DALLAS (PRWEB) OCTOBER 04, 2020

SqwaQ, a pioneering leader in air-to-ground (A2G) LTE connectivity that enables safe BVLOS drone flights, has been recognized by the AUVSI with a 2020 Xcellence Award for Technology & Innovation. Winners were selected from a pool of accomplished applicants across various categories.

“The AUVSI XCELLENCE Awards honor innovators with a demonstrated commitment to advancing autonomy, leading and promoting safe adoption of unmanned systems and developing programs that use these technologies to save lives and improve the human condition,” said Brian Wynne, president and CEO of AUVSI.

The SqwaQbox is the first carrier approved 4G/LTE modem for Airborne LTE Operations (ALO) that delivers robust, multi-redundant connectivity for safe BVLOS flights. The 270 gram device enables multiple cameras and sensors to stream video in real time with nationwide Command and Control (C2) of the aircraft. This provides the remote pilot with an in-the-cockpit experience that includes pilot view cameras, the capability to fly in controlled airspace, remote operation of ADSB or Mode-S transponders, voice communication to the remote air traffic control tower using aviation VHF radio, and more. The remote pilot can safely integrate with manned aircraft traffic and even take off or land at the world’s busiest airports. These capabilities, and more like it, are already patented by SqwaQ and part of a longer range roadmap that integrates unmanned traffic, rather than UTM segregation which is restrictive and not practical.

A major obstacle facing the UAS industry has been the ability to maintain command and control over long distances via a multi-redundant communication link that not only streams video and sensor data, but can pass muster with FAA safety requirements. SqwaQ understood this from the outset and manufactures the AS9100 Certified SqwaQbox to those aviation standards, with an eye toward additional FAA certifications that may become mandatory for all UASs the future.

Over the last ten years, the drone industry has been guided by robotics engineers and drone enthusiasts with little knowledge of FAA rules or FAR safety guidelines. This has led to challenging FAA authority over the airspace and ignoring aviation safety guidelines in hopes of allowing tens of thousands of flimsy drones to invade the safest airspace in the world. To the FAA this is a dangerous threat. SqwaQ technology is the missing component that resolves this conflict and integrates all connected aircraft in the sky, allowing safe integration of any properly built Remotely Piloted Aircraft.

Today in 2020, major aviation manufacturers are quietly designing their own Remotely Piloted Aircraft solutions with an eye toward full FAA type class certification and safety compliance. That’s not a Part 107 waiver or Part 135 exemption that restricts operations. It means passing a rigid safety certification like Boeing, Bell and Airbus routinely undertake with manned aircraft, to fly unfettered in the airspace and deliver value to customers that toy drones cannot achieve.

SqwaQ is engaged with many aviation manufacturing partners to lead the transformation to certified Remotely Piloted Aircraft. That RPA moniker will denote a real aircraft, flown freely across controlled airspace by a real pilot holding a conventional pilot certification and pedigree. SqwaQ anticipates that OEMs using its BVLOS technology may eliminate 75% of their competitors in the drone industry, as certified aircraft push out the flimsy toys being fobbed off, particularly in public safety.

