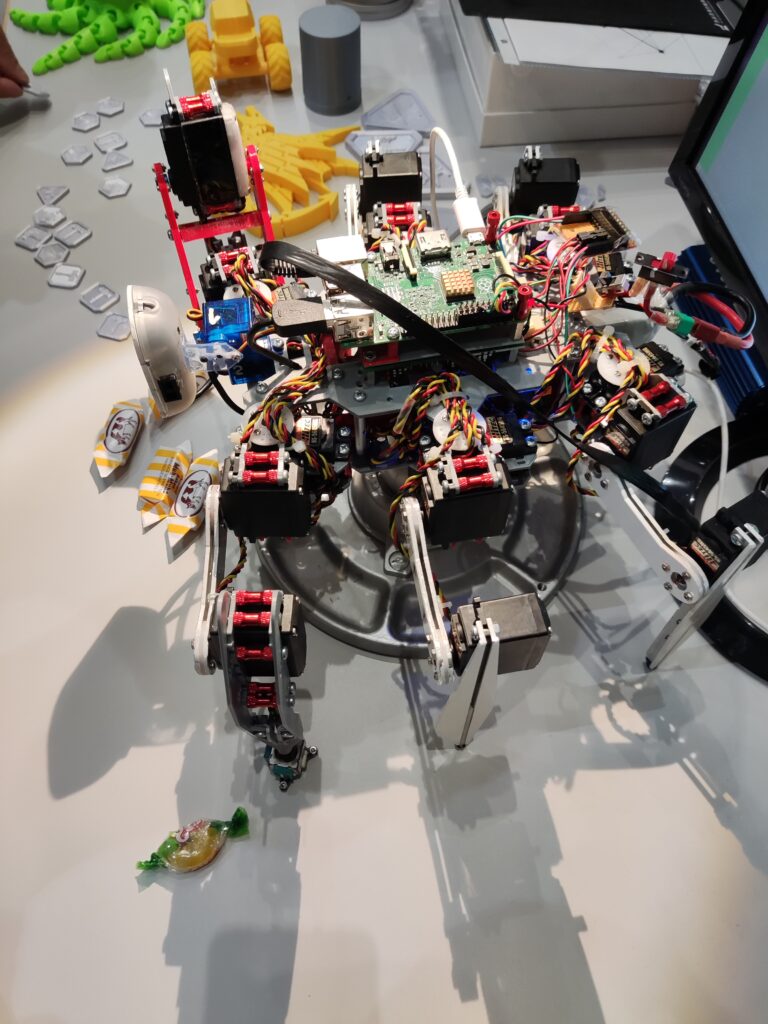

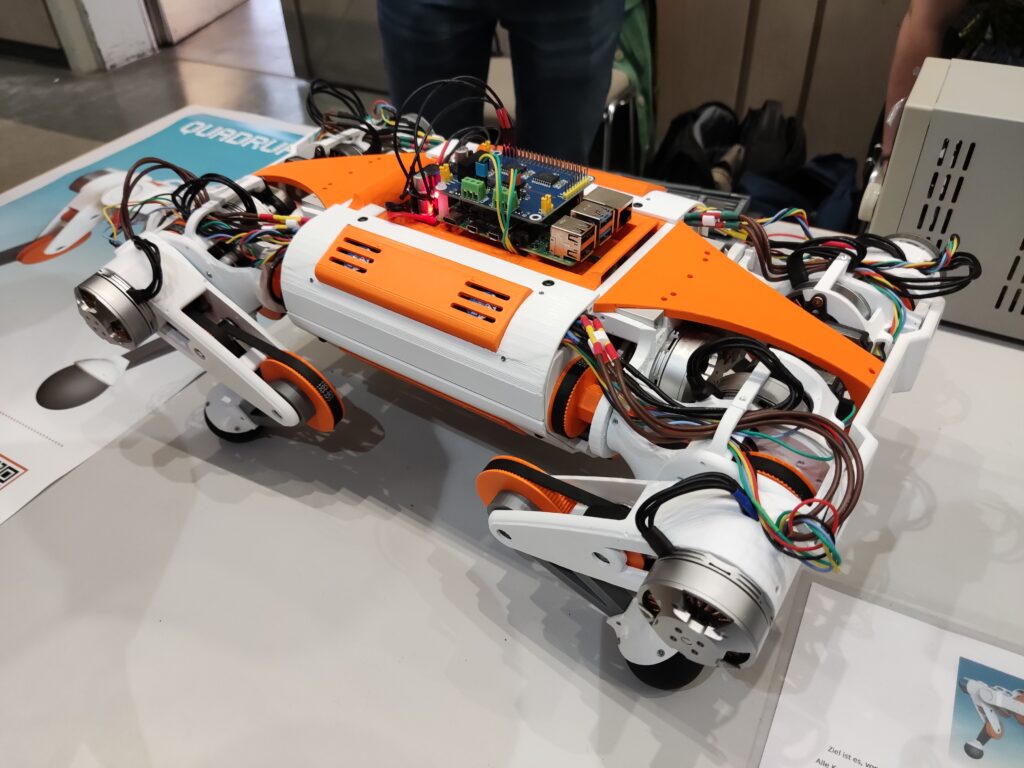

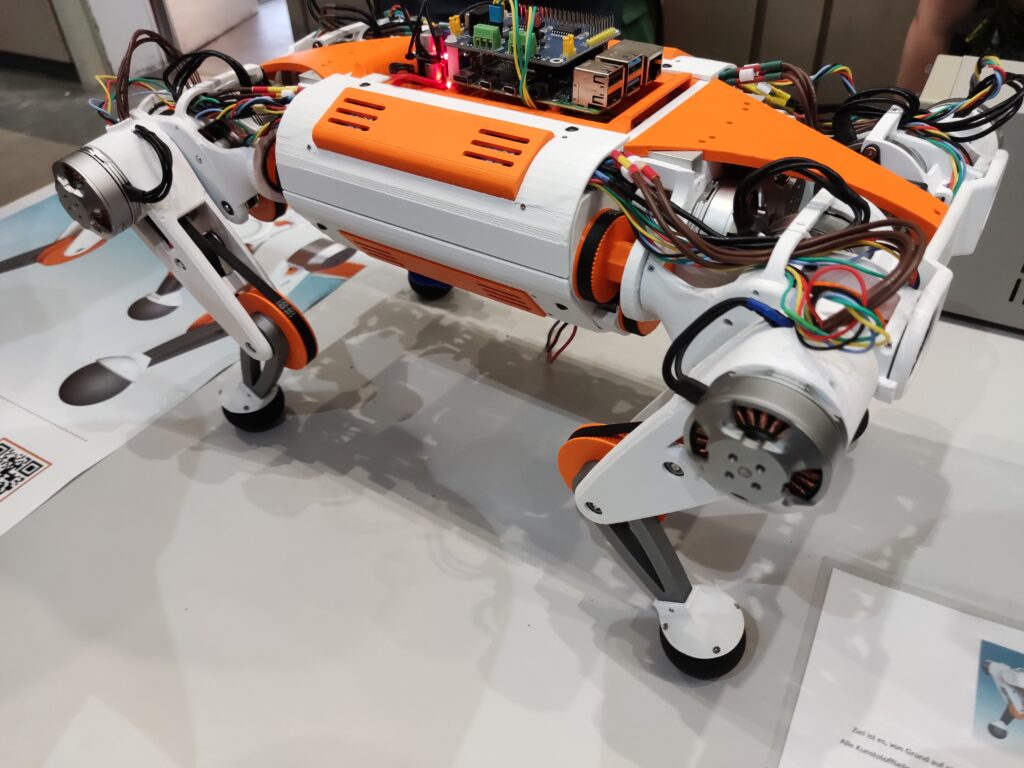

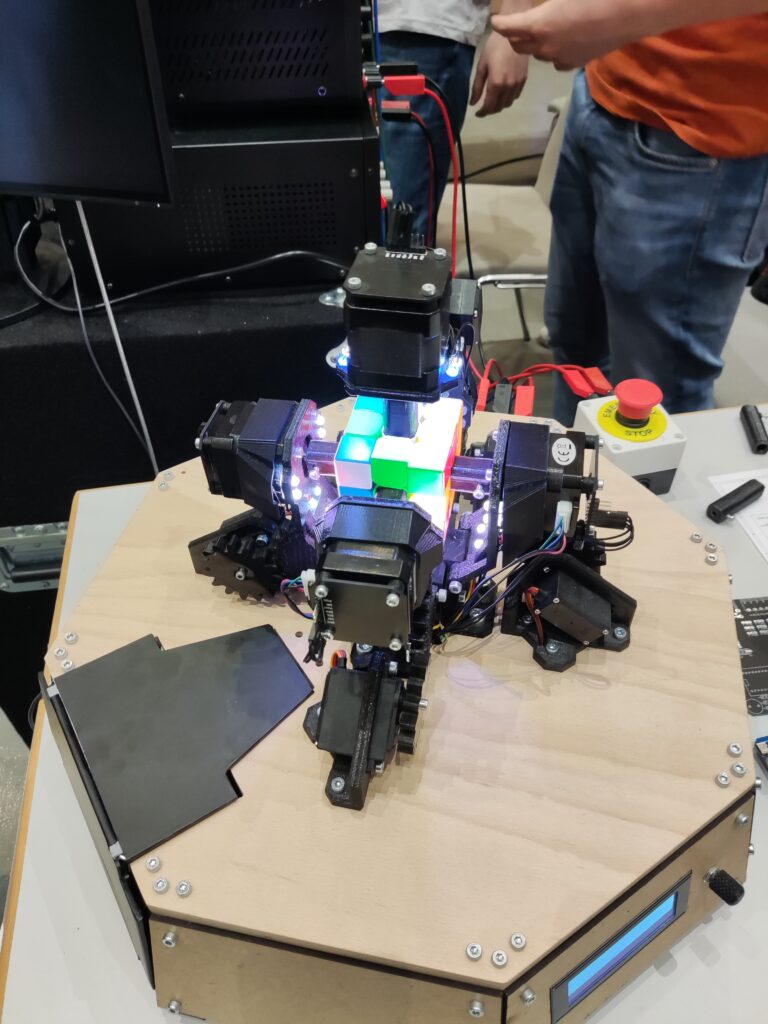

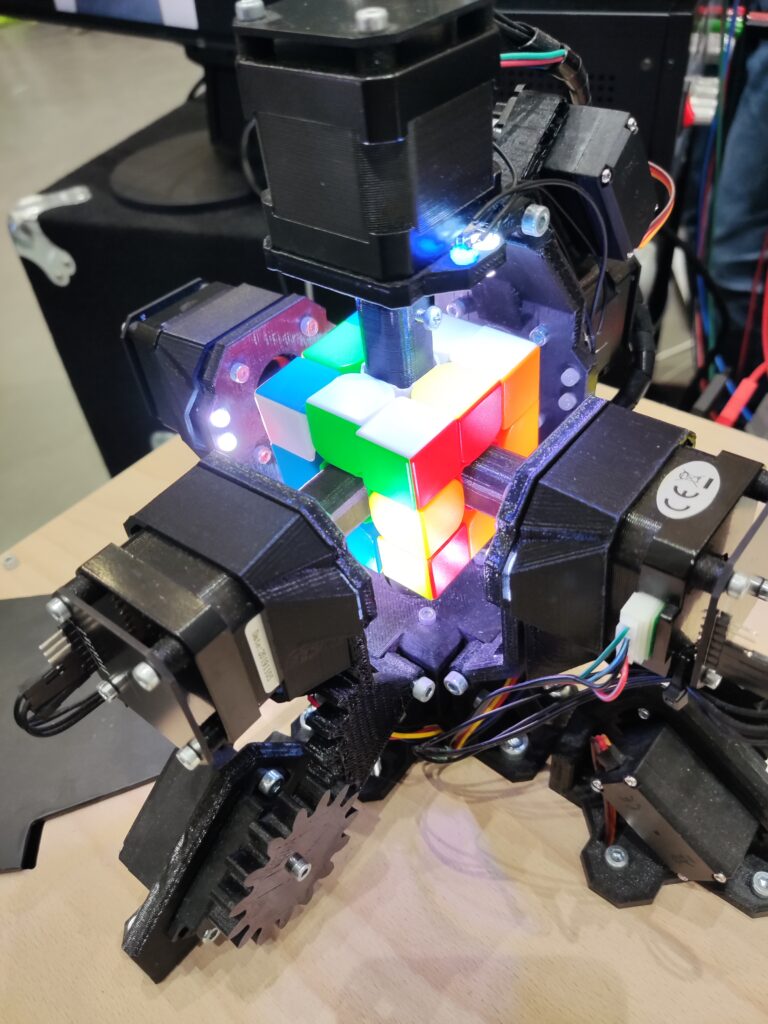

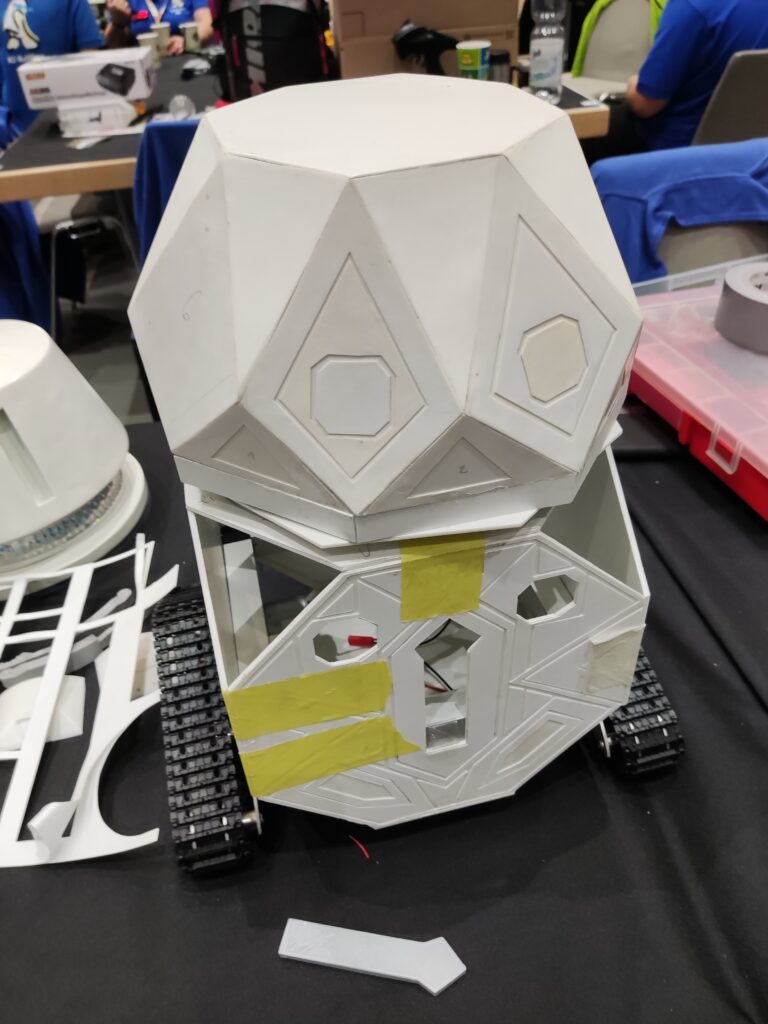

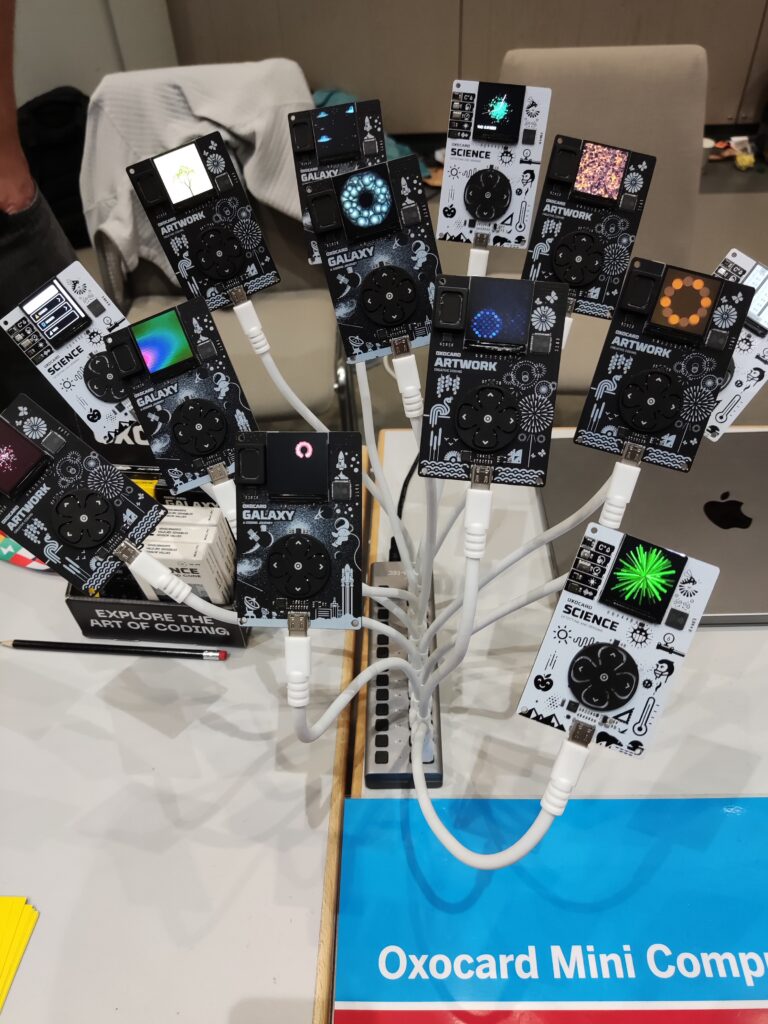

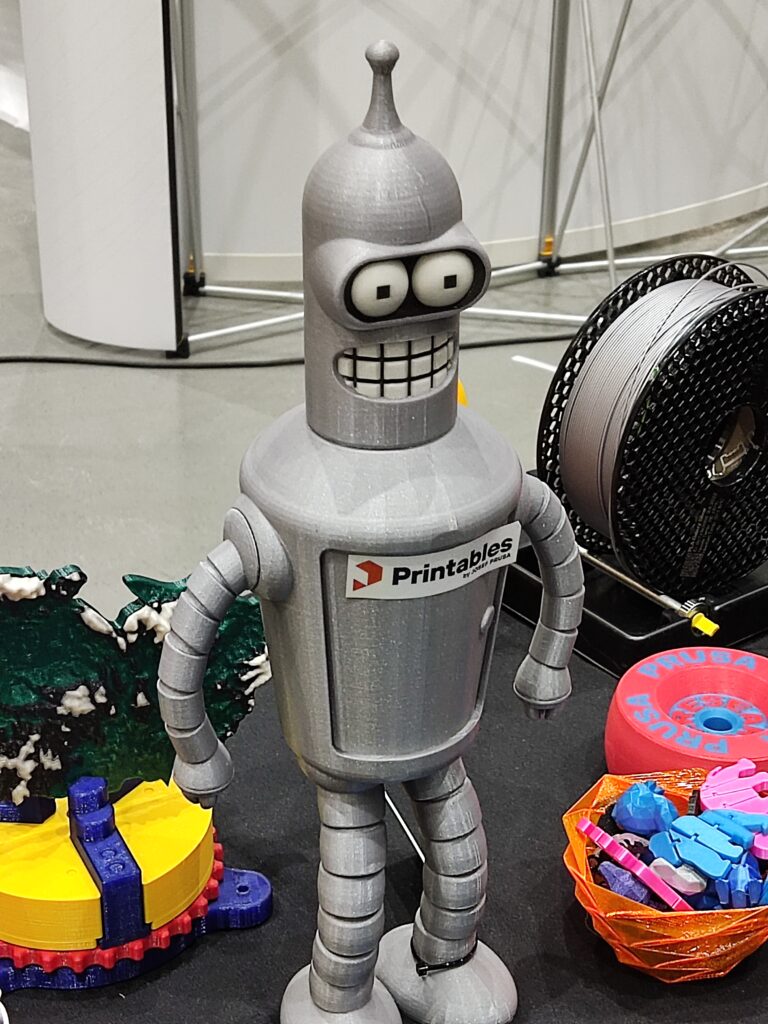

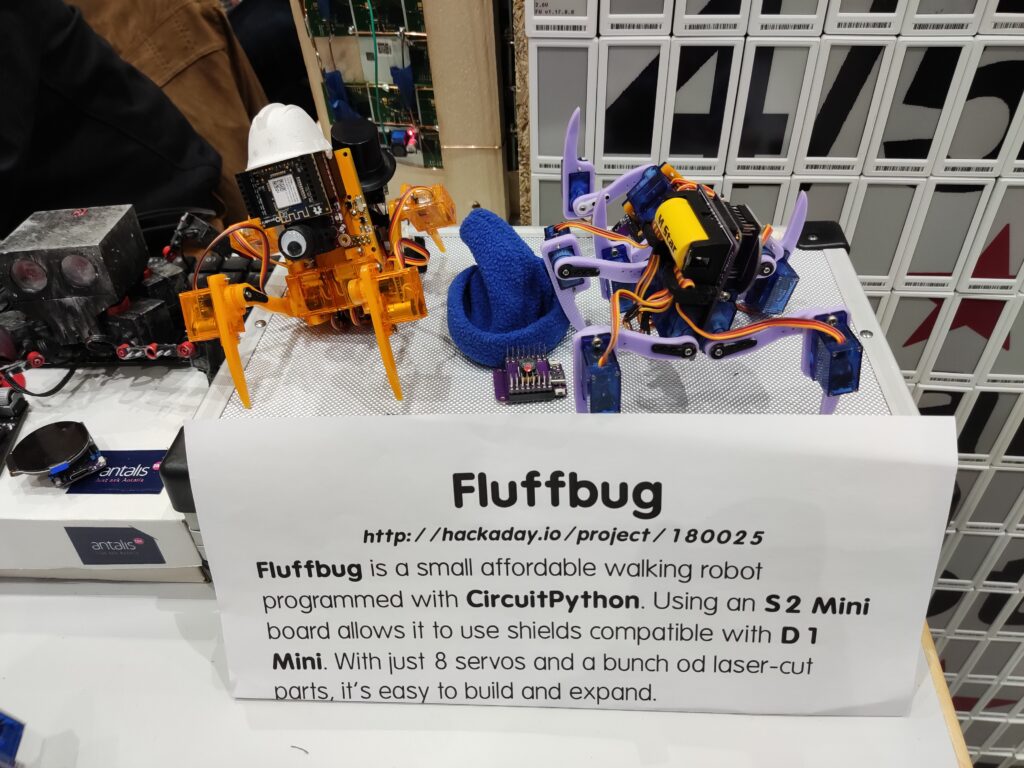

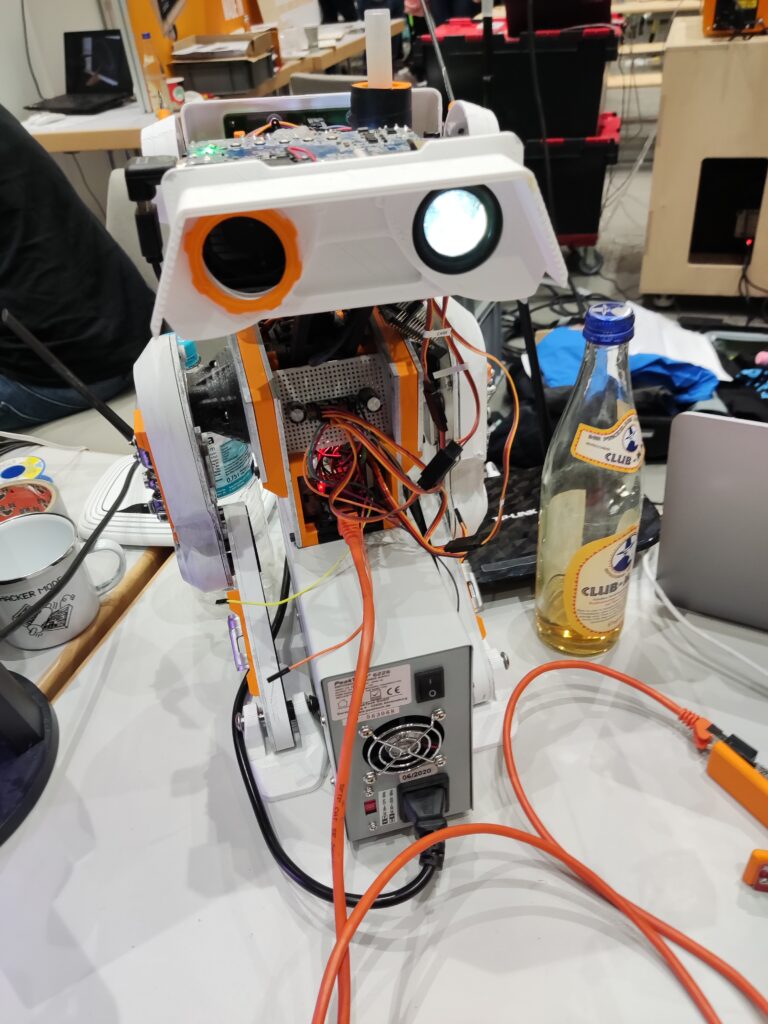

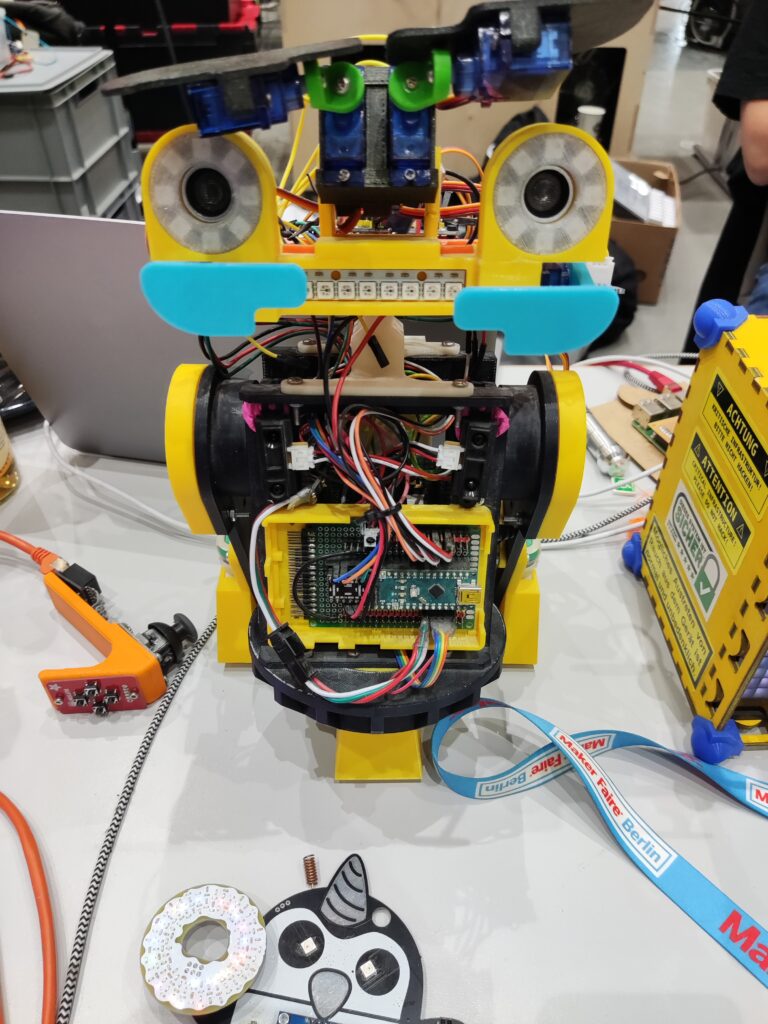

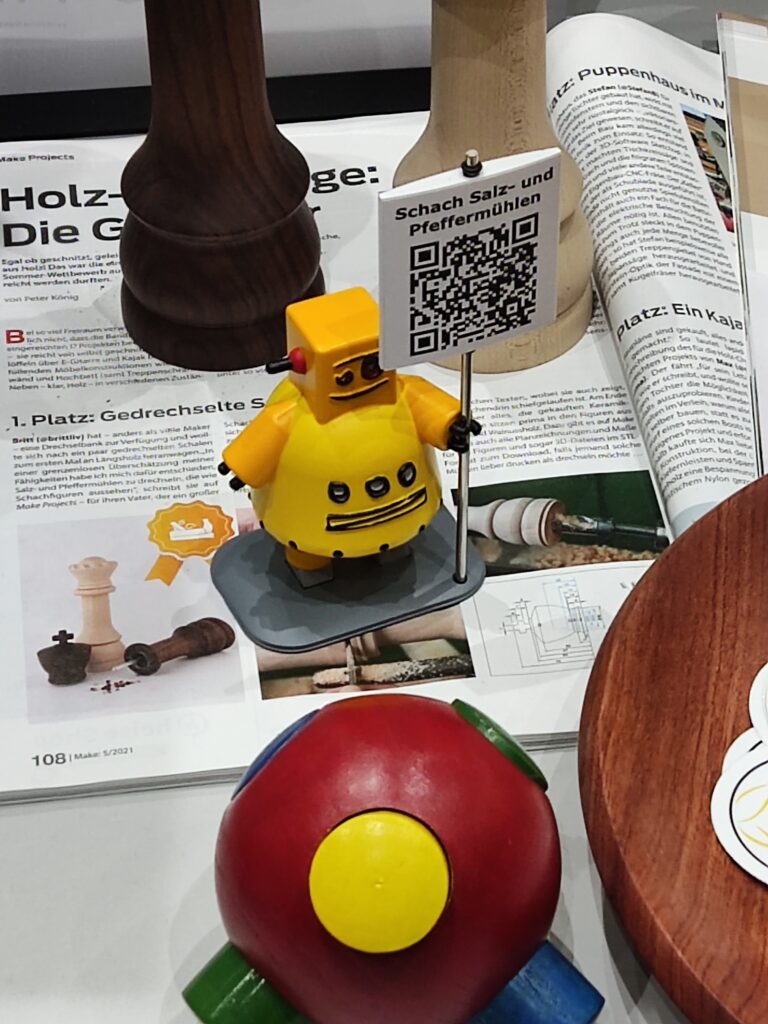

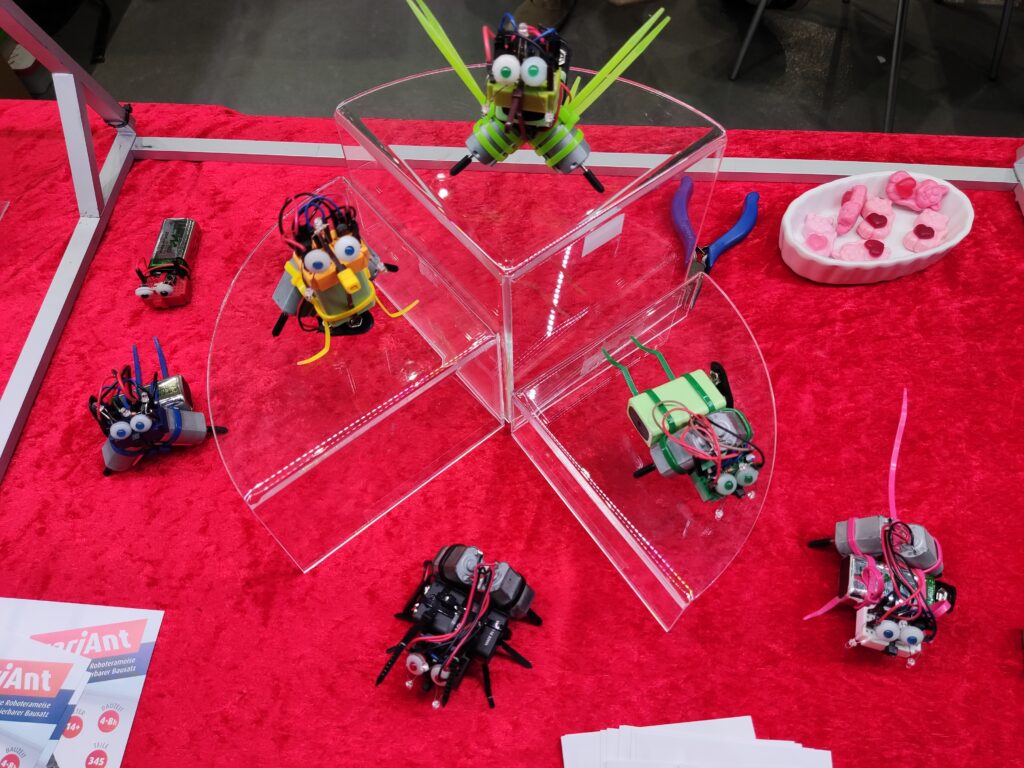

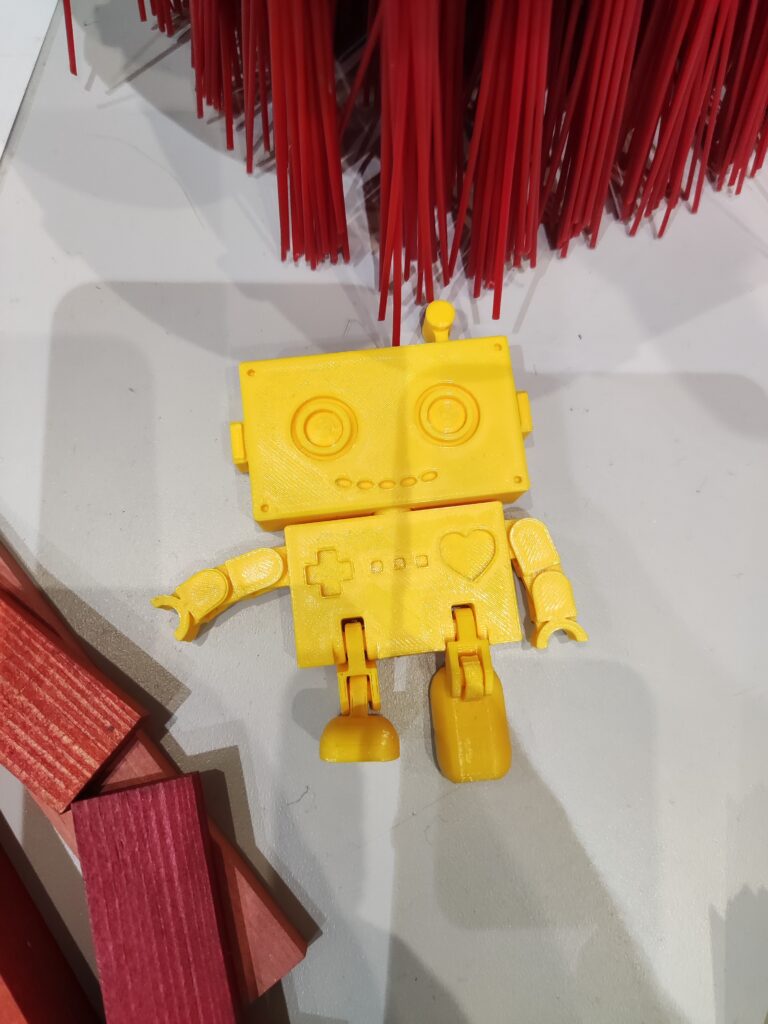

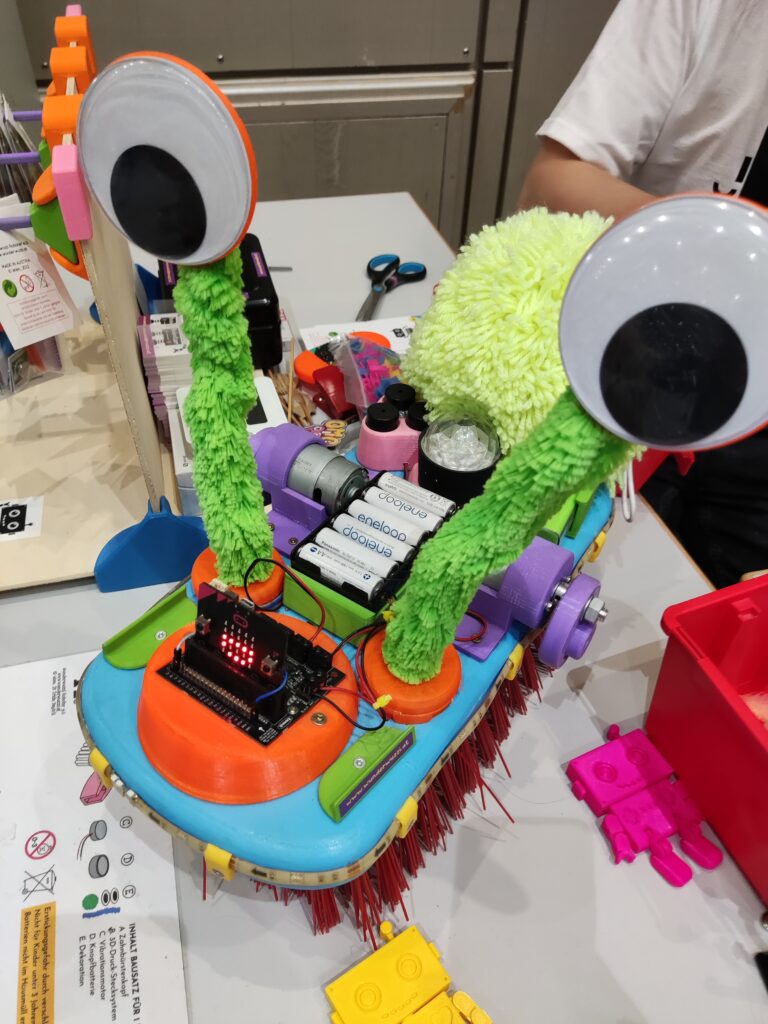