Discover the cosmos of HORST

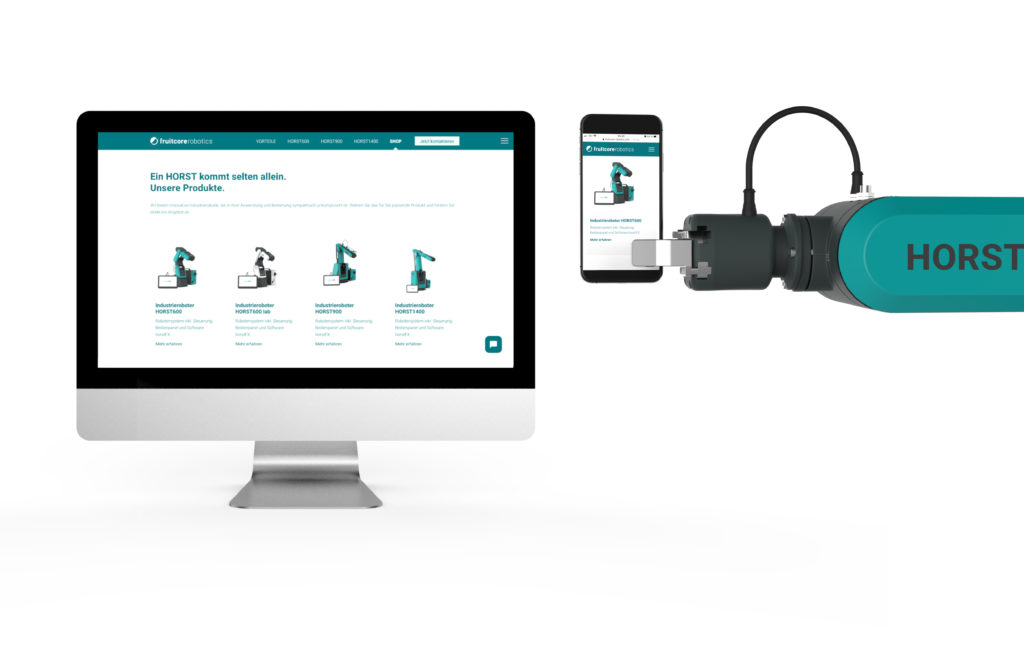

fruitcore robotics adds two new digital services to its online offering: The Constance-based company is launching its fruitcore store and the digital robotics portal horstCOSMOS. Both digital services complement the existing services and offer users a large range of new options.

Constance, 24.09.2020 – fruitcore robotics has supplemented and expanded its online offering by introducing the fruitcore store. In the well-arranged store (https://fruitcore-robotics.com/shop/), users and prospective users can obtain detailed informations about HORST600, HORST600lab, HORST900 and HORST1400 and discover the fruitcore robot family. Fans of HORST also have the opportunity to order the affordable and easy-to-use industrial robot for their particular applications directly and quickly – with just a few clicks straight from your desk. This simplifies the entry into the world of automation even more.