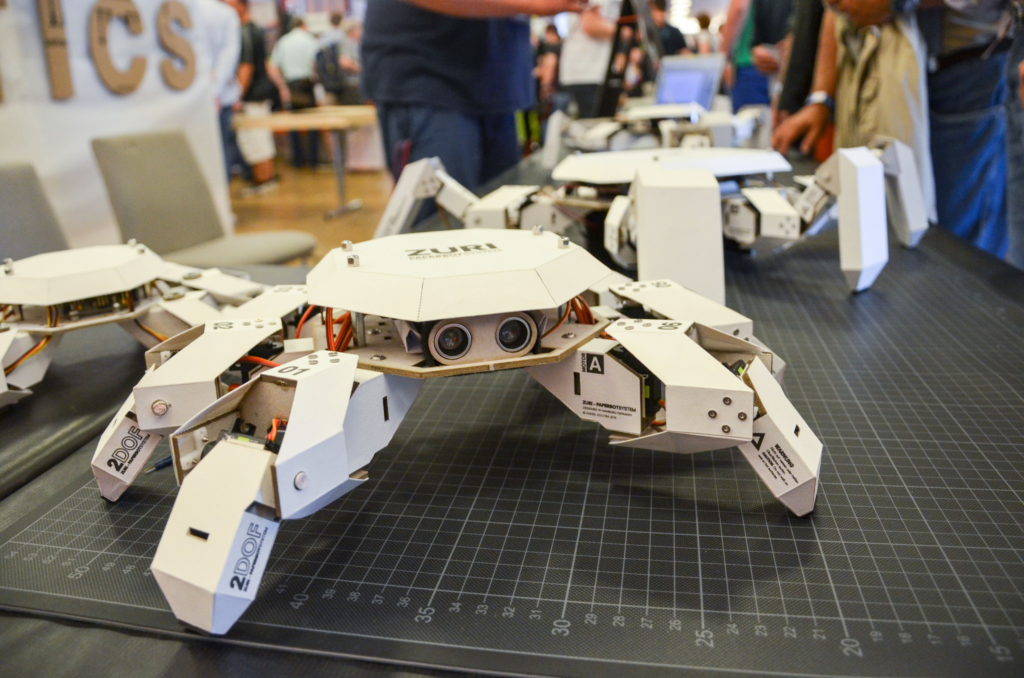

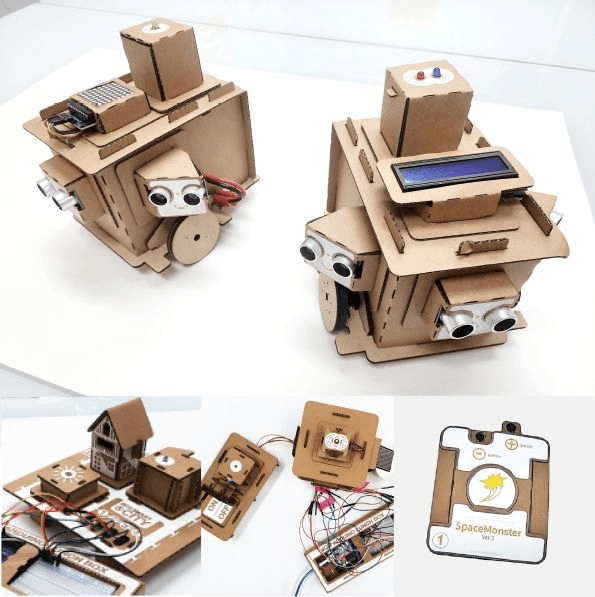

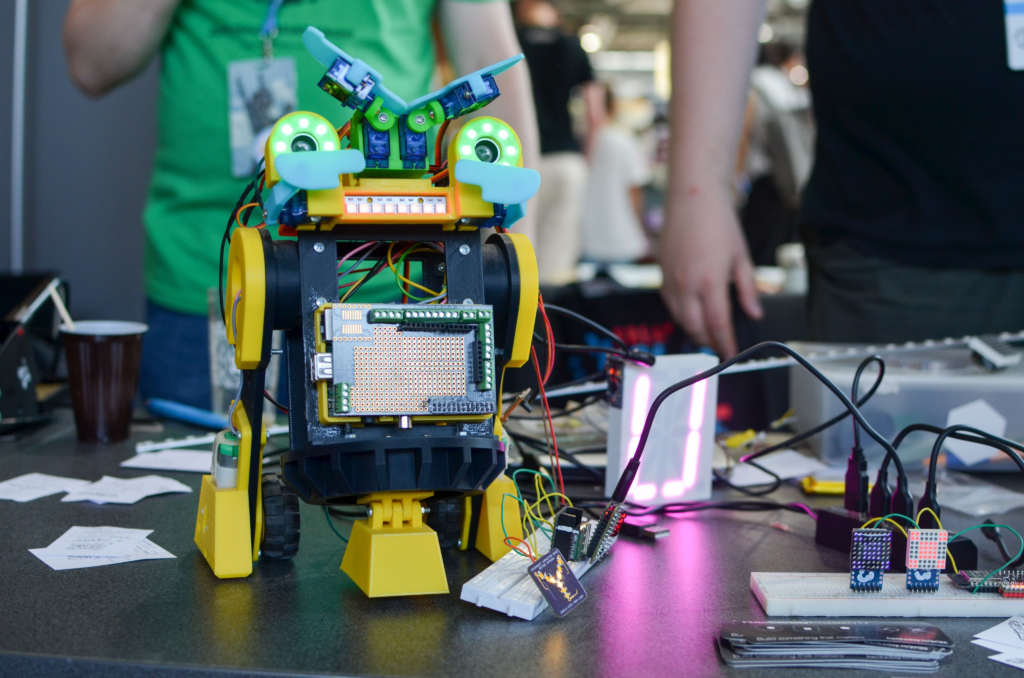

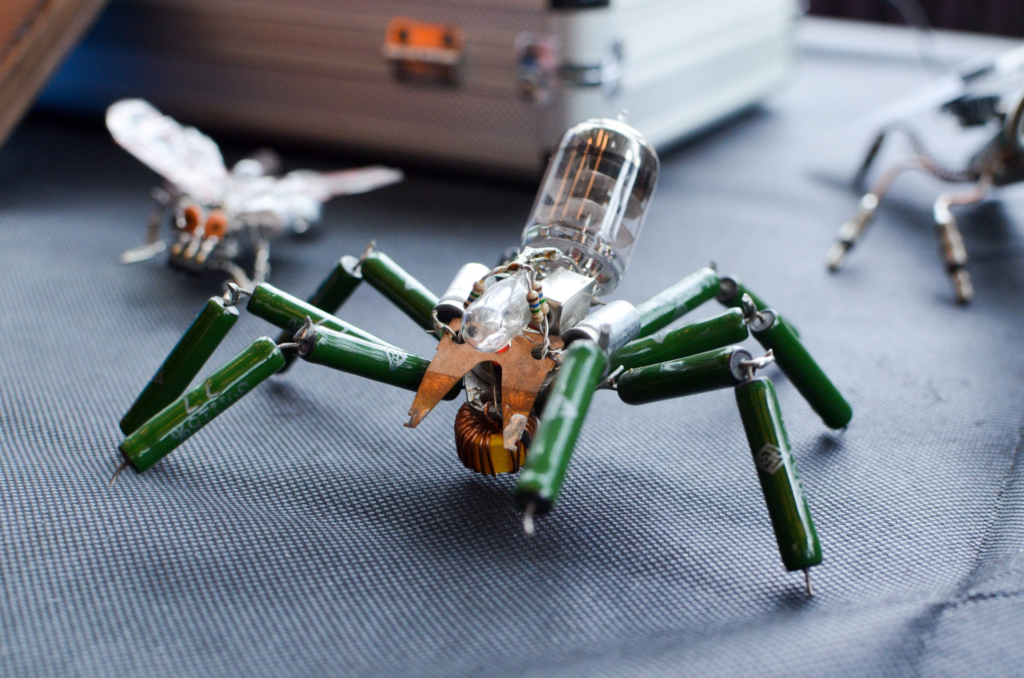

In drei Ausstellungshallen sowie im Außenbereich zeigen die Selbermacher, an welchen faszinierenden Projekten sie in ihren Werkstätten gearbeitet haben. Die Palette ist breit: Zu sehen gibt es fahrende Roboter, blinkende Kleidung, Lego-Kunstwerke, verrückte Computerbasteleien, außergewöhnliche Licht- und Soundinstallationen, Lasercutter und 3D-Druck, etwas andere Handwerkskünste oder kuriose Neuigkeiten aus dem Modellbau.

Ein echter Hingucker ist auch der knapp drei Meter hohe Schlagzeug-Roboter, den der Maker und Musiker Quentin Thomas-Oliver aus Texas zur Maker Faire mitbringt. Gemeinsam mit seiner Partnerin Hilary begleitet Quentin die Roboter-Percussion mit den klassischen Instrumenten Cello und Bratsche und bietet den Zuhörerinnen und Zuhörern einen Musikgenuss der besonderen Art.