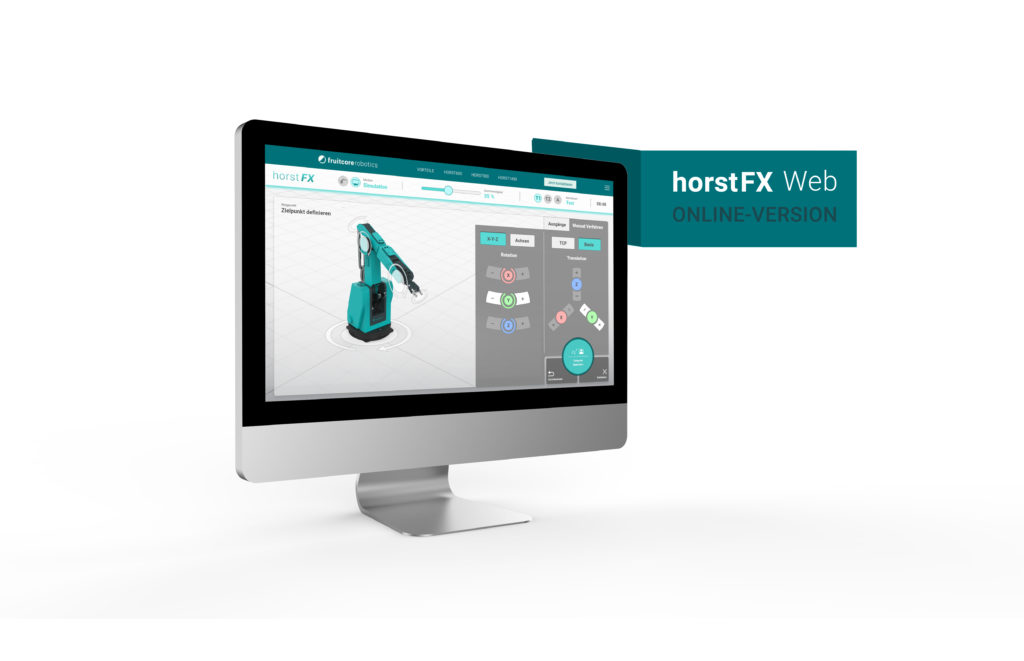

At the same time the Constance-based company has launched its online robotics portal horstCOSMOS. The robotics portal is designed as an interface for an easy interaction between HORST users, partners and fruitcore robotics. For the launch of the portal, interested customers can try out the software horstFX Web for free for a period of 15 days at https://horstcosmos.com/ and discover the advantages offered by the intuitive operation of HORST. On horstCOSMOS, users also have the opportunity to download data sheets and technical documentation, watch videos and tutorials and learn about all aspects of straightforward automation using industrial robot HORST. fruitcore robotics will further expand horstCOSMOS in the future: a chat function, additional apps and practical services will be added to horstCOSMOS.

webshop: https://fruitcore-robotics.com/shop/

horstCOSMOS: https://horstcosmos.com/

With Only Limited Quantities in North America, Presents Pets Puppies Are Already Topping Toy Wish Lists

TORONTO, Sept. 24, 2020 /CNW/ – Spin Master Corp. (TSX: TOY; www.spinmaster.com), a leading global children’s entertainment company, revealed today its newest, imaginative toy packed with innovation, love and excitement – introducing Present Pets puppies, the interactive pets so excited to meet their new owners they unbox themselves.

Inspired by the childhood dream of being gifted an adorable puppy in a bow-topped box, these soft interactive puppies are wrapped in a truly magical unboxing experience the whole family will love. Anticipation for these furry friends is already building with Amazon naming Present Pets puppies one of the top 25 toys this holiday, earning the 8th spot on its „Toys We Love List“ and landing a coveted spot on The Toy Insider’s Hot 20 list.

The magic of Presents Pets puppies is revealed when the child pulls the oversized gift tag, sparking the pup inside to bark and paw its way out of the box and into their heart. After about two minutes of box shaking anticipation and heart bursting excitement the front of the box will topple down revealing a new pup and forever best friend. Early toy testers were blown away by the experience declaring that, „the unboxing is genius!“

With two themes to choose from, Fancy Pups and Glitter Pups, there are one of two possible pups in every box, an additional layer of surprise and delight to this must-have toy. Quantities for the North American market are limited, igniting pre-sale orders on numerous online retailer sites including Amazon, Walmart and Target.

„We cannot wait to surprise the whole family with the magical experience of unboxing their very own Present Pet puppy,“ said Jean Gomez, Spin Master’s VP Marketing & Global Business Unit Lead. „It’s a dream come true for children to unwrap a surprise puppy, and we are delighted to bring that joy to families this holiday season. We hope to see lots of exciting reactions when children open their Present Pets toys.“

Present Pets puppies are available now at major retailers for a suggested retail price of $49.99, recommended for children ages 4+. For more information on Present Pets toys visit http://www.presentpetstoy.com/en_us.

IFR presents World Robotics 2020 – #WorldRobotics2020

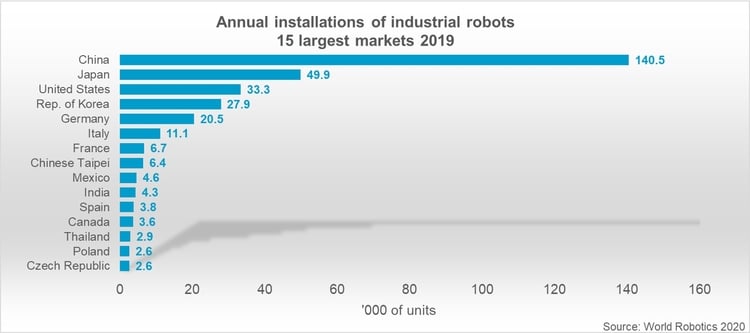

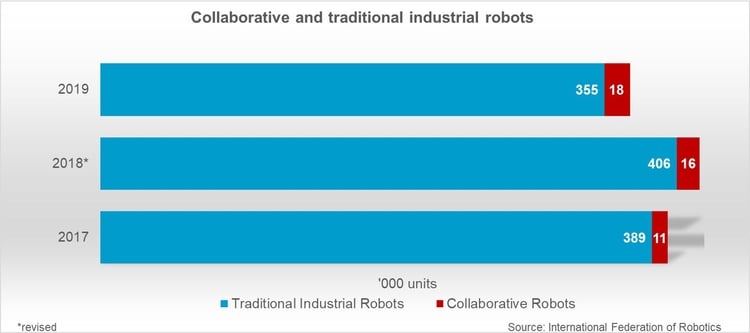

Frankfurt, Sep 24, 2020 — The new World Robotics 2020 Industrial Robots report shows a record of 2.7 million industrial robots operating in factories around the world – an increase of 12%. Sales of new robots remain on a high level with 373,000 units shipped globally in 2019. This is 12% less compared to 2018, but still the 3rd highest sales volume ever recorded.

“The stock of industrial robots operating in factories around the world today marks the highest level in history,” says Milton Guerry, President of the International Federation of Robotics. “Driven by the success story of smart production and automation this is a worldwide increase of about 85% within five years (2014-2019). The recent slowdown in sales by 12% reflects the difficult times the two main customer industries, automotive and electrical/electronics, have experienced.”

“In addition to that, the consequences from the coronavirus pandemic for the global economy cannot be fully assessed yet,” proceeds Milton Guerry. “The remaining months of 2020 will be shaped by adaption to the ´new normal´. Robot suppliers adjust to the demand for new applications and developing solutions. A major stimulus from large-scale orders is unlikely this year. China might be an exception, because the coronavirus was first identified in the Chinese city of Wuhan in December 2019 and the country already started its recovery in the second quarter. Other economies report to be at the turning point right now. But it will take a few months until this translates into automation projects and robot demand. 2021 will see recovery, but it may take until 2022 or 2023 to reach the pre-crisis level.”

Asia remains the strongest market for industrial robots – operational stock for the region´s largest adopter China rose by 21% and reached about 783,000 units in 2019. Japan ranks second with about 355,000 units – plus 12 %. A runner-up is India with a new record of about 26,300 units – plus 15%. Within five years, India has doubled the number of industrial robots operating in the country´s factories.

The share of newly installed robots in Asia was about two thirds of global supply. Sales of almost 140,500 new robots in China is below the record years of 2018 and 2017 but still more than double the numbers sold five years ago (2014: 57,000 units). Installations of top Asian markets slowed down – in China (minus 9%) and Japan (minus 10%).

In China, the broad majority of 71% of new robots was shipped in from foreign suppliers. Chinese manufacturers still mainly cater to the domestic market, where they gain increasing market shares. Foreign suppliers deliver some 29% of their units to the automotive industry, while it is only around 12% for Chinese suppliers. Therefore, foreign suppliers are more affected by the decline of business in the Chinese automotive industry than the domestic suppliers.

Europe reached an operational stock of 580,000 units in 2019 – plus 7%. Germany remains the main user with an operational stock of about 221,500 units – this is about three times the stock of Italy (74,400 units), five times the stock of France (42,000 units) and about ten times the stock of the UK (21,700 units).

Robot sales show a differentiated picture for the largest markets within the European Union: About 20,500 robots were installed in Germany. This is below the record year 2018 (minus 23%) but on the same level as 2014-2016. Sales in France (+15%), Italy (+13%) and the Netherlands (+8%) went up. Robotics in the United Kingdom remains on a low level – new installations slowed down by 16%. The newly installed 2,000 units in the UK are about ten times less than the shipments in Germany (20,500 units), about five times less than in Italy (11,100 units) and about three times less than in France (6,700 units).

The USA is the largest industrial robot user in the Americas, reaching a new operational stock record of about 293.200 units – up 7%. Mexico comes second with 40,300 units, which is a plus of 11% followed by Canada with about 28,600 units – plus 2%.

New installations in the United States slowed down by 17% in 2019 compared to the record year of 2018. Although, with 33,300 shipped units, sales remain on a very high level representing the second strongest result of all time. Most of the robots in the USA are imported from Japan and Europe. Although, there are not many North American robot manufacturers, there are numerous important robot system integrators. Mexico ranks second in North America with almost 4,600 units – a slowdown of 20%. Sales in Canada are 1% up to a new record of about 3,600 shipped units.