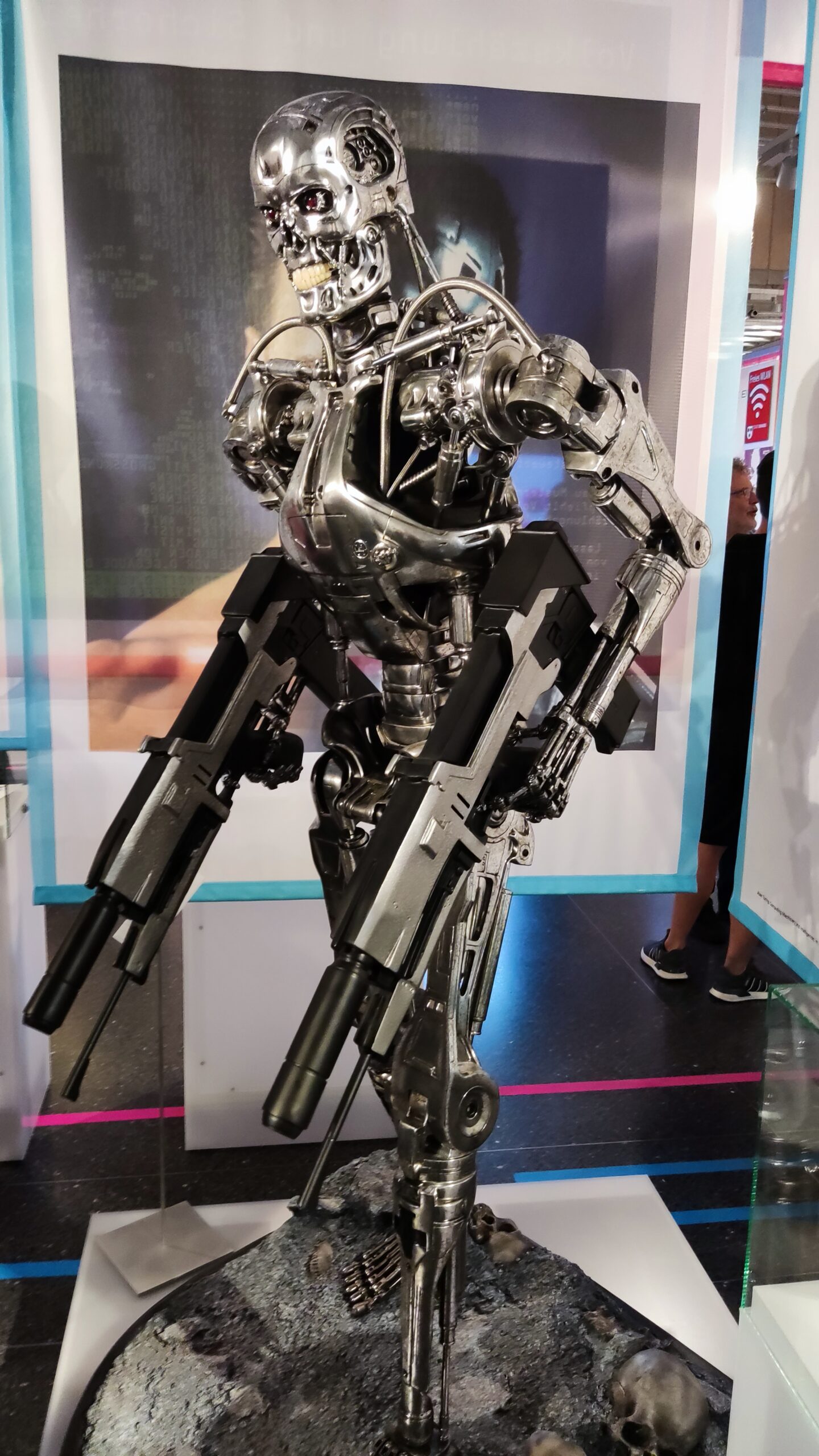

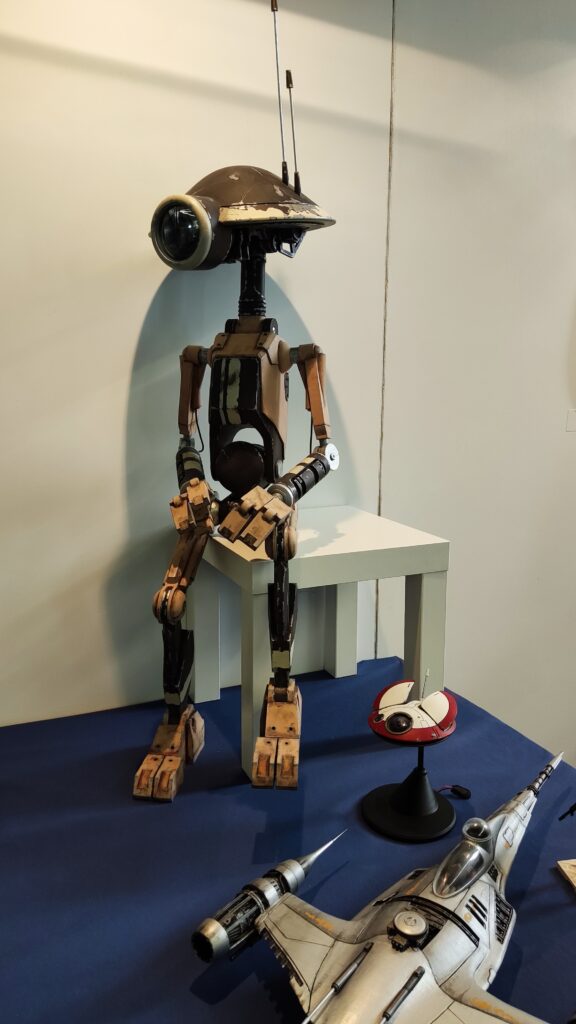

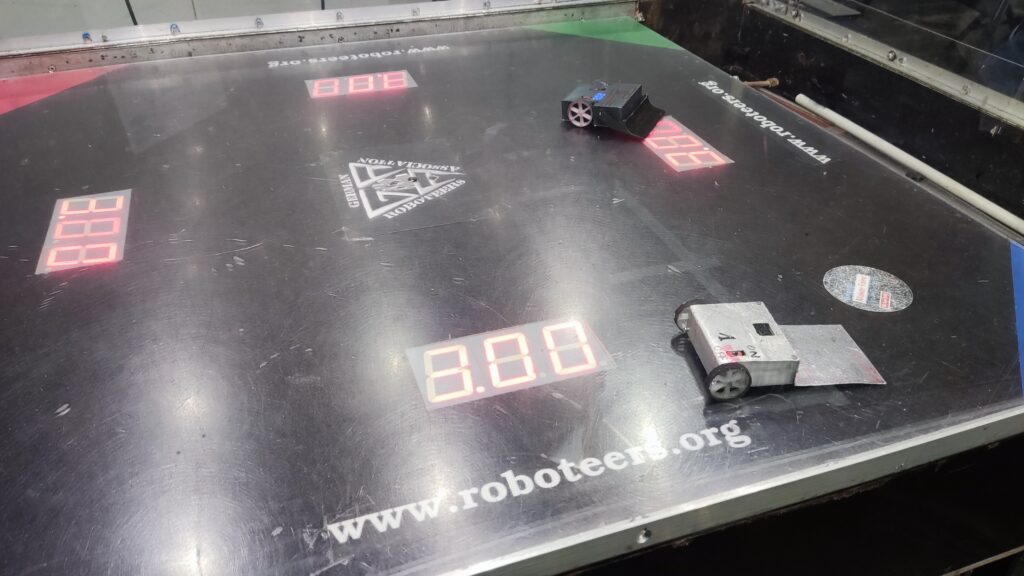

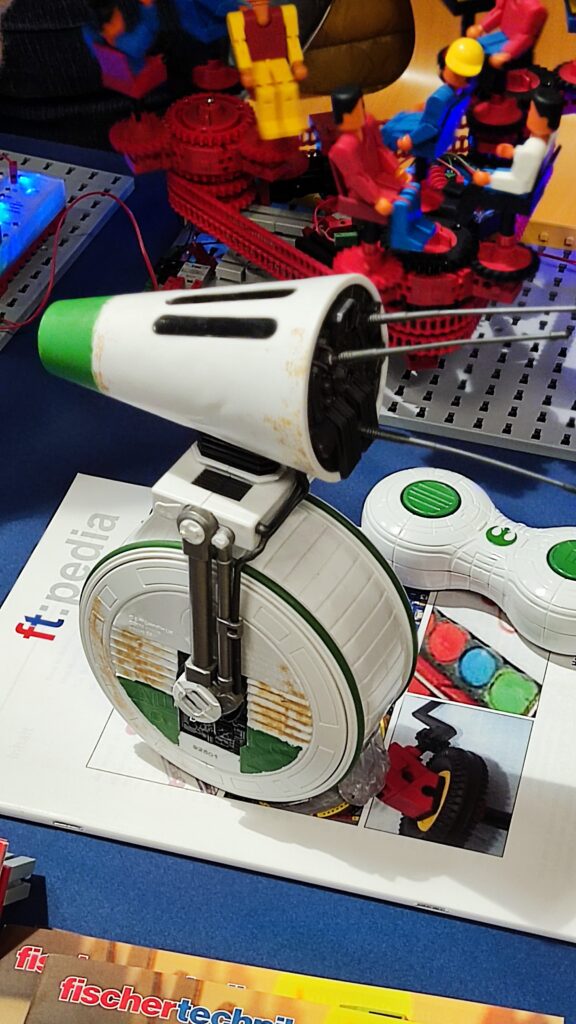

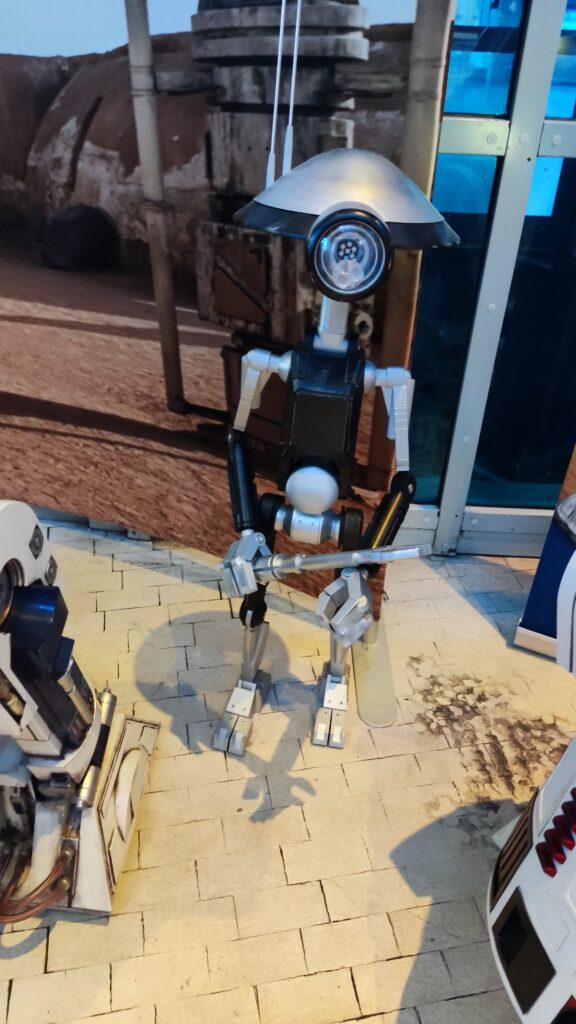

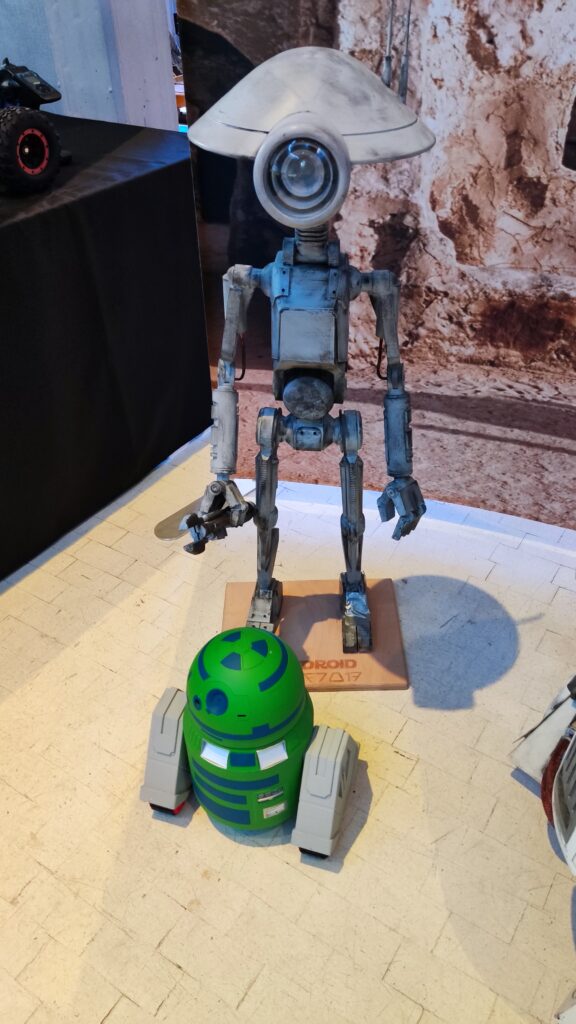

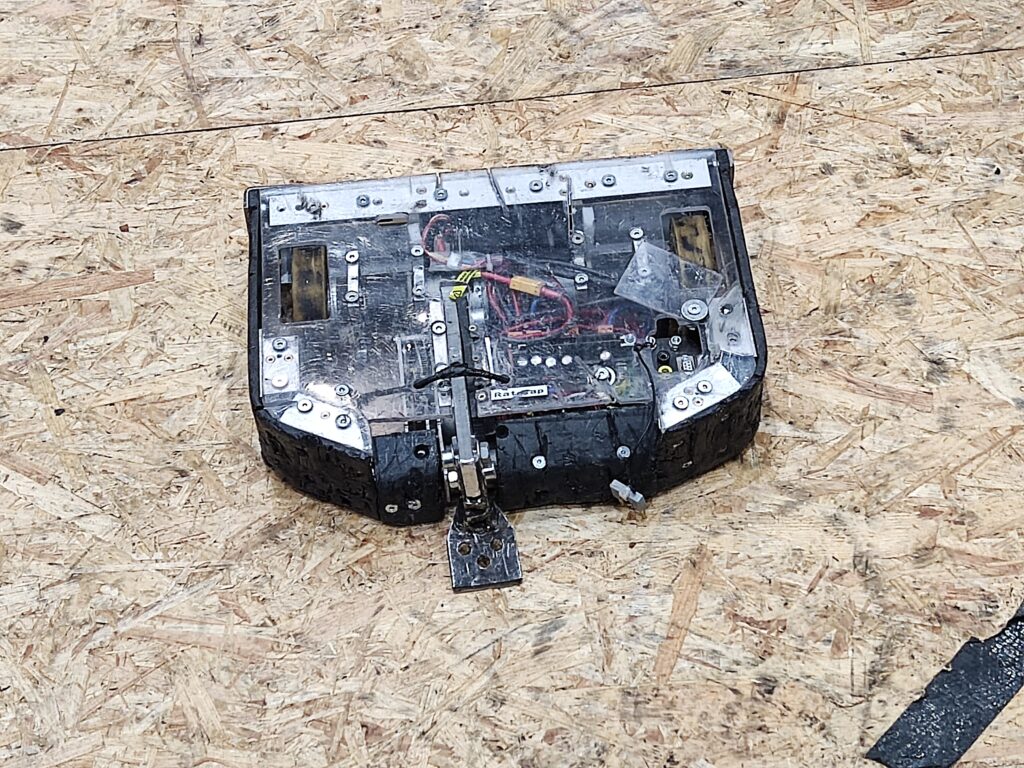

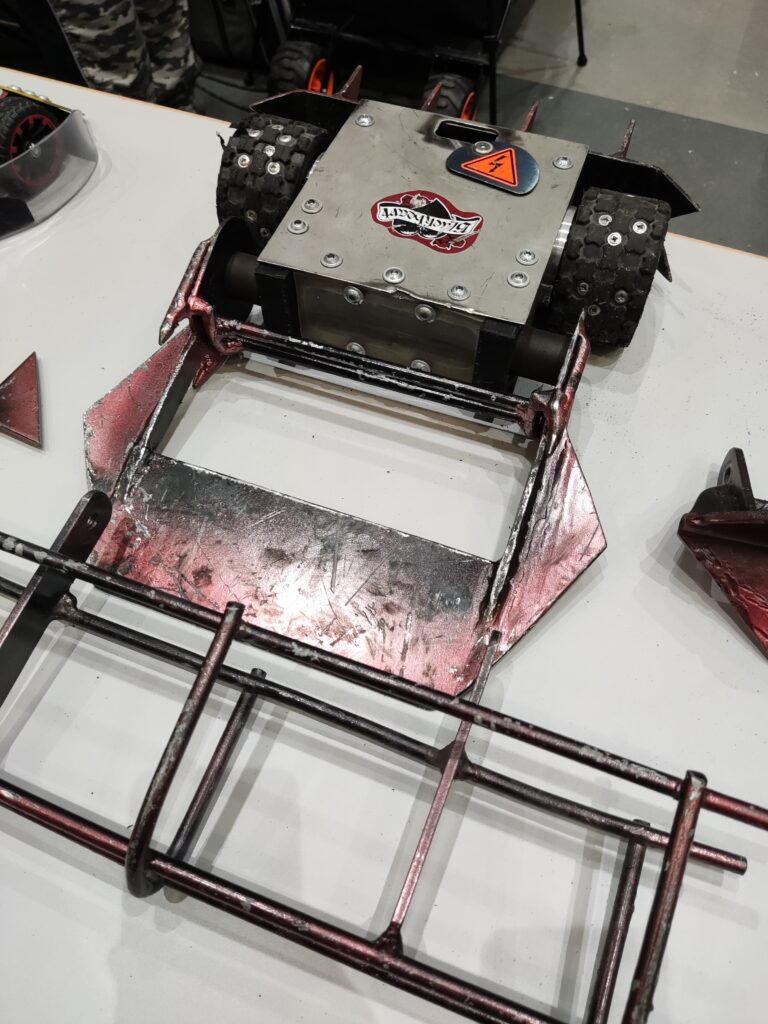

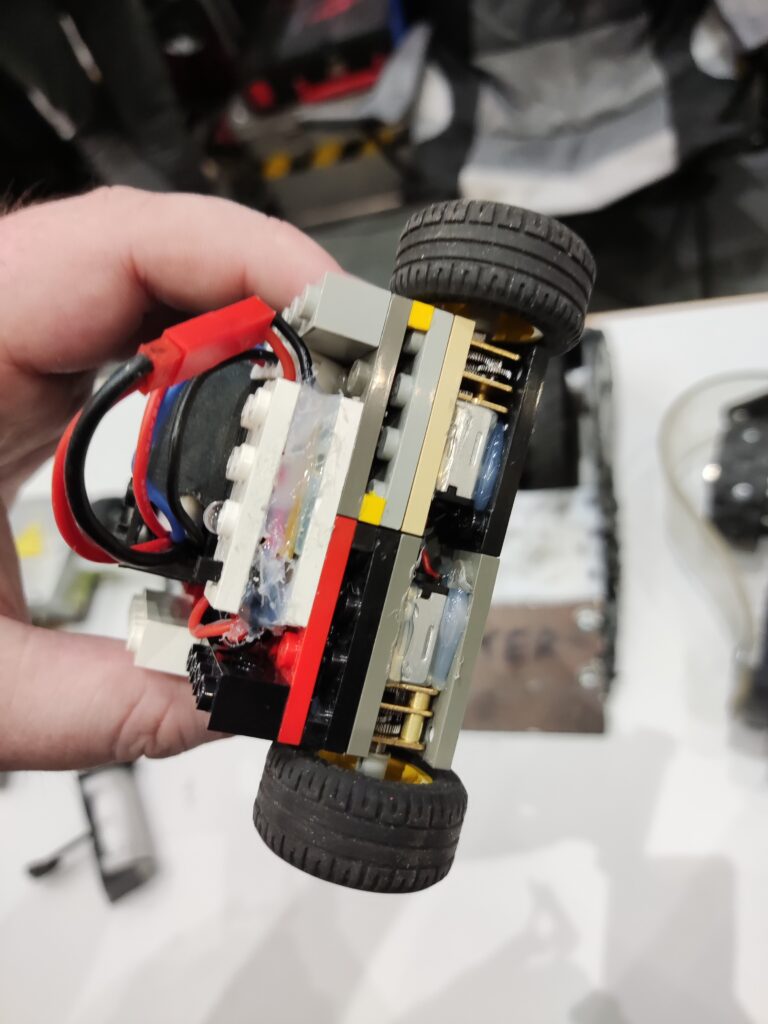

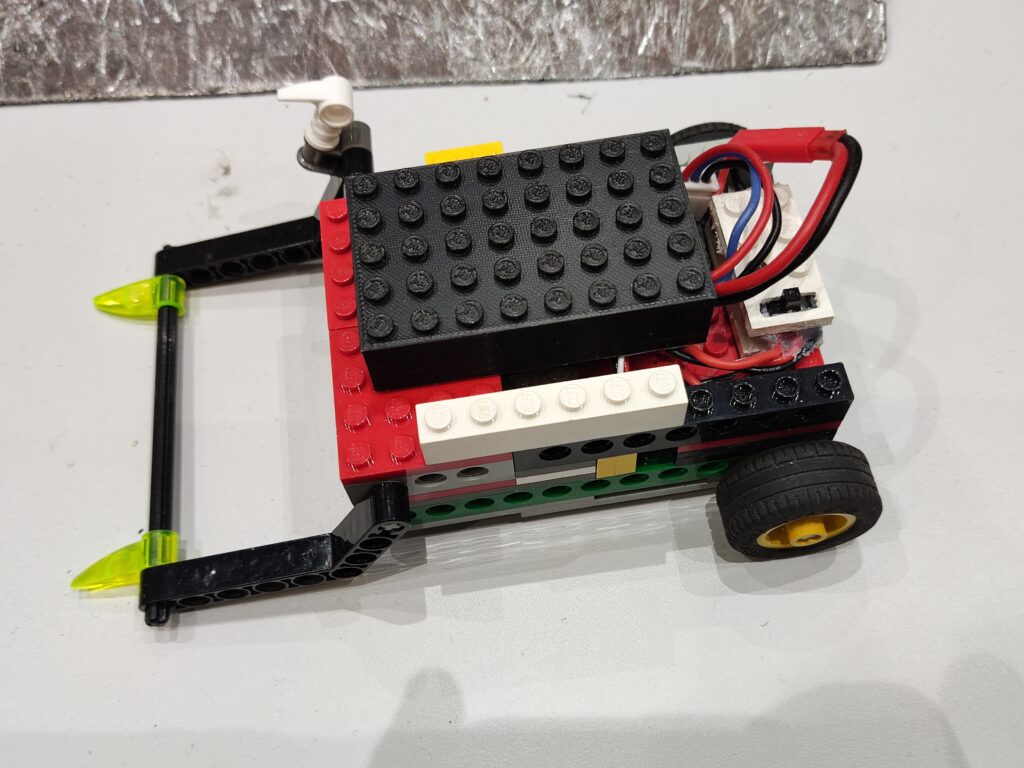

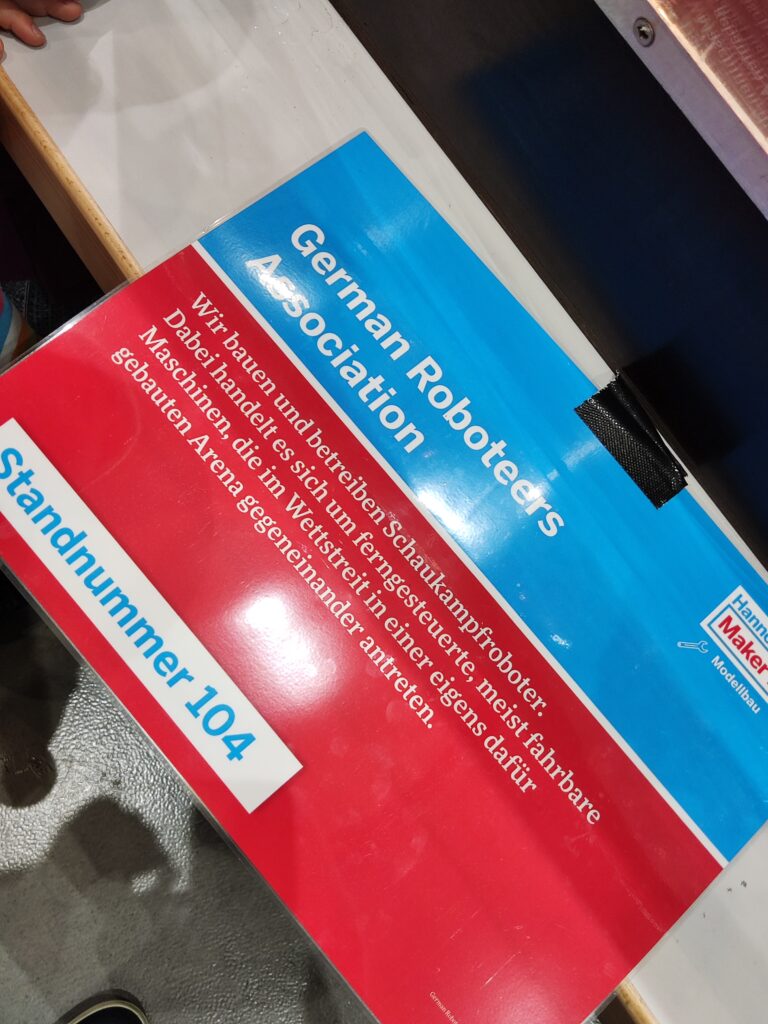

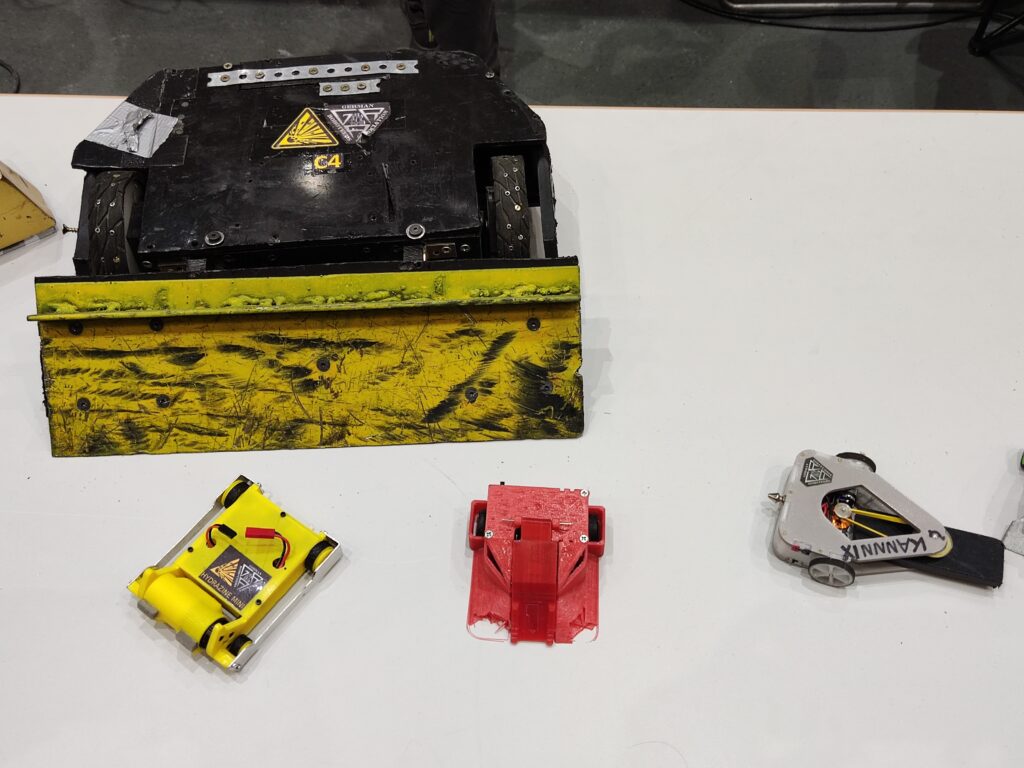

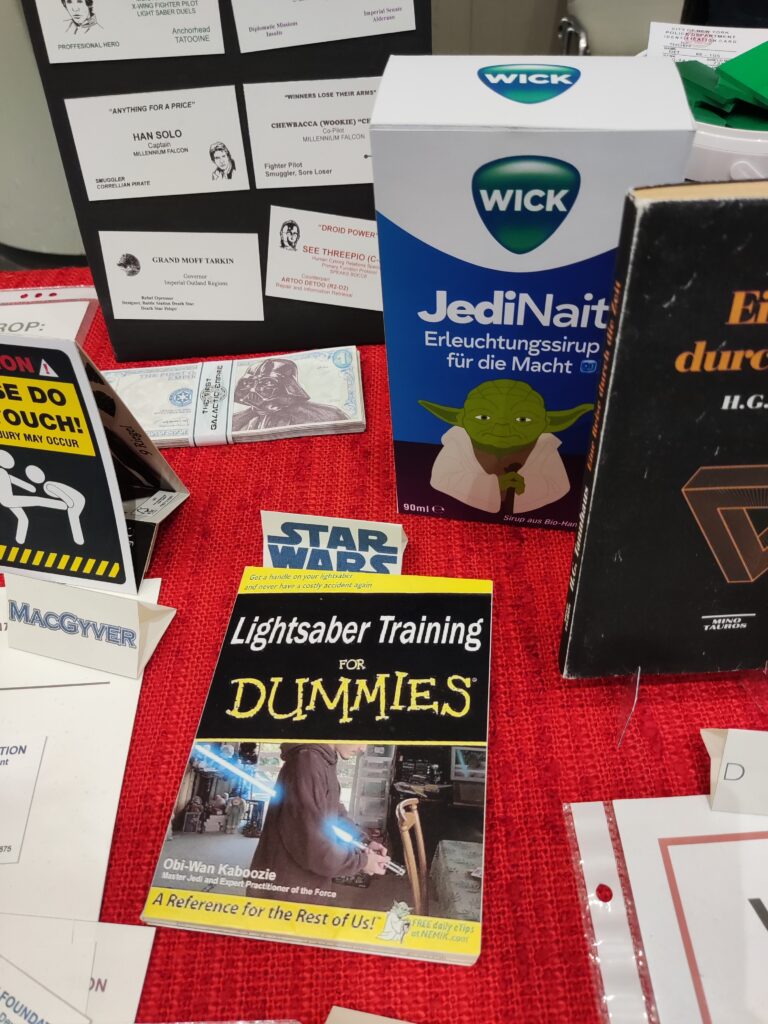

Zu den weiteren Attraktionen – insbesondere für Star-Wars-Fans – zählen auch in diesem Jahr die originalgetreuen R2D2-Nachbauten des R2-Builders-Clubs sowie die packenden Kampfroboterduelle der bekannten Mad Metal Machines.

„Auch zur 9. Maker Faire Hannover haben wir wieder ein vielfältiges Programm auf die Beine gestellt und bieten der Maker-Szene eine Bühne für ihre zukunftsweisenden Ideen. Wir freuen uns sehr, mit Jorà Ferré und der Gruppe ‚Antigua i Barbuda‘ aus Barcelona ganz besondere Künstler gewonnen zu haben, die mit ihrem riesigen Eisenpferd und einer Show mit Musik und Tanz ein absoluter Besuchermagnet sind.“