South America´s number one operational stock is in Brazil with almost 15,300 units – plus 8%. Sales slowed down by 17% with about 1,800 installations – still one of the best results ever – only beaten by record shipments in 2018.

The adoption of human-robot collaboration is on the rise. We saw cobot installations grew by 11%. This dynamic sales performance was in contrast to the overall trend with traditional industrial robots in 2019. As more and more suppliers offer collaborative robots and the range of applications becomes bigger, the market share reached 4.8% of the total of 373,000 industrial robots installed in 2019. Although this market is growing rapidly, it is still in its infancy.

Globally, COVID-19 has a strong impact on 2020 – but also offers a chance for modernization and digitalization of production on the way to recovery. In the long run, the benefits of increasing robot installations remain the same: Rapid production and delivery of customized products at competitive prices are the main incentives. Automation enables manufacturers to keep production in developed economies – or reshore it – without sacrificing cost efficiency. The range of industrial robots continues to expand – from traditional caged robots capable of handling all payloads quickly and precisely to new collaborative robots that work safely alongside humans, fully integrated into workbenches.

Orders for World Robotics 2020 Industrial Robots and Service Robots reports can be placed online and grant immediate access to the 2019 figures.

STRYK is Launching the Next Evolution of Combat Sports Training with its Unique Robotic Fighting Coach, RXT-1

Created by a U.S. Army Special Forces Veteran, the company’s innovative robot trainer is designed with four foam arms, a head target, and a torso pad option to help improve fighters‘ reaction time, mental processing speed, and hand-eye coordination.

SEATTLE, Sept. 23, 2020 /PRNewswire/ — The robots are coming to combat sports training with a new company, STRYK, https://www.strykusa.com/, launching its unique robotic fighting coach, RXT-1, promising the next evolution in fight training.

Created by a former U.S. Army Special Forces Explosives Specialist and a long-time combat sports participant, the company’s innovative RXT-1 robot is designed with four foam arms, a head target, and a torso pad option, and offers three different training mode options: Practice, Spar, and Combinations. The RXT-1 is not intended to replace human sparring partners but to complement such training through improving the users‘ reaction time, mental processing speed, and hand-eye coordination.

Think of it as man vs. machine to enable you to enhance your fighting skills. Or a sparring partner that never gets tired. The RXT-1 allows you to get in extra sparring rounds without risking injury while training at variable tempos, speeds, and attack stimuli you wouldn’t easily experience with comparable human partners.

„It’s truly a unique product. The RXT-1 strikes at fighters in a realistic yet unpredictable fashion. There has never been a striking pad system that hits back. There is only one robot fight coach in the world — RXT-1,“ said Brent Verdialez, founder and CEO of STRYK and inventor of the RXT-1. „If practiced with daily, users will notice results within a week. We offer the first physical human and robot interactive coach in the sports industry. The future of fight training is here today with our innovative robot coach.“

Top benefits of the RXT-1 include:

Additional RXT-1 product features include:

STRYK has launched a Kickstarter campaign, https://www.kickstarter.com/projects/stryk/in-home-mma-striking-and-agility-trainer-the-rxt-1-robot?ref=4ozhzi, to spread awareness about the company’s affordable and revolutionary robot fighting coach, RXT-1.

ABOUT STRYK

Created by a former 10-year U.S. Army Special Forces Explosives Specialist and long-time combat sports participant, STRYK, https://www.strykusa.com/, is launching its unique robotic fighting coach, RXT-1, promising the next evolution in fight training.

The wait is over! The Robo Wunderkind Explorer Kits are finally available for pre-order In this blog post, find out what makes our newest robotics kits lineup so special, and why it is bound to become a highlight of this Christmas for your child.

Redesigned building blocks, extended functionally, and even more room for fun and learning – all you can think of in STEM represented in the Robo Wunderkind Explorer Kits. Besides the awesome perks you get by pre-ordering early, you and your child will benefit from the unique play and learning experiences these kits bring along. Ready to find out about the coolest features?

This new, cube-shaped block offers so many possibilities for kids to be creative! Draw pictures and emotions, display them on the 16*16 resolution screen, and add some artistry to your coding creations. This building block supports animations, so your kid can create projects with short cartoons or text scroll.