In der Dark Gallery gibt es ebenfalls neue Maker-Projekte zu bestaunen. Hier ist insbesondere die spektakulär illuminierte und sich langsam drehende Murmelbahn „Marbles“ in einer Gesamtlänge von 60 m, und einer Höhe von 3,50 Meter des niederländischen Lichtkünstlers Gertjan Adema zu erwähnen.

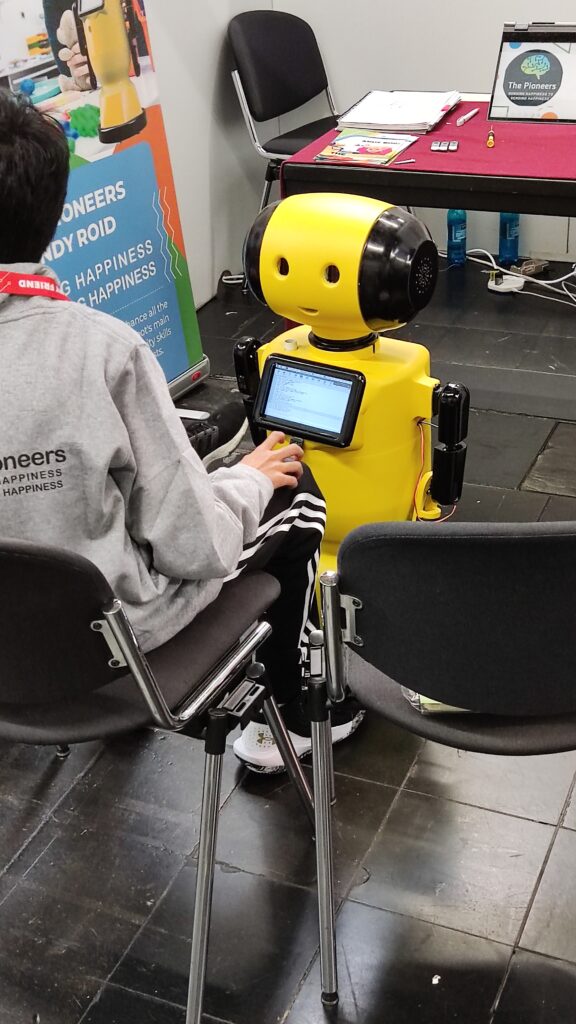

Der humanoide Roboter „Klara Robot“, selbst konstruierte Saiten-Musikinstrumente, die es so nicht im Handel zu kaufen gibt, eine induktive E-Auto-Ladestation, die hilft Ladeprozesse von E Autos zu vereinfachen oder das Upcycling-Projekt „Ventilkappenfantasy“, bei dem ausrangierte Gegenstände zu stylischen Fahrradaccessoires umgebaut werden: das sind nur vier Ideen von hannoverschen Bastlern und Makern, die dieses Jahr das erste Mal auf dem bunten DIY-Festival ausstellen. Zudem sind aus Hannover der Lobomat, ein Automat der Lob auf Knopfdruck ausspuckt, das Zukunftsmobil der Uni Hannover, die Silberbilder des Fotografen Thilo Nass und der Robotik-Podcast dabei.