Another new feature that our community has been looking forward to: the Line Follower block is our newest addition to the array of building pieces! With this block, your child’s robots can detect and follow lines drawn on the floor. Besides providing many ideas for super fun activities and games, this block is also an essential element of robotics – plenty of learning outcomes guaranteed!

This sensor will help Robo to find its way around: it can recognize which way is up, down, left, and right! You can measure gravitational forces with an accelerometer, just like an astronaut in space. Programmed with our Python API, this sensor will also allow you to calculate your robot’s orientation in 3D space.

Each Robo Wunderkind Explorer Kit is now equipped with our new Smart Motors! Besides driving to a precise distance and turning, they now support relative angular positioning of anything you place on top of them.

The coolest feature is coming to Robo Wunderkind apps: they will be even more fun to play with having our brand new project sharing functionality. Soon, you’ll be able to not only create your own code but also share it with friends and send them to other devices you have at home. Sharing is caring!

Excited for your little inventor to have fun and learn coding with these cool features? Pre-order Robo Wunderkind today, and get a 15% discount on any kit, a free t-shirt for your child, a possibility to upgrade your purchase, and even win an iPad mini! Delivery: end of September 2020.

Pre-order now!

Another step for the integral didactic concept of Bionics4Education

Festo Didactic presents a new product for the bionics didactic concept of Bionics4Education. What is new: the orientation towards the maker movement approach and the 4Cs. The aim is inspiring learners, finding new ways and solutions, dealing creatively with provided materials, and sharing these experiences with others to prepare them for the digital world of tomorrow.

Inspired by the plant world

The Bionic Flower is a construction kit inspired by the plant world. Festo Didactic developed the Bionic Flower following the models of mimosa plants and water lilies in cooperation with SkySpirit. The Bionic Flower opens and closes its petals as a reaction to external influences such as touch, proximity or light. These mechanisms can be discovered in a playful way by pupils in the classroom using sensors and control technology integrated in the Bionic Flower. The design, as well as the transfer of principles from the plant world, rounds off the teaching of curriculum topics in STEM education (Science, Technology, Engineering, and Maths). The topic of biodiversity can also be discussed in class.

Bionic work didactically prepared

One Bionic Flower can be used by up to three students at a recommended age of 10 and over. The petals contain the first bionic topic: the folding technique. The petals gain the necessary mechanical stiffness by folding. The mechanism for opening and closing the petals is electrically actuated with a stepper motor which opens and closes the petals one after the other. The movement and the light effects are controlled via Wi-Fi-enabled smartphones, tablets or PCs. If required, the microcontroller can be programmed with the graphic coding interface „Open Roberta“. Experienced students can also program their Bionic Flower in C++. The code is open source. This enables teachers to teach technical content via a new, interdisciplinary educational path. Accompanying teaching material, as well as the assembly manual, can be downloaded free of charge from our website www.bionics4education.com.

An expanded approach to promoting valuable skills

Students learn different aspects of STEM with the Bionic Flower – in a digital, creative and interdisciplinary way. The Bionic Flower combines bionics and technical education and is thus based on the competencies of the 4Cs: collaboration, communication, critical thinking and creativity to empower learners for the digital world of tomorrow.

In addition, soft skills such as working in a team are reinforced.

New in the concept: the maker movement approach

The maker movement is based on the DIY (do it yourself) culture and the idea of finding new ways and solutions, dealing creatively with materials, and sharing these experiences with others. The Bionic Flower takes this approach and combines Maker Education and STEM Education. In addition to assembling the Bionic Flower, learners can customize and expand on the Bionic Flower by using 3D printers, other materials, hardware and software.

With intelligent navigation, Clean Base® Automatic Dirt Disposal, personalized cleaning and a new look, the Roomba® i3+ robot vacuum fits into your life

BEDFORD, Mass., Sept. 17, 2020 /PRNewswire/ — iRobot Corp. (NASDAQ: IRBT), the leader in consumer robots, today expanded its Roomba® robot vacuum lineup with the launch of the new Roomba® i3+, a stylish new Roomba vacuum packed with advanced features. Starting at $599 USD, the Roomba i3+ offers intelligent navigation, self-emptying capability with Clean Base® Automatic Dirt Disposal, and an expanded range of personalized cleaning features powered by the recently launched iRobot Genius™ Home Intelligence.

Experience the interactive Multichannel News Release here: https://www.multivu.com/players/English/8620652-irobot-roomba-i3-plus-vacuum/

„Innovative cleaning experiences have been, and always will be, foundational to our product offerings,“ said Keith Hartsfield, executive vice president and chief product officer at iRobot. „We have a proven track record of delivering products that make consumers‘ lives easier. The Roomba i3+ expands our lineup to offer not only exceptional cleaning performance and value, but greater personalization and control delivered by iRobot Genius. The iRobot Genius platform also allows the Roomba i3+ to evolve and get smarter over time, providing new ways for customers to clean their unique homes.“

Take vacuuming off your plate

Similar to the iRobot Roomba i7+ and Roomba s9+ robot vacuums, the Roomba i3+ comes equipped with the Clean Base® Automatic Dirt Disposal. With Clean Base Automatic Dirt Disposal, the robot empties debris on its own, with no intervention from the user. Consumers don’t have to think about emptying the bin for months at a time or worrying the robot won’t finish the job due to a full bin. The Roomba i3+ automatically empties up to 60 days‘ worth of dirt and debris into the Clean Base, which doubles as the robot’s charging station. The debris is then locked away in the Clean Base’s enclosed AllergenLock™ bag that uses four layers of allergen blocking material to trap 99 percent of pollen and mold.

The Roomba i3+ purposefully and logically cleans in neat rows to navigate multiple rooms within the home, across hard floors and carpet. If the robot’s battery runs low, the Roomba i3+ will automatically recharge and resume cleaning until the job is complete.

The Roomba i3+ is also equipped with a High-Efficiency Filter that captures 99 percent of pollen, mold, dust mites, and cat and dog allergens. The robot’s 3-Stage Cleaning System consists of Dual Multi-Surface Rubber Brushes that work together to effectively clean, a specially designed Edge-Sweeping Brush to get into corners, and 10X the Power-Lifting Suction as compared to Roomba 600 Series. Using patented Dirt Detect™ technology, the Roomba i3+ knows where dirt builds up and focuses cleaning in those specific areas.

Adapts to your life, listens to your voice

The Roomba i3+ brings a thoughtful new design that fits well into consumers‘ homes, with a durable, woven texture that minimizes fingerprints and collects less dust. The hidden-until-lit light ring helps the robot blend into the background, only lighting up to communicate robot behaviors or notifications when the robot is actively cleaning.

Users can also get more out of their Roomba i3+ with the newly redesigned iRobot Home App, powered by iRobot Genius™, which takes users beyond standard app control to give them a personalized cleaning experience. Available for iOS and Android devices, iRobot’s state-of-the-art artificial intelligence and home understanding capabilities enable the Roomba i3+ to learn how you like to clean. The Roomba i3+ will offer personalized suggestions via the iRobot Home App, such as recommended cleaning schedules based on past cleaning jobs and helpful cleaning suggestions during pet-shedding or allergy seasons.

Event-based automations can be set up directly within the iRobot Home App, an exclusive capability for iRobot customers that is powered by iRobot Genius™ and IFTTT Connect. Whether you’re heading off to work or going for a hike, the Roomba i3+ can begin cleaning when prompted by location-based services like Life360 or from smart home devices, like the August Wi-Fi Smart Lock. When paired with Alexa enabled devices or the Google Assistant, users can control the Roomba i3+ with just the sound of their voice. The Roomba i3+ also supports Imprint Link™ Technology so that it can team up with the iRobot Braava jet® m6 mopping robot to deliver an extra level of clean.

Pricing and Availability

The Roomba i3+ robot vacuum is available immediately for purchase online in the U.S. ($599 USD) and Canada ($749 CAD) on www.irobot.com and www.irobot.ca, and in retailers later this September. The Roomba i3 robot vacuum can also be purchased without the Clean Base® starting at $399 USD and $499 CAD. The Roomba i3+ is expected to be available in other international markets beginning in Q1 2021.