Eine Maker Faire heißt nicht nur staunen, sondern auch Lernen, Fachsimpeln, Netzwerken, Ausprobieren und vor allem Selbermachen. Für den wissbegierigen Nachwuchs ist die Maker Faire ein Ort für spielerisches Lernen. MINT-Themen werden hier kreativ vermittelt. Die Hacker School aus Hamburg bietet Workshops, in denen Kinder programmieren lernen, und Maker Jan Klingenberg zeigt, wie sich auch schon die Kleinsten mit einer Dosengitarre ein Musikinstrument bauen können. Darüber hinaus findet am Samstag wieder ein Lehrertag statt, an dem Maker Inhalte für den Unterricht vorgestellt werden.

Das YouTuber-Panel mit bekannten und einflussreichen Makern aus der Handwerk-Szene, darunter erstmals die Schreinerin Julia Maria Spielvogel, gibt ebenfalls Impulse zum Nachahmen.

Übrigens: Wie in den Jahren zuvor haben Cosplayer, Steampunker und Star-Wars-Fans in ihren Kostümen freien Eintritt, um die Maker Faire noch ein bisschen bunter zu machen.

Die Maker Faire im HCC ist am Samstag von 10 bis 18 Uhr und am Sonntag von 10 bis 17 Uhr geöffnet. Familientickets gibt es ab 28 Euro, die Tickets können online gebucht werden, auch an der Tageskasse kann nur bargeldlos bezahlt werden.

Infos und Tickets zum bunten DIY-Familienfestival gibt es unter www.maker-faire.de/hannover